Suspended formwork structure of steel structure composite floor slab

A technology for steel structures and steel structure beams, which is applied in building construction, formwork/formwork/work frame, and on-site preparation of building components, etc., can solve the difficulty in tying steel bars of steel truss formwork and take up the vertical transportation time of cranes. , the cumbersome binding of steel bars, etc., to achieve the effect of being beneficial to the control of quality defects, saving construction work space, and being beneficial to interspersed operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

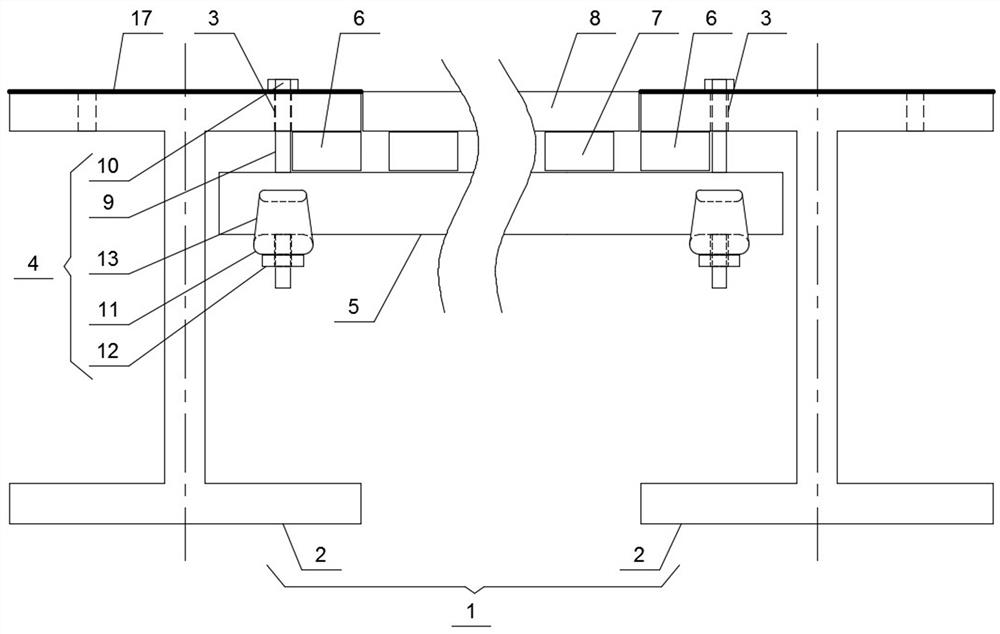

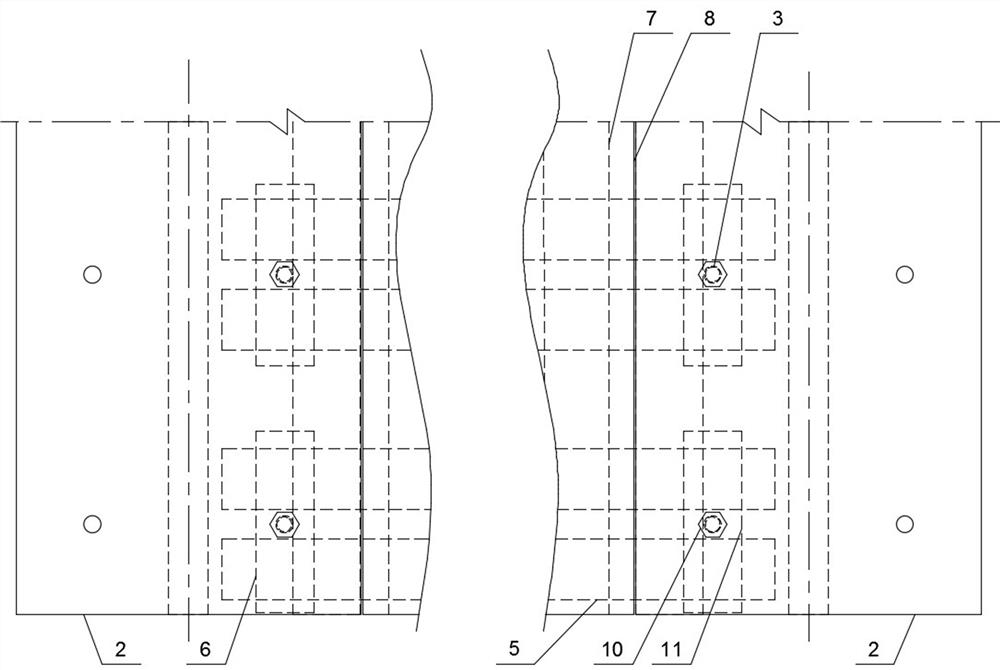

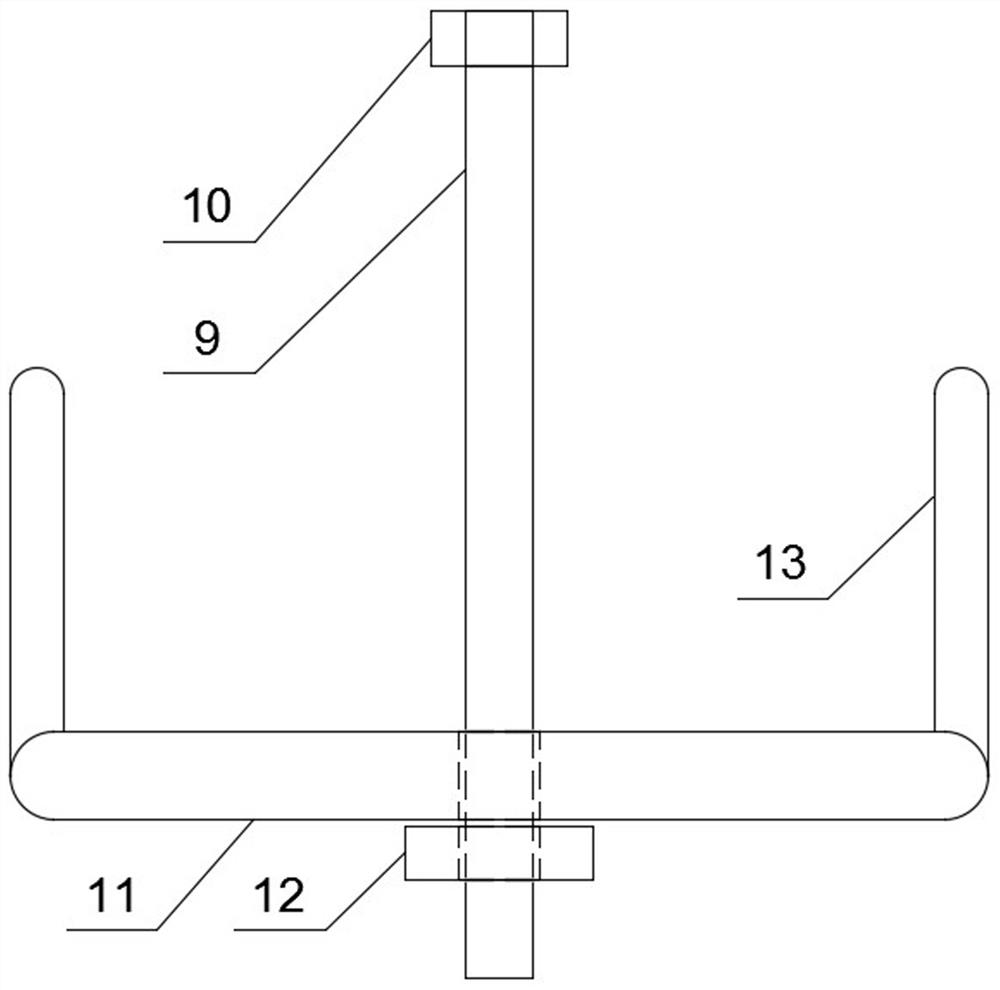

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the following will be combined with the appended Figure 1-5 , clearly and completely describe the technical solutions of the embodiments of the present invention. Apparently, the described embodiments are some, not all, embodiments of the present invention. All other embodiments obtained by those skilled in the art based on the described embodiments of the present invention belong to the protection scope of the present invention.

[0028] Such as Figure 1-5 Shown: a hanging formwork structure for a steel structure composite floor slab, including a steel structure beam, a row of first installation holes are respectively spaced on the inside of a pair of I-beams along the length direction of the steel structure beam, and each first installation hole A hanging part is installed in each of them, and the two rows of first installation holes on the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com