Structure and method of repairing corrugated steel pipe culvert by using expanded annular steel belt

A technology of annular steel belt and corrugated steel pipe is applied in the structural field of repairing corrugated steel pipe culvert pipes by expanding annular steel belts, which can solve the problems of difficult repair, uneven deformation of foundation, leakage of culverts, etc. Repairing effect, effect of enhancing radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

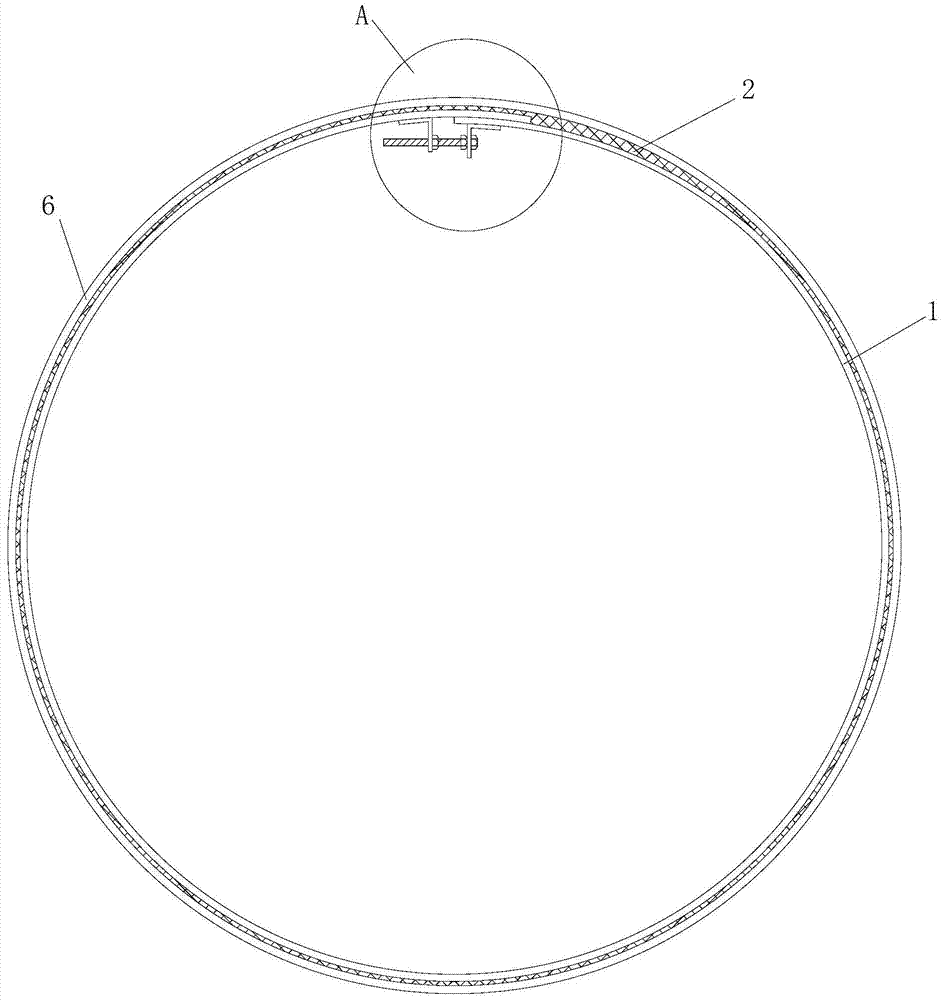

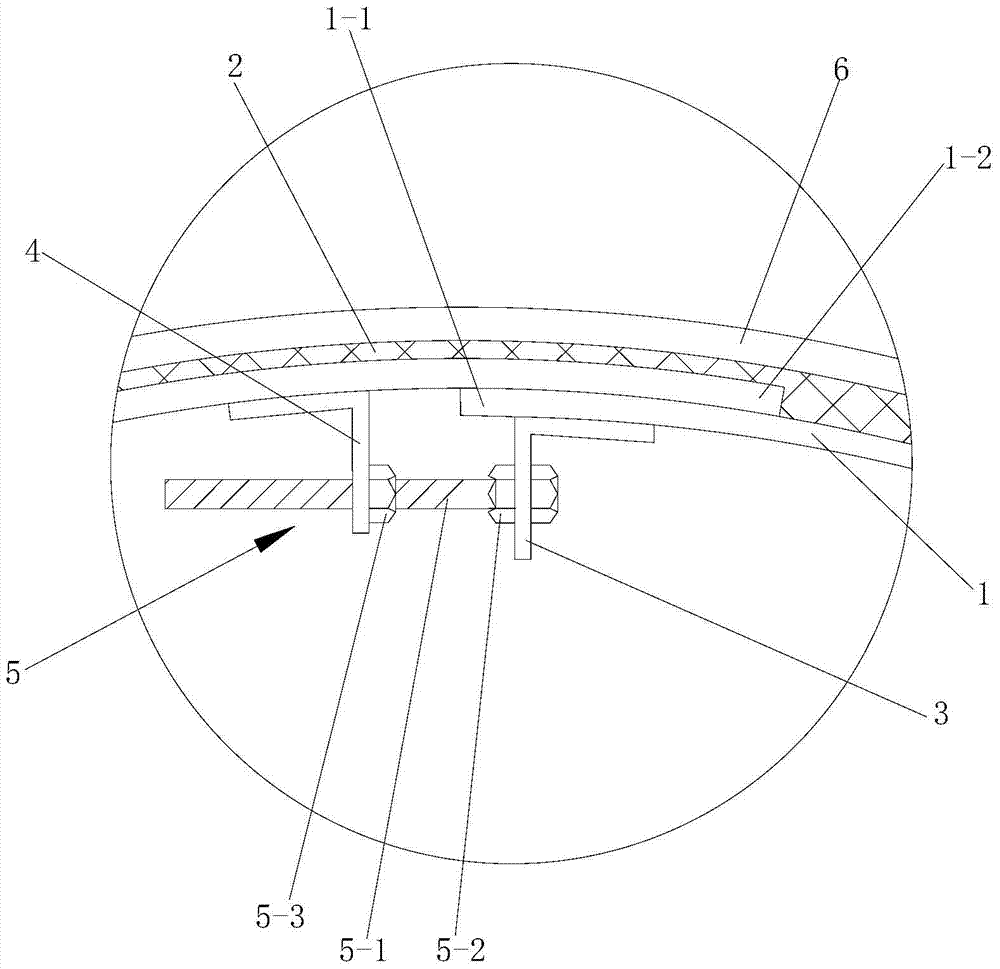

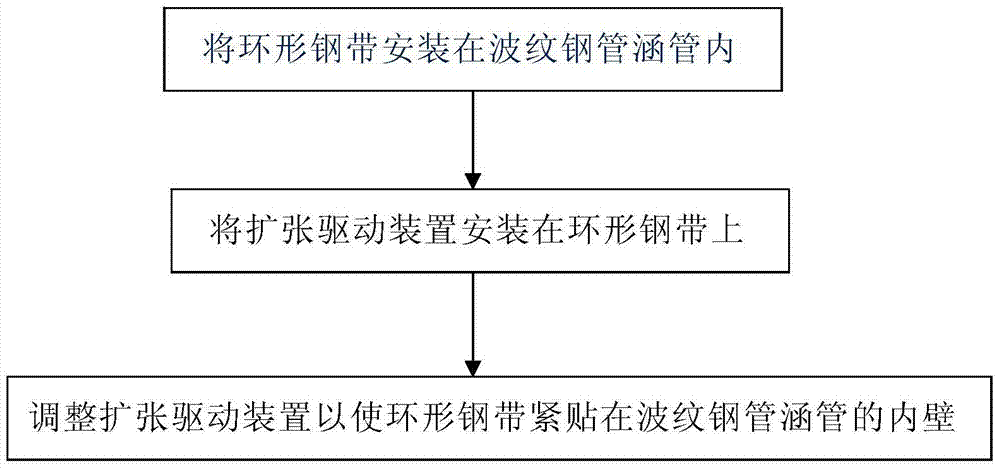

[0039] Such as figure 1 and figure 2 The repair structure of a corrugated steel pipe culvert shown includes an inner supporting annular steel belt 1 arranged inside the corrugated steel pipe 6, the two ends of the annular steel belt 1 overlap each other, and the annular steel belt 1 is installed There are a first angle steel 3 and a second angle steel 4 oppositely arranged and parallel to each other, the first angle steel 3 is set at the inner end 1-1 of the overlapping part of the endless steel belt 1, and the second angle steel 4 is set On the side of the first angle steel 3 away from the outer end 1-2 of the overlapping part of the endless steel belt 1, the first angle steel 3 and the second angle steel 4 are used to expand the distance between them so that the endless steel belt 1 is in close contact with each other. The expansion drive device 5 on the inner wall of the corrugated steel culvert 6 is connected, and the curvature of the annular steel belt 1 is consistent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com