Patents

Literature

37results about How to "Reduce Temporary Support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Excavation construction method of ultra-shallow buried uneven weathered stratum of tunnel

The invention relates to an excavation construction method of an ultra-shallow buried uneven weathered stratum of a tunnel. A segmented step method is used for construction, and a tunnel section is divided into a left side of an upper station, a right side of the upper station, a middle station and a lower station; each segment of step is sequentially constructed circularly, one-time excavation length of each segment of step is not larger than 30m preferably, and a middle partition wall is changed into a straight wall from the traditional curved wall at the left side of the upper station. Thus, for the uneven weathered stratum in the shallow buried area of wall rocks, the dynamic construction method using the segmented step method has little process interference, reduces the construction cost, has simple operation, safety, reliability, less temporary support, low fund investment and high construction speed, is suitable for large machinery for construction, and ensures that the whole construction process is in a safe, stable, high-quality and high-speed controllable state.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

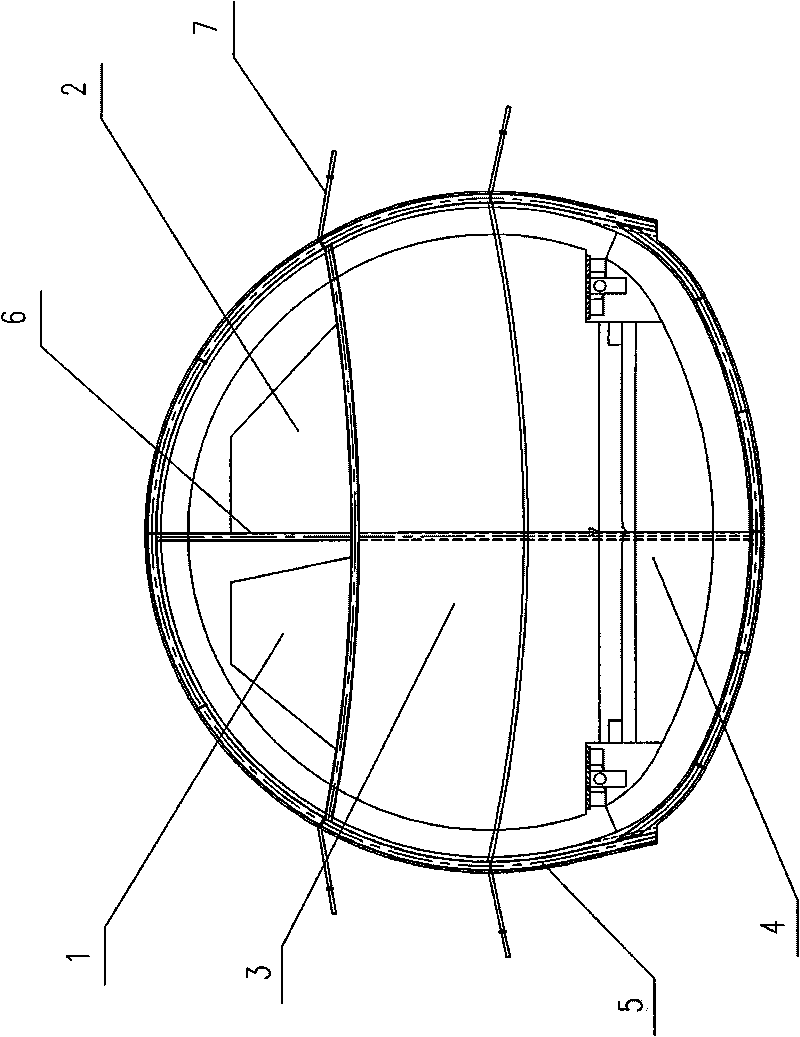

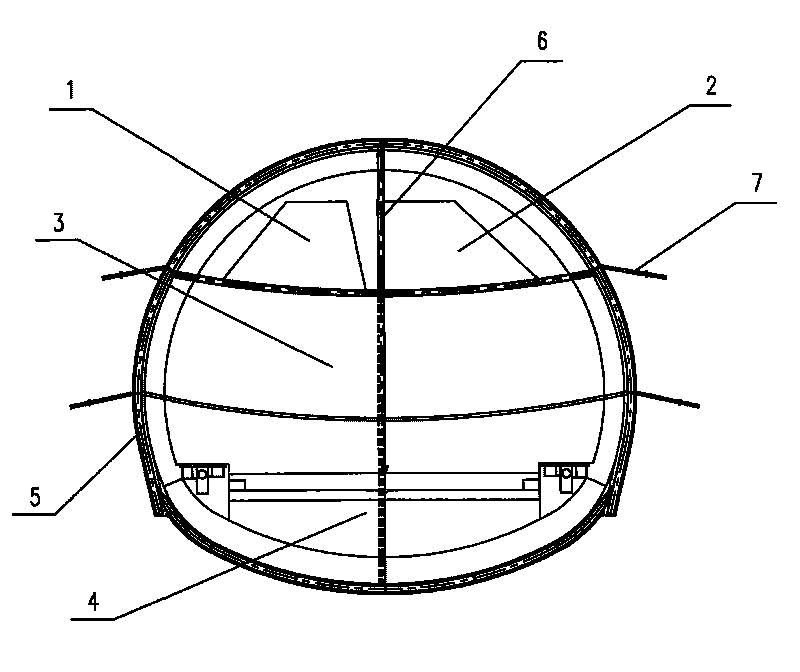

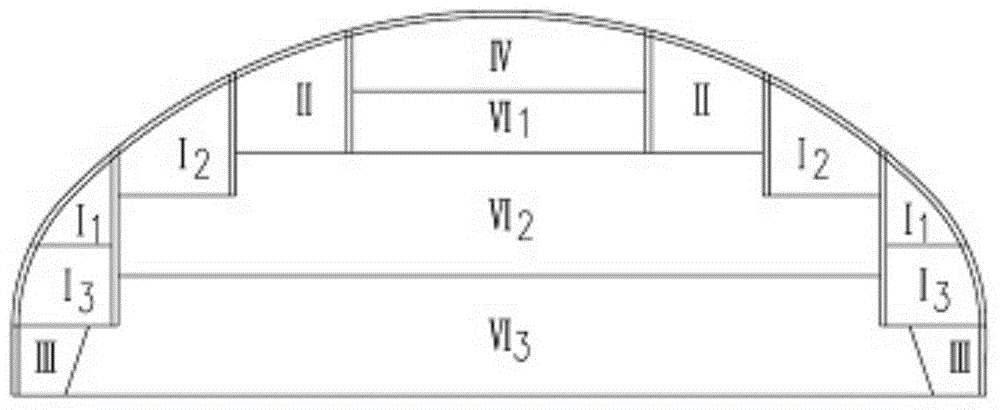

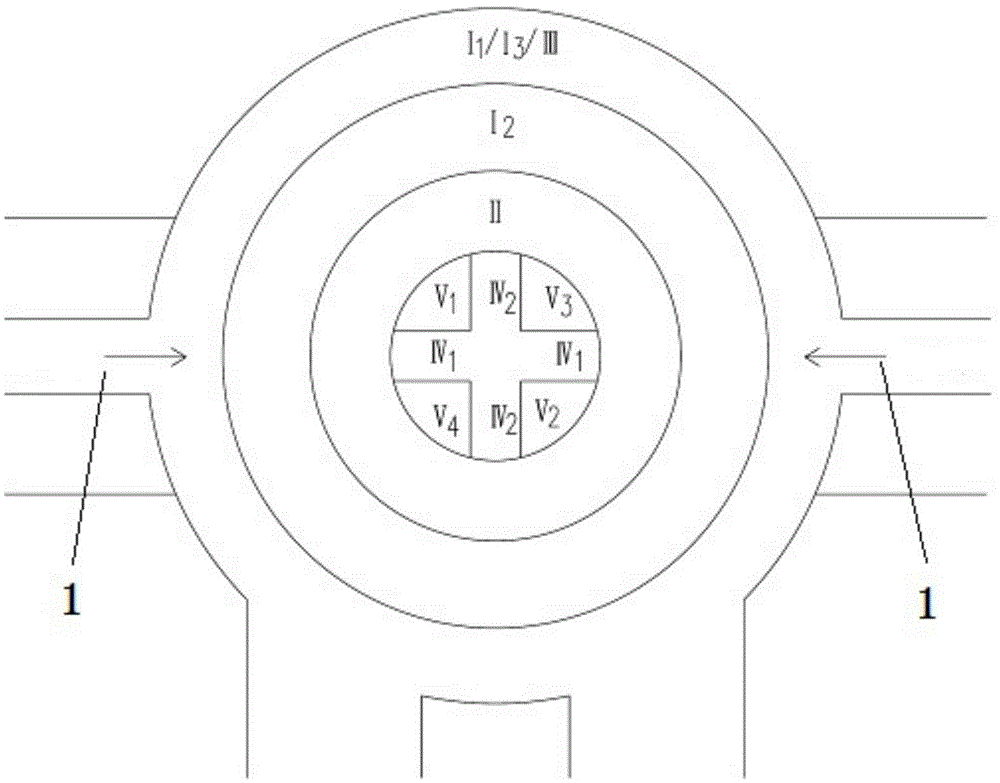

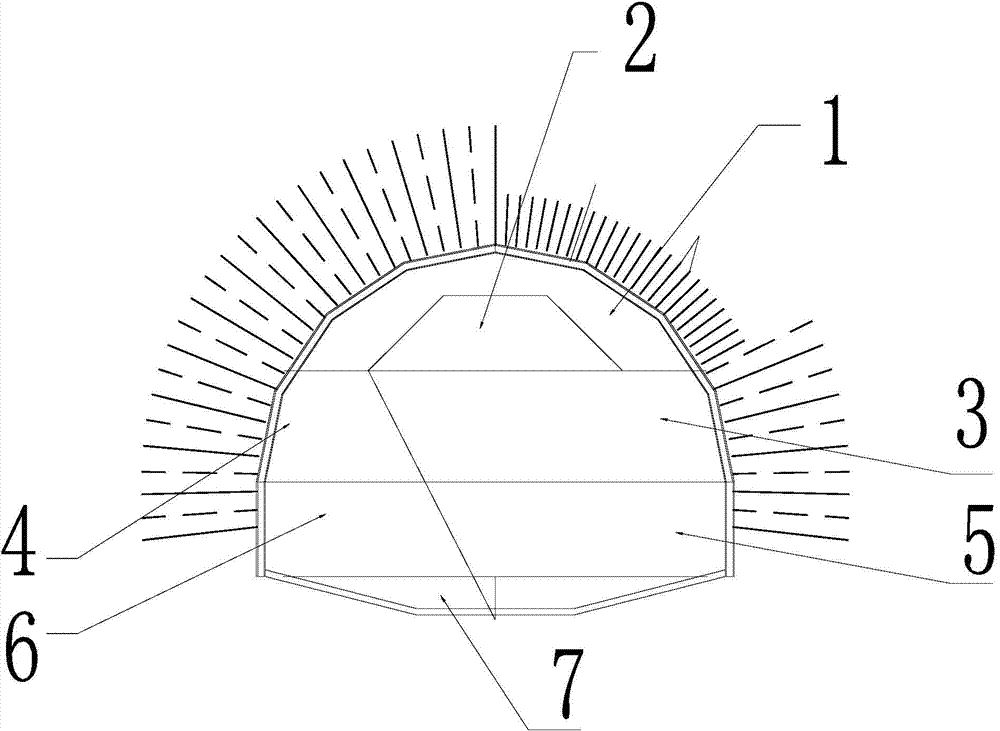

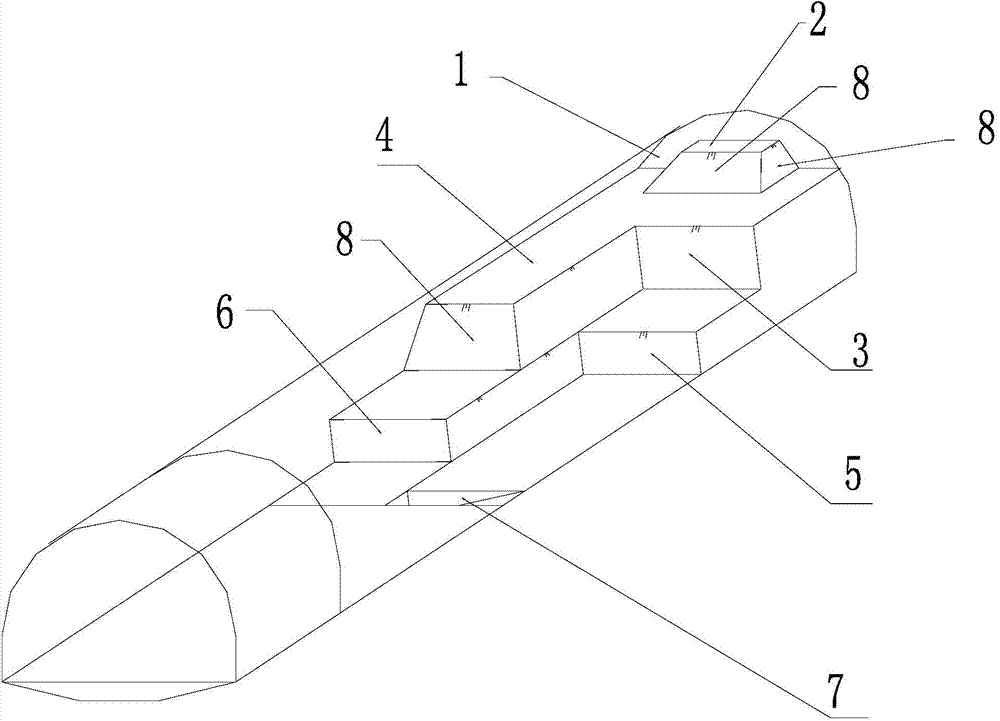

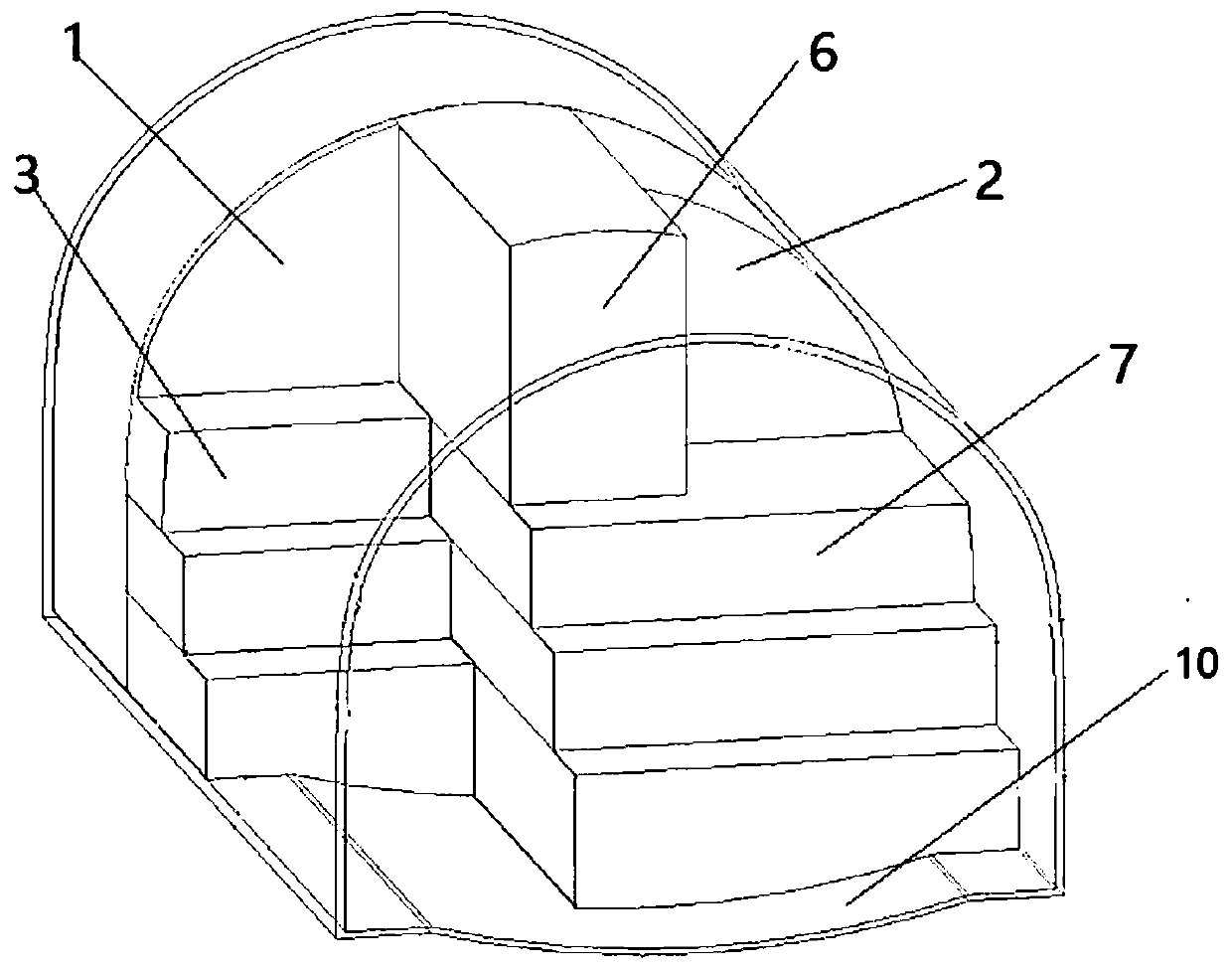

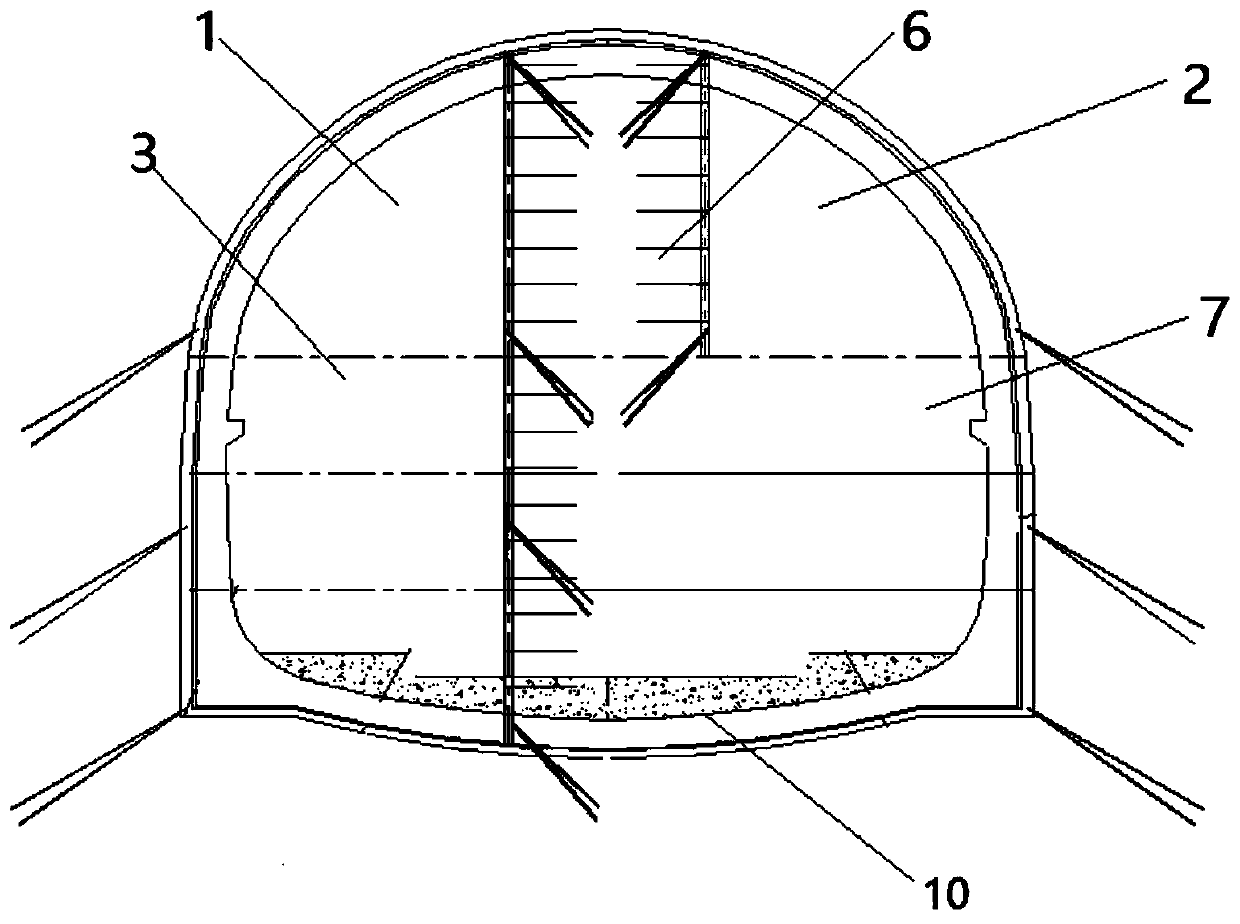

Underground dome excavation construction arrangement structure and excavation method

ActiveCN104806252AImprove stabilityImprove securityUnderground chambersTunnel liningBuilding constructionCivil engineering

The invention relates to the technical field of the underground construction and particularly relates to an underground dome excavation construction arrangement structure and an excavation method. The construction arrangement structure comprises a centre strut and a construction passage; the construction passage extends to the centre strut from the outside of an underground dome; the centre strut is of a step-shaped columnar structure which is decreased from bottom to top; an excavation connection exposure face of an III ring-shaped pilot tunnel, an excavation connection exposure face of an I3 ring-shaped pilot tunnel, an excavation connection exposure face of an I1 ring-shaped pilot tunnel, an excavation connection exposure face of an I2 ring-shaped pilot tunnel and an excavation connection exposure face of an II ring-shaped pilot tunnel are sequentially formed on the lateral surface of the centre strut from bottom to top; a crossed excavation connection exposure face is formed in the centre strut. In the excavating process, firstly, the centre strut is reserved; next, surrounding rocks of the ring-shaped pilot tunnels of the dome are excavated; then the centre strut is excavated. According to the construction arrangement and the excavation method, temporary supports can be reduced, construction cost is saved and meanwhile, stability of the surrounding rocks and construction safety in the dome excavating process are improved.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

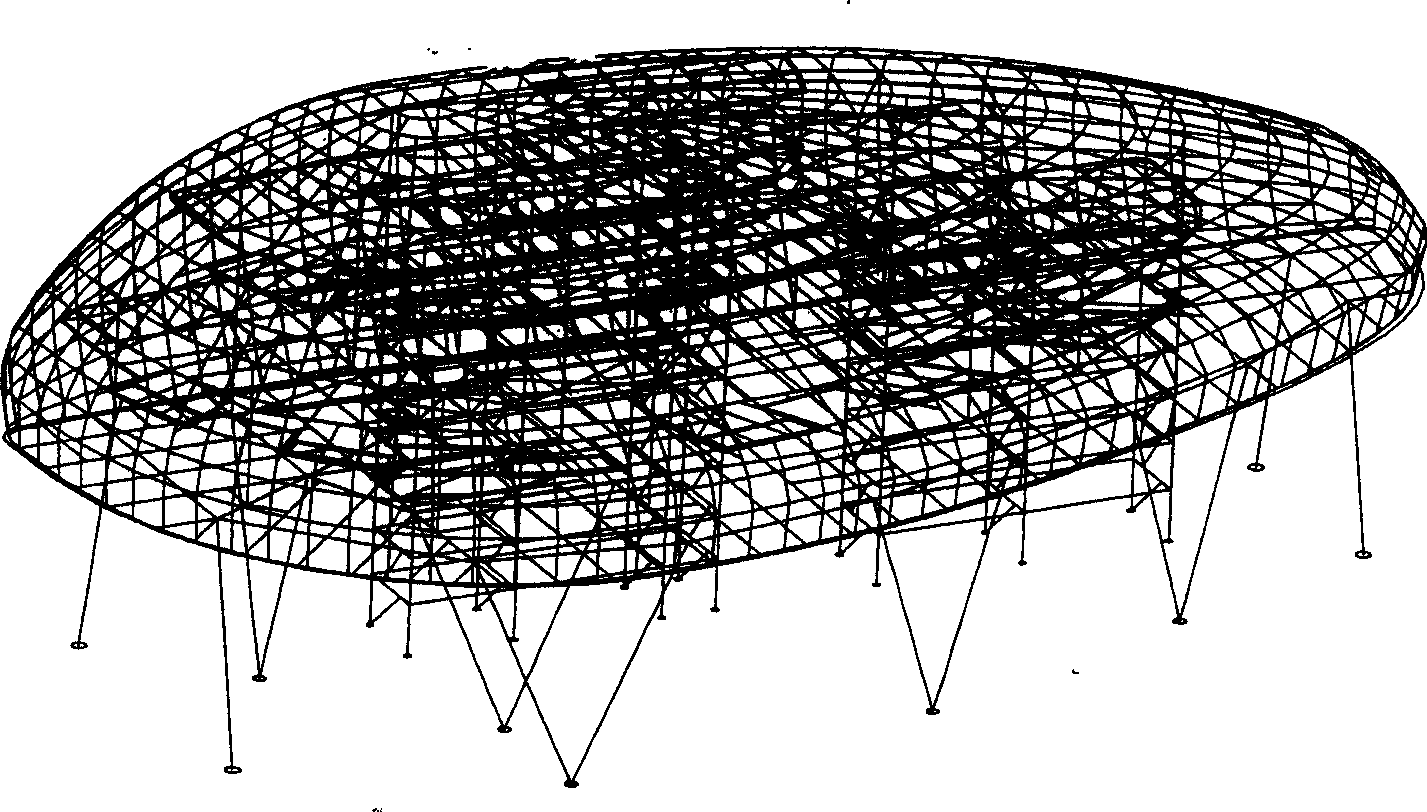

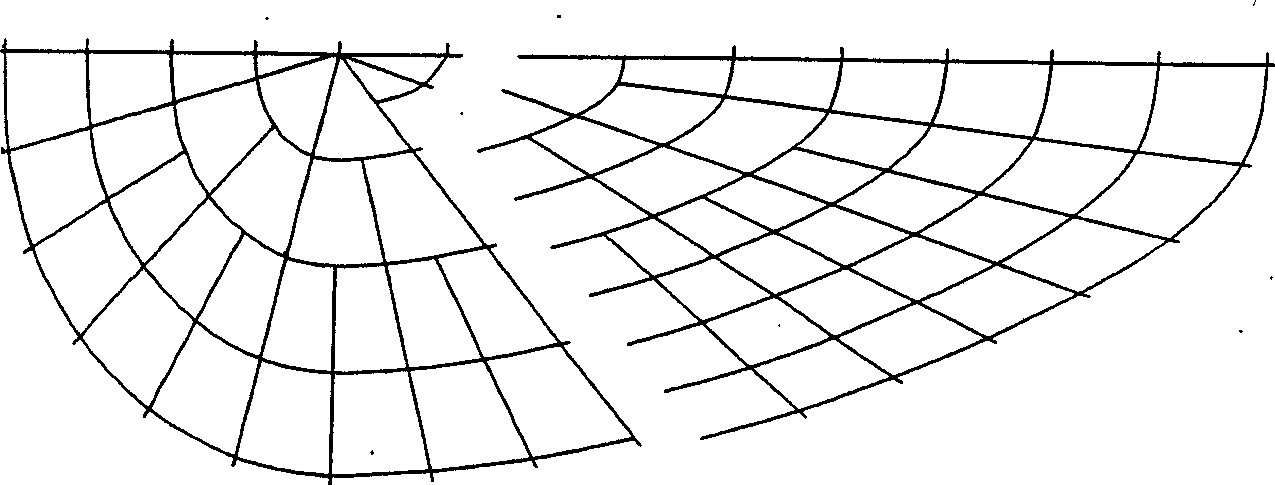

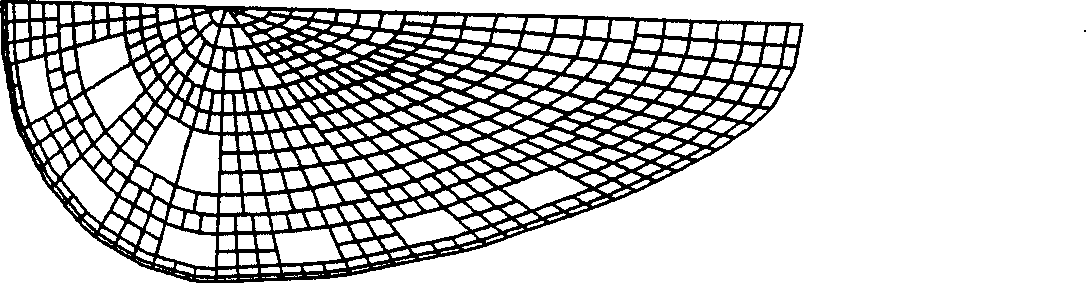

'Drip shaped' radial monolayer steel pipe reticulated shell block and installation method

InactiveCN101451378AReduce Temporary SupportSolving the Cumulative Error ProblemArched structuresVaulted structuresEconomic benefitsGrid partition

The invention relates to a method for partitioning and assembling a 'droplet-shaped' radial single-layer steel pipe grid shell. The method comprises: a southern side grid shell consists of radial steel pipes and a plurality of annular contour steel pipes; the local is provided with a large-area sightseeing window, and a smooth grid shell curved surface is formed; and a northern side grid shell consist of vertical and horizontal steel pipe meshes, and a cambered surface with larger curvature is formed. The method is characterized in that the grid shell is divided into top ring girders, and lower parts of the top ring girders are subjected to grid partitioning along various radial axial lines; projections of the radial axial lines are all radial straight line segments; and after the lower parts of the top ring girders are partitioned according to the radial axial lines, the horizontal position between various blocks can be positioned through main axis pipes on both sides of each block, and the blocks are subjected to filling connection by spare parts. The method has the advantages of effectively solving the problems of lifting and positioning of the 'droplet-shaped' radial single-layer steel pipe grid shell and accumulative errors between grid shells during grid shell assembly, reducing the upper-air welding workload, creating conditions for shortening the duration of a project, saving temporary supporting during grid shell construction, and creating certain economic benefit.

Owner:SHANGHAI MECHANIZED CONSTR GRP

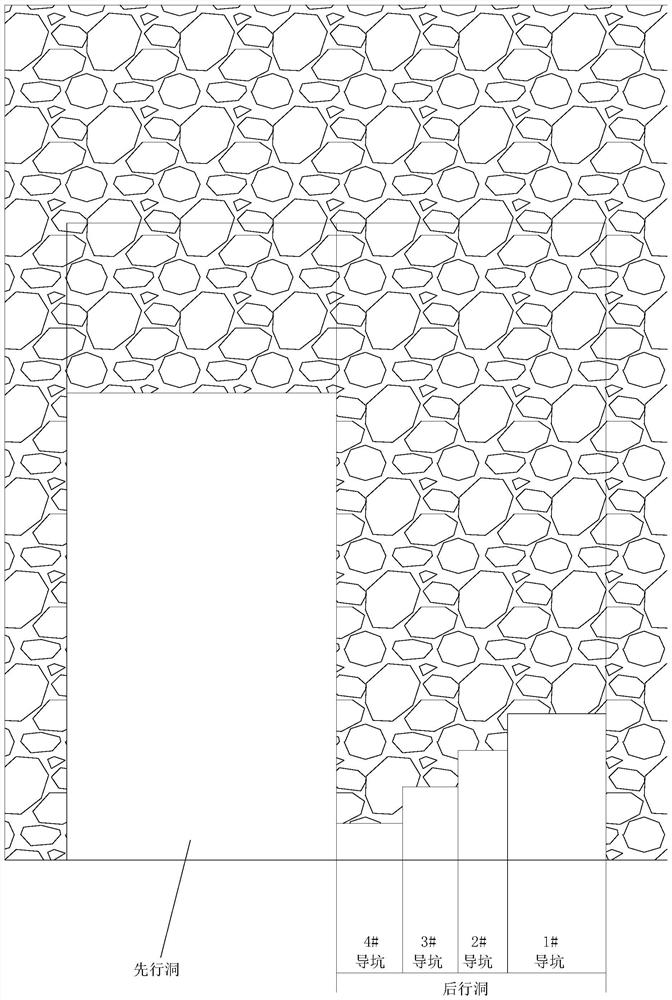

CD-method construction method for improving loess tunnel with super-large cross section

InactiveCN105240021AConstruction does not interfere with each otherImprove construction progressUnderground chambersTunnel liningSoil columnBuilding construction

The invention relates to a CD-method construction method for improving a loess tunnel with a super-large cross section. The method comprises the following steps: (1) excavating an anterior top pilot tunnel, constructing a primary support and a temporary support, and excavating an arch center space; (2) after the excavation depth of the anterior top pilot tunnel reaches 10m, excavating a subsequent top pilot tunnel, and excavating the arch center space; (3) excavating an anterior bottom pilot tunnel, and excavating the arch center space; reserving a soil-column soil body in the temporary support, and meanwhile backfilling the finished anterior bottom pilot tunnel with the excavated soil and carrying out back pressing; (4) excavating a subsequent bottom pilot tunnel, and excavating the arch center space; reserving the soil-column soil body in the temporary support, and meanwhile backfilling the finished subsequent bottom pilot tunnel with the excavated soil and carrying out back pressing; (5) dismantling the temporary support, excavating soil columns in the temporary support, fully excavating a central ditch and an inverted arch, and enabling the inverted arch to form a ring in one time; constructing a secondary lining inverted arch and filling, and then constructing secondary lining. The method has the advantages that large machinery can simultaneously reach the working faces of the top and bottom pilot tunnels and realizes non-interference during construction, the construction progress is fast, and the cost is low.

Owner:GANSU ROAD & BRIDGE CONSTR GROUP +1

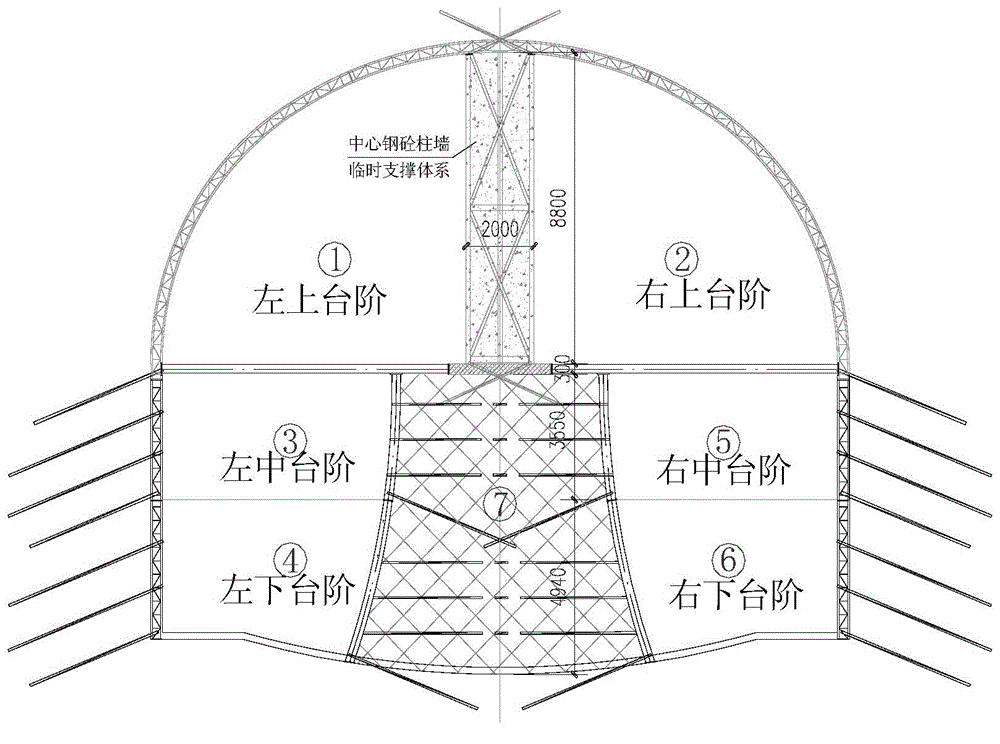

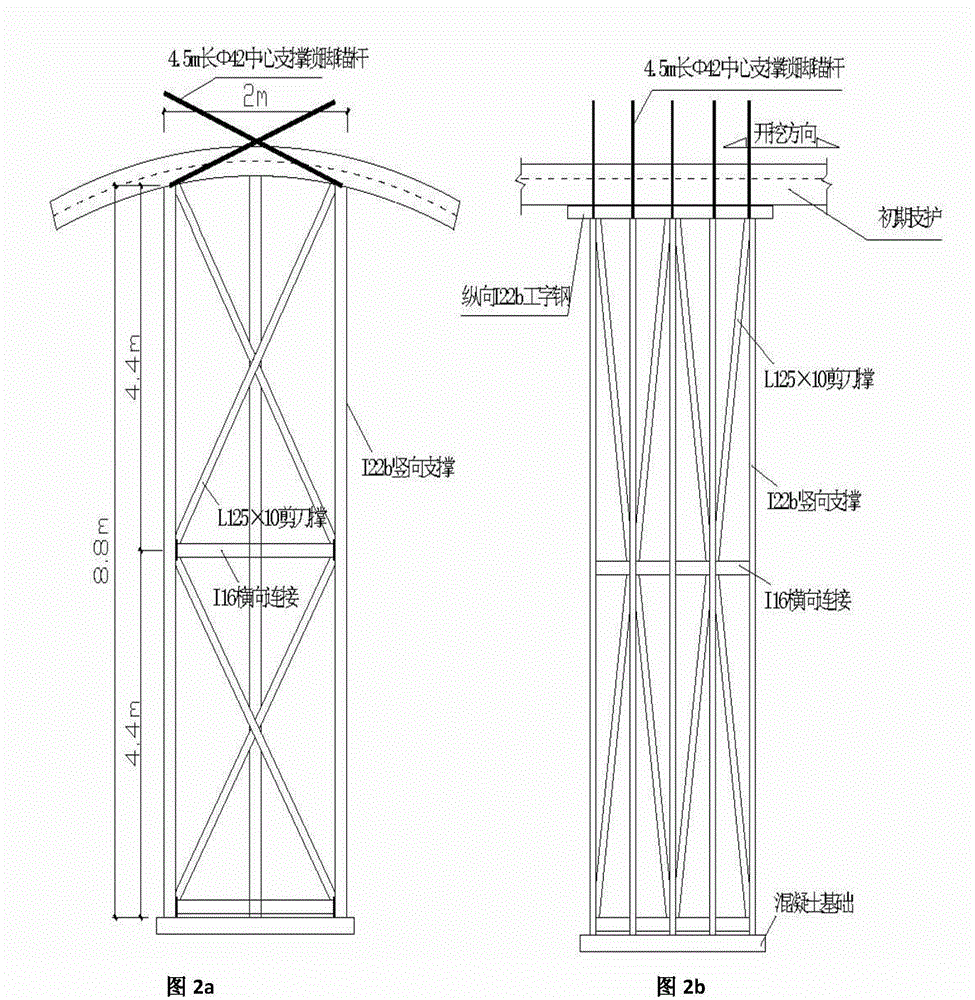

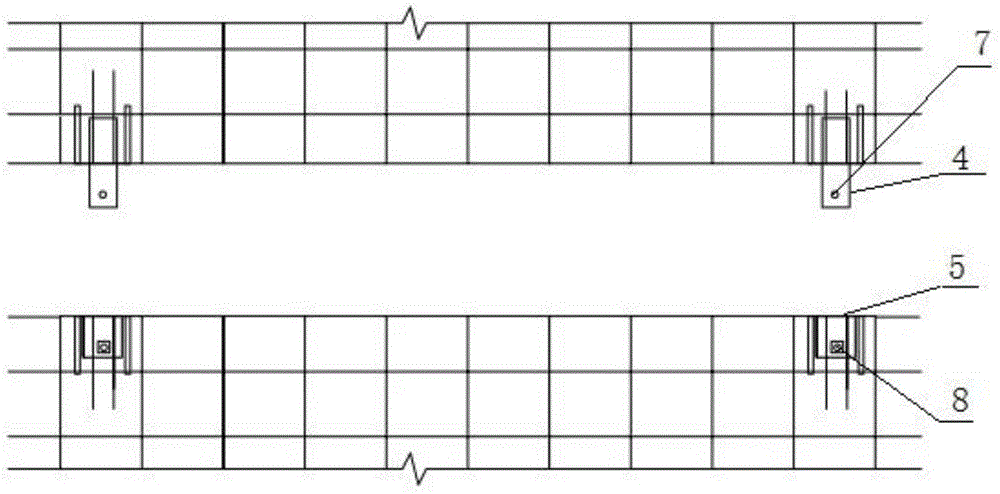

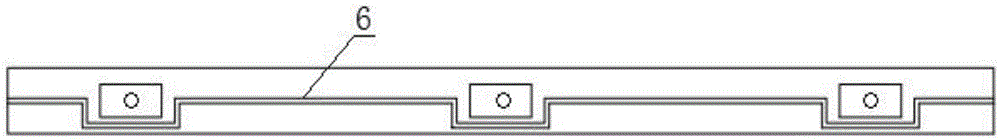

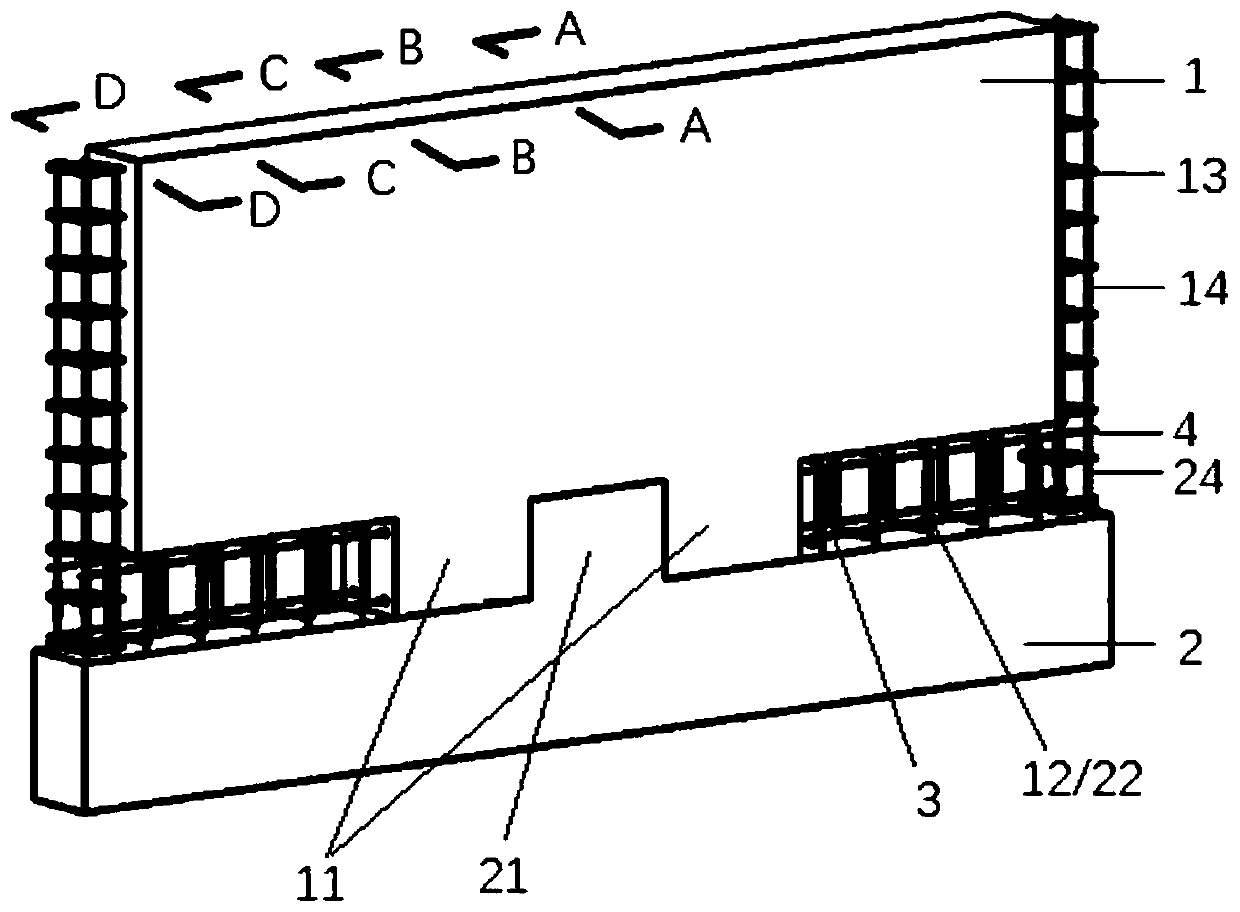

Construction technology of step temporary support and partial double side walls

InactiveCN103334778ASpeed upEasy to doTunnelsProtective coversReinforced concrete columnSupporting system

The invention relates to a construction technology of a step temporary support and partial double side walls. The construction technology is characterized in that an upper half cross section is excavated by a step method; a center reinforced concrete column wall temporary support system is constructed; and a lower half cross section adopts the double side walls. For the center reinforced concrete column wall temporary support system, a plurality of rows of vertical steel supports are arranged vertically; the distances between the vertical steel supports are 1.0m; the vertical steel supports are internally provided with cross connections, longitudinal connections and bridgings; feet-lock bolts are constructed at vaults on the two sides of the vertical steel supports; mortar bolts are constructed at arch springs on the two sides of the vertical steel supports; the vertical steel supports, the cross connections, the longitudinal connections, the bridgings, the feet-lock bolts and the mortar bolts form a reinforcement framework; the reinforcement framework is poured with concrete to form a concrete solid column in size of 2.0*2.0m-4.0*4.0m; the interval between every two concrete solid columns in a whole tunnel is 4-8m; and a steel arch injection concrete enclosed wall body is arranged between every two concrete solid columns. With the adoption of the technology, on the premise that construction safety is ensured, the construction period of a project is shortened by 15% entirely, and construction cost is saved by 6% approximately.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

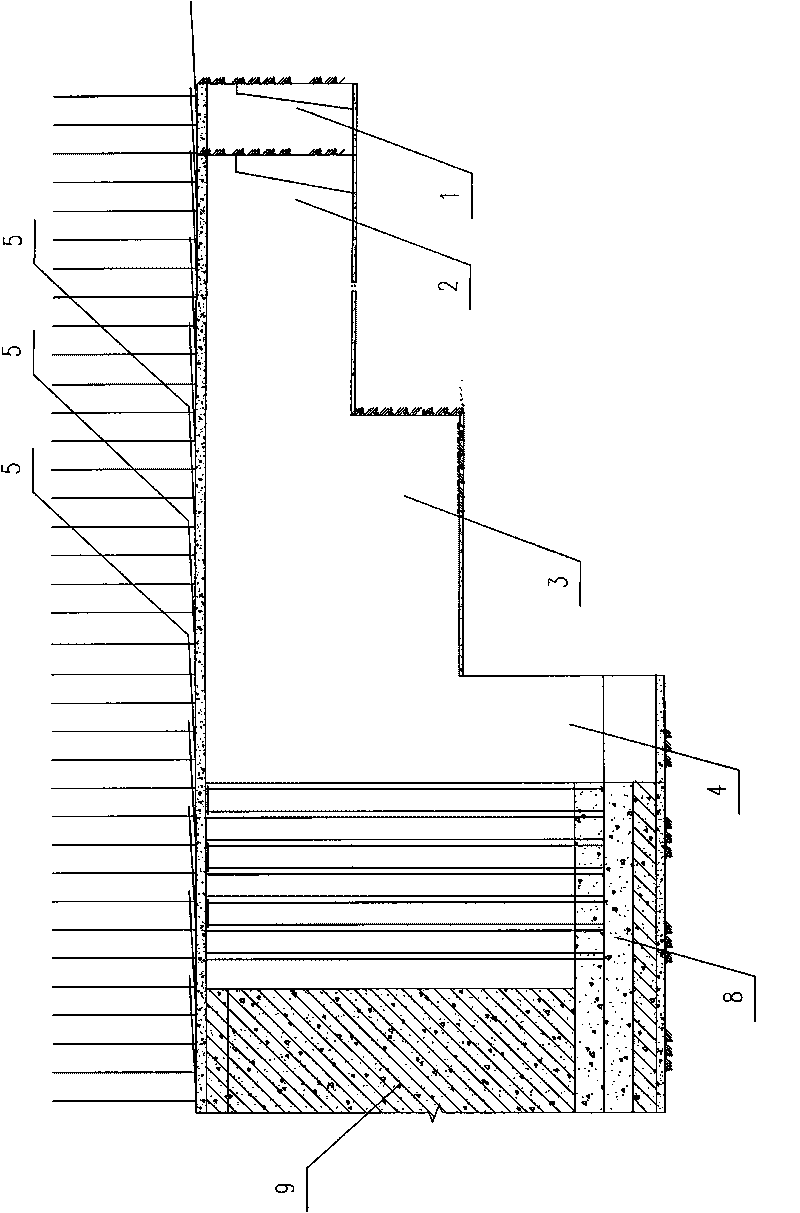

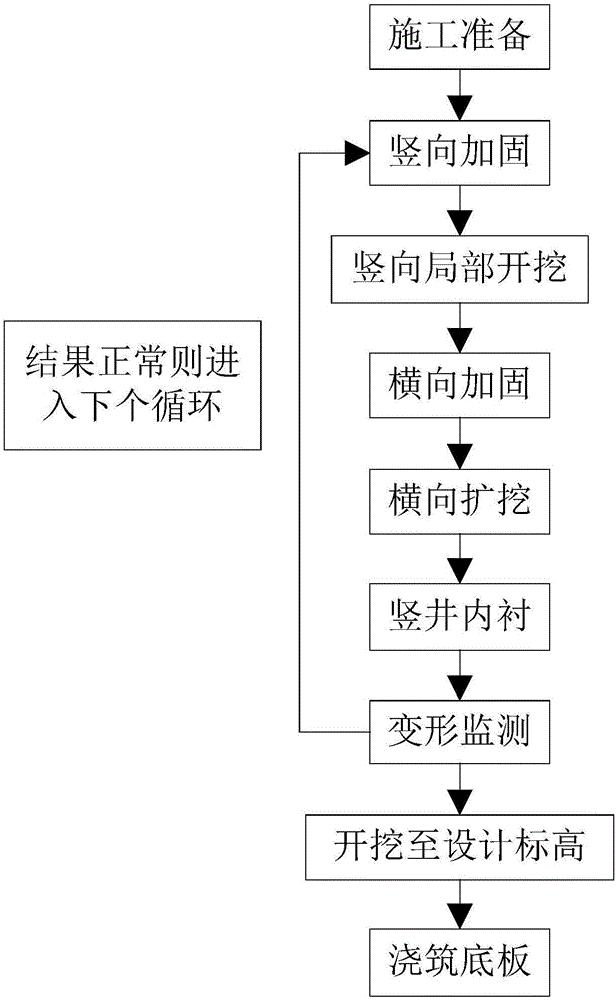

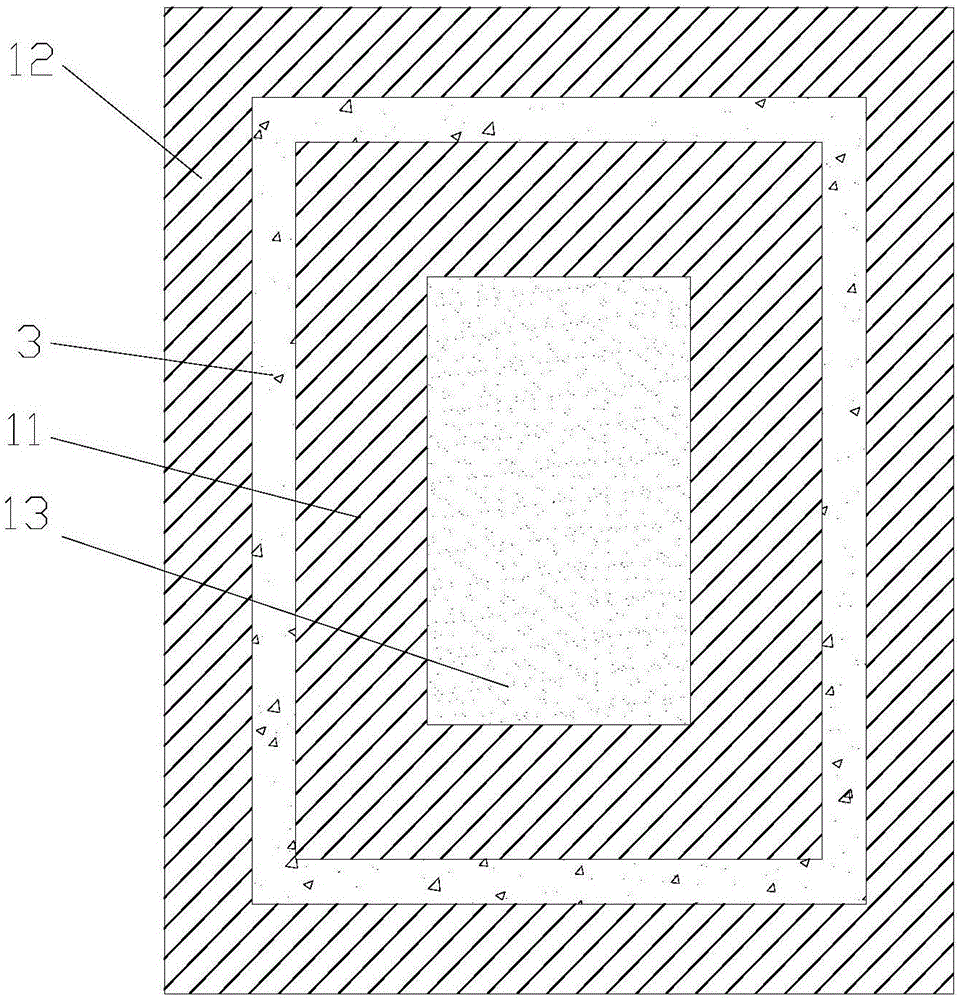

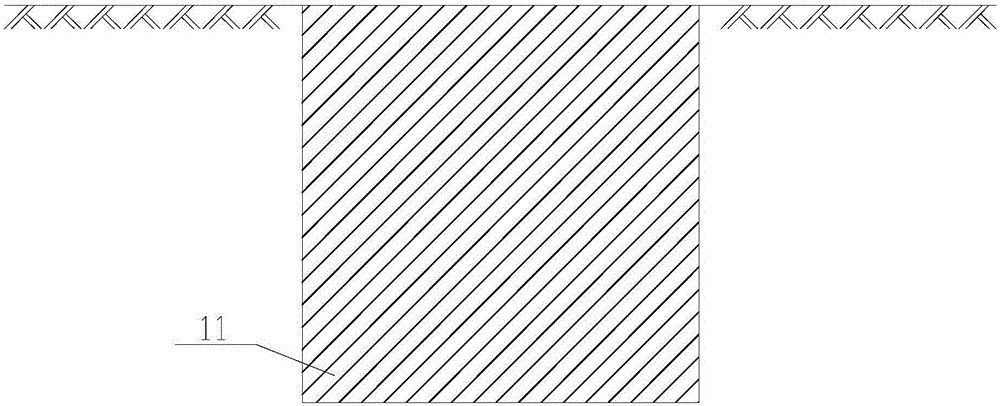

Excavation method for subway shaft reinforcement in weak water-rich strata

InactiveCN104895570BGuaranteed stabilityImprove securityShaft sinkingSocial benefitsDeformation monitoring

The invention discloses a reinforced excavation method for a shaft of a subway of a weak water formation. The reinforced excavation method for the shaft of the subway of the weak water formation comprises the following steps of (1) performing vertical reinforcement; (2) performing vertical local excavation; (3) performing transverse reinforcement; (4) performing transverse expanding excavation; (5) performing shaft lining; (6) monitoring deformation; (7) repeating the step (1), the step (2), the step (3), the step (4), the step (5) and the step (6) and excavating the formation to a designed elevation; and (8) bottom plate pouring: performing pouring on the bottom of the shaft after the formation is excavated to the designed elevation. Compared with the traditional excavation method, the layered and segmented excavation method has the advantages that the stability of the shaft can be guaranteed well and safety of construction is improved greatly. A water stopping effect can be high by layered and segmented reinforcement and excavation, circumstances of water burst, mud burst and the like in an excavation process are avoided, and the method is particularly suitable for excavating the shaft of the weak water formation. By the layered and segmented excavation, the stability of the shaft is improved greatly, the construction risk is greatly reduced, and the social benefit and the economic benefit are high.

Owner:FUJIAN UNIV OF TECH

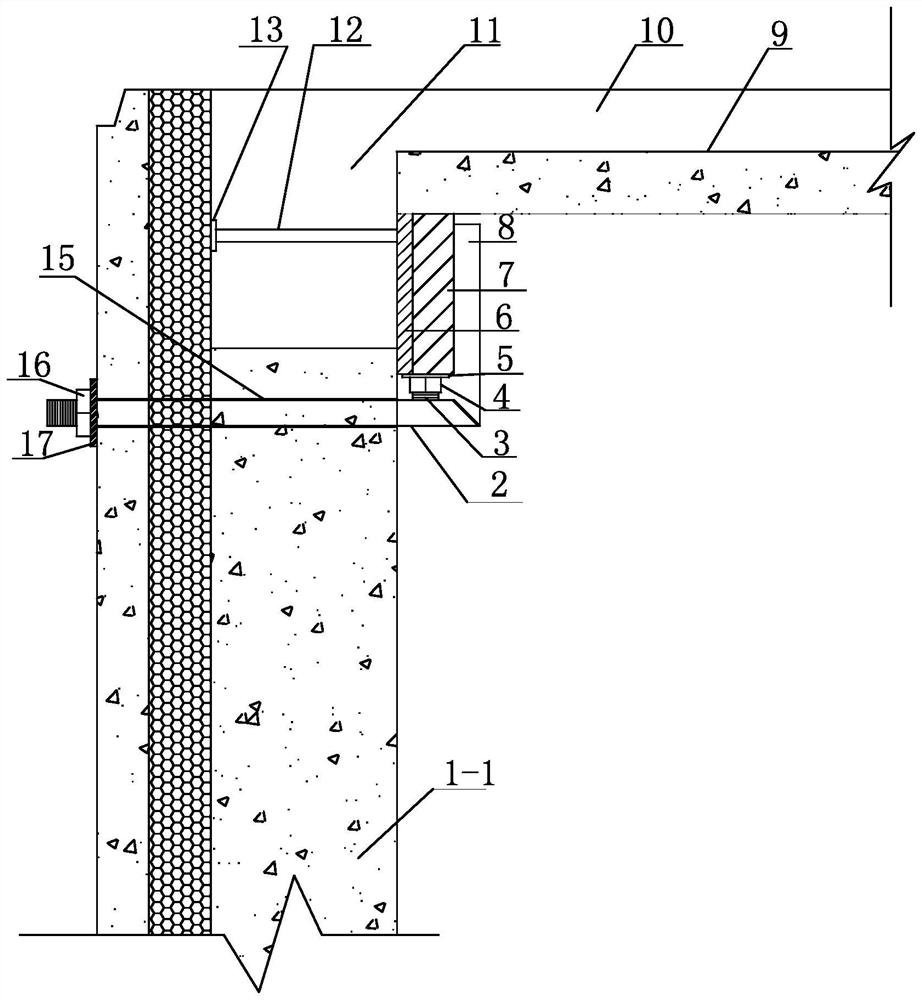

Assembled shear wall post-pouring ring beam template and plate support integrated design and construction method

ActiveCN110397268AReduce Temporary SupportTo achieve the effect of fair-faced concreteForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemIntegrated design

The invention belongs to the field of assembled building construction, and particularly relates to an assembled shear wall post-pouring ring beam template and plate support integrated design and construction method. The assembled shear wall post-pouring ring beam template and plate support integrated design and construction method comprises the first step of template system calculation model determining, the second step of template system bearing capacity checking calculation, the third step of prefabricated plate support system calculation model determining, the fourth step of prefabricated plate support system bearing capacity checking calculation, the fifth step of template system component material determining, the sixth step of back ridge manufacturing, the seventh step of template manufacturing, the eighth step of right-angle bolt manufacturing, the ninth step of template inner support manufacturing, the tenth step of template installing, the eleventh step of prefabricated platehoisting and the twelfth step of concrete pouring. The assembled shear wall post-pouring ring beam template and plate support integrated design and construction method solves the key technical problems about difficult post-pouring ring beam template fixing, plate bottom slurry leakage, displacement and the like, template and prefabricated plate support integration is achieved, prefabricated platebraces are saved, post-pouring ring beams meet the bare concrete requirement, the template standardization degree is high, factory production and assembled installation are achieved, cyclic usage is repeated, and the national environment protection and energy saving requirements are met.

Owner:SHANDONG GOLDENCITY CONSTR

Fabricated wallboard and fabricated station building

The invention discloses a fabricated wallboard. A special concrete layer is arranged on an outsourcing layer, two layers of keel net layers connected into a whole are embedded into the outsourcing layer, and the space between the keel net layers is filled with a heat preservation and sound insulation material. A first connecting pipe and / or a second connecting pipe are / is pre-buried in the connecting face, connected with another wallboard, of the wallboard, the first connecting pipe comprises a pre-buried segment pre-buried in the wallboard and a stretching segment stretching out of the surface of the wallboard, and the second connecting pipe comprises a pre-buried segment pre-buried in the wallboard. The outer diameter of the first connecting pipe is smaller than the inner diameter of the second connecting pipe, and the first connecting pipe and the second connecting pipe are in matching connection. The invention further provides a station building assembled by the fabricated wallboard. The advantages of being high in precision, long in service life, firm, capable of preventing thefts, capable of achieving heat preservation and sound insulation, quite good in fireproof performance, quite high in station building speed, short in period and the like are achieved.

Owner:BOSS GRP HLDG LTD

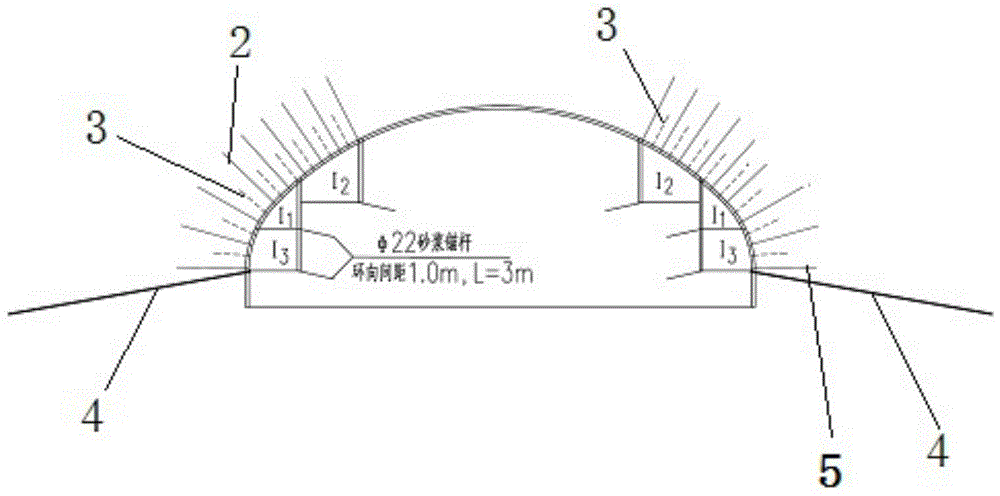

Tunnel excavation method in shallow-buried bias-pressure toppling-deformation bulk solid and strong-unloading rock structure

InactiveCN104500079AReduce self-supporting capacitySave on temporary support measuresTunnelsProtective coversLandslideSelf-stabilization

The invention relates to a tunnel excavation method in the shallow-buried bias-pressure toppling-deformation bulk solid and strong-unloading rock structure, in particular to the tunnel excavation method in shallow-buried bias-pressure toppling-deformation bulk solid and strong-unloading rock structure in the field of tunnel construction and aims to reduce temporary support workload and prevent landslide triggered by tunnel excavation and oversize deformation of tunnels. The method includes steps of a, dividing a tunnel to be excavated into an upper step, a middle step, a lower step and an inverted arch; b, excavating the upper step and supporting; c, excavating the middle step and supporting; d, excavating the lower step and supporting; e, excavating the inverted arch and supporting. According to self-stabilization of the surrounding rock the corresponding tunnel excavation way is determined, slope excavation is realized by sufficiently utilizing self-stabilization of the surrounding rock and temporary support is reduced. By the tunnel excavation method, construction is speeded up, investment is reduced and construction safety is ensured.

Owner:POWERCHINA CHENGDU ENG

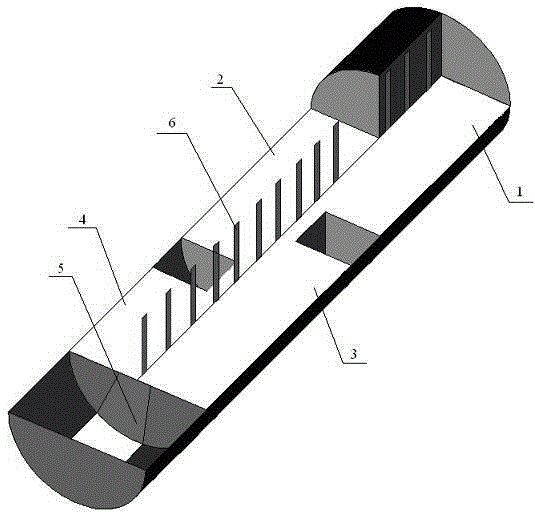

Super-large-section subsurface tunnel tall core soil dismounting method

ActiveCN110145314AImprove demolition efficiencyImprove work efficiencyUnderground chambersTunnel liningBuilding constructionEngineering

The invention provides a super-large-section subsurface tunnel tall core soil dismounting method. The method includes the following steps that (1) a first pilot pit is formed through excavation on theupper portion of one side of upper core soil in the longitudinal direction of a tunnel, and the first pilot pit is in a horizontal state; (2) a second pilot pit in a horizontal state is formed through excavation on the upper portion of the other side of the upper core soil in the longitudinal direction of the tunnel, the first pilot pit and the second pilot pit are pushed in the excavation direction, and then the upper core soil is excavated so that a transverse channel which is perpendicular to the first pilot pit and the second pilot pit can be formed; (3) a first step group which comprisesa plurality of steps is formed by excavating the first pilot pit, and the length of each step of the first step group is 3-5 m; (4) the upper core soil is dismounted transversely, and thus a step full-section with the length being 6 m is formed; (5) downward excavation is performed below the second pilot pit, and thus a second step group which comprises a plurality of steps is formed; (6) excavation of a core soil inverted arch and construction of an inverted arch second lining are performed; and (7) tunnel large-section second lining construction is performed.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

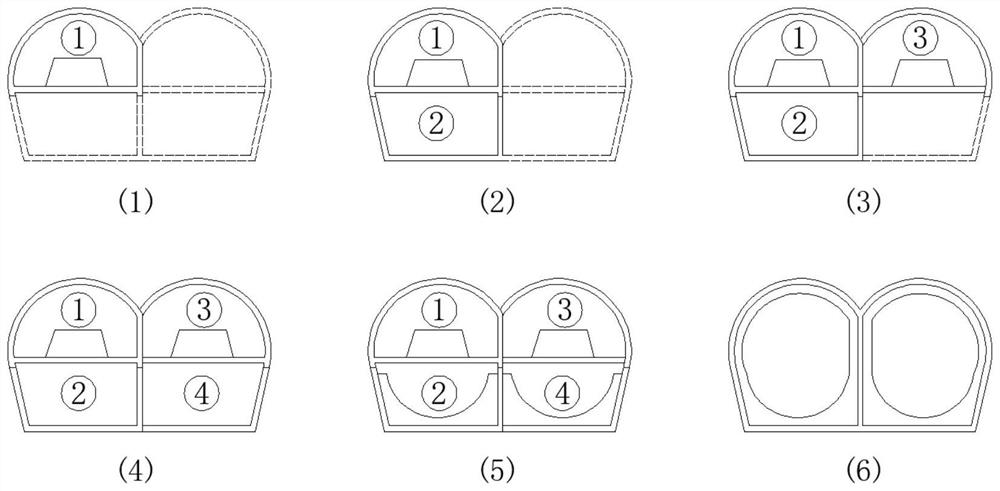

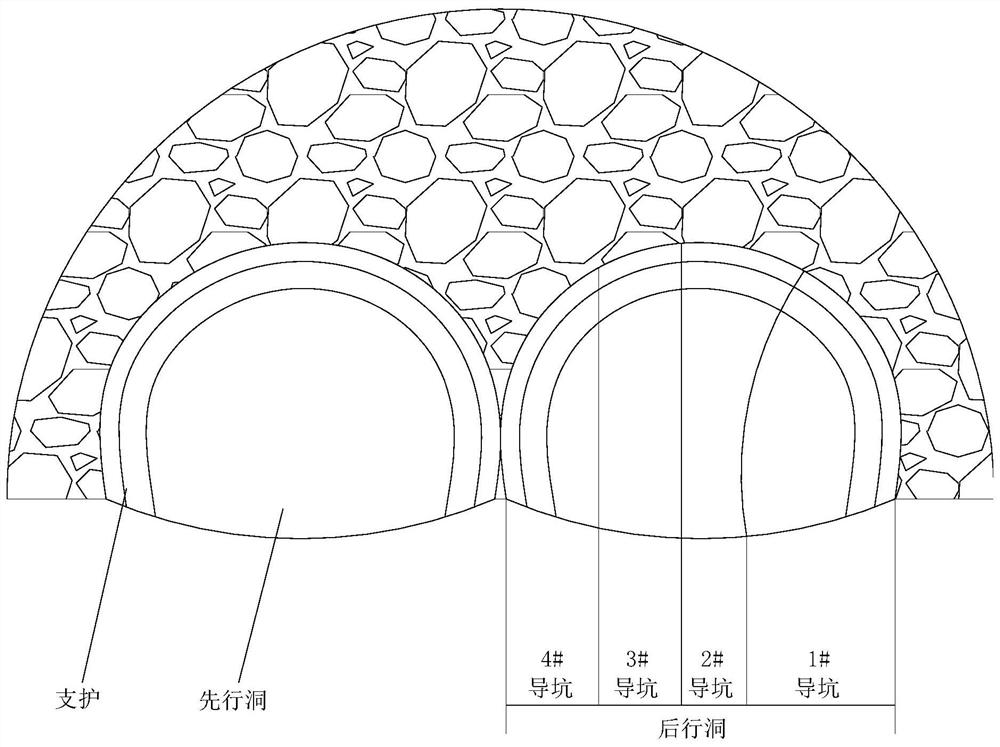

Construction method of multi-arch tunnel without middle wall

InactiveCN105275472AReduce the number of disturbancesAvoid deformationUnderground chambersTunnel liningRough surfaceStructure of the Earth

The invention discloses a construction method of a multi-arch tunnel without a middle wall. The construction method comprises the steps of digging a right-side tunnel, performing primary supporting and secondary lining, constructing the external surface of a right-side tunnel early-period support to a step-shaped contact surface which is also a rough surface, pouring a reinforcing bar in each step, wherein one part of the reinforcing bar is poured in the early-period support and the other part is exposed to outside; digging a left-side tunnel, performing left-side tunnel early-period supporting and secondary lining; constructing the surface of the left-side tunnel early-period support to a step-shaped contact surface which matches the external surface of the right-side tunnel early-period support, thereby matching the step-shaped contact surface of the right-side tunnel, and fully pouring the reinforcing bars which is exposed to outside in a previous step into the left-side tunnel early-period support in injection; and forming an integral force bearing system. The construction method of the multi-arch tunnel without the middle wall has advantages of simple construction process, high speed and stable connection structure.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

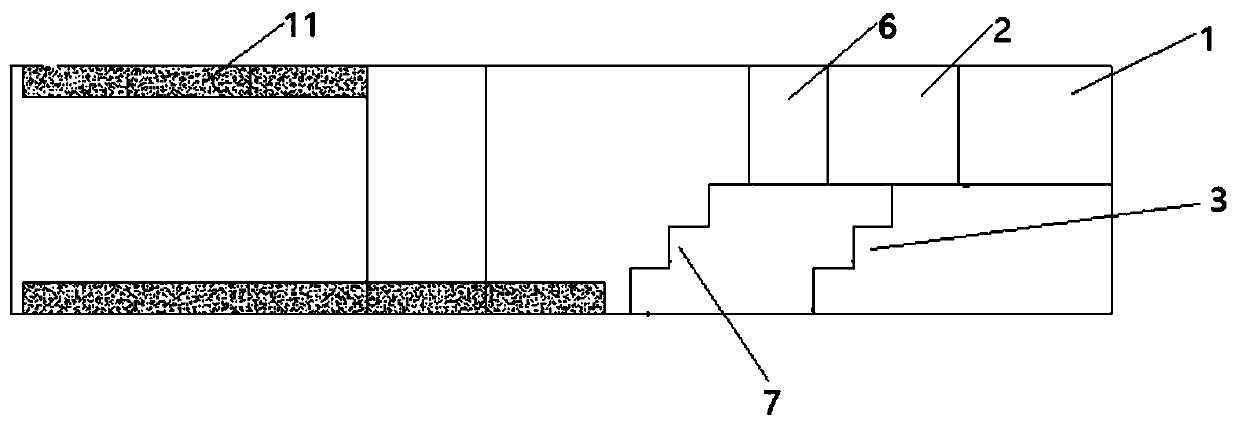

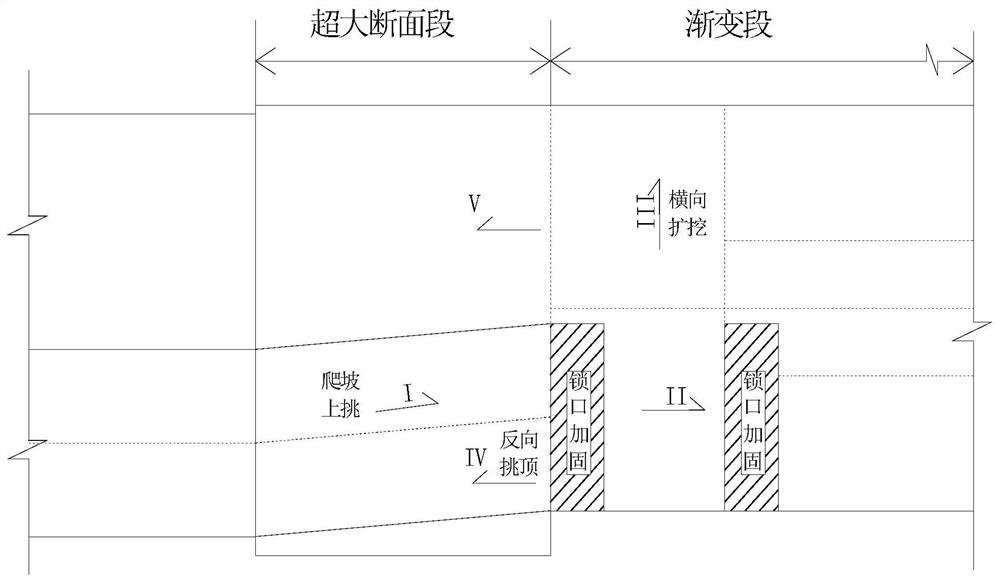

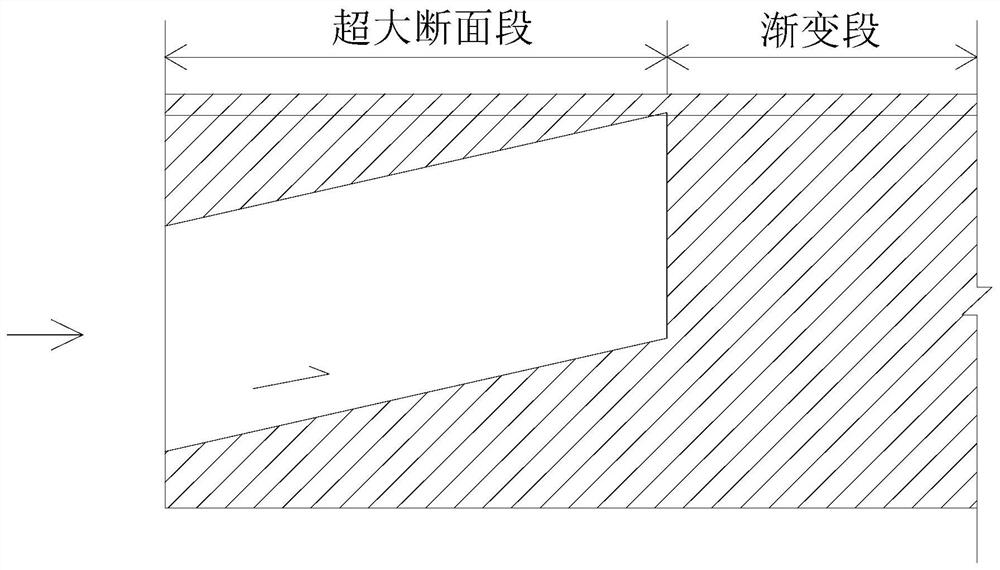

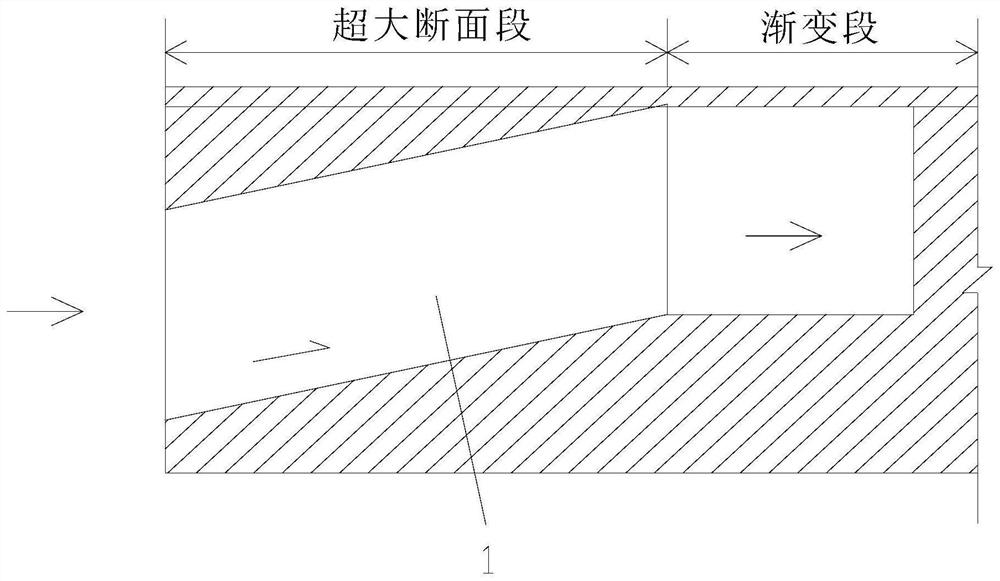

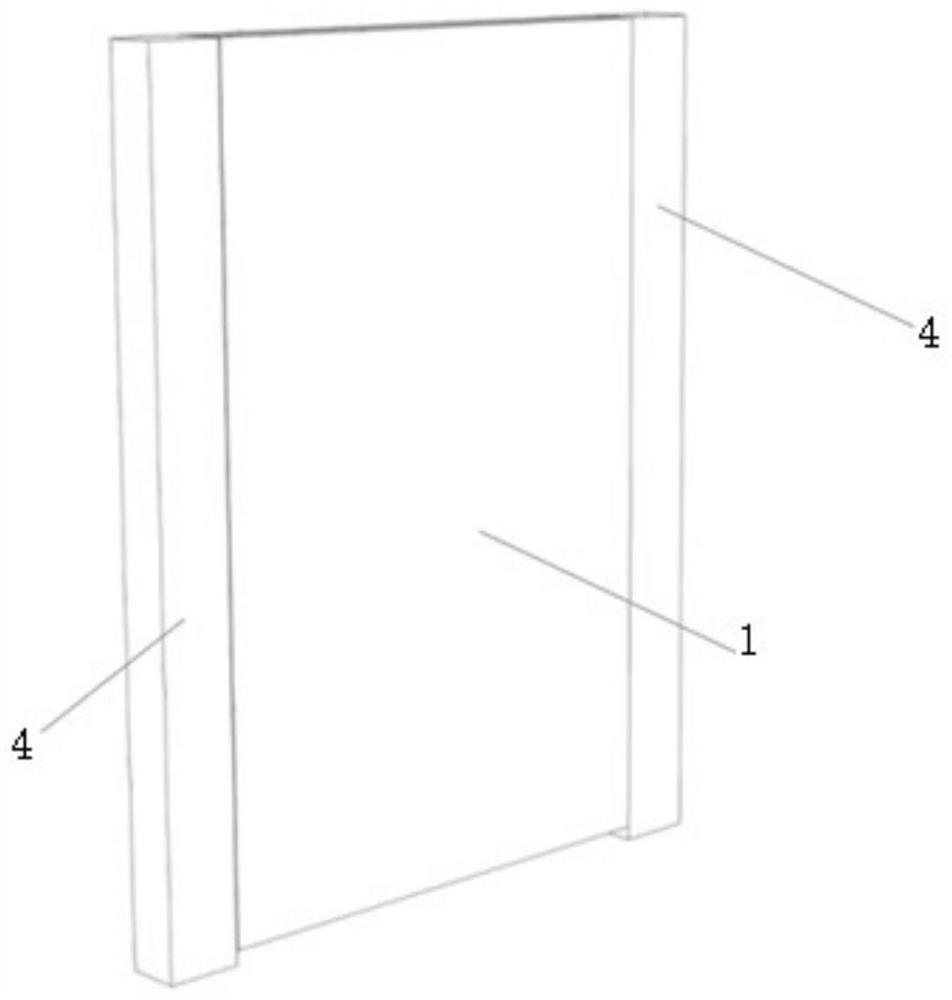

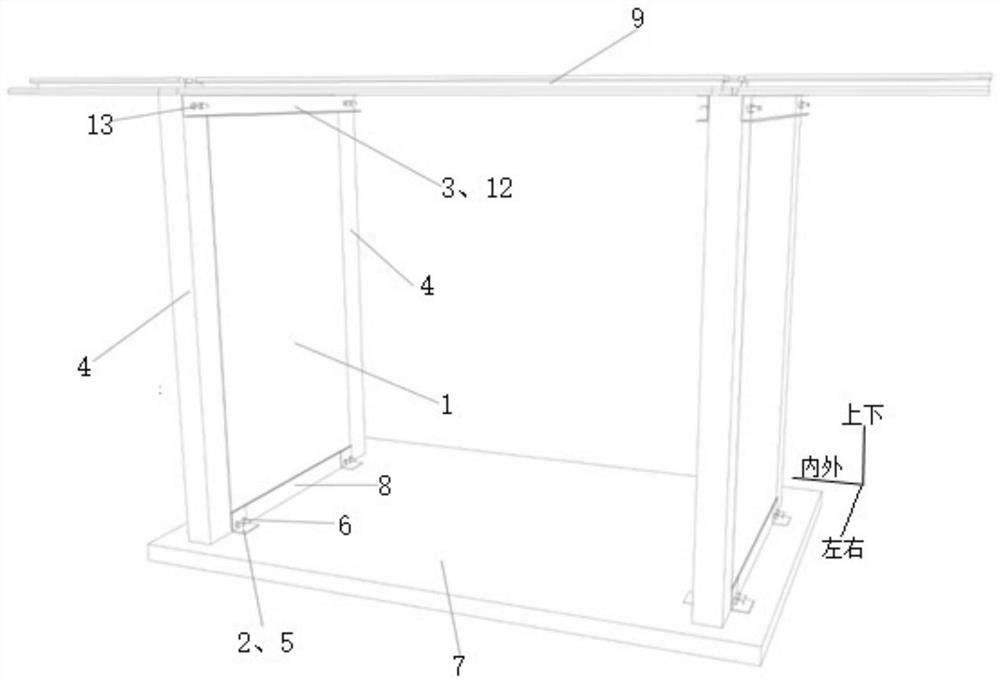

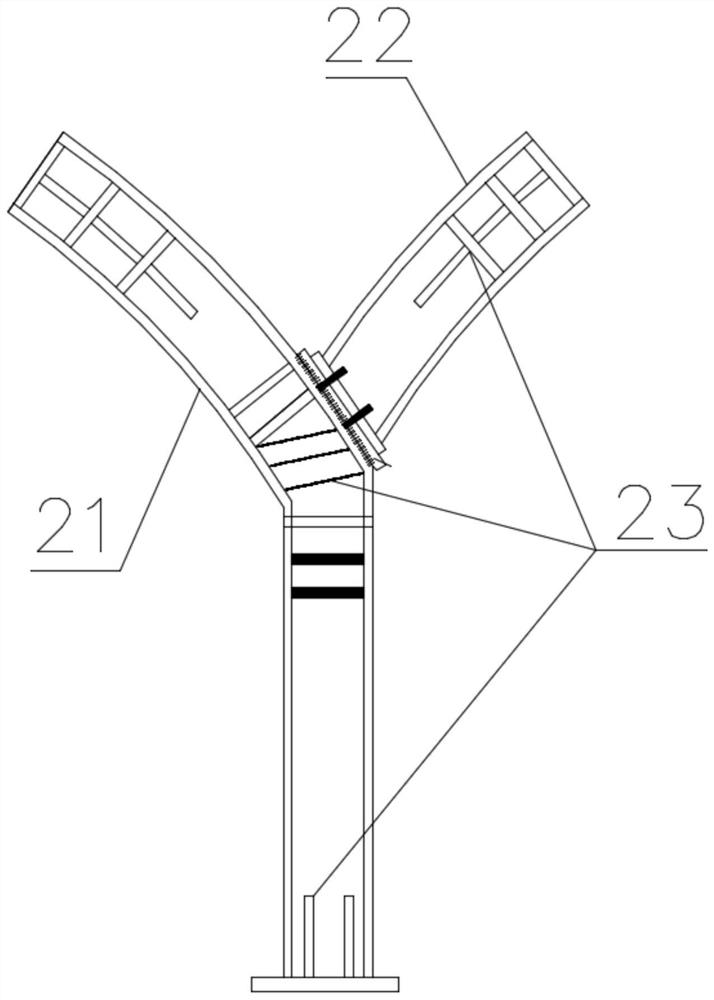

Construction method for super-large section and transition section of road tunnel bifurcation

ActiveCN112610221AEnsure excavation safetyReduce Temporary SupportUnderground chambersTunnel liningArchitectural engineeringCivil engineering

The invention discloses a construction method for a super-large section and a transition section of a road tunnel bifurcation, and belongs to the technical field of tunnel engineering. The construction method comprises the steps that 1) excavation is conducted from the end of a bifurcation way on the right side of a tunnel to the transition section, and an upper right pilot tunnel is excavated in a large section; 2) temporary support is conducted on the upper right pilot tunnel excavated in the step 1); 3) the transition section of the tunnel is excavated forwards horizontally from an upper step of the upper right pilot tunnel of the large section, and an upper step of a pilot tunnel on the right side of the transition section is formed after a certain distance is excavated; and 4) primary support is conducted on the upper right pilot tunnel excavated in the step 3), and meanwhile locking opening reinforcing and the like are conducted. According to the construction method for the super-large section and the transition section of the road tunnel bifurcation, the pilot tunnel is adopted to penetrate through the super-large section in advance, and support of the head section and the tail section of the super-large section is strengthened; through the special excavation method and the support mode, the safety of the excavation process can be ensured, and the situations of excessive vault settlement, arch wall convergence, unstable arch springing, serious heaving floor and the like caused by the fact that the section is too large can be avoided; and compared with an existing excavation method, the construction method has the advantages that the number of temporary supports is small, and support dismounting is easier.

Owner:CHONGQING UNIV +1

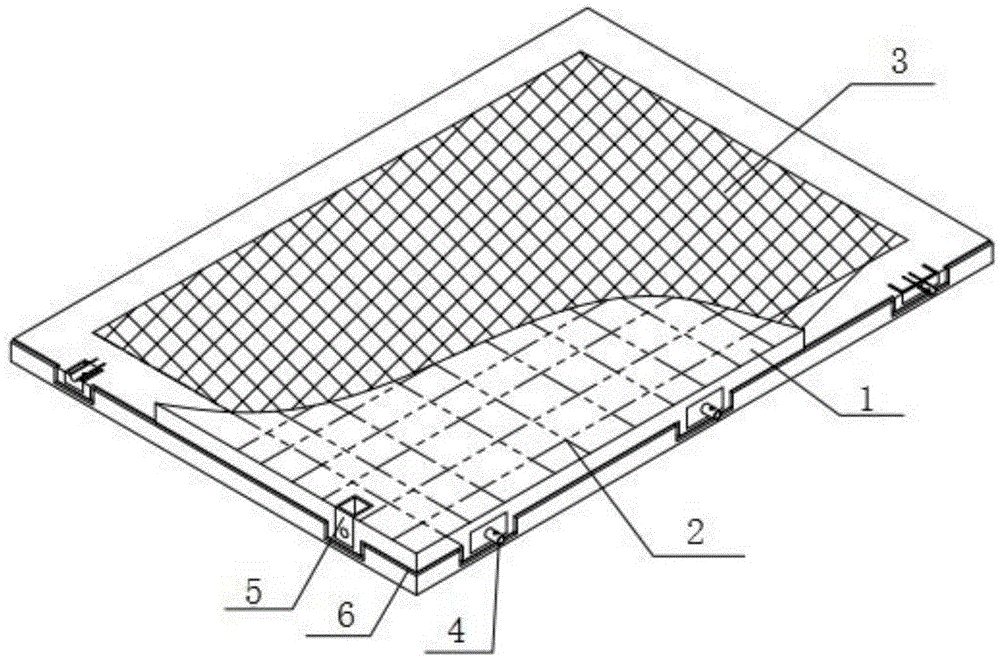

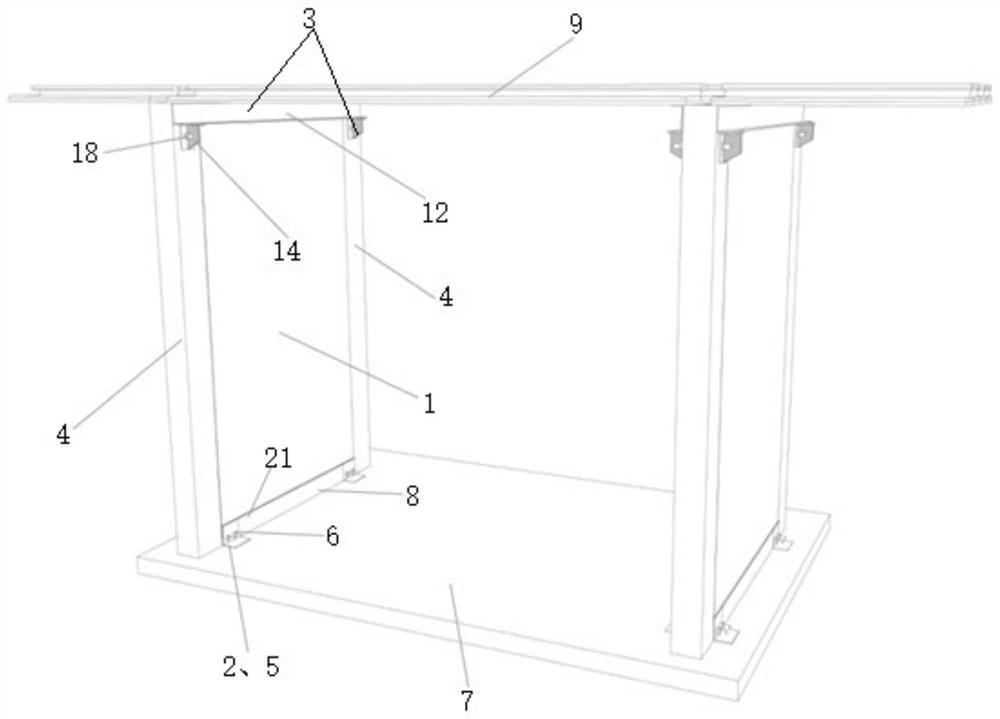

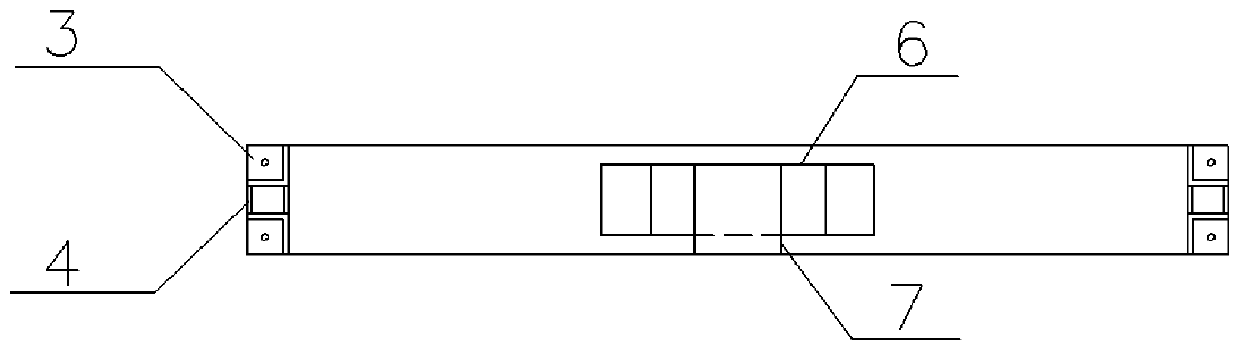

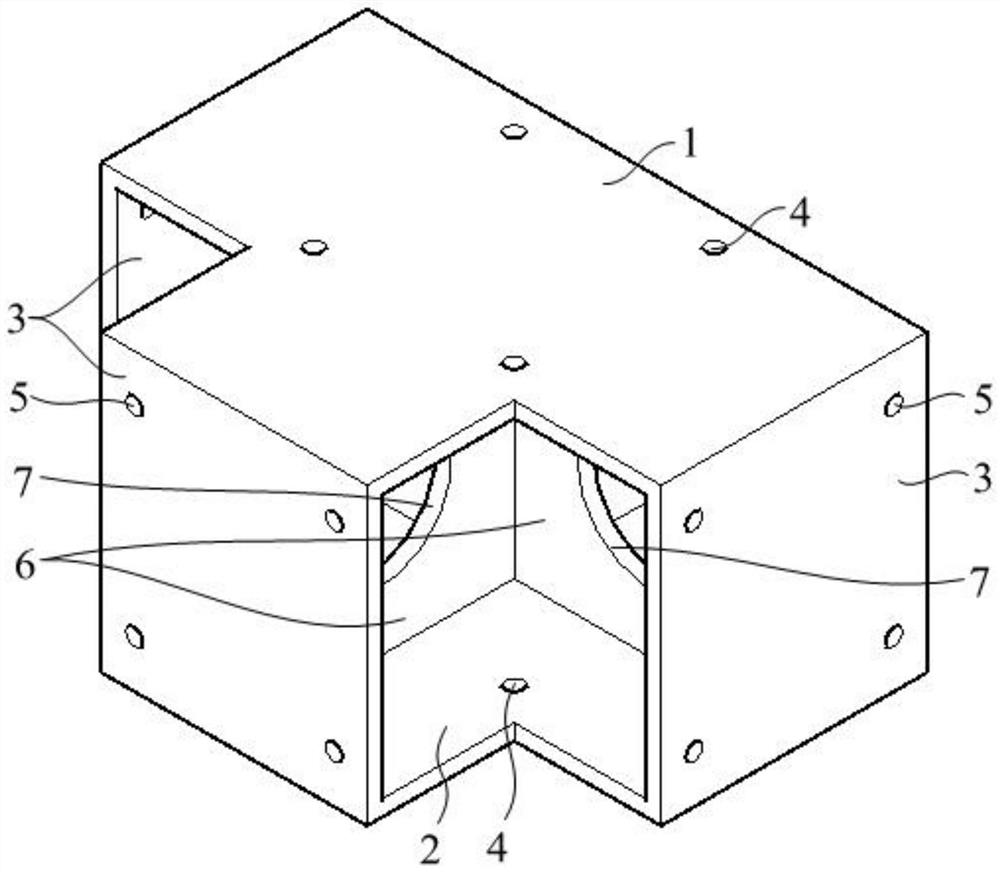

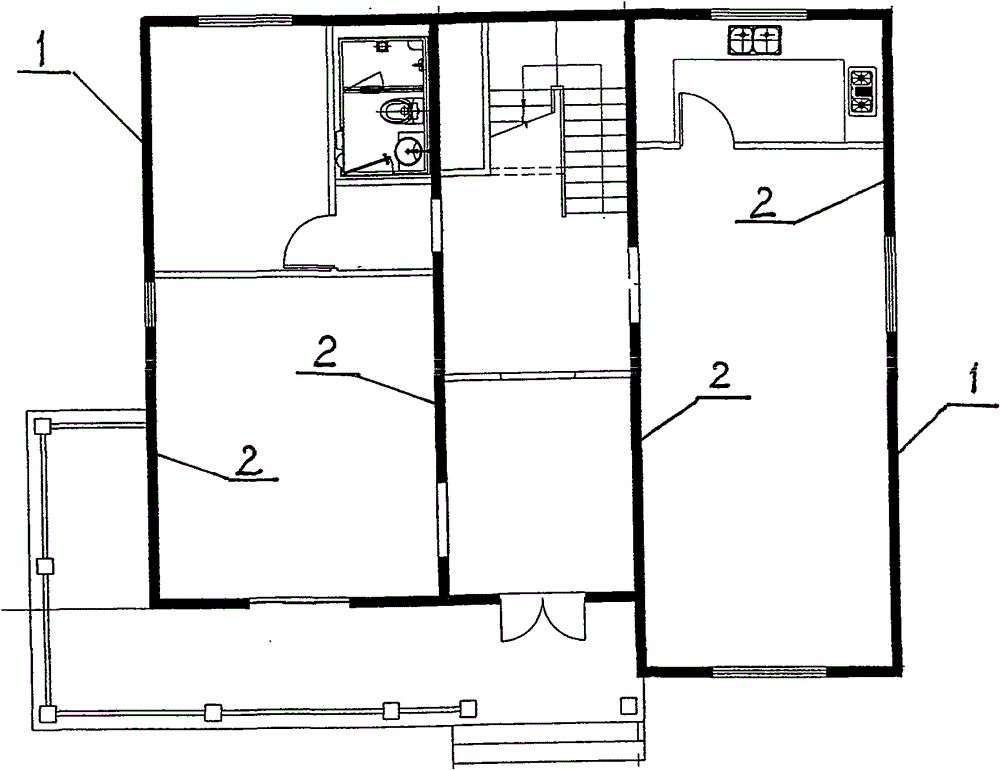

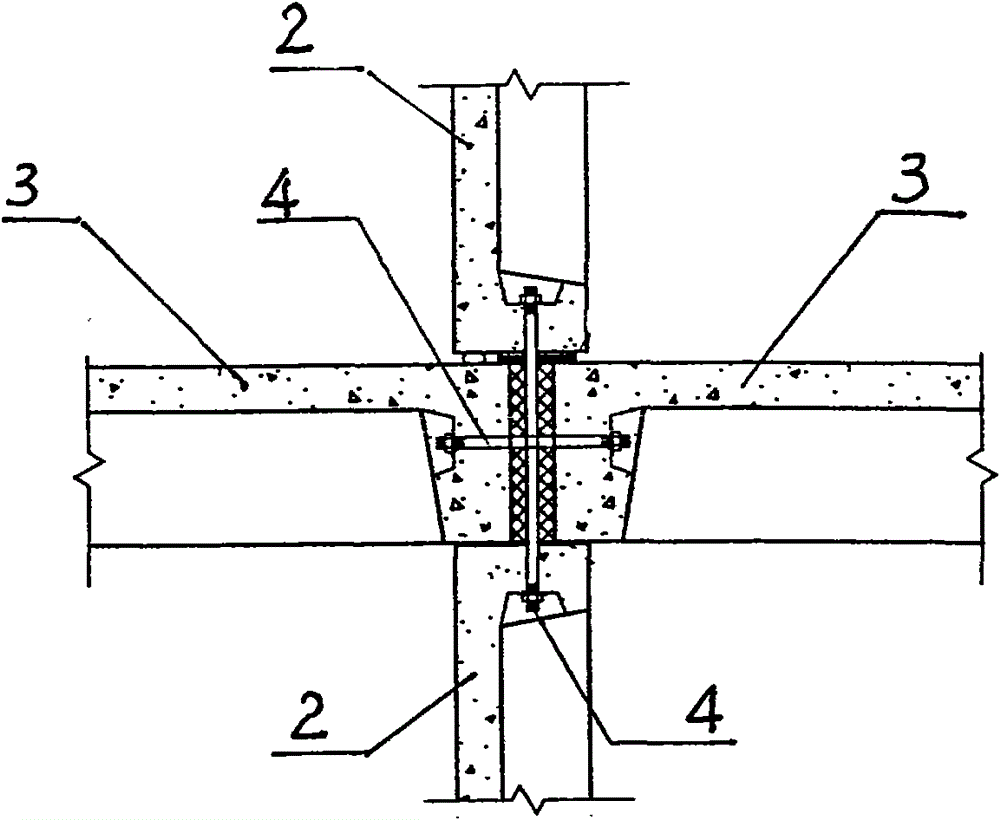

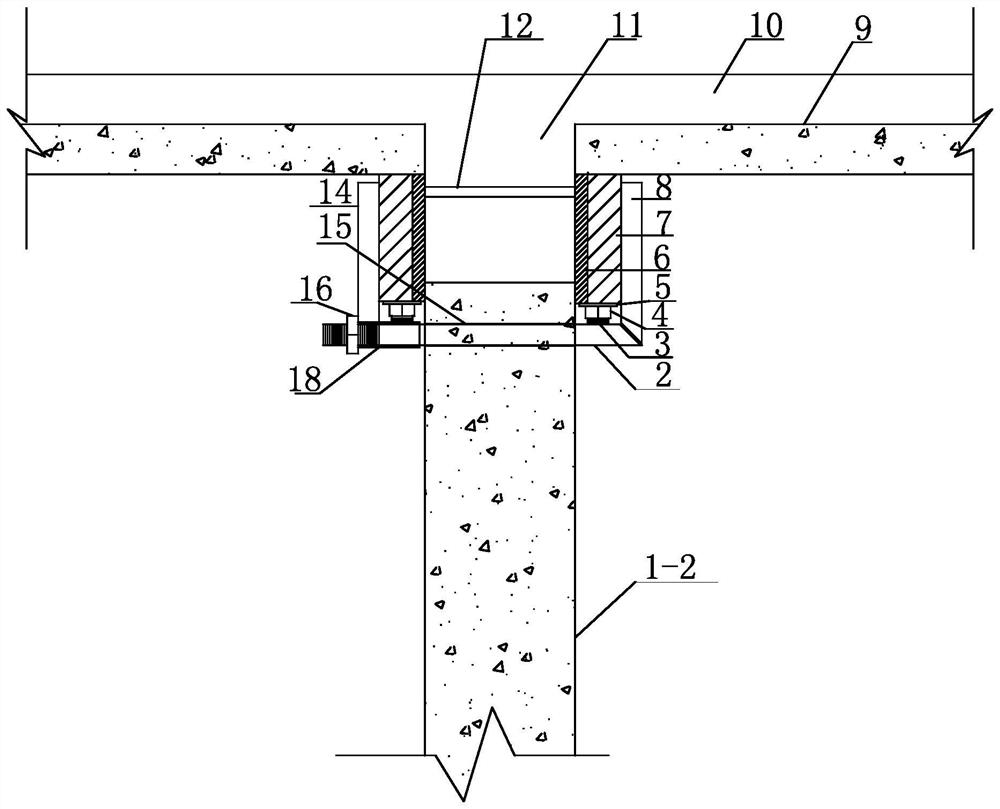

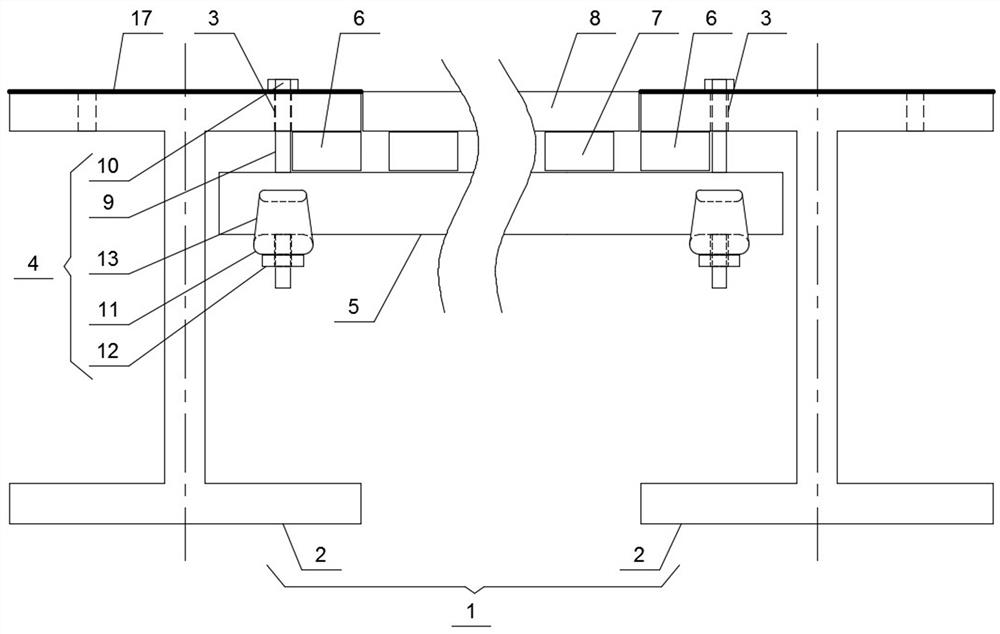

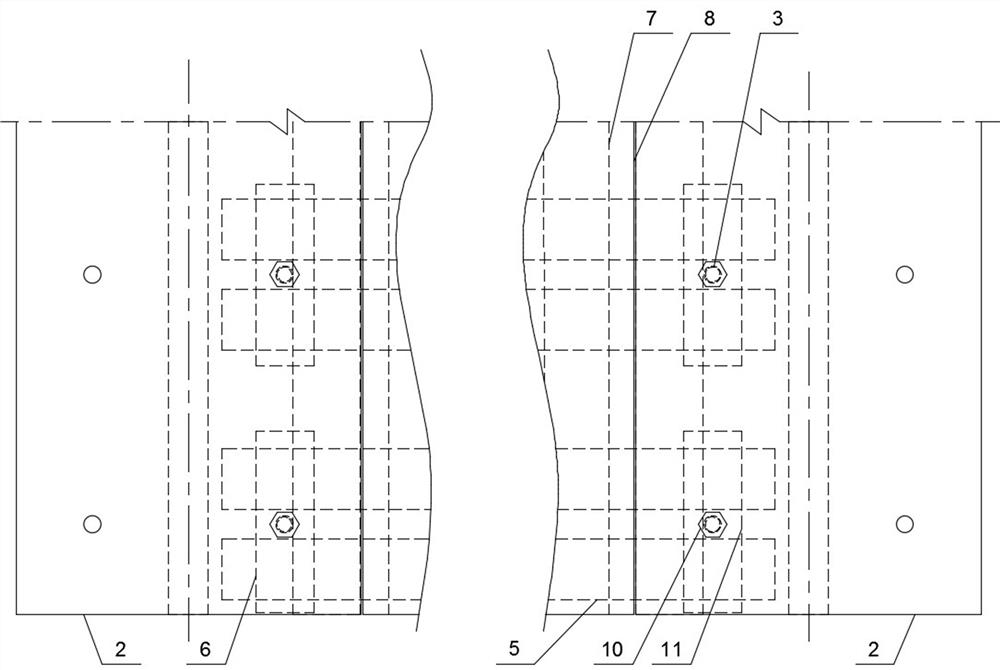

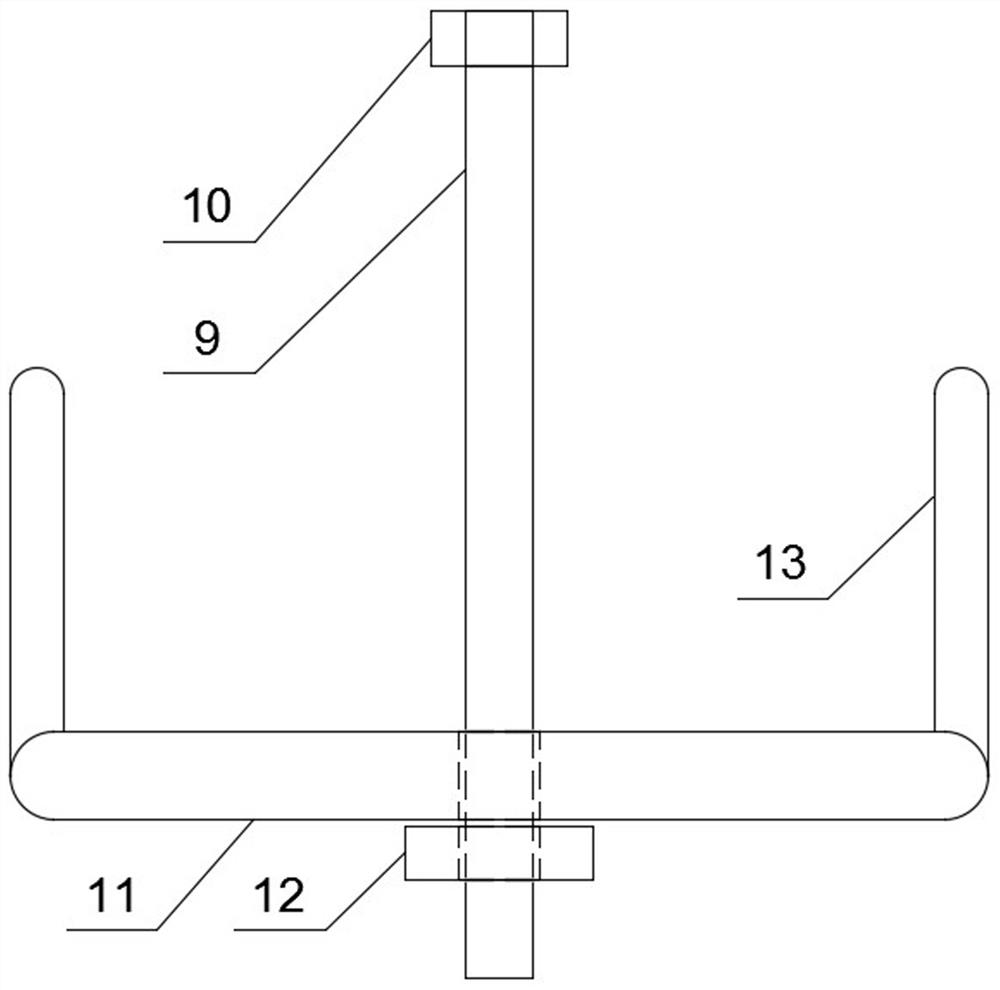

Prefabricated superimposed shear wall mounting system and method

InactiveCN112922359AReduce in quantityLow costWallsBuilding material handlingFloor slabArchitectural engineering

The invention discloses a prefabricated superimposed shear wall mounting system and method, and belongs to the field of buildings. The prefabricated superimposed shear wall mounting system comprises a prefabricated superimposed shear wall body, a bottom supporting piece and a top supporting piece; a steel pipe edge constraint piece is arranged on the side surface of the prefabricated superimposed shear wall; a first group of bolt holes are formed in two unit parts of the bottom supporting piece at a certain height from the bottom surface, are connected together through a first group of through bolts, and keep a certain distance between the two unit parts; the bottom of the prefabricated superimposed shear wall is placed on the first group of through bolts and is clamped and fixed, and a plugging side mold is arranged at the bottom of the prefabricated superimposed shear wall; and the top supporting piece is mounted at the top of the prefabricated superimposed shear wall, and an upper-layer prefabricated superimposed floor slab is placed on the top face of the top supporting piece. The temporary supports on the construction site are greatly reduced, the construction space is saved, the construction efficiency is improved, the cost is reduced, and the temporary supports can be detached and reused.

Owner:山东千悦建筑科技有限公司 +1

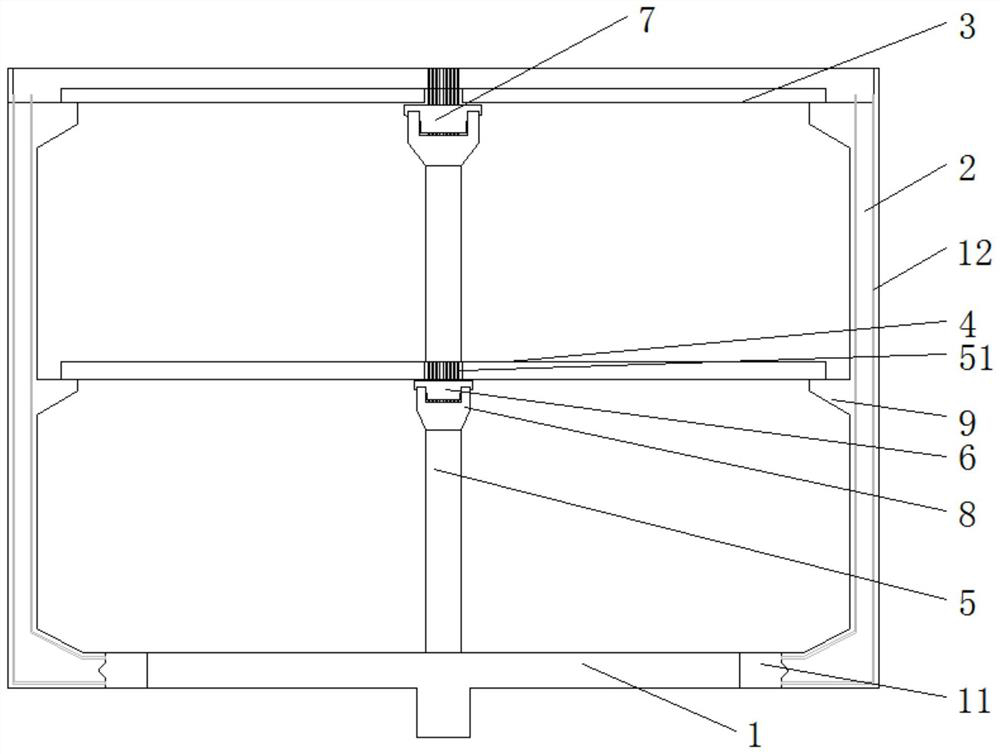

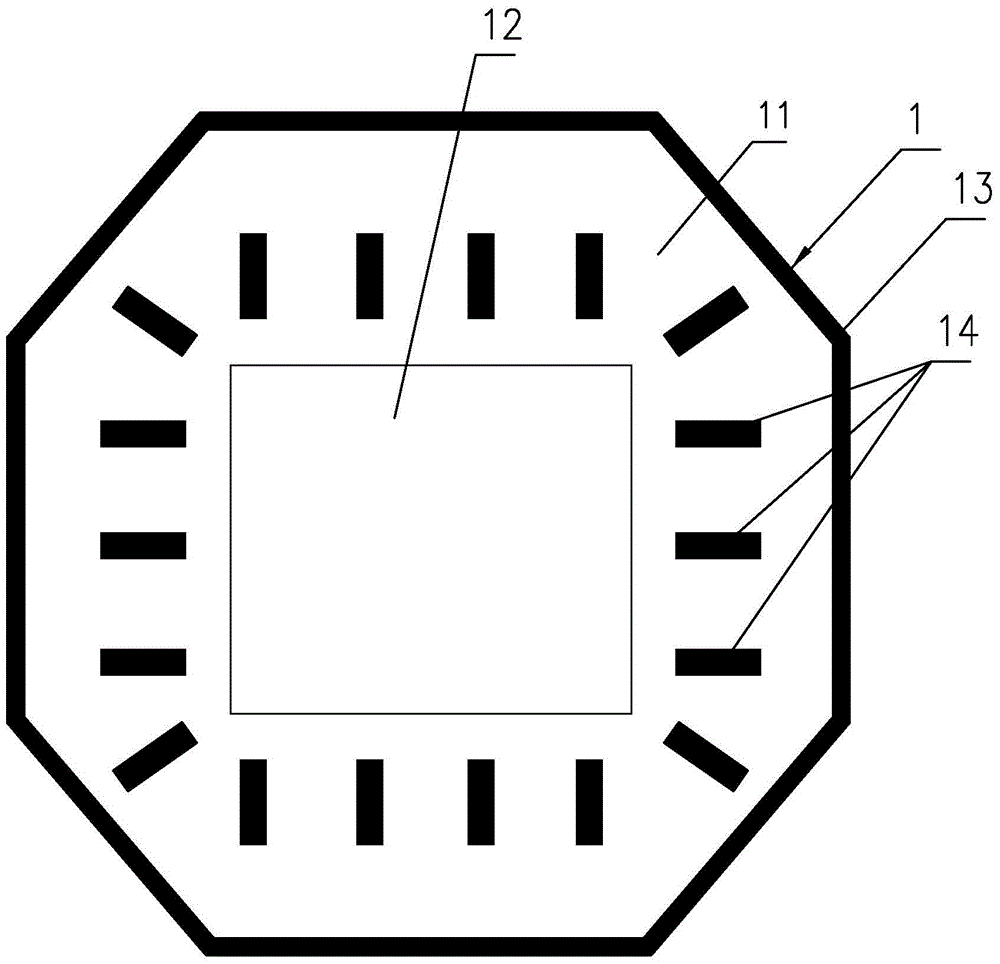

Assembled integral type subway station structure

PendingCN114875965AEasy to transportImprove integrityArtificial islandsProtective foundationArchitectural engineeringSubway station

The invention discloses an assembled integral subway station structure which comprises a cast-in-place bottom plate, prefabricated side walls, a prefabricated top plate, a prefabricated middle plate, a prefabricated middle column, a middle longitudinal beam and a top longitudinal beam. The prefabricated side walls are arranged on the two sides of the cast-in-place bottom plate, and the prefabricated middle column is arranged on the middle side of the upper portion of the cast-in-place bottom plate; the top longitudinal beam and the middle longitudinal beam are arranged on the upper portion and the middle of the prefabricated middle column respectively, and the prefabricated middle column is a double-layer integrated segment column. According to the assembled integral type subway station structure, through organic combination of a prefabricated structure and cast-in-place and UHPC post-pouring at the joints, rigid connection of the joints is achieved, the structural integrity is good, safety and reliability are achieved, compared with full prefabrication, components are lighter, transportation and hoisting are convenient, the requirement for prefabrication and installation precision is low, the construction period can be shortened by 20%, and mold-free and support-free effects are basically achieved; and the on-site labor amount is reduced.

Owner:青岛中科坤泰装配建筑科技有限公司

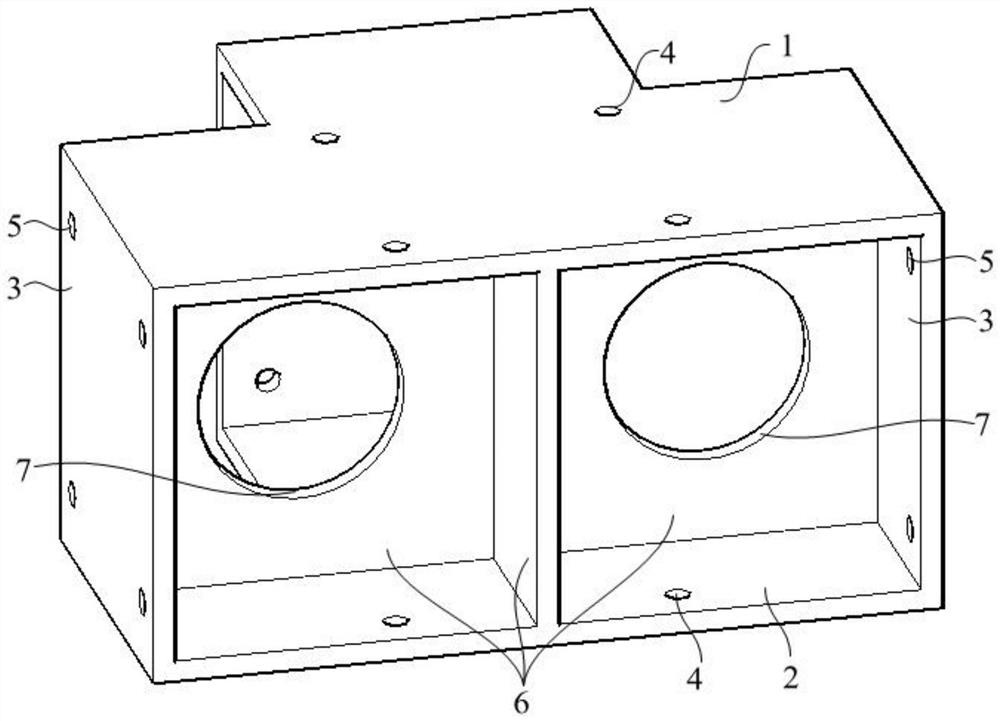

Building structure assembled by concrete dense rib plate box body units

ActiveCN101994346AIncrease stiffnessImprove integrityBuilding constructionsFloor slabLoad-bearing wall

The invention relates to a building structure assembled by concrete dense rib plate box body units. Concrete dense rib plates are adopted for prefabricating box body units, the box body units are connected and fixed with each other through screw bolts to form the building structure, the concrete dense rid plates are used as load bearing walls and floor slabs of the box body units, and the concrete dense rib plates are connected and fixed through screw bolts. The box body units of the invention can realize standardized and industrialized production, have reliable quality, save the building time and the building cost, and have the advantages of precision, high speed, economy and no pollution.

Owner:长沙远大魔方科技有限公司

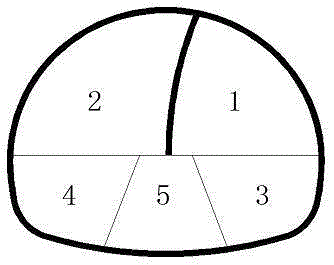

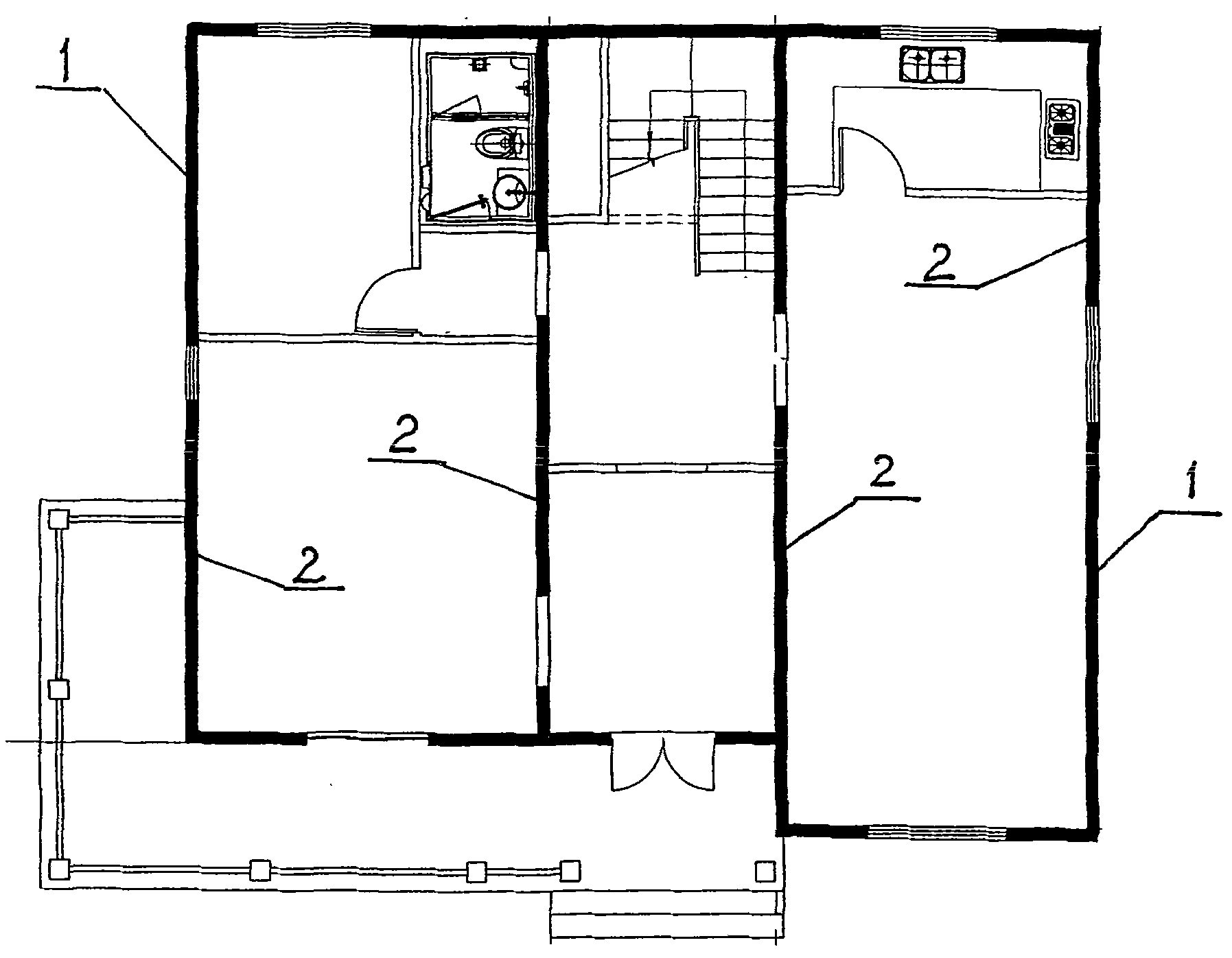

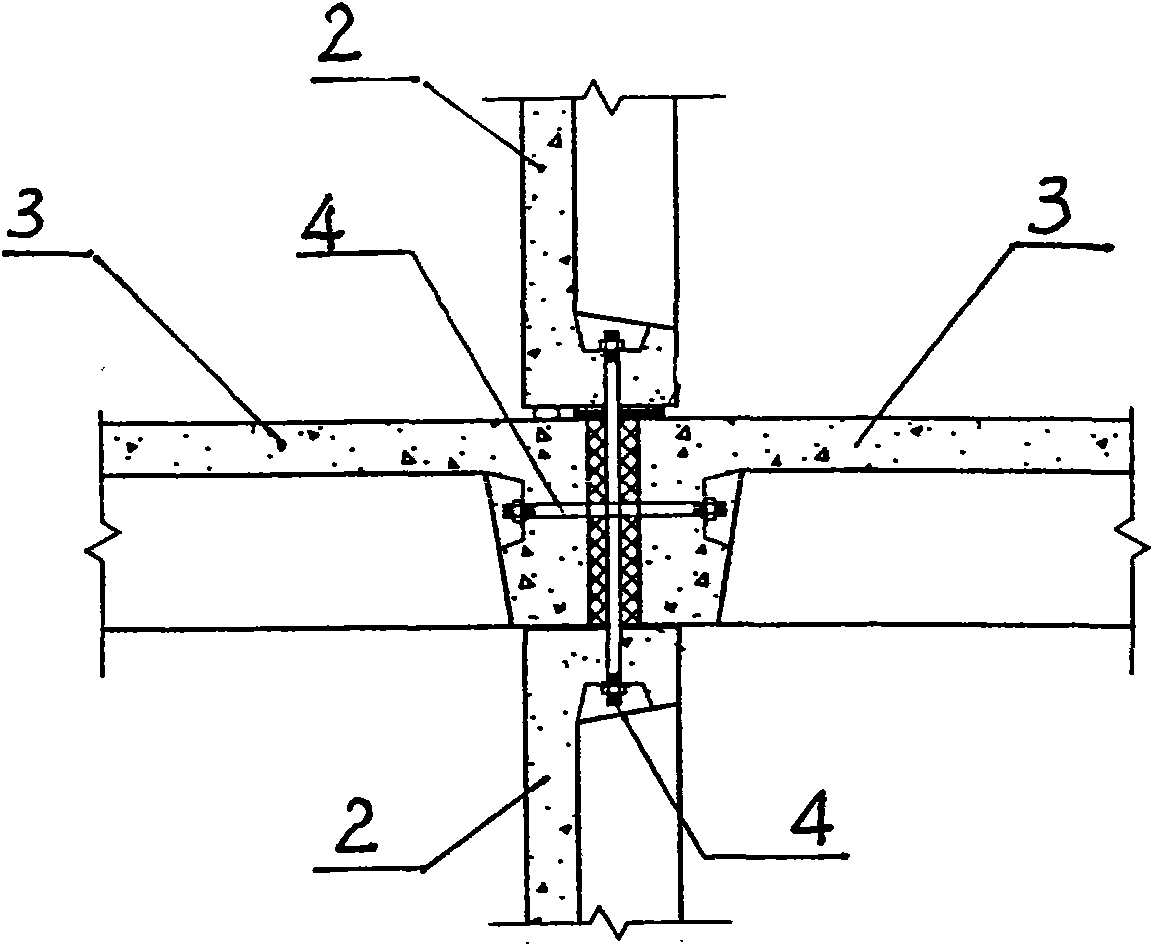

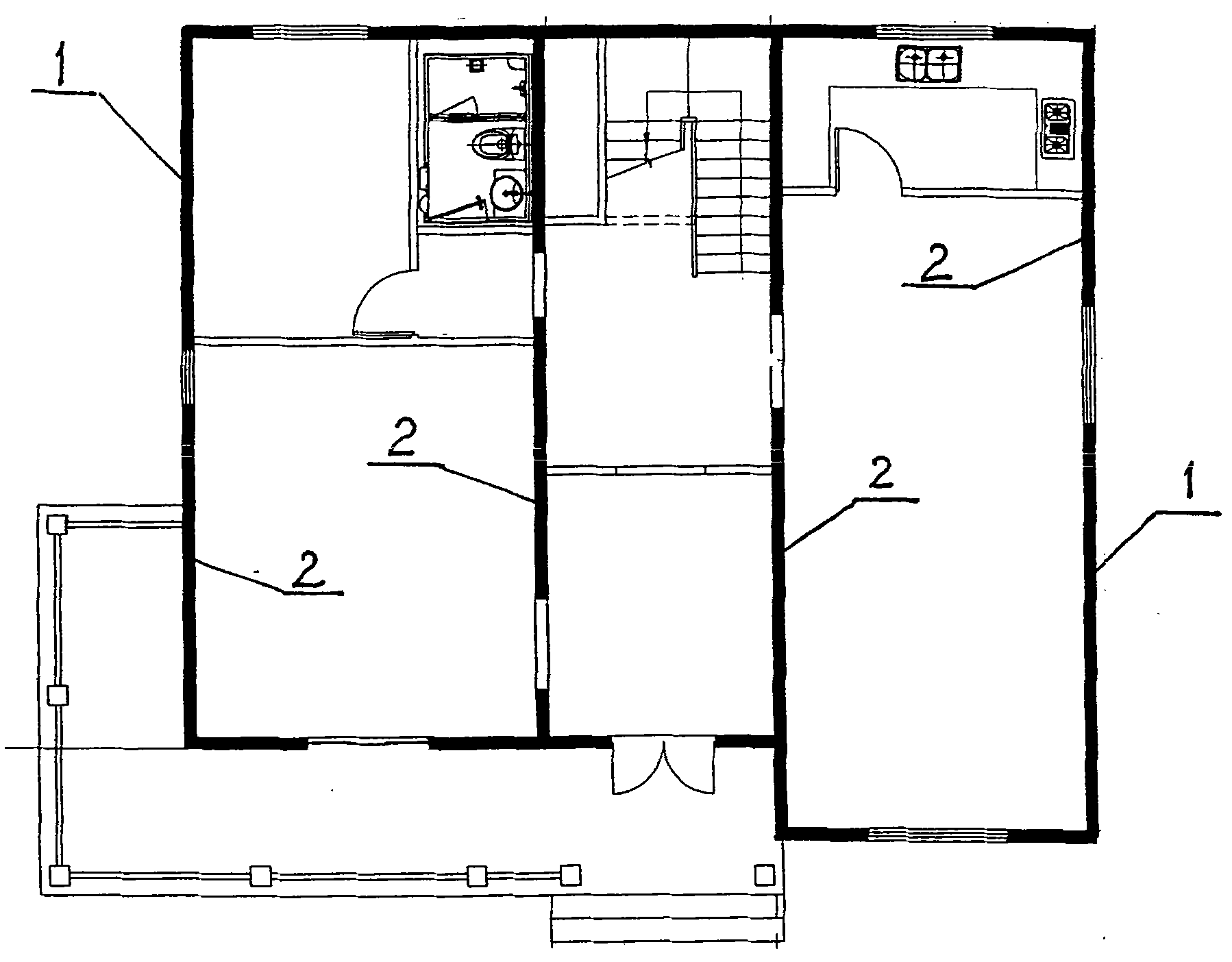

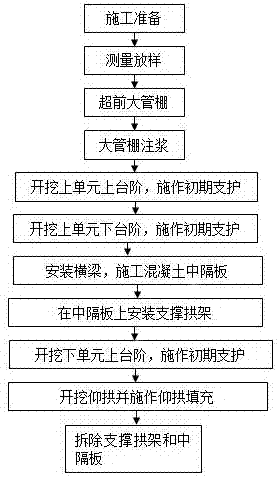

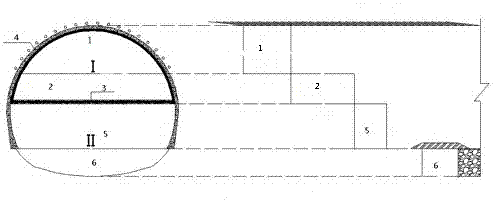

Two-unit and six-step construction method for shallow-buried large-span tunnel

ActiveCN107191206APrevent seepage of stored waterProtect the surrounding environmentUnderground chambersTunnel liningTunnel constructionBuilding construction

The invention relates to the technical field of tunnel construction, in particular to a two-unit and six-step construction method for a shallow-buried large-span tunnel. The two-unit and six-step construction method solves the problem that a construction method which is simple in technology, can achieve the effects of isolation and supporting in the tunnel construction process is lacked in existing soft soil tunnel construction in a water-saturated area. The two-unit and six-step construction method includes the steps of excavating an upper bench of an upper unit and constructing preliminary supporting; excavating an lower bench of the upper unit and constructing preliminary supporting; mounting a cross beam at the separation position of an upper unit body and a lower unit body and constructing a concrete center septum; mounting a support arching on the center septum; excavating an upper bench of an lower unit and constructing preliminary supporting; and excavating and constructing an inverted arch and filling of the inverted arch, and completing enclosing of a tunnel face and forming a ring. By adoption of the two-unit and six-step construction method, water stored in a reservoir is effectively prevented from seepage, not only is the surrounding environment of the reservoir is protected, but also the construction safety is ensured, special equipment is not needed to be invested in construction, the construction quality meets the structural requirements, and the construction method is convenient to operate, and has strong generalization performance.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

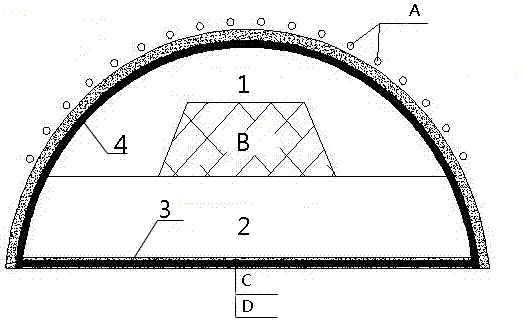

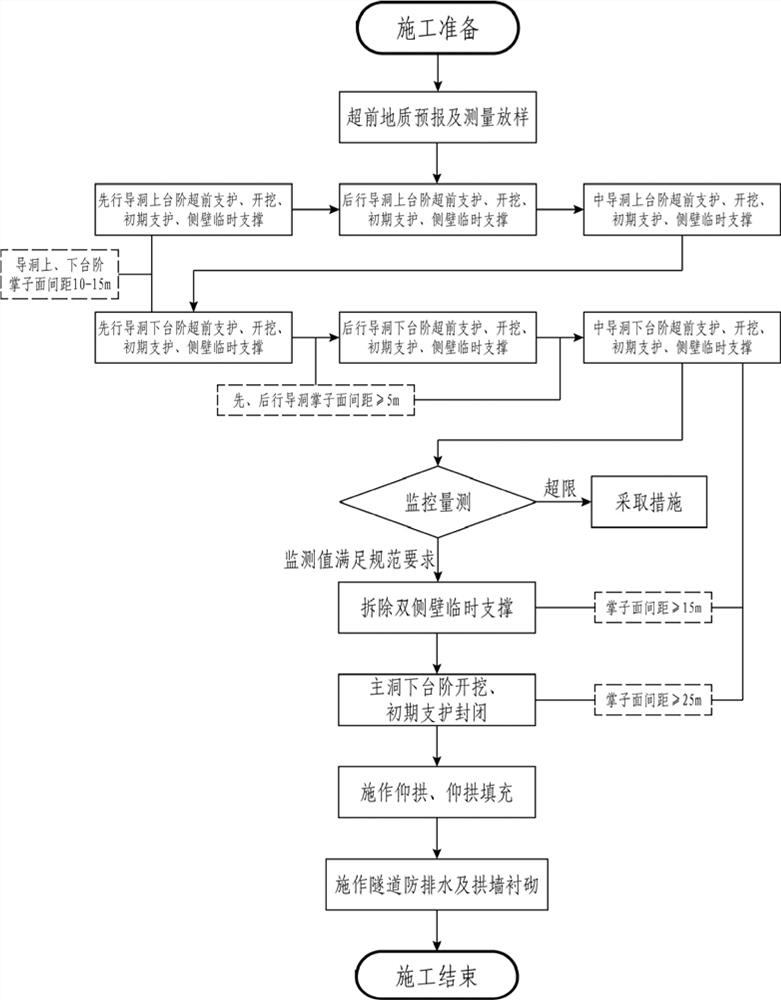

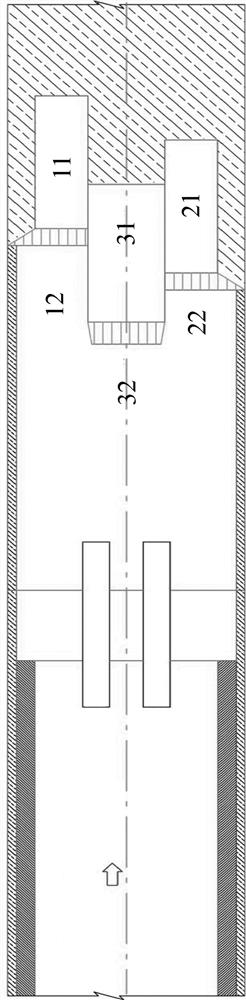

Large-section tunnel excavation method based on double-side-wall pilot tunnel method

PendingCN113417645ALarge construction spaceFacilitate mechanized constructionUnderground chambersDrainageArchitectural engineeringArch bridge

The invention relates to the field of tunnel construction, in particular to a large-section tunnel excavation method based on a double-side-wall pilot tunnel method. The large-section tunnel excavation method comprises the steps that step 1, construction preparation is conducted and is characterized by further comprising the following steps that step 2, an upper step of a pilot tunnel is constructed; step 3, an upper step of the following pilot tunnel is constructed; step 4, an upper step of the middle pilot tunnel is constructed; step 5, a lower step of the pilot tunnel is constructed; step 6, a lower step of the following pilot tunnel is constructed; step 7, a lower step of the middle pilot tunnel is constructed; step 8, monitoring and measuring are performed; step 9, dismantling is performed; step 10, sealing is performed; step 11, inverted arch construction is conducted; and step 12, arch bridge construction is conducted. The large-section tunnel excavation method is convenient to construct and high in efficiency.

Owner:SHANGHAI BAOYE GRP CORP

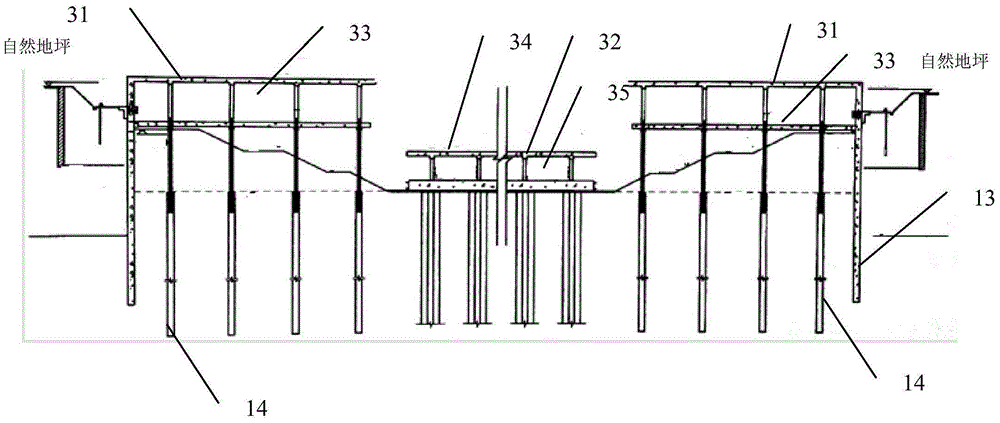

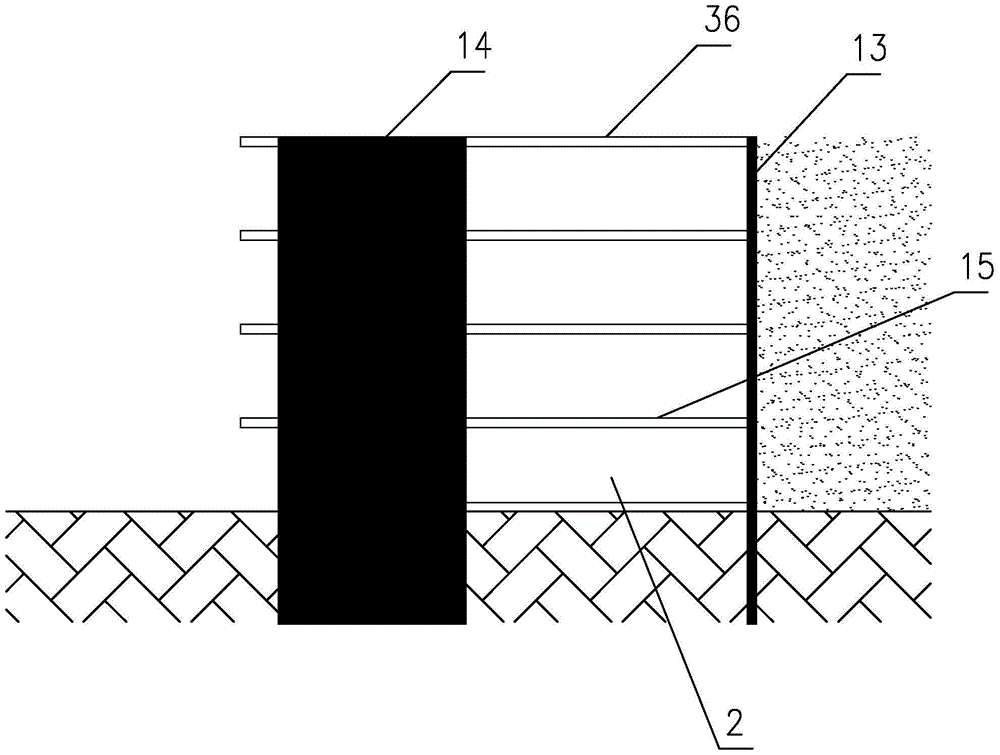

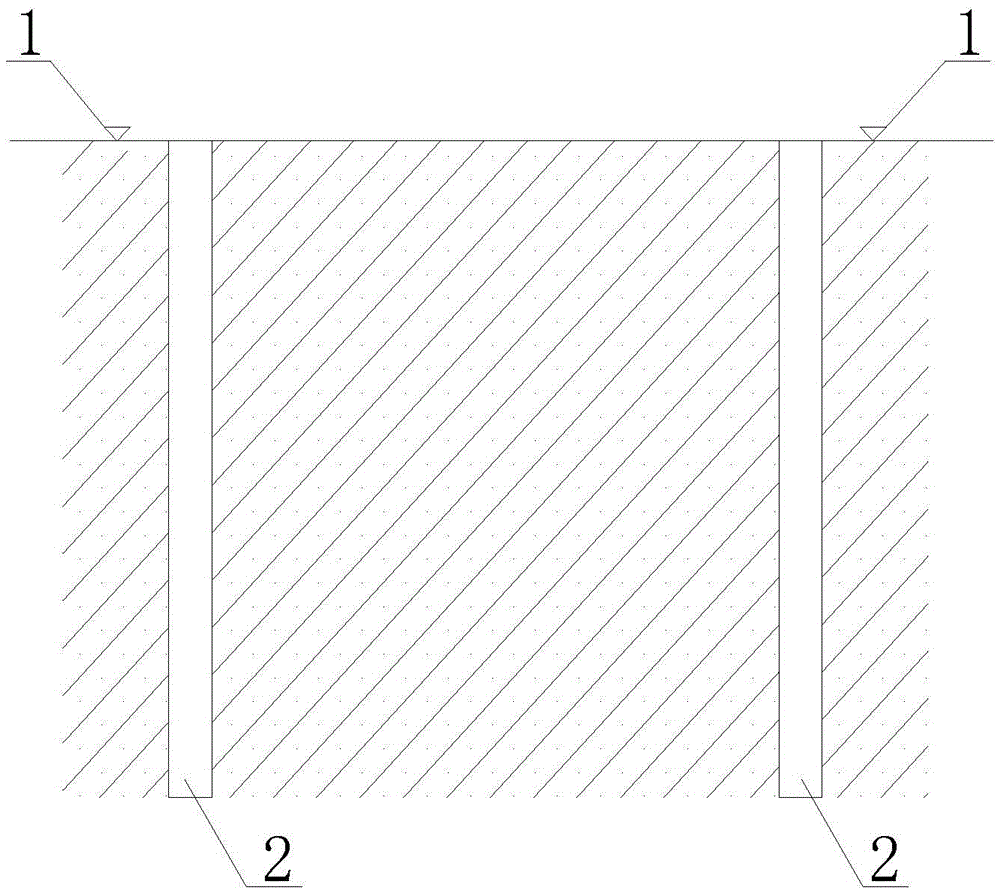

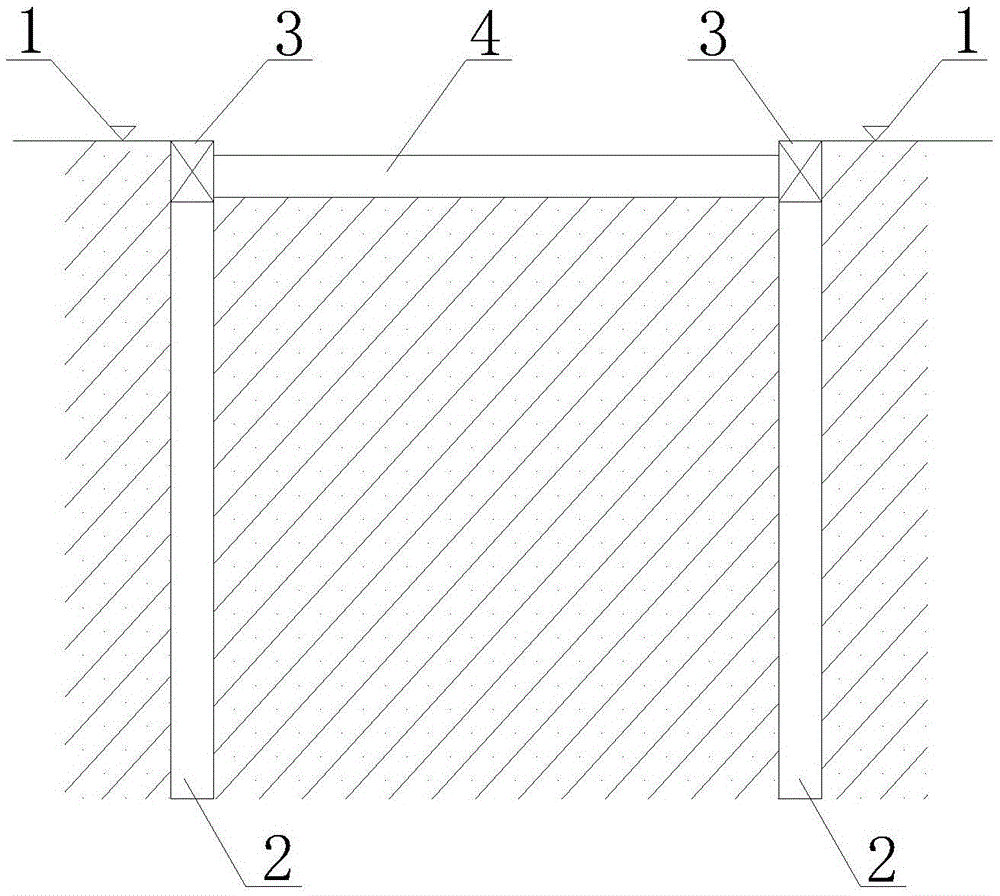

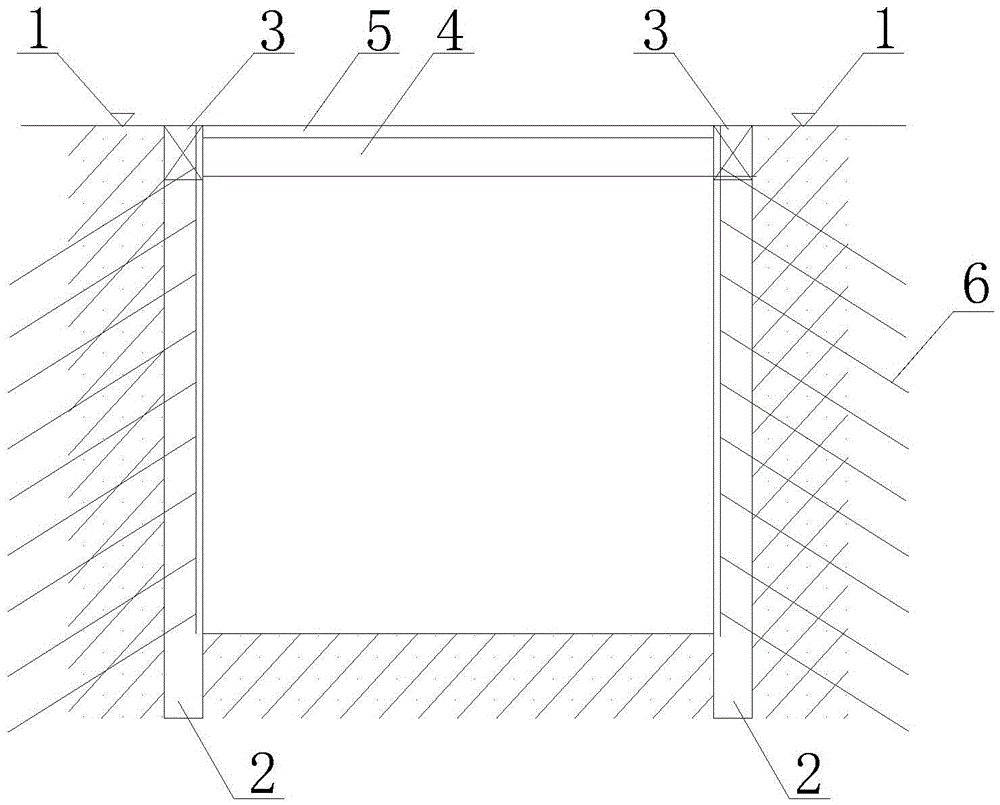

Foundation Pit Containment System and Construction Method Using Underground Diaphragm Wall as Vertical Cantilever Fulcrum

ActiveCN105113514BSimplify construction difficultyShorten the construction periodProtective foundationExcavationsSlurry wallBasement

The invention discloses a foundation pit enclosure system using an underground diaphragm wall as a vertical cantilever supporting point and a construction method. The foundation pit enclosure system comprises a basement, wherein the basement is mainly formed by correspondingly connecting basements located in the peripheral region of a foundation pit and basements located in residual regions of the foundation pit through respective floor slabs. Each basement located in the peripheral region of the foundation pit comprises the underground diaphragm wall, lateral shear resisting walls and floor slabs, the underground diaphragm wall is arranged along the circumference of the inner wall of the foundation pit and serves as the peripheral edge of the peripheral region of the foundation pit, the inner edge of the peripheral region of the foundation pit serves as a boundary for the central region of the foundation pit and the peripheral region of the foundation pit, the lateral shear resisting walls are distributed in the peripheral region of the foundation pit, and the floor slabs are arranged on the lateral shear resisting walls and the underground diaphragm wall in a layered mode. The lateral shear resisting walls serve as supporting structures at an early stage and are also the constituent parts of a main body structure, so that the problem that temporary supports are needed to be erected in construction and then are needed to be removed in the prior art is solved, construction difficulty is simplified, a construction period is shortened, and construction cost is reduced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Dry and wet mixed connection method of fabricated shear wall

The invention discloses a fabricated shear wall dry-wet mixed connection method. The left ends and the right ends of upper-layer prefabricated wall plates and lower-layer prefabricated wall plates areconnected in a positioned mode through nuts, and then cast-in-place shearing force key structures are formed in the middles of the upper-layer prefabricated wall plates and the lower-layer prefabricated wall plates. According to the fabricated shear wall dry-wet mixed connection method, four steel bar connectors are arranged at the two ends of each upper-layer wall plate correspondingly, groovesare formed in the bottoms of the upper-layer prefabricated wall plates, concrete is poured into the grooves to form the shearing force key structures, connecting steel bars anchored on the lower-layerprefabricated wall plates are locked on the steel bar connectors, and thus the connecting structures of the upper-layer prefabricated wall plates and the lower-layer prefabricated wall plates are convenient to construct and reliable in performance; and the advantages of dry-type connection and wet-type connection are combined, the problems that as for an existing connecting mode, on-site construction is difficult, and the quality is not prone to being ensured are solved effectively, the construction process can be simplified, the assembling quality is improved, the mechanical performance of ashear wall after assembling is improved, and the purpose of reducing cost is achieved.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

Tooth-groove-type connection structure of upper-layer inner wallboard of assembly-type shear wall and lower-layer inner wallboard of assembly-type shear wall

The invention discloses a tooth-groove-type connection structure of an upper-layer inner wallboard of an assembly-type shear wall and a lower-layer inner wallboard of the assembly-type shear wall. Each inner wallboard comprises two contact locating structures of the upper-layer inner wallboard which are respectively arranged at two ends of each wallboard and a post-pouring concrete structure. The post-pouring concrete structure is located between the two contact locating structures. Upper grooves are formed in the bottom surface of the upper-layer inner wallboard, upper tooth-shaped grooves are formed in the bottoms of the upper grooves, and vertically-distributed rebars of the upper-layer inner wallboard stretch out from the upper grooves. Lower grooves are formed in the top surface of the lower-layer inner wallboard, lower tooth-shaped grooves are formed in the bottoms of the lower grooves, and vertically-distributed rebars of the lower-layer inner wallboard stretch out from the lower grooves. When the upper-layer inner wallboard is connected with the lower-layer inner wallboard, notches of the upper grooves are connected with notches of the lower grooves in a butt joint mode, forming grooves of the post-pouring concrete structure are formed, and the vertically-distributed rebars of the lower-layer inner wallboard and the vertically-distributed rebars of the upper-layer inner wallboard are correspondingly connected in a lap joint mode. The tooth-groove-type connection structure of the upper-layer inner wallboard of the assembly-type shear wall and the lower-layer inner wallboard of the assembly-type shear wall is easy and convenient to construct and reliable in structure.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

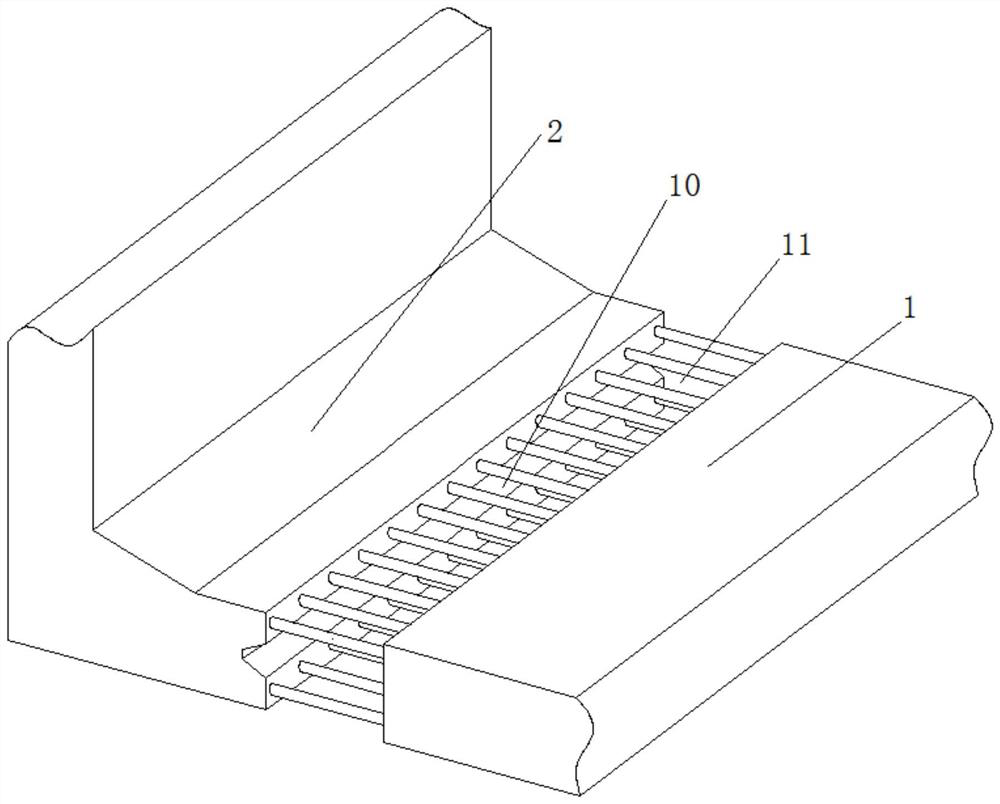

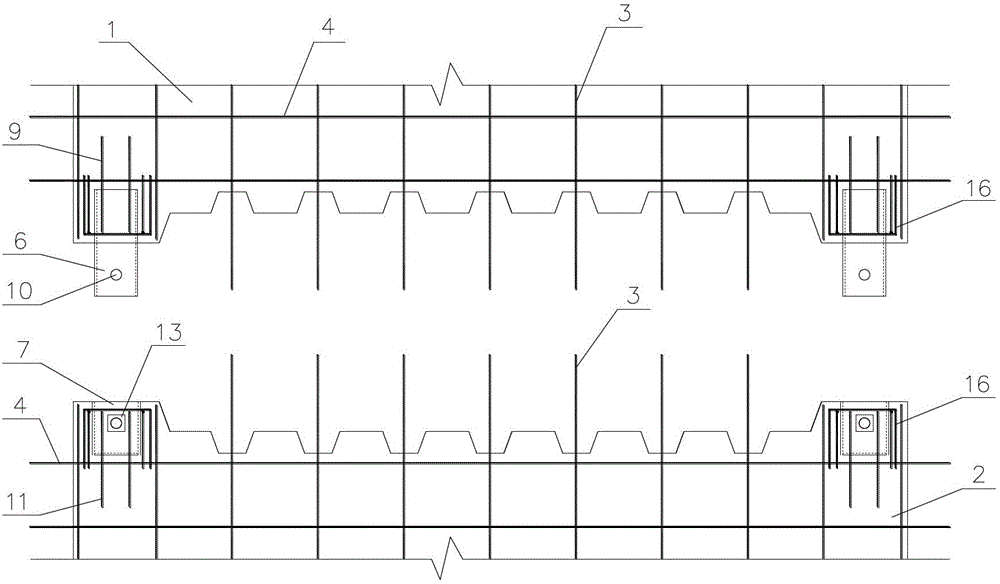

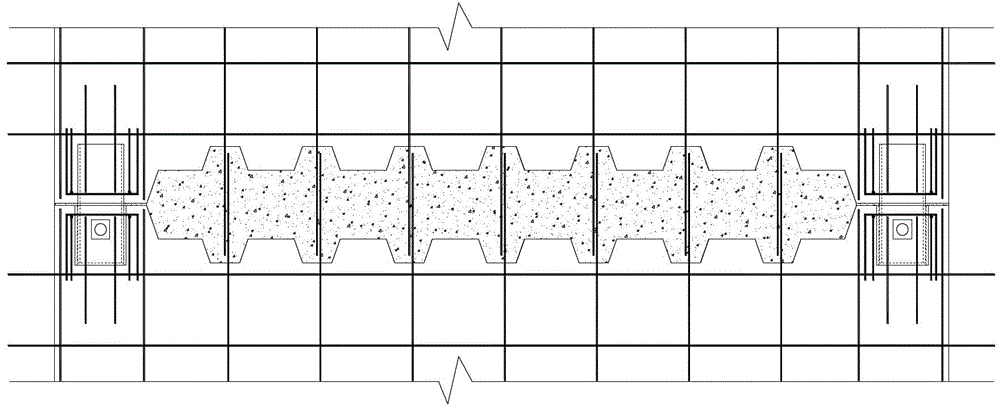

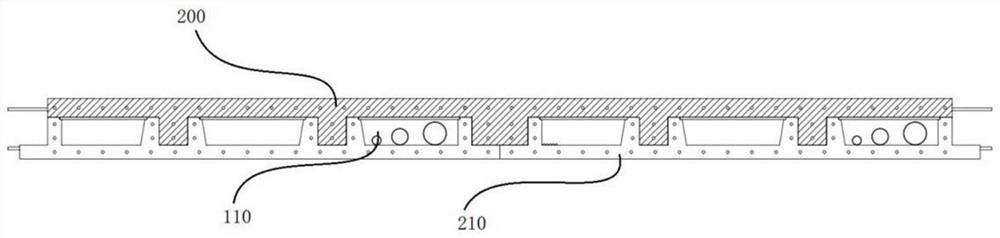

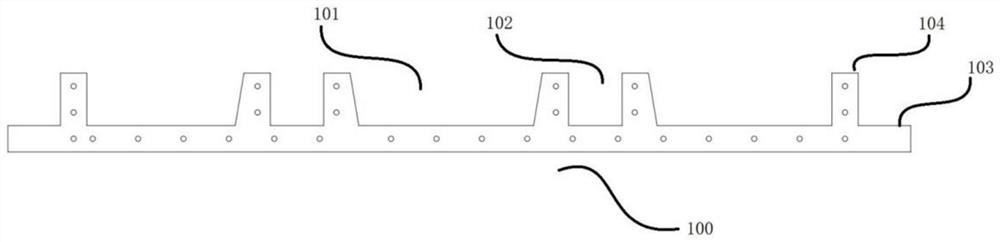

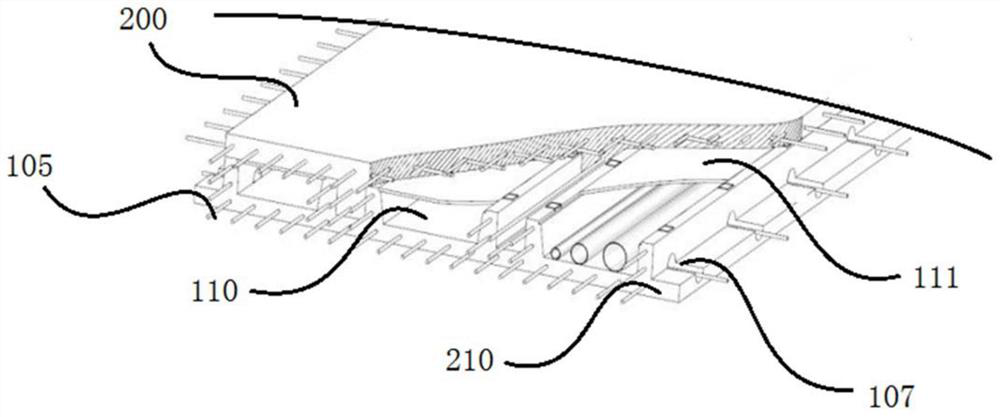

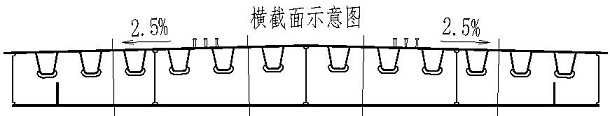

Assembled multi-groove reinforced composite floor slab

The invention discloses an assembled multi-groove reinforced composite floor slab. The assembled multi-groove reinforced composite floor slab comprises a mould board and a cast-in-place concrete layer poured on the mould board, wherein the mould board comprises a bottom board and reinforcing ribs, the reinforcing ribs and the bottom board are of an integrated structure, the reinforcing ribs are upwards perpendicular to the bottom board, functional intervals and / or structural intervals are formed between the reinforcing ribs, the upper ends of the functional intervals are sealed with cover plates to form cavities or are filled with functional materials, stressed steel bars are uniformly distributed in the bottom plate, the stressed steel bars extend out of the bottom board, the cast-in-place concrete layer comprises a steel bar net formed by laying horizontal steel bars and vertical steel bars and concrete, and the steel bar net is fixedly connected with the reinforcing ribs. By adopting the floor slab structure comprising the template comprising the bottom board and the reinforcing ribs and the cast-in-place concrete layer poured on the mould board, the overall strength and bearing capacity of the composite floor slab can be enhanced, the overall rigidity of a traditional small-span composite floor slab can be improved, the slab bottom cracking and overall deformation in the production process are prevented, and the requirements of a larger-span assembled floor slab are met.

Owner:王勇

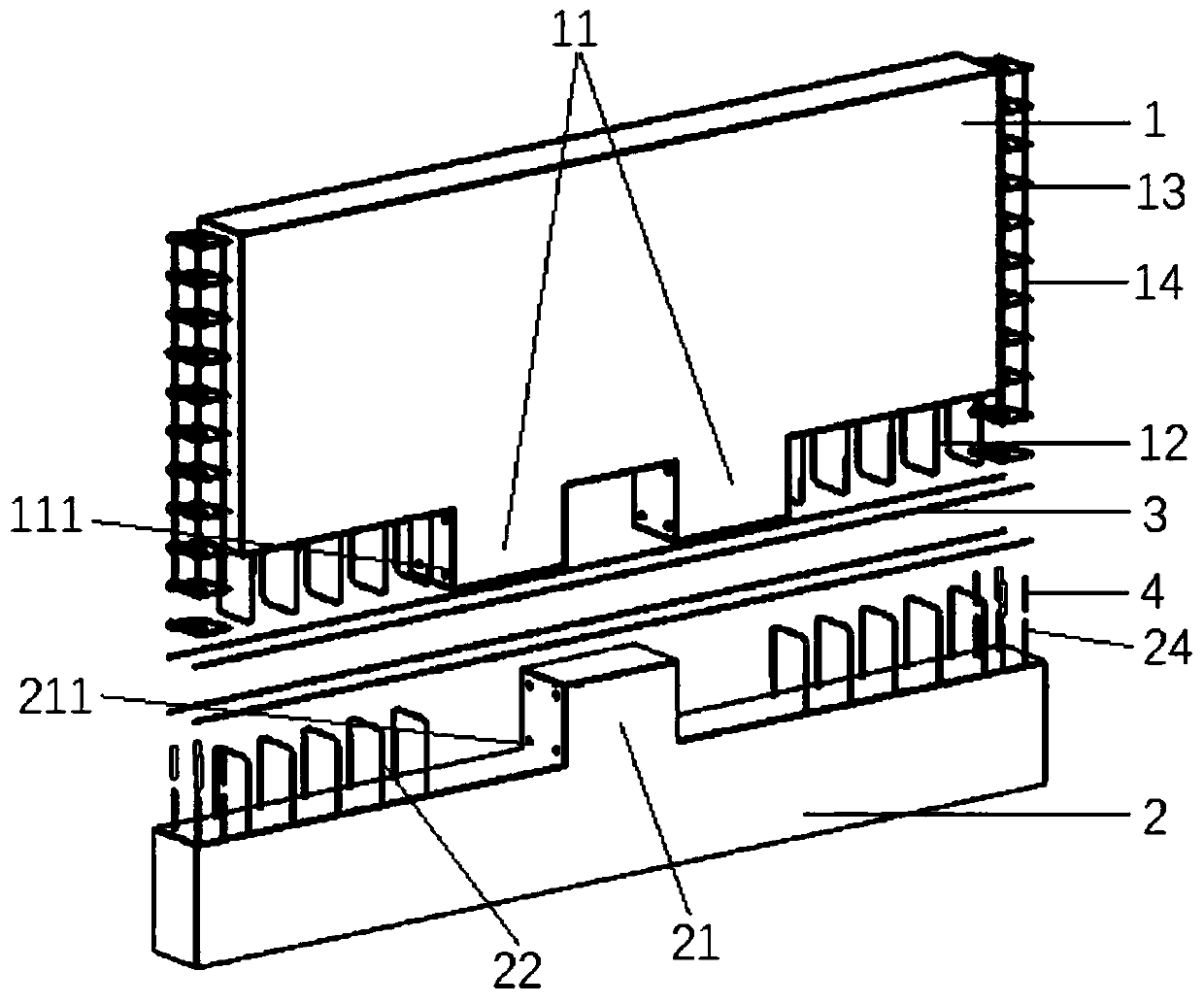

A construction method for cover and excavation of ultra-shallow buried tunnel

ActiveCN104452809BHas little effectShorten the timeArtificial islandsUnderwater structuresThird partyEnvironment effect

The invention discloses an ultra-shallow buried tunnel cover-excavation construction method. According to the technical scheme, first, ground transportation for construction is evacuated; fender pile operation is performed on the two sides of an underground project to be implemented; a load-bearing beam and a structural top plate are manufactured on the top of a pile foundation, and then road surface traffic is restored; the position below the structural top plate is excavated to reach the elevation of a structural bottom in a three-step excavation mode, and soil supports between fender piles are constructed at the same time; a cushion layer and a bottom waterproof layer are reinforced; the major structure and the remaining waterproof layer of the underground project are implemented; sand is blown back so that a gap between a cover plate and the major structure can be backfilled with the sand. Compared with the prior art, the time for occupying a road because of construction is shortened, and influences on the external environment of construction are small; the horizontal displacement of the structure is small; the structural plate is used for excavation of a foundation pit so that a temporary support can be omitted; influences caused by external weather are small; the collapse risk of the ultra-shallow section underground project and the loss risk of a third party are avoided.

Owner:NO 3 ENG LIMITED OF CR20G

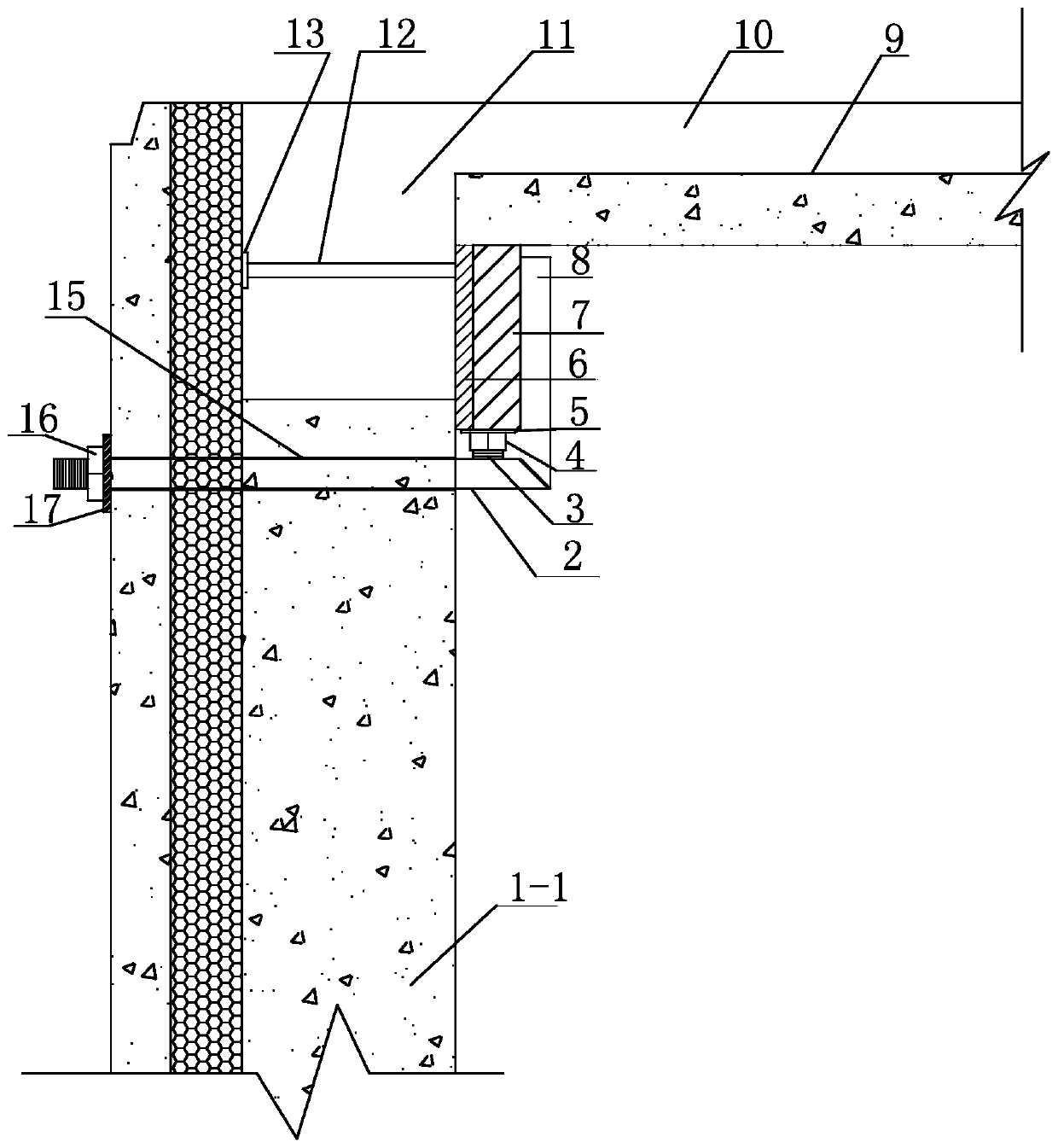

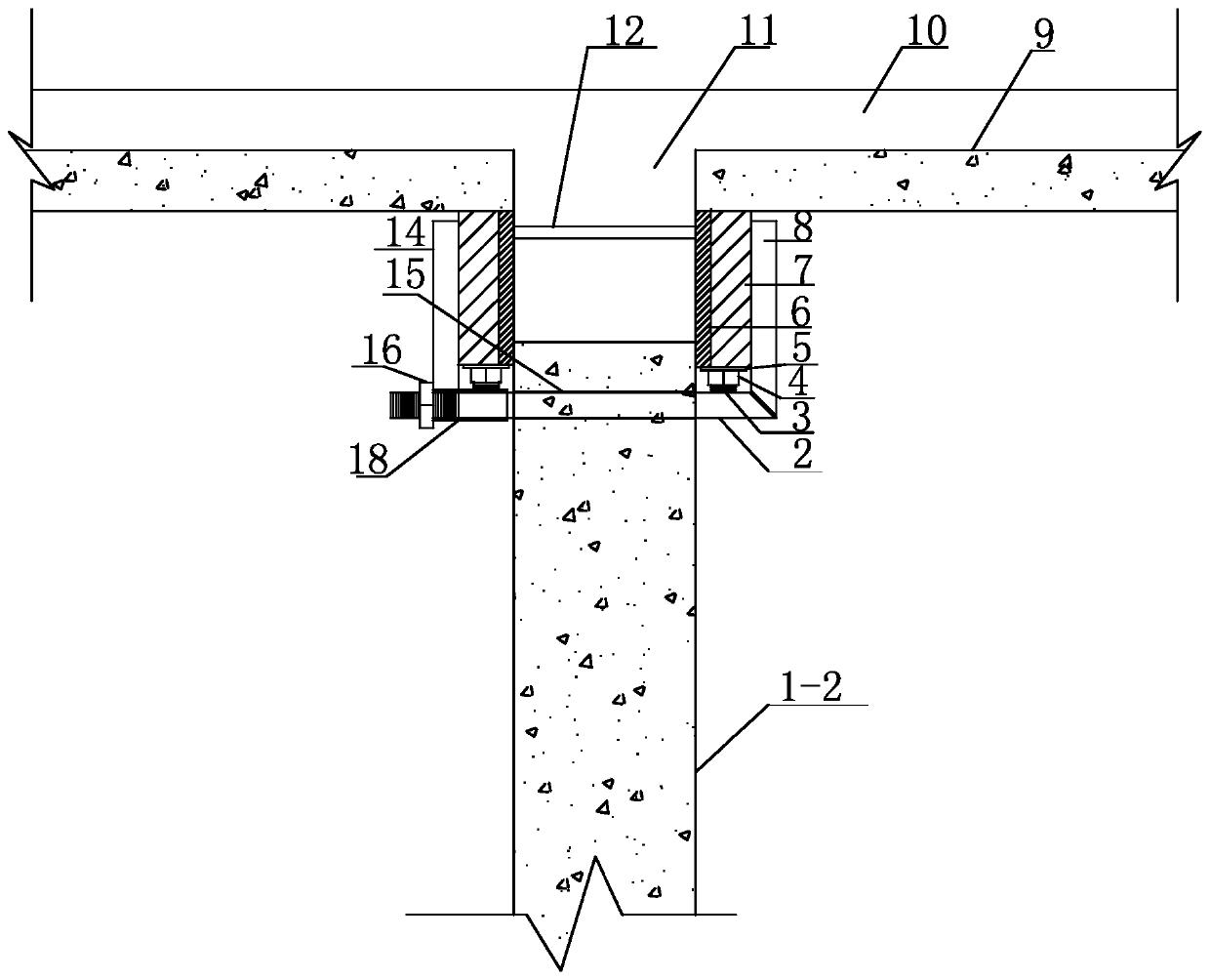

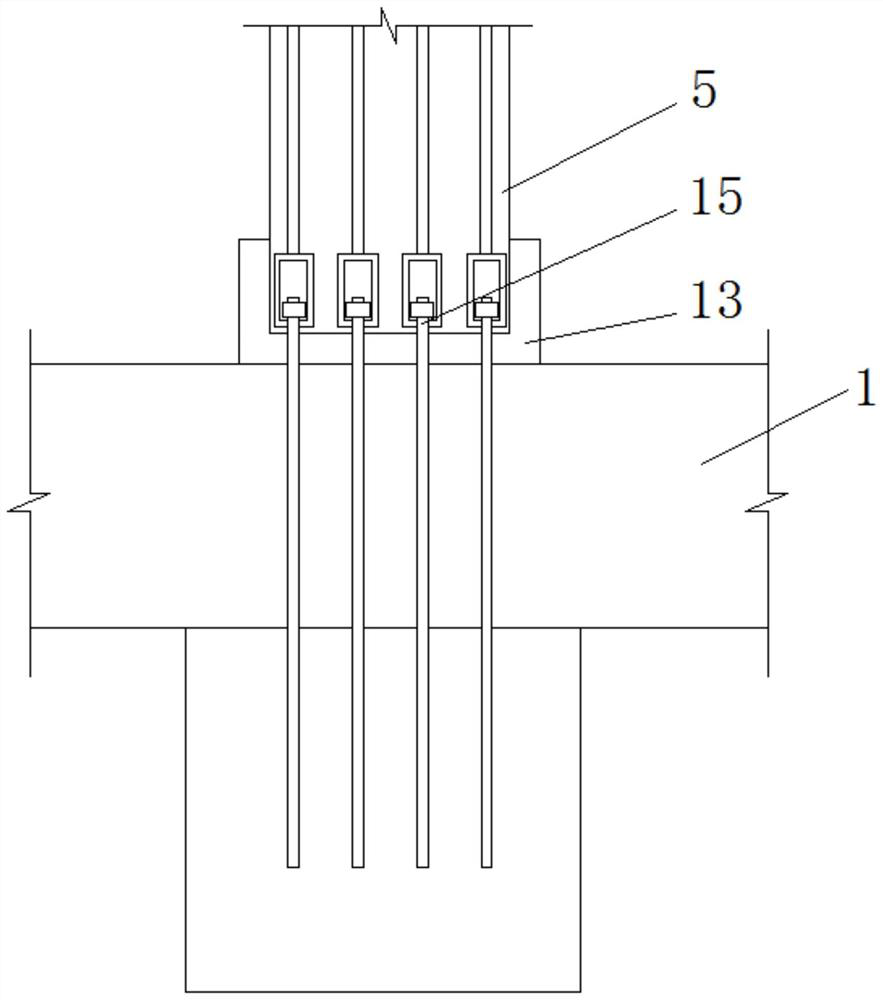

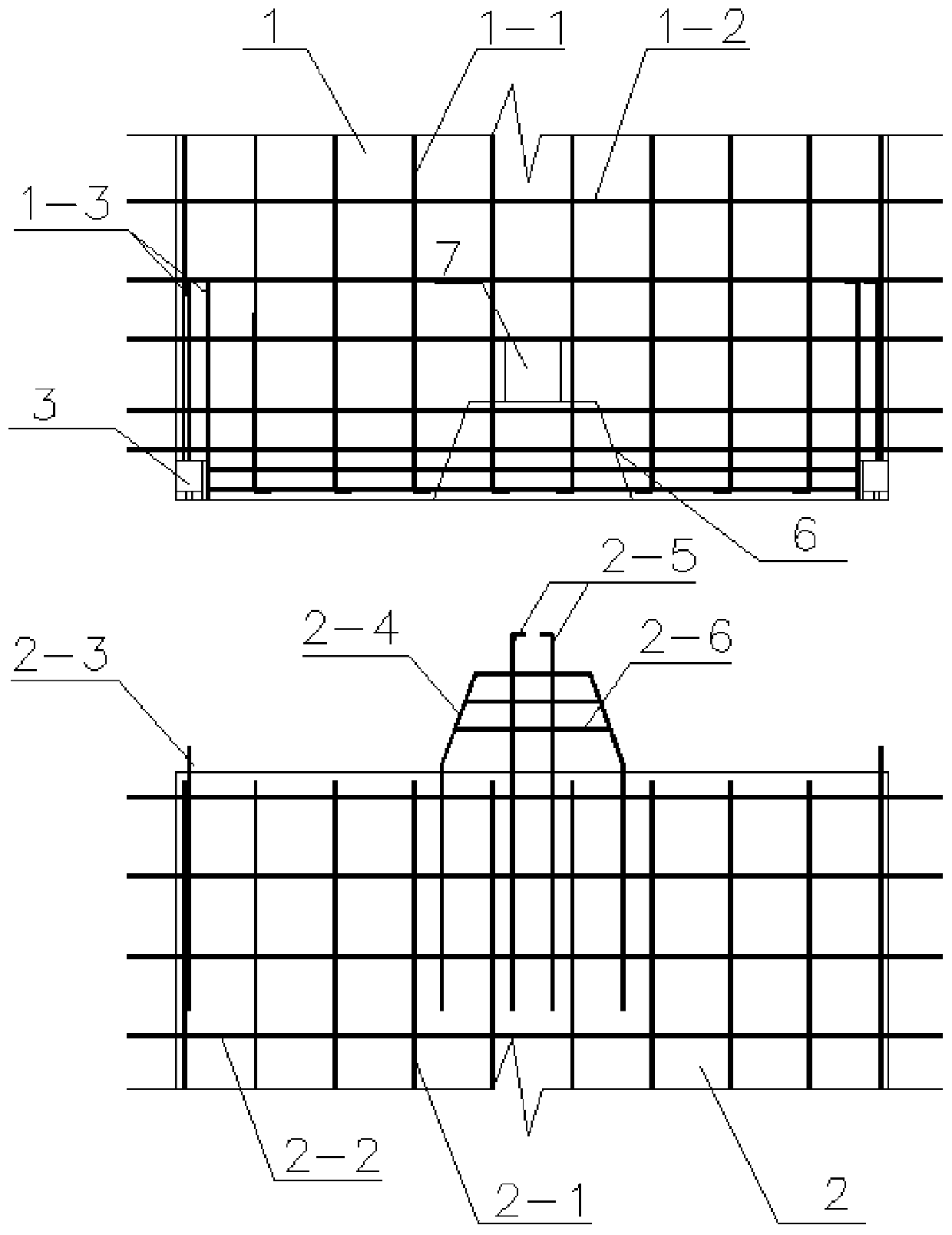

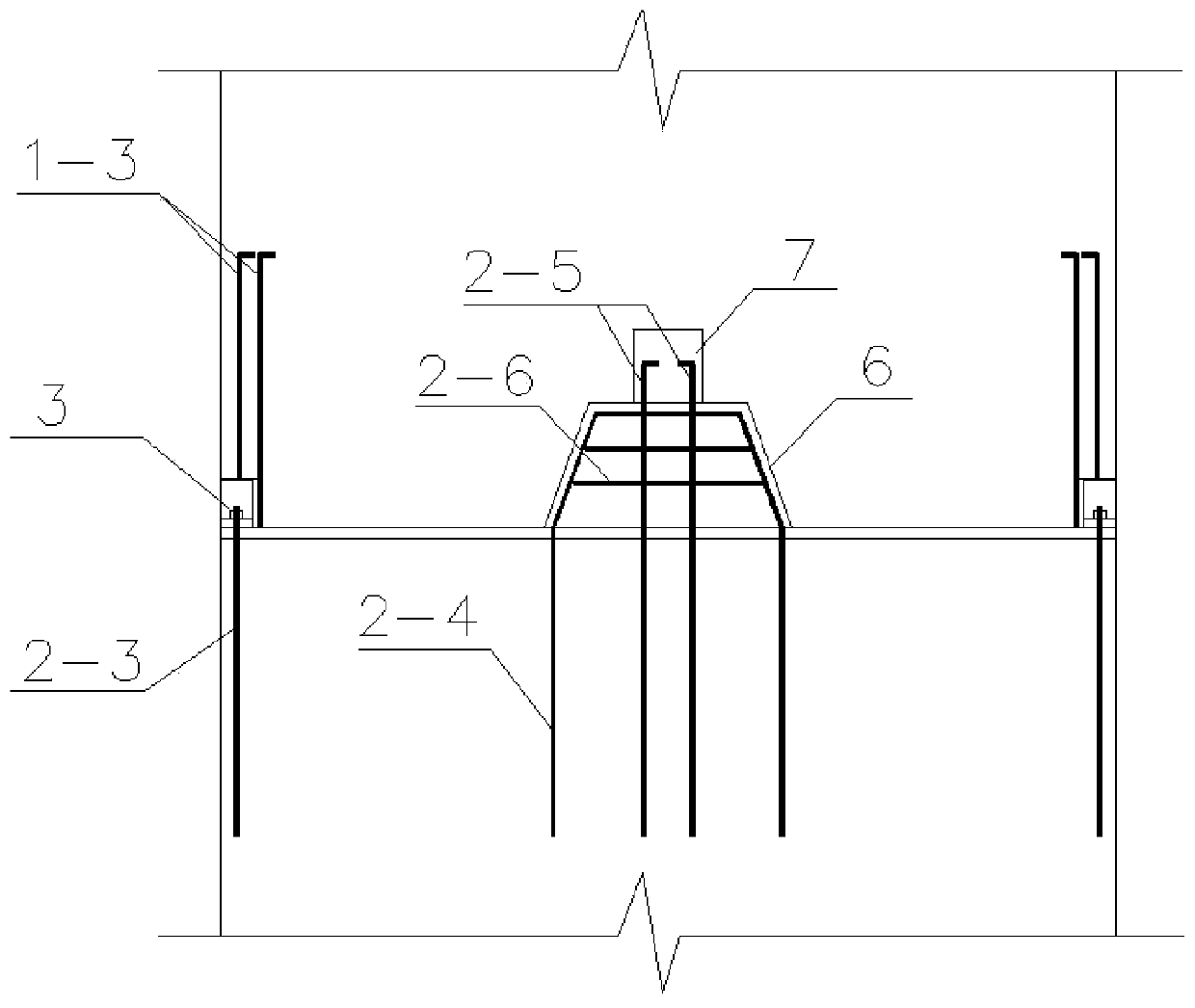

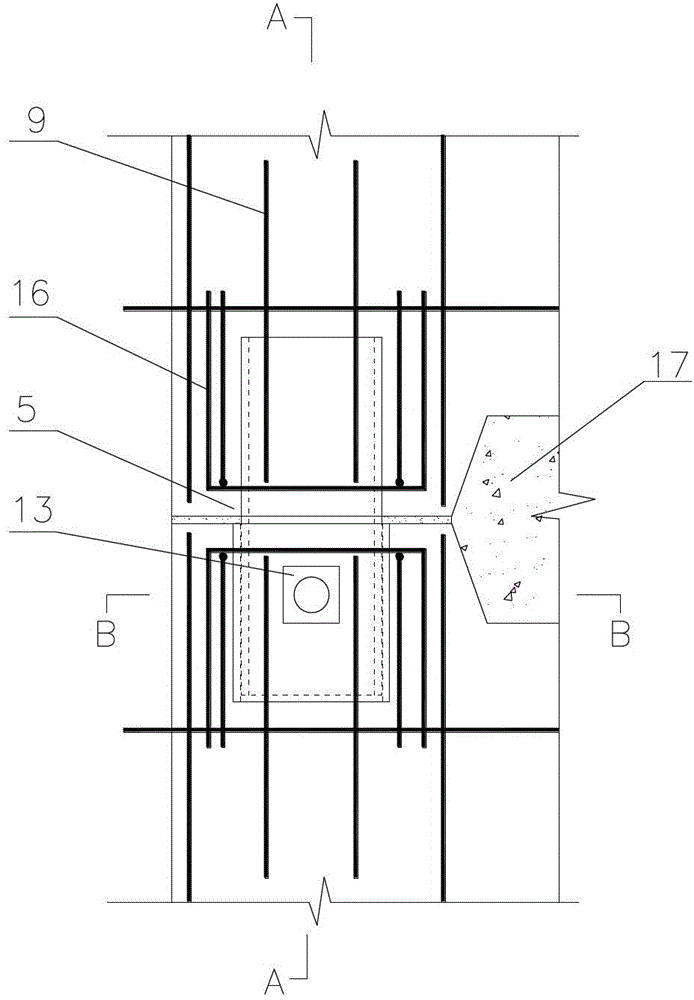

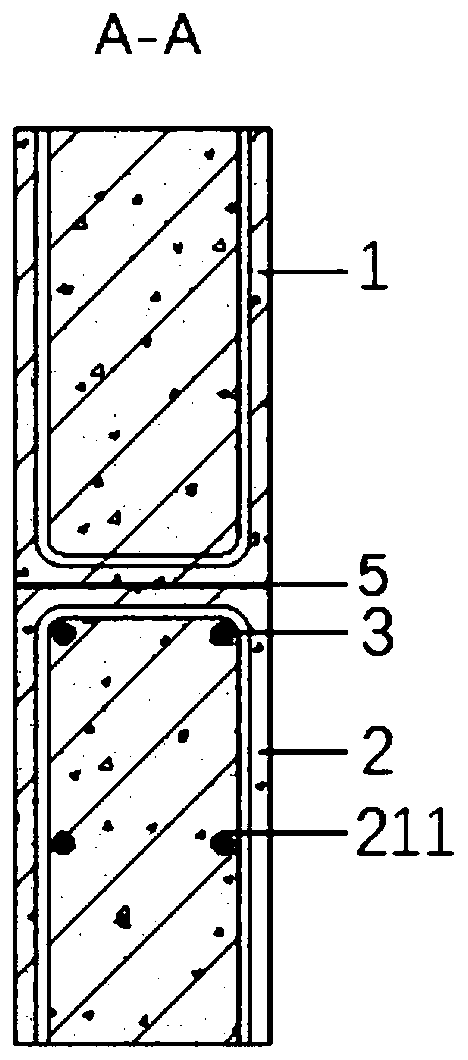

Joint structure of prefabricated shear wall and its splicing method

InactiveCN109736479BReduce Temporary SupportGuaranteed stabilityWallsBuilding material handlingArchitectural engineeringRebar

Owner:CENT SOUTH UNIV

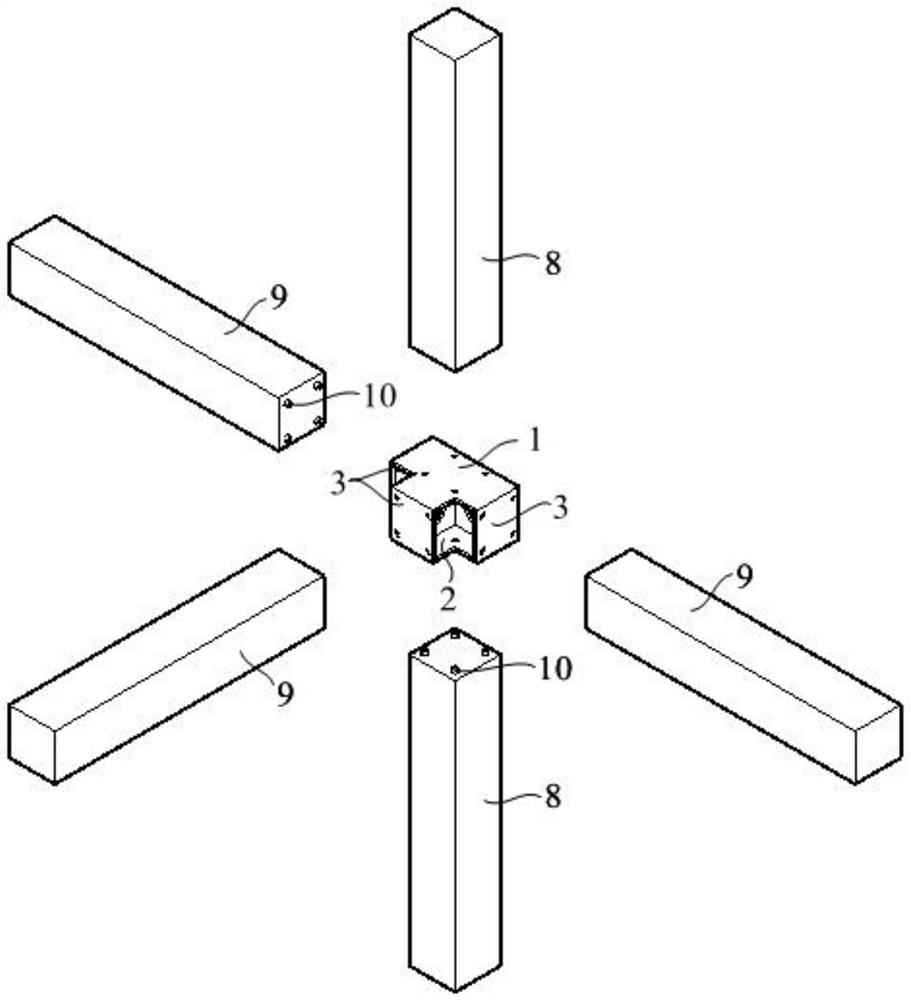

Beam column connecting piece and construction method of wall

The invention relates to the technical field of fabricated buildings, and discloses a beam-column connecting piece and a wall construction method.The beam-column connecting piece comprises an upper connecting plate and a lower connecting plate, a side connecting plate is connected between the upper connecting plate and the lower connecting plate, and the upper connecting plate and the lower connecting plate are each provided with at least two first through holes; at least two second through holes are formed in the side connecting plates, the first through holes are used for fixing connecting steel bars of the constructional columns, and the second through holes are used for fixing connecting steel bars of ring beams or ground beams; the construction method of the wall comprises the steps that the constructional columns and the ring beams are connected through the beam column connecting pieces to form a wall framework which is fixed to the floor, and wall construction is completed by sequentially splicing and fixing the wallboards; the constructional column and the ring beam are connected with each other through the beam column connecting piece, so that the situation that connecting steel bars of the constructional column and the ring beam occupy each other is avoided, the constructional column and the ring beam can be accurately in place in the installation process, the space of a connecting joint is increased, connection and fixation are facilitated, the construction speed of a wall is increased, the construction period is shortened, and the construction cost is saved.

Owner:四川迈铁龙科技有限公司

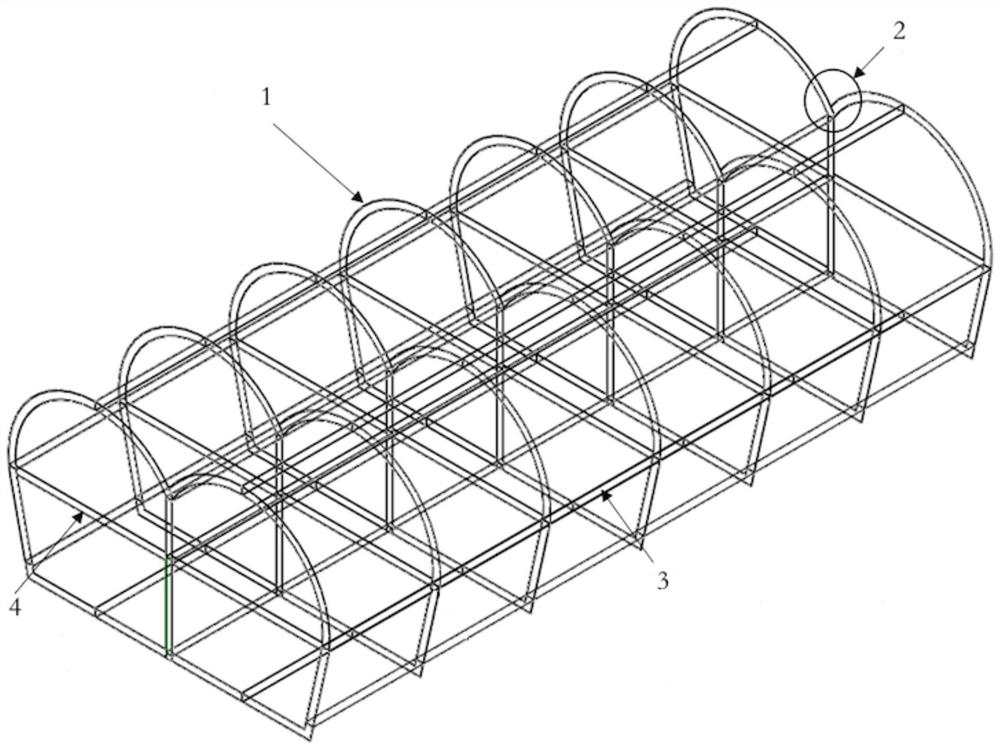

Multi-arch tunnel integral supporting structure and rapid construction method thereof

PendingCN114483113AReduce the number of disturbancesReduce temporary supportUnderground chambersTunnel liningStructure supportRapid construction

According to the integral supporting structure of the multi-arch tunnel and the rapid construction method of the integral supporting structure, a main hole is directly excavated in a segmented mode, combined supporting is arranged, the disturbance frequency is reduced, and the stability of the tunnel and surrounding rock is improved. Primary supports and waterproof structures can be independently constructed, adjacent cavern primary supports are supported in a connected mode, the deformation control effect is good, and the waterproof effect is good. Compared with a conventional construction method, the technology is less in temporary support and simple in process; the support construction is simple, and the quality is good; excavation and support construction of the left and right caverns can be separated in a left and right cavern staggered distance mode and a middle partition wall, cross operation can be effectively avoided, and the engineering quality is guaranteed. According to the technology, the problems existing in a traditional construction method can be effectively solved, the construction requirements of double-multiple-arch tunnels or even multiple-multiple-arch tunnels in China are met, and the application prospect is wide.

Owner:FUJIAN UNIV OF TECH

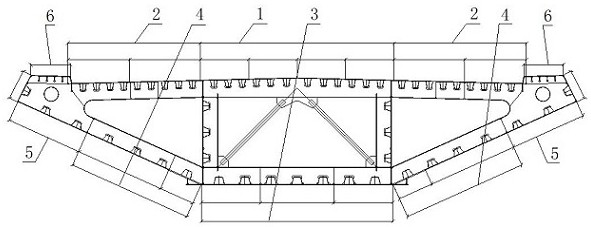

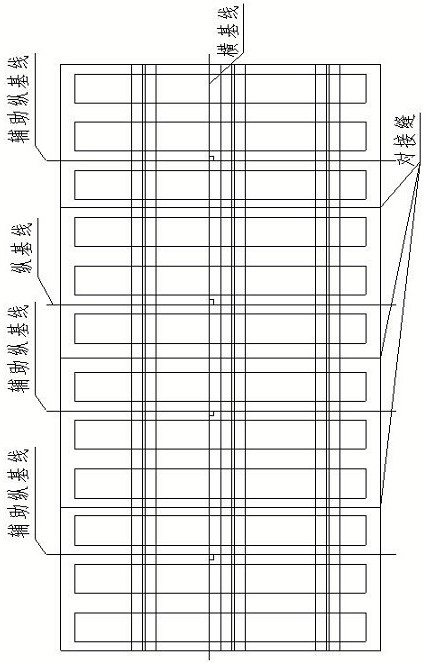

Multi-plate unit structure of steel box girder and combined manufacturing method

PendingCN114687275ASolve the problem of a long period of total consolidationAvoid construction height difficultiesWelding apparatusBridge materialsStructural engineeringIndustrial engineering

The invention relates to a multi-plate unit structure of a steel box girder and a combined manufacturing method, which can effectively shorten the total splicing manufacturing period, reduce the construction difficulty and save the production cost, and comprises the steel box girder, four top plate units positioned on the steel box girder, and two sides of the four top plate units are respectively welded with two top plate units, the bottom plate three-splicing unit is located at the bottom of the steel box girder, the two sides of the bottom plate three-splicing unit abut against the inclined plate two-splicing units, the inclined surface of the steel box girder on the two sides of the bottom plate three-splicing unit is provided with the inclined bottom plate two-splicing units, and the cladding plate unit is arranged between the inclined bottom plate two-splicing units and the top plate four-splicing unit. The method has the advantages that the problem that the period is long when the steel box girder is generally spliced is effectively solved, and the production efficiency is improved; 2, the difficulty of the construction height of the steel box girder during total splicing is avoided, the construction difficulty is reduced, and the overall manufacturing precision and the appearance of a welding seam are ensured; and thirdly, during total splicing, a plurality of plate unit assemblies are integrally hoisted at one time, so that temporary supports in the box can be effectively reduced, the number of tools is greatly reduced, and the production cost and the workload are saved.

Owner:中铁宝桥(扬州)有限公司 +1

Building structure assembled by concrete dense rib plate box body units

Owner:长沙远大魔方科技有限公司

Blasting process for hard rock multi-arch tunnel

PendingCN113818888AWide applicabilityBlast Disturbance ReductionUnderground chambersTunnel liningArchitectural engineeringWall rock

The invention relates to the technical field of tunnel construction, and discloses a blasting process of a hard rock multi-arch tunnel. According to the blasting process of the hard rock multi-arch tunnel from the optimization angle of the tunneling area and sequence of a tunnel face, the structure of surrounding rock is fully used, a support middle pilot tunnel does not need to be excavated, variable actual working conditions can be met, the precision requirement is low, and the operability is high. The blasting process can be widely applied to the construction process of the hard rock multi-arch tunnel, a working face and temporary supports are reduced, the tunnel is flexibly and conveniently excavated and supported, additional materials are not needed, the construction cost is reduced, integral blasting excavation can be performed after a stepped section is formed, the engineering progress is accelerated, and a great popularization value and wide application prospects are achieved.

Owner:四川省交通勘察设计研究院有限公司 +1

Integrated design and construction method of post-cast ring beam formwork and slab support for prefabricated shear walls

ActiveCN110397268BReduce Temporary SupportTo achieve the effect of fair-faced concreteForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemArchitectural engineering

The invention belongs to the field of prefabricated building construction, and in particular relates to an integrated design and construction method of prefabricated shear wall post-cast ring beam formwork and slab support. The steps are: 1. Determine the formwork system calculation model; 2. Formwork system bearing Force checking; 3. Determine the calculation model of the prefabricated slab support system; 4. Check the bearing capacity of the precast slab support system; 5. Determine the material of the formwork system components; 6. Make the back corrugated; 7. Make the formwork; 9. Making the inner support of the formwork; 10. Installing the formwork; 11. Hoisting the prefabricated panels; 12. Pouring concrete. The invention solves the key technical problems such as difficulty in fixing the post-cast ring beam formwork, grout leakage and displacement at the bottom of the slab, realizes the integration of the formwork and the prefabricated slab support, saves the support of the prefabricated slab, and makes the post-cast ring beam meet the requirements of fair-faced concrete. High degree of standardization, factory production, prefabricated installation, repeated recycling, in line with national environmental protection and energy saving requirements.

Owner:SHANDONG GOLDENCITY CONSTR

Suspended formwork structure of steel structure composite floor slab

ActiveCN113789958APrevent corrosion of rebarReduced service lifeClimate change adaptationForms/shuttering/falseworksFloor slabShaped beam

The invention provides a suspended formwork structure of a steel structure composite floor slab, and belongs to the technical field of building construction. The suspended formwork structure comprises a steel structure beam; the inner sides of a pair of I-shaped beams of the steel structure beam along the length direction are respectively provided with a row of first mounting holes at intervals; each first mounting hole is internally provided with a hanging part; the two rows of first mounting holes in the inner sides of the pair of I-shaped beams are in one-to-one correspondence; steel pipes are erected on the two hanging parts in one-to-one correspondence in the width direction of the steel structure beam; first square battens are arranged between the upper portions of the two ends of each steel pipe and the corresponding I-shaped beam in a clamped mode; second square battens are arranged on all the steel pipes in the length direction of the steel structure beam at intervals; a formwork is placed on the upper portion of the second square battens; and the upper surface of the formwork is flush with the upper surface of the steel structure beam. According to the suspended formwork structure of the steel structure composite floor slab, the structure is simple and reliable, the construction efficiency is high, the lower construction operation space is saved, interpenetration operation is facilitated, the construction period is shortened, most parts can be reused, and the cost is saved.

Owner:河南中企建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com