Spring type fiber reinforced plastic micro-expanded concrete member

A technology of micro-expansion concrete and fiber reinforcement, which is applied to building components, structural elements, building reinforcements, etc., can solve the problems of restricting the large-scale application of fiber reinforcement and low compressive strength of fiber reinforcement, so as to improve the axial bearing capacity, Effects of avoiding corrosion of steel bars and improving corrosion resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

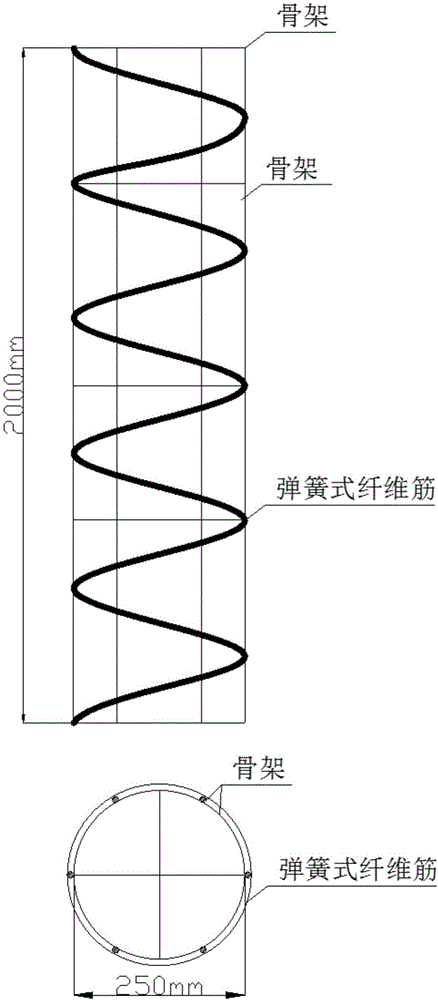

[0029] Along the longitudinal direction of the concrete column, 6 vertical bars and transverse bars at both ends and in the middle are arranged to form a skeleton, and a spring-type fiber bar is wound around the erecting bars, and the axial intercept of the spring-type fiber bar is 400mm; Before the concrete components are poured, the skeleton is placed in the mold, and the end plates connected with the hoop plates are respectively installed at both ends of the skeleton; the ready-mixed concrete material is transported into the horizontally placed mold body through a concrete mixer, and the skeleton is The cage is slightly expanded and stretched; after 1-3 days of curing, the mold can be removed. The spring-type fiber bars used are basalt fiber bars, and the concrete used is shrinkage-compensating concrete. The schematic diagram of the concrete member of this embodiment is shown in the attached figure 1 .

Embodiment 2

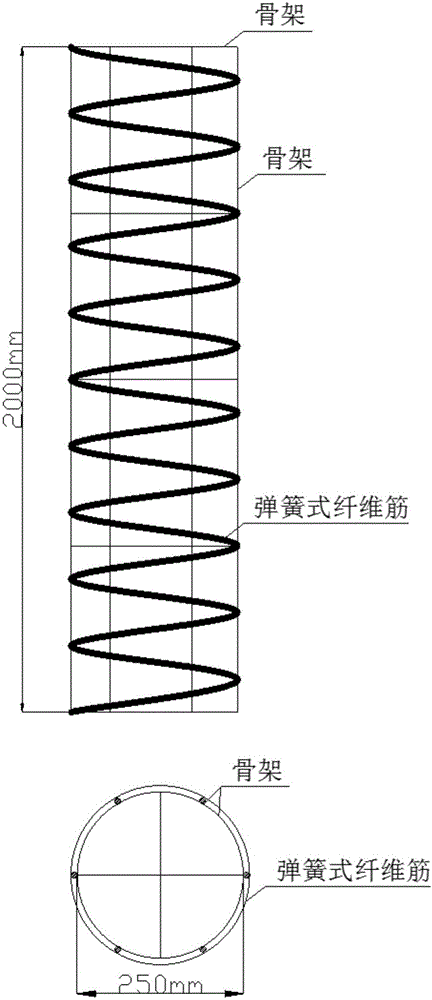

[0031] Arrange 6 vertical bars along the longitudinal direction of the concrete column and transverse bars at both ends and in the middle. The two form the skeleton. A spring-type fiber bar is wound around the erection bar. The axial intercept of the spring-type fiber bar is 200mm; Before the concrete components are poured, the skeleton is placed in the mold, and the end plates connected with the hoop plates are respectively installed at both ends of the skeleton; the ready-mixed concrete material is transported into the horizontally placed mold body through a concrete mixer, and the skeleton is The cage is slightly expanded and stretched; after 1-3 days of curing, the mold can be removed. The spring-type fiber bars used are glass fiber bars, and the concrete used is shrinkage-compensating concrete. The schematic diagram of the concrete member of this embodiment is shown in the attached figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com