Construction method of spun expanded steel pipe pile

A construction method and a technology of steel pipe piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems that are not conducive to maintaining the overall verticality of steel pipe piles, the steel pipe piles are not easy to drill into the ground, and affect construction efficiency To achieve the effect of ensuring the pull-out resistance and supporting performance, improving the construction efficiency and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the scope of protection of the present invention is not limited to the following examples and accompanying drawings.

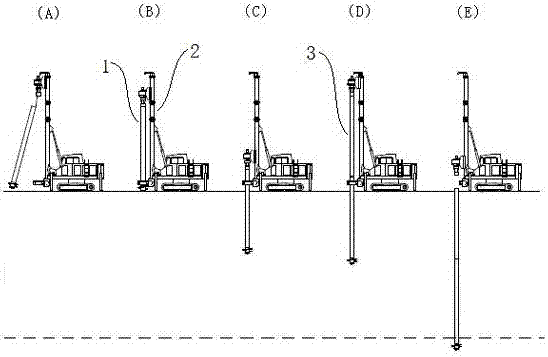

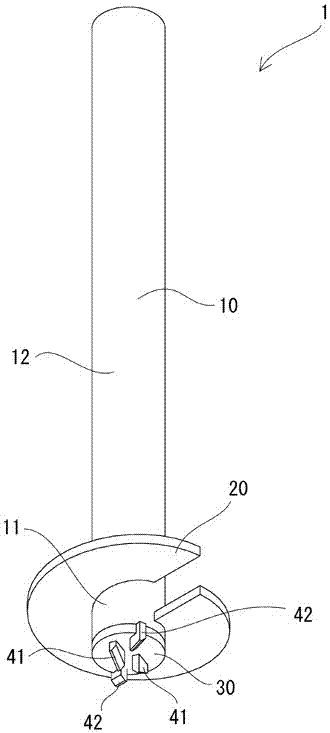

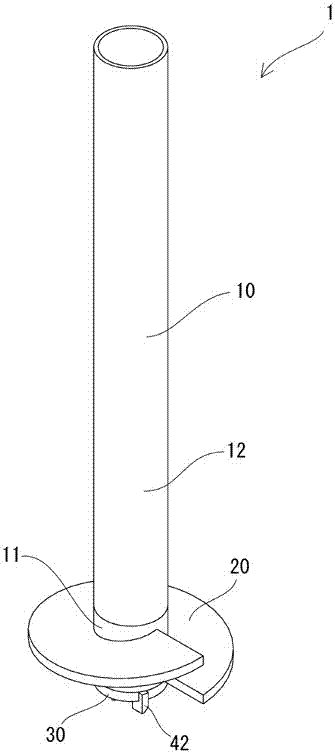

[0044] combine figure 1 Shown, a kind of construction method of spinning steel pipe pile with expanding head, comprises the following steps:

[0045]S1. The piling equipment 2 with spinning drive device is in place, that is, figure 1 As shown in part (A), install the spinning and expanding head steel pipe pile with continuous spiral blades on the outer peripheral surface to the spinning driving device of piling equipment 2, align the design position of the pile, and adjust the verticality of the steel pipe pile , that is, if figure 1 (B);

[0046] S2. The spinning driving device rotates, driving the steel pipe pile to rotate and drill down into the formation, that is, figure 1 As shown in (C), until the design depth required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com