Cable trench construction method using integral movable formwork device

A construction method and cable trench technology, applied in the field of cable trench construction, can solve problems affecting the appearance of the cable trench, uneven appearance of the cable trench, and easy deformation of the formwork, so as to save the loss of the main material of the steel bar and improve the appearance quality Good, overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

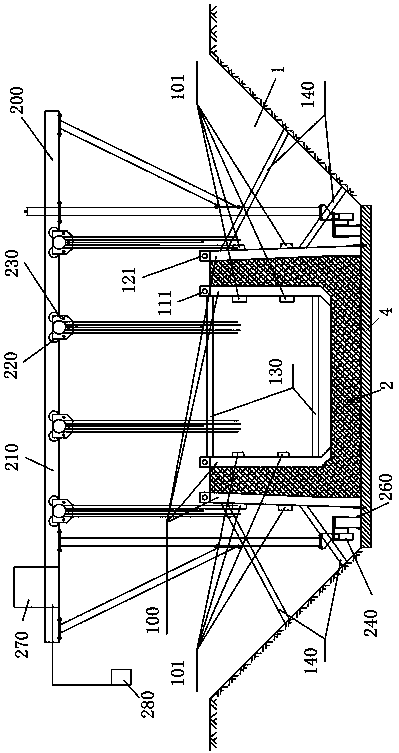

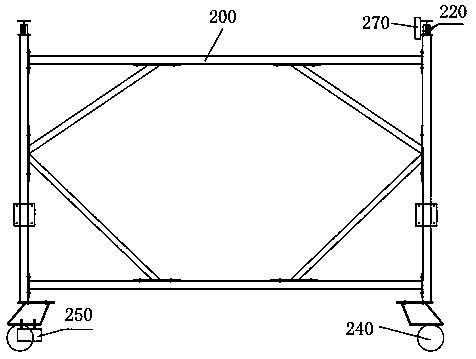

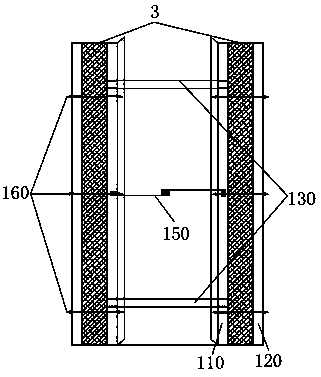

[0034] refer to Figure 1 to Figure 9

[0035] A cable trench construction method using an integral mobile formwork device, comprising the following steps:

[0036] 1) Lay the cushion 4 in the foundation pit 1 of the cable ditch;

[0037] 2) Bind the steel bars of the cable trench on the cushion, and complete the welding of the embedded parts;

[0038] 3) Lay guide rails 260 on the two outer sides of the steel bars, the guide rails are along the forming direction of the cable trench and located outside the cable trench;

[0039] 4) Install the portal mobile frame 200 of the integral mobile formwork device, and hoist the cable trench steel formwork 100 formed by the wall 3 for casting the cable trench. The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com