Fabricated sash beam and fabricated rectangular arrangement side slope protection structure

A prefabricated and framed beam technology, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of many quality control points, difficulty in guaranteeing project quality, and many construction steps of cast-in-place reinforced concrete framed beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

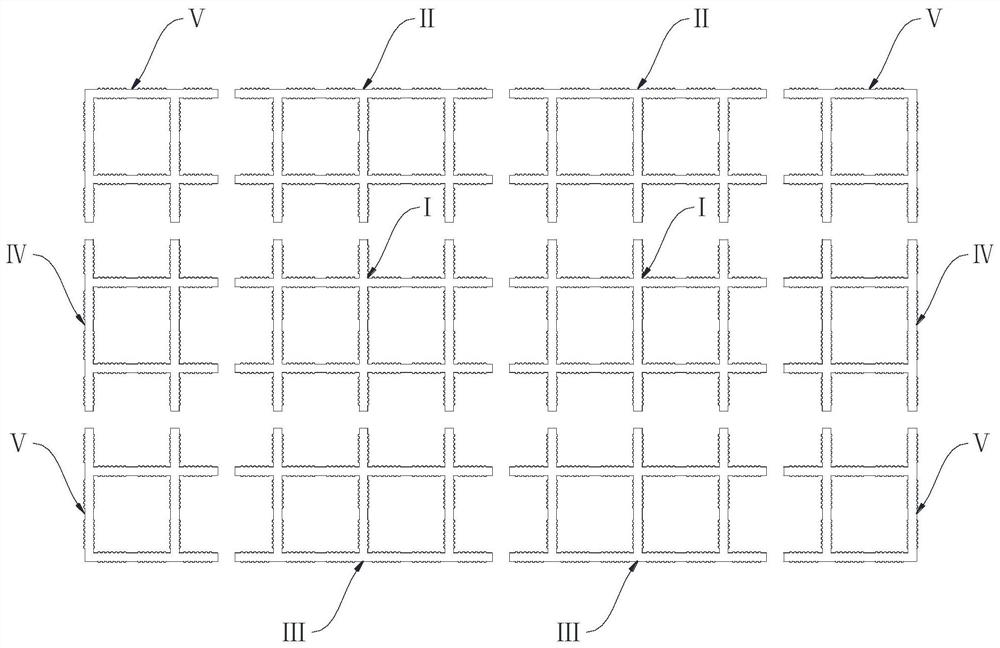

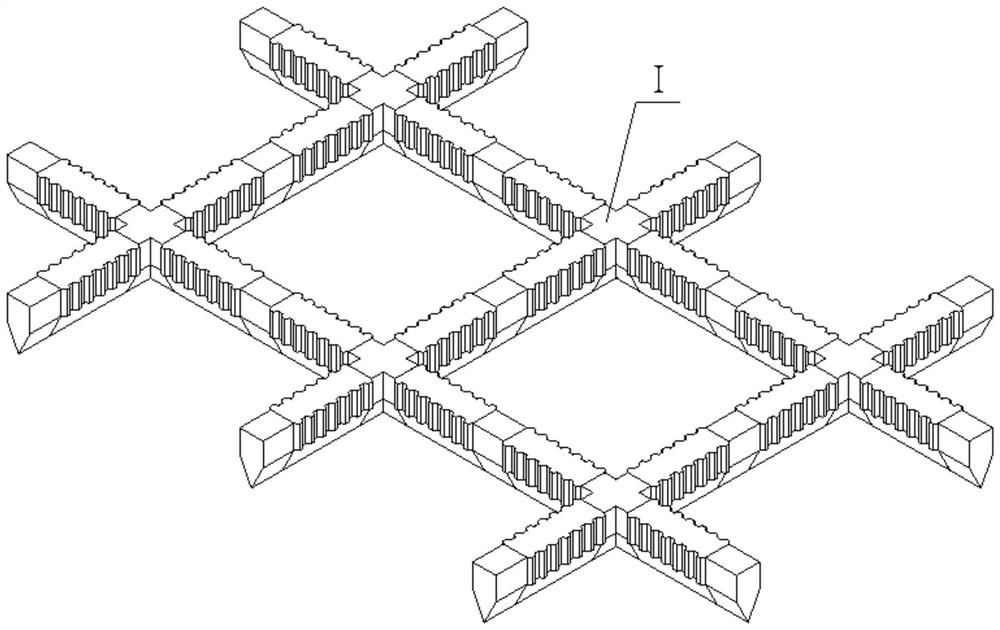

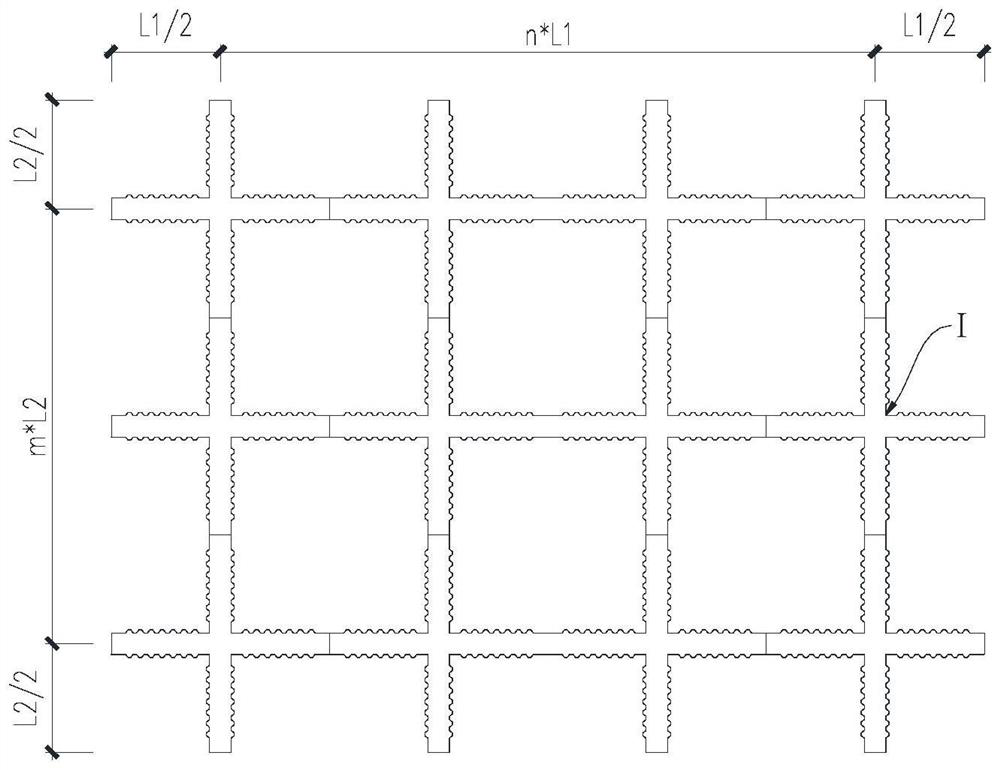

[0034] The assembled frame beam of the present invention is used to be arranged on a side slope to form a slope protection structure. Such as figure 1 As shown, the prefabricated sash beam includes five modules. According to the position of each module after the slope construction, they are the middle assembly module I, the top assembly module II, the bottom assembly module III, the side assembly module IV and the corner assembly module. Part Assembly Module V. Joints are reserved around the middle assembly module Ⅰ for arrangement in the middle of the slope, such as figure 1 with figure 2 shown. Joints are reserved on the left and right sides and bottom of the top assembly module II, and no joints are reserved on the top of the top assembly module II, which is used for arrangement on the top of the slope. Joints are reserved on the left and right sides and top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com