Fabricated concrete prefabricated column and assembly method thereof

An assembly method and technology for prefabricated columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of increasing the weight of components, increasing the cost of on-site hoisting, and increasing transportation costs, so as to increase fluidity and reduce production and transportation costs. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

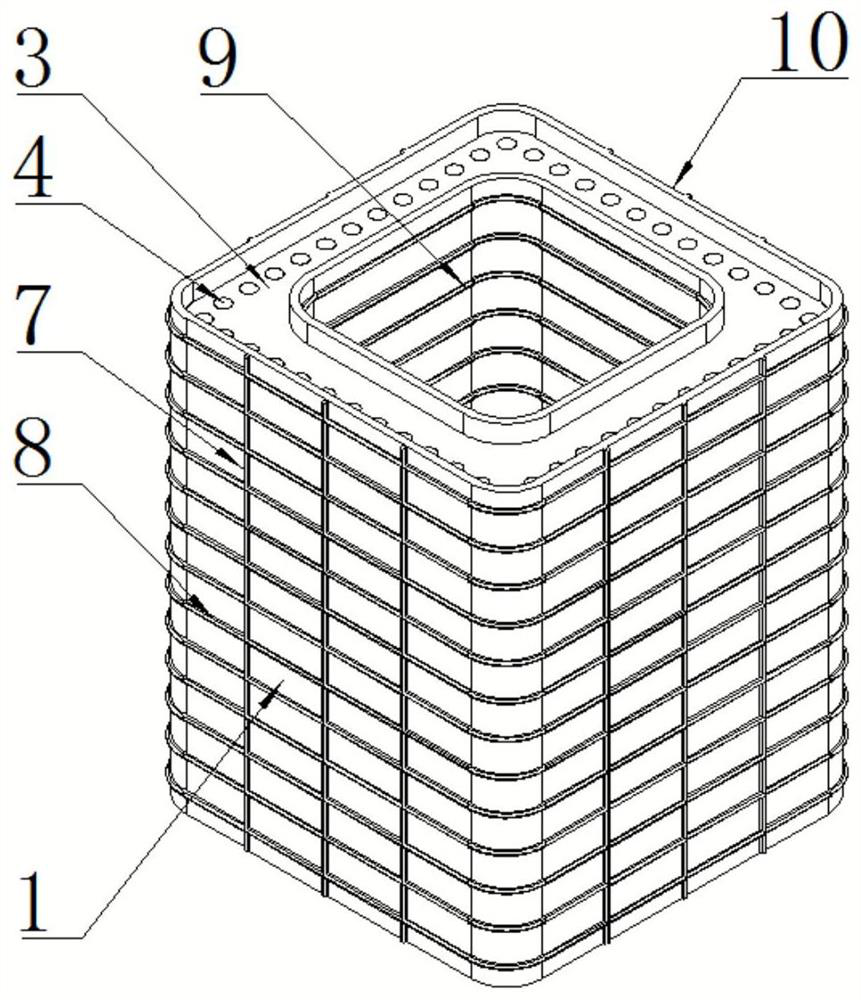

[0051] refer to Figure 1-6 , an assembled concrete prefabricated column is provided with at least one segmental column 1 to prevent the buckling failure of the integral prefabricated column 2 which is too long.

[0052] Among them: two segmental columns 1 are connected up and down to form an integral prefabricated column 2; and in order to effectively reduce the weight of a single segmental column 1, reduce production and transportation costs, and make hoisting more convenient, the segmental column 1 is set as Hollow rectangular columnar structure.

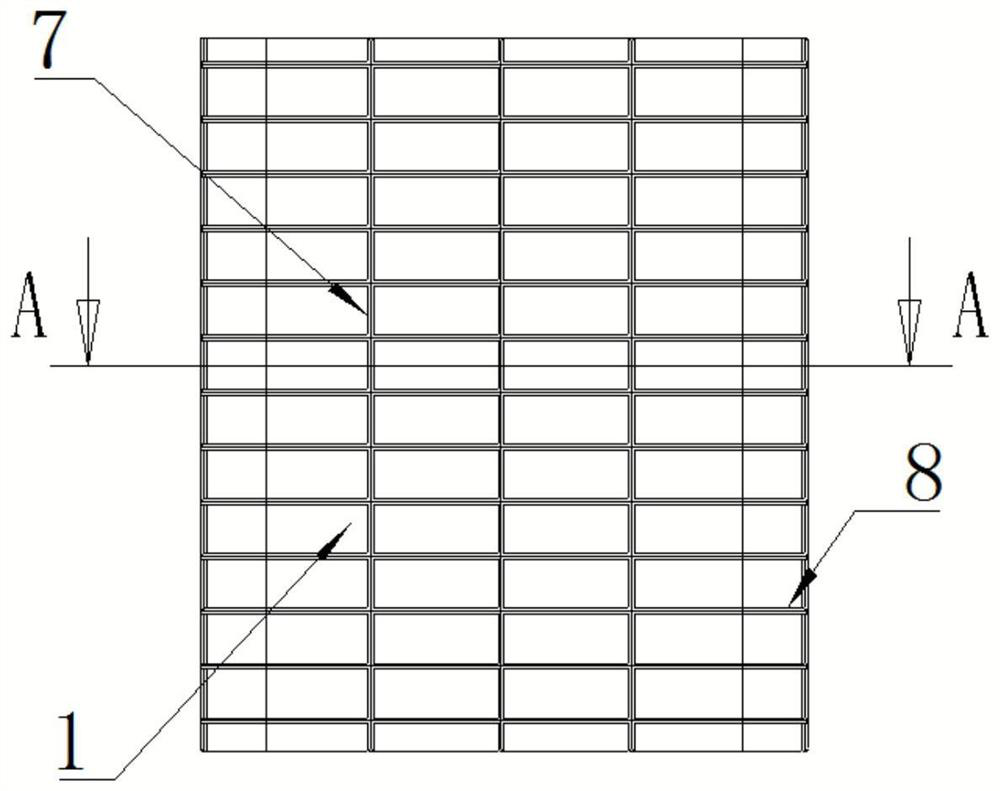

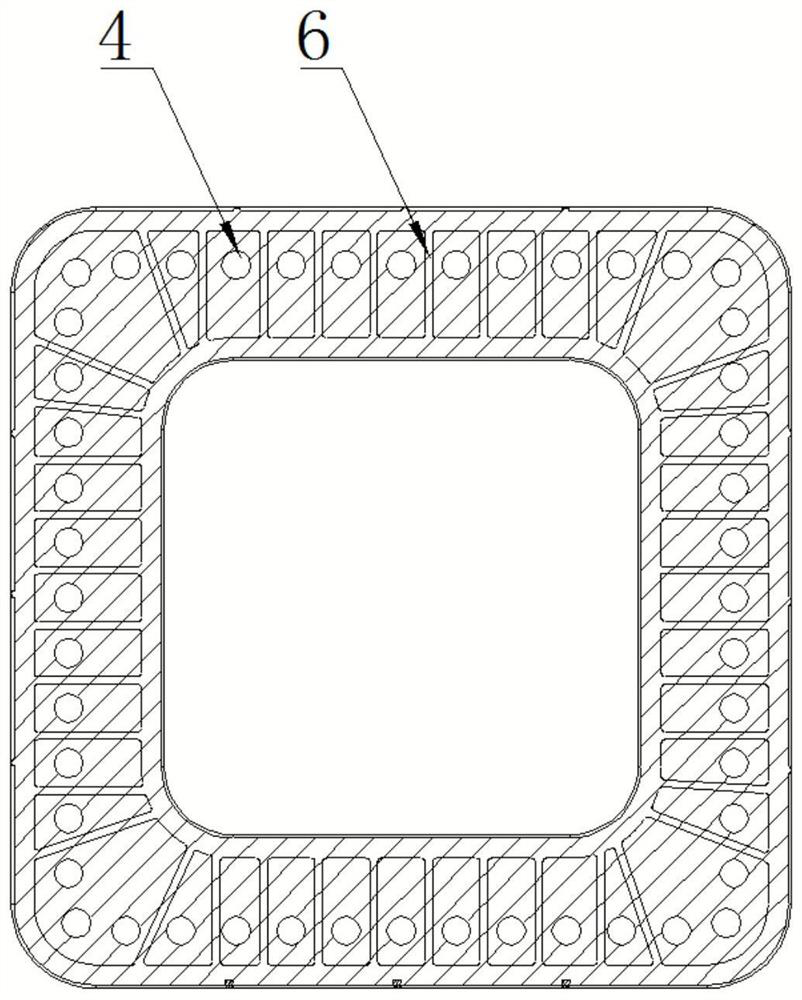

[0053]In order to make the overall structure of the segmental column 1 stable and reliable, horizontal tie bars 6 and vertical structural bars 7 are uniformly arranged inside the segmental column 1, and the tie bars 6 are evenly arranged inside the segmental column 1; the structural bars 7 are arranged on The outer wall and inside of the segmental column 1; the outer wall around it is provided with multiple rows of outer ring st...

Embodiment 2

[0060] Be applied to the assembly method of embodiment 1, it comprises the following steps:

[0061] Step 1 production and transportation: the segmental column 1 is manufactured in the prefabrication factory, and the prefabricated segmental column 1 is transported to the construction site;

[0062] Step 2 hoisting and positioning: the operator installs and positions a segmental column 1 as the lower segmental column 12 through a lifting device;

[0063] Step 3: grouting the lower segmental column 12: insert a full-length steel bar 5 into the metal bellows sleeve 4 of the lower segmental column 12, and then inject the grouting material into the hollow position in the middle of the lower segmental column 12 and the metal bellows;

[0064] Step 4: apply epoxy glue seam cushion 10: apply epoxy glue seam cushion 10 on the top of the upper end back-shaped groove 3 of the downward segment column 12;

[0065] Step 5 Weld the full-length steel bar 5: lengthen the length of the full-le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com