Joint structure of prefabricated shear wall and its splicing method

A shear wall and prefabricated technology, applied in the direction of walls, building components, building structures, etc., to ensure the overall strength, ensure accurate installation and reduce temporary support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

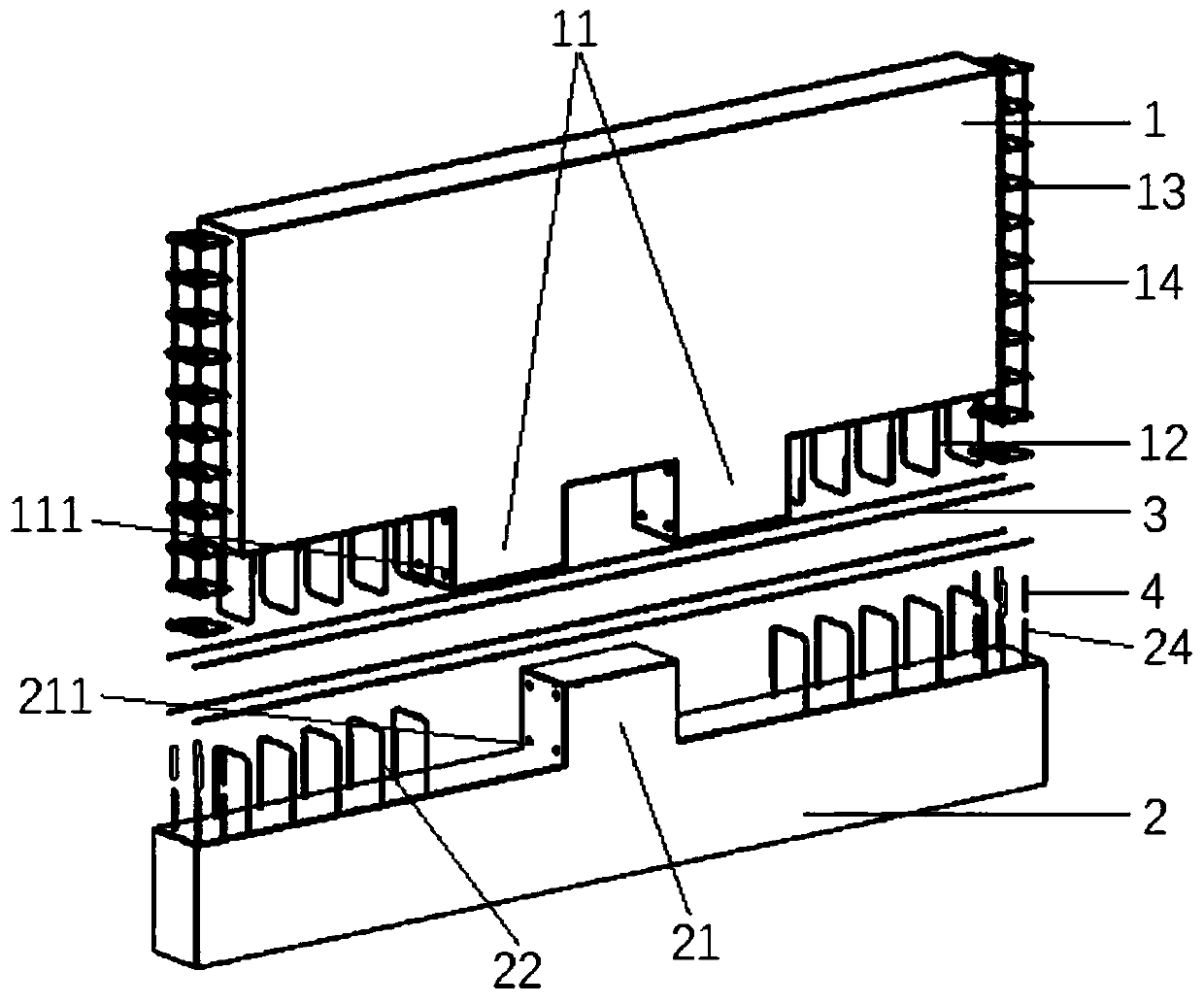

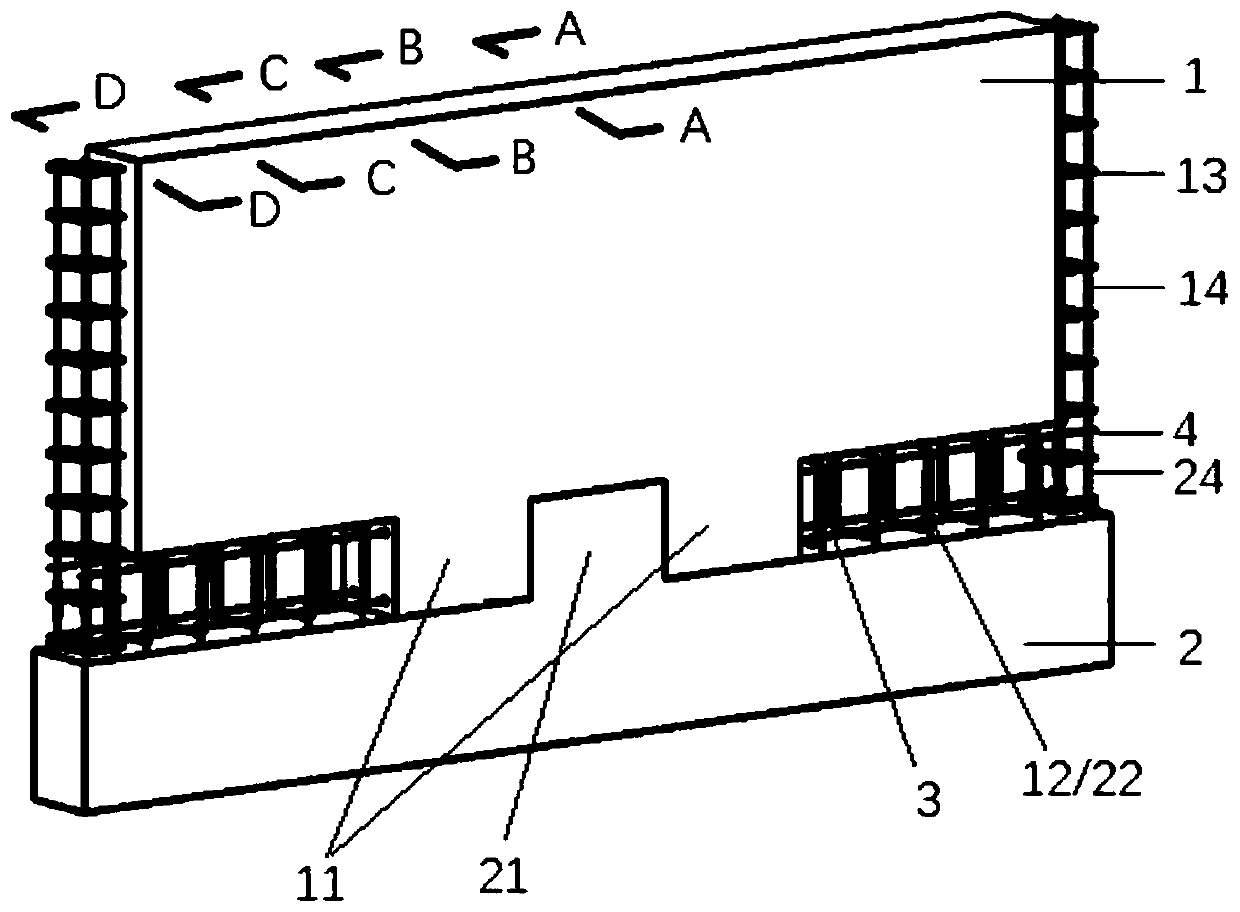

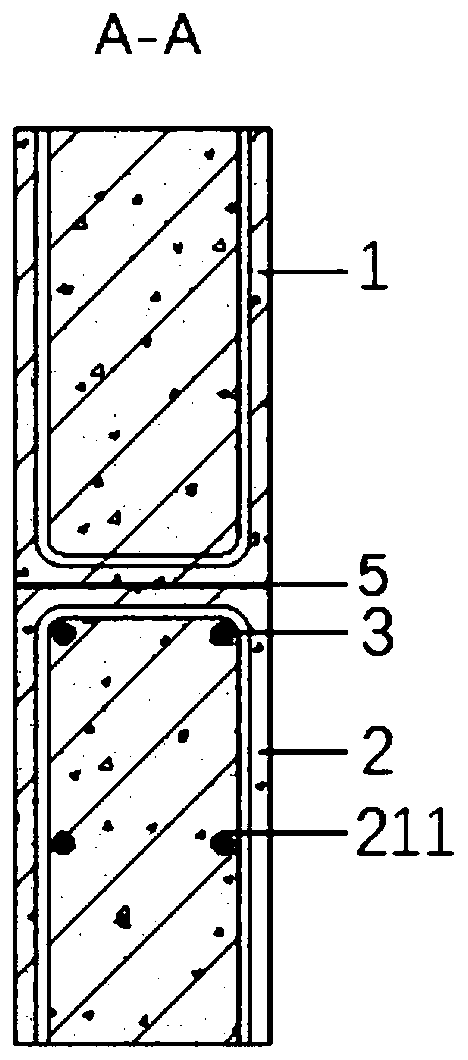

[0043] see figure 1 and figure 2 , the upper wall panel 1 and the lower wall panel 2 in the illustration are specific implementations of the fabricated shear wall of the present invention. The bottom side of the upper wall panel 1 and the top side of the lower wall panel 2 are spliced to form a seam. After the prefabrication of the upper wall panel 1 and the lower wall panel 2 is completed in the workshop, they are spliced together on site through the joint structure to form a shear force. wall.

[0044] Specifically, two sets of upper positioning teeth 11 and upper vertical hoop steel bars 12 on both sides of the upper positioning teeth are provided on the seam side of the upper wallboard 1, and are provided on the vertical sides of the upper wallboard 1. There are edge restraint stirrups 13 and upper edge vertical reinforcements 14; a set of lower positioning teeth 21 and lower vertical hooping reinforcements 22 on both sides of the lower positioning teeth are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com