A mixed-strength shear connection based on pressure-bearing high-strength bolts

A high-strength bolt and mixed-strength technology, applied in construction, building construction, etc., can solve the problems of unreasonable bolt arrangement, low efficiency of steel utilization, limited number of bolts, etc., to improve material utilization and high-efficiency material utilization. , the effect of reducing the overlapping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

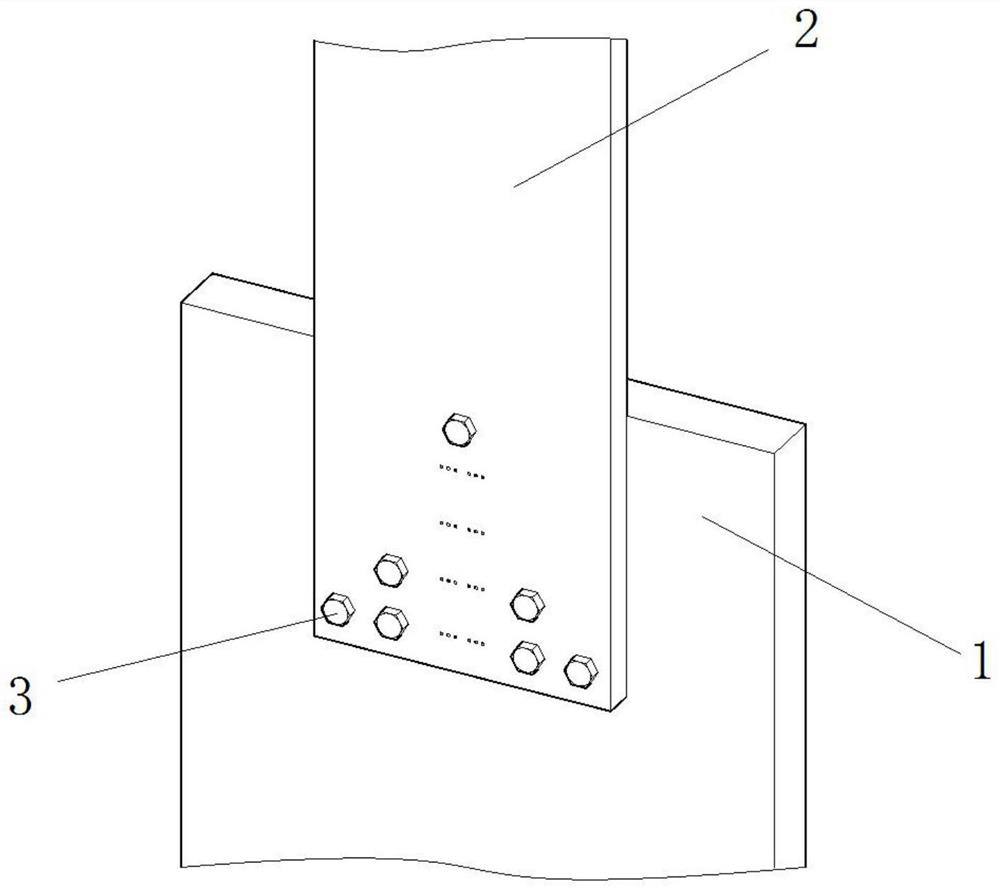

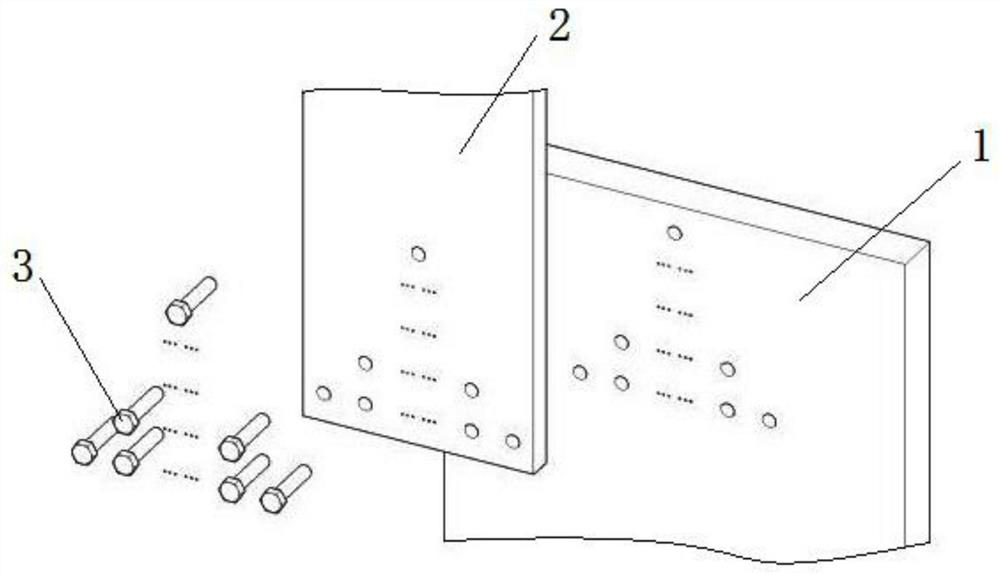

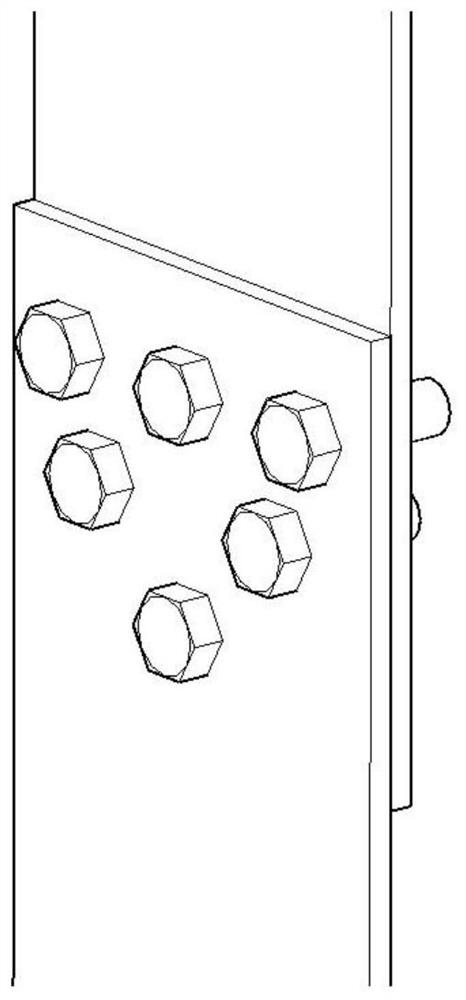

[0024] A mixed-strength shear connection joint based on pressure-bearing high-strength bolts, used for steel plates with different cross-sectional tensile strengths connected by lap joints, the steel plates with different cross-sectional tensile strengths include the first steel plate with high cross-sectional tensile strength The steel plate 1 and the second steel plate 2 with low cross-sectional tensile strength are fixedly connected by n bolts 3 between the first steel plate 1 and the second steel plate 2. From the end of the second steel plate 1 close to the connection end, n bolts are sequentially connected to each other. The bolts 3 are arranged in m rows, wherein the number of bolts 3 in the first row is n1, the number of bolts 3 in the second row is n2, and so on until the number of bolts 3 in the mth row is nm; The number of bolts 3 in the row, the second row... to the mth row monotonically decreases in turn, that is, n1>=n2...>=nm>0.

[0025] In this embodiment, when...

Embodiment 2

[0030] This implementation provides a mixed-strength shear joint based on pressure-bearing high-strength bolts according to the requirements of Example 1, which includes two steel plates with different tensile properties, namely the first steel plate 1, the second steel plate 2 and High-strength bolts 3.

[0031] For the node instance of this embodiment, see image 3 , the design shear capacity of the gusset plate is 402.6kN.

[0032] see image 3 , this node includes the second steel plate 2 with low section tensile strength, the first steel plate 1 with high section tensile strength, and the arrangement example of bolt 3 .

[0033] Among them, the second steel plate 2 with low cross-sectional tensile strength in this node is a Q235 steel plate with a width of 216 mm and a thickness of 10 mm; the first steel plate 1 with a high cross-sectional tensile strength is a Q345 steel plate with a width of 216 mm and a thickness of 10 mm;

[0034] In this embodiment, an example of ...

Embodiment 3

[0041] The main structure of this embodiment is the same as that of Embodiment 2. see Figure 5 , Figure 6 , the difference is that the first steel plate 1 with high section tensile strength in the node is a Q235 steel plate with a width of 216 mm and a thickness of 20 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com