A kind of steel pipe pile construction method

A construction method and technology of steel pipe piles, which are applied in sheet pile walls, infrastructure engineering, construction and other directions to achieve the effects of increasing the contact area, preventing damage and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

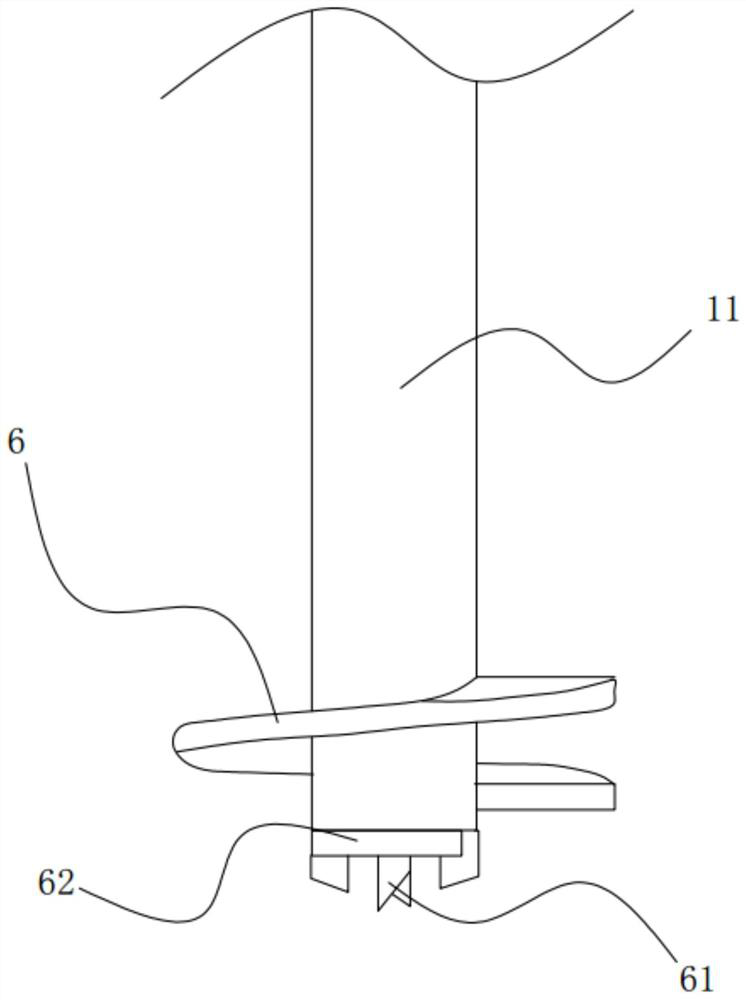

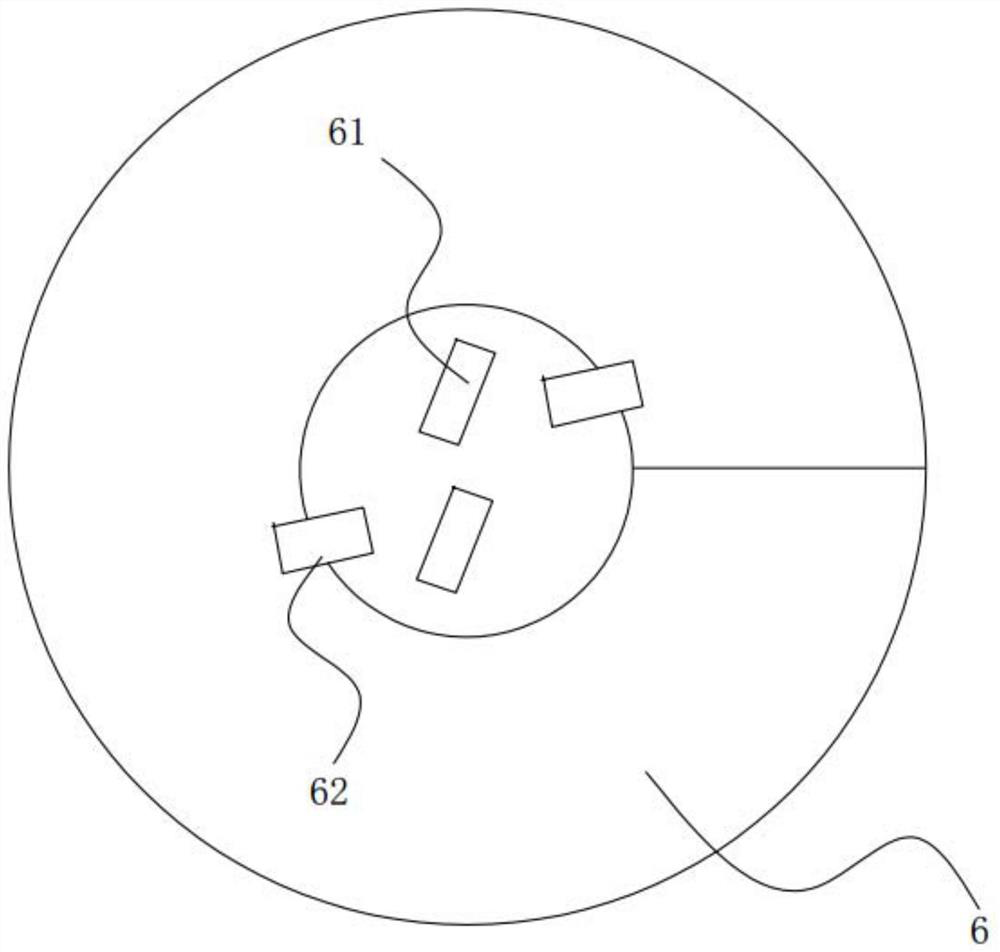

[0039] A steel pipe pile, such as figure 1 As shown, it includes a pile foundation main body 11, a spiral blade 6, an inner excavation cutter 61, and an outer excavation cutter 62. The formation is pushed through the rotation of the pile foundation main body 11, buried to a designated position (depth), and used as the foundation of a structure or a building. piles are used. In this embodiment, the term "building" mentioned below may also be represented as a structure. The pile foundation main body 11 used in this embodiment has a cylindrical shape (cylindrical shape here) extending linearly in the longitudinal direction.

[0040] Such asfigure 1 As shown, a continuous spiral blade 6 is provided on the outer peripheral surface of the front end of the pile foundation main body 11; in more detail, the outer diameter of the spiral blade 6 is larger than that of the pile foundation main body 11, and is fixed on the front end of the pile foundation main body 11. The outer peripher...

Embodiment 2

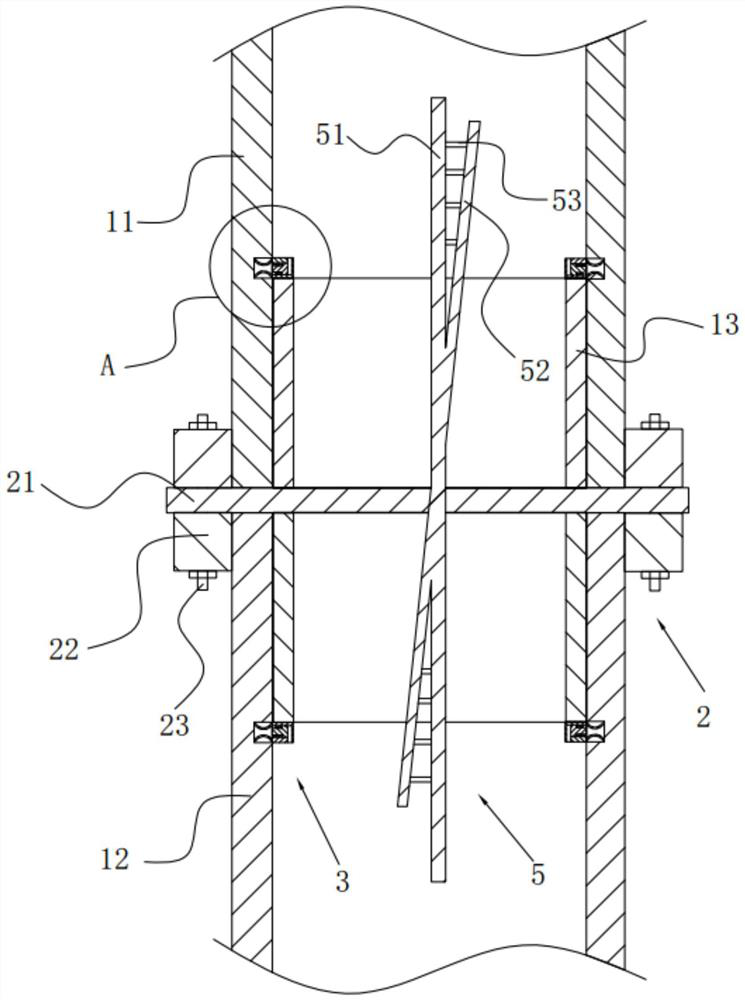

[0044] A steel pipe pile, such as image 3 As shown, when the construction requirements of steel pipe piles do not reach the design depth and the pile needs to be continued, the main body of the pile foundation is also included, and a hollow connector 13 is installed between the main body of the pile foundation 11 and the main body of the extended pile foundation 12. Connecting head 13 is externally connected with fixing structure 2 for fixing pile foundation main body 11 and extending pile foundation main body 12, and connecting head 13 is internally connected with supporting structure 3 for supporting and increasing compressive capacity, so the pile foundation main body is made 11 and the extended pile foundation body 12 are better fixed on the connector 13, and the fixed structure 2 relieves the expansion force of the cement slurry inside the connector 13 after solidification during the working process, reducing the internal pressure of the connector 13, and Through the com...

Embodiment 3

[0051] A steel pipe pile construction method, such as Figure 1-Figure 4 shown, including the following steps:

[0052] S1. The piling equipment with spinning driving device is in place, and the spinning and expanding head steel pipe pile with continuous spiral blades on the outer peripheral surface is installed on the spinning driving device of the piling equipment, aligned with the design position of the pile, and the steel pipe pile is adjusted. Verticality of pipe piles;

[0053] S2. The spinning driving device rotates to drive the steel pipe pile to rotate and drill down into the ground until the design depth required for the construction of the steel pipe pile is reached, and the piling equipment is separated from the steel pipe pile;

[0054] S3, judging whether to continue the pile, if not, then complete the construction of the steel pipe pile, if necessary, then enter step S4;

[0055] S4. Connect the steel pipe pile with the extended steel pipe pile body and fix it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com