Fabricated high-strength and high-ductility concrete sleeve-free connection structure and method

A high-ductility concrete and sleeve connection technology, which is applied to structural elements, building components, building structures, etc., can solve problems such as excessively long lap length, poor connection performance, and impact on the construction period, so as to shorten the lap length and solve the problem of Crowding of steel bars and improvement of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

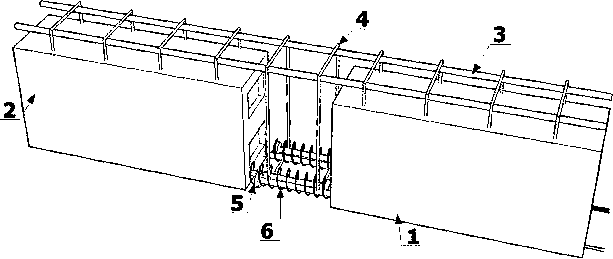

[0031] This embodiment provides a figure 1 The shown assembled high-strength and high-ductility concrete sleeve-free connection structure includes prefabricated reinforced concrete beams, the prefabricated reinforced concrete beams include a prefabricated reinforced concrete left beam 2 and a prefabricated reinforced concrete right beam 1, and the prefabricated reinforced concrete beams include hoops The reinforcement and the longitudinal reinforcement of the overlapping section arranged at the lower part of the beam, the upper part of the stirrup is exposed, and the outer side of the longitudinal reinforcement of the overlapping section is provided with a reserved stirrup 4;

[0032] The prefabricated reinforced concrete left beam 2 and the lower part of the prefabricated reinforced concrete right beam 1 are staggered and overlapped by the longitudinal reinforcement of the overlapping section, and the overlapping section of the longitudinal reinforcement is provided with a spi...

Embodiment 2

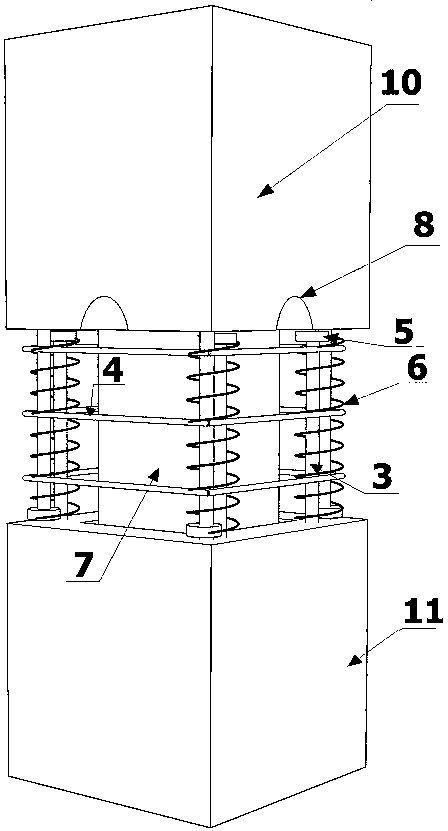

[0034] On the basis of embodiment 1, this embodiment provides a kind of figure 2 The shown assembled high-strength and high-ductility concrete sleeve-free connection structure also includes a prefabricated reinforced concrete upper column 10 and a prefabricated reinforced concrete lower column 11, and the prefabricated reinforced concrete upper column 10 is reserved with post-casting holes 8, and the lower A prefabricated core column 7 is prefabricated in the center of the end face, and the prefabricated core column 7 is used to support the prefabricated reinforced concrete upper column 10 during assembly, and the four corners of the prefabricated reinforced concrete upper column 10 and the prefabricated reinforced concrete lower column 11 are provided with overlapping Sectional longitudinal reinforcement, each end of the longitudinal reinforcement of the overlapping section is provided with an anchor plate 5, and the prefabricated reinforced concrete upper column 10 and the p...

Embodiment 3

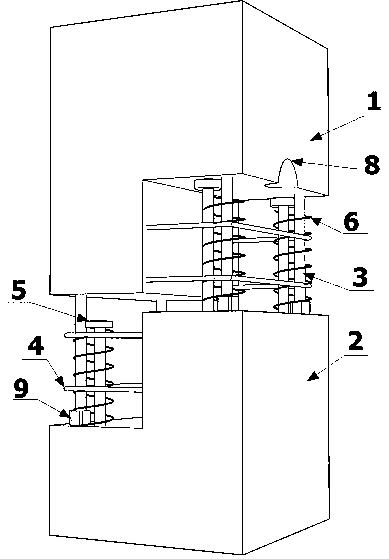

[0041] On the basis of embodiment 1, this embodiment provides a kind of image 3 The shown assembled high-strength and high-ductility concrete sleeve-free connection structure also includes a prefabricated reinforced concrete upper column 10 and a prefabricated reinforced concrete lower column 11, and the prefabricated reinforced concrete upper column 10 and prefabricated reinforced concrete lower column 11 are respectively inverted steps shape and step shape, and the two steps are opposite to form two overlapping sections, the upper and lower steps of the prefabricated reinforced concrete upper column 10 and the prefabricated reinforced concrete lower column 11 are preset with longitudinal reinforcement of the overlapping section and reserved stirrups 4. Post-casting holes 8 are reserved on the prefabricated reinforced concrete upper column 10, leveling nuts 9 are provided at the ends of the longitudinal bars of the overlapping section of the prefabricated reinforced concrete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com