High-strength and high-ductility concrete fabricated frame structure system and connecting system thereof

A technology of high ductility concrete and frame structure, applied in the direction of truss structure, building structure, construction, etc., can solve the problems of difficult to determine the state of the sleeve, hidden dangers, affecting the construction period, etc., to improve the integrity and seismic performance, high Tensile strain hardening, solving the effect of bar crowding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

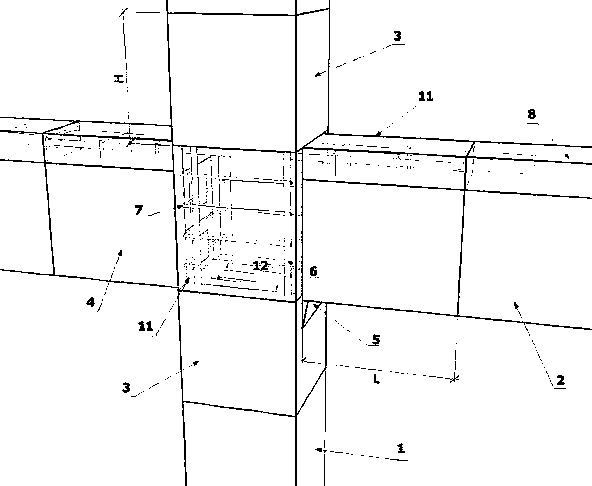

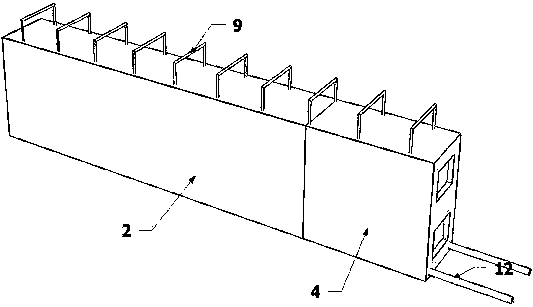

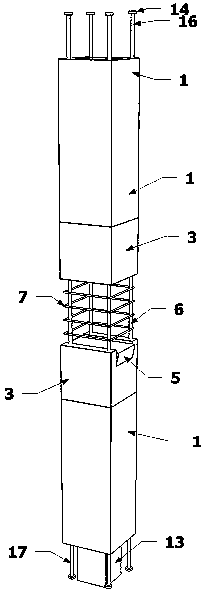

[0036] This embodiment provides a figure 1 The high-strength and high-ductility concrete fabricated frame structure system shown includes a prefabricated reinforced concrete column 1, a prefabricated reinforced concrete beam 2, and the joint core area is formed at the connection between the prefabricated reinforced concrete column 1 and the prefabricated reinforced concrete beams 2 on both sides. The prefabricated reinforced concrete column 1 includes a concrete prefabricated column, a column longitudinal bar 6 and a column stirrup 7, and the column longitudinal bar 6 runs through the upper and lower ends of the concrete precast column to form an upper reserved column longitudinal bar 16 and a lower reserved column longitudinal bar 17 respectively. In addition, the core area of the node is exposed, and column stirrups 7 are reserved outside the column longitudinal reinforcement 6 of the exposed part. The top of the prefabricated reinforced concrete column 1 in the core area o...

Embodiment 2

[0041] On the basis of Embodiment 1, this embodiment provides a high-strength and high-ductility concrete assembled frame structure system. The prefabricated reinforced concrete column 1 is provided with a prefabricated core column 13 in the middle of the lower end, and the prefabricated core column 13 is used for assembly. When supporting the prefabricated reinforced concrete column 1, the longitudinal reinforcement 16 of the upper reserved column and the longitudinal reinforcement 17 of the lower reserved column are all fixedly provided with an anchor plate 14 at the end of the longitudinal reinforcement;

[0042] The upper prefabricated reinforced concrete column 1 and the lower prefabricated reinforced concrete column 1 are staggered and overlapped through the corresponding longitudinal reinforcement 17 of the lower reserved column and longitudinal reinforcement 16 of the upper reserved column. Lap the outside of the lap joint with reserved stirrups. Prefabricated reinforced...

Embodiment 3

[0051] On the basis of Embodiment 1, this embodiment provides a high-strength and high-ductility concrete assembly frame structure system, and the parts of the prefabricated reinforced concrete columns 1 and prefabricated reinforced concrete beams 2 near the node core area are respectively high-strength and high-ductility concrete Prefabricated column ends 3 and high-strength and high-ductility concrete prefabricated beam ends 4, the height H of the high-strength and high-ductility concrete precast column ends 3 is 0 to 2 times the column width, and the length L of the high-strength and high-ductility concrete precast beam ends 4 is 0-2 times 2 times the beam height.

[0052] Such as Figure 4 As shown, the high-strength and high-ductility concrete prefabricated beam end 4 of the prefabricated reinforced concrete beam 2 is prefabricated by high-strength and high-ductility concrete, and the rest is ordinary concrete. The post-cast high-strength high-ductility concrete layer 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com