Integrated design and construction method of post-cast ring beam formwork and slab support for prefabricated shear walls

A construction method and shear wall technology, which are applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, and on-site preparation of building components, etc., can solve formwork slippage, post-casting The beam formwork cannot bear the construction load of the floor and other problems, so as to achieve the effect of stable and reliable quality, significant social and economic benefits, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

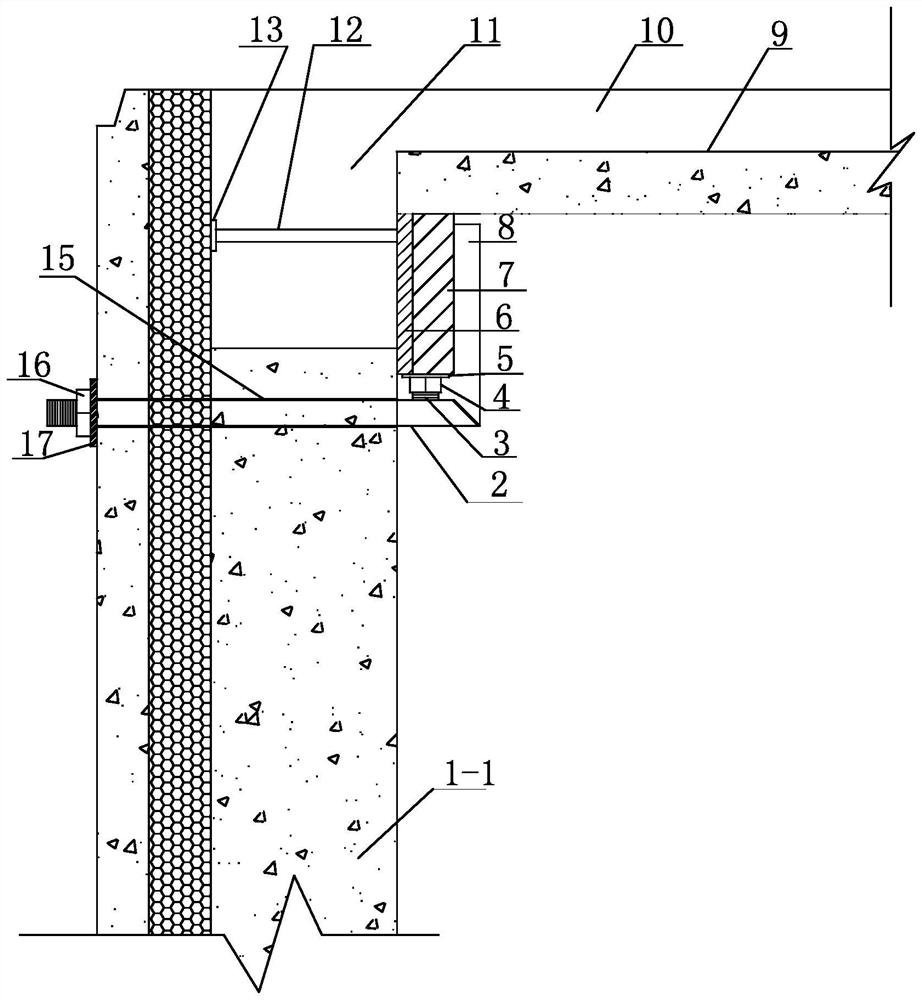

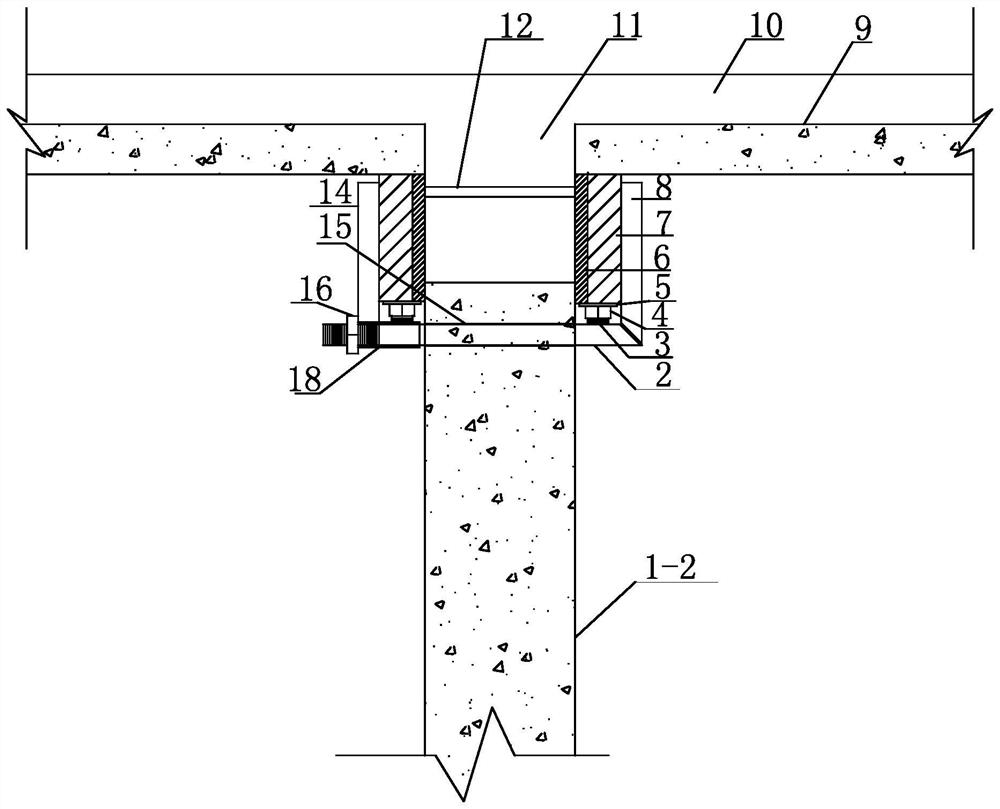

[0199] Such as Figure 1-2 As shown, the integrated design and construction method of the prefabricated shear wall post-cast ring beam formwork and plate support of the present invention, the following steps are taken:

[0200] 1. Determine the formwork system calculation model:

[0201] 1.1. Determine the template calculation model:

[0202] The formwork is supported by the back flute 14 and the vertical bar 8, and the calculation model of the formwork is determined according to the three-span and equal-span continuous beam;

[0203] 1.2. Determine the calculation model of corrugated beam:

[0204]1) The post-casting ring beam formwork of the external prefabricated shear wall 1-1 uses the vertical bar 8 as the corrugated beam, and the calculation model of the corrugated beam is determined according to the cantilever beam;

[0205] 2) The post-cast ring beam formwork of the inner prefabricated shear wall 1-2 uses the vertical bar 8 and the back corrugated beam 14 as corruga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com