Building structure assembled by concrete dense rib plate box body units

A technology of building structure and dense rib plate, applied in the direction of building structure, construction, etc., can solve the problems of high labor intensity of workers, difficult construction management, difficult quality assurance, etc., and achieve the effect of saving time, easy isolation, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

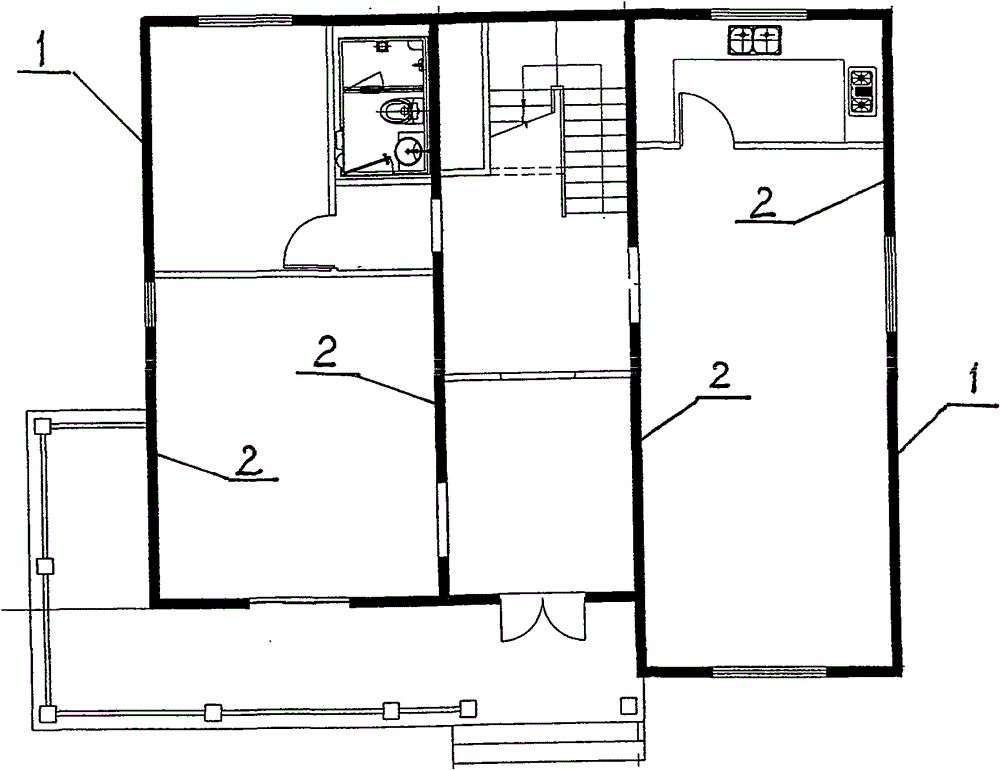

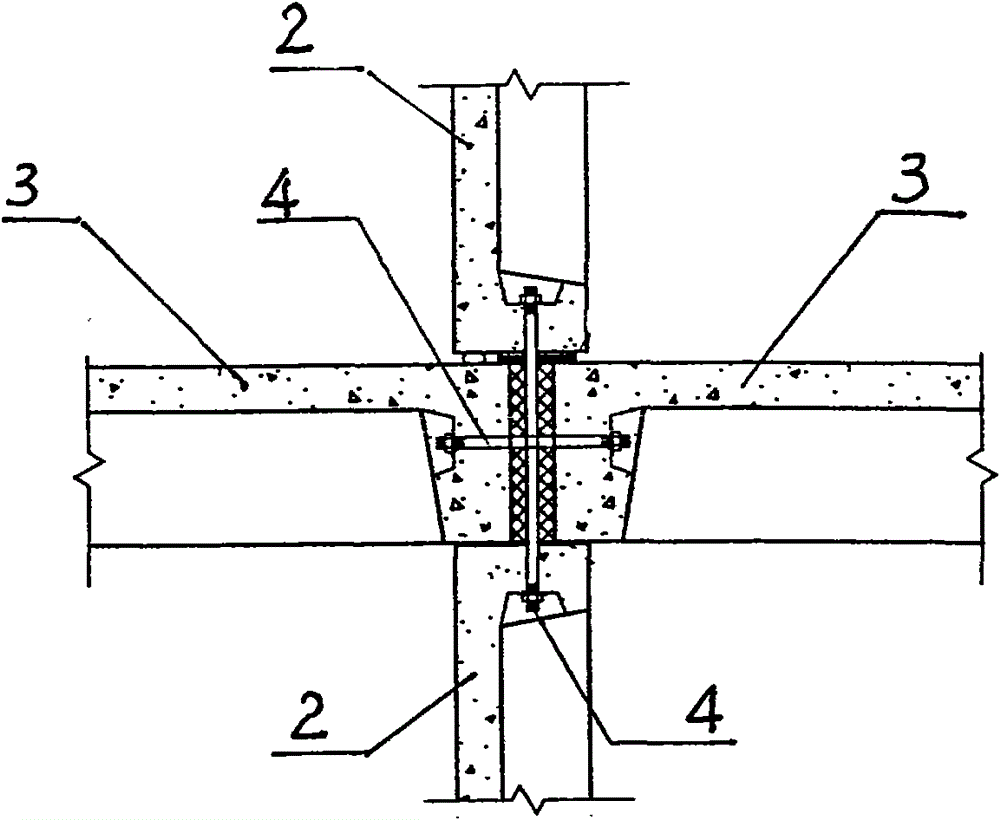

[0023] see figure 1 , figure 2 , the present invention adopts the prefabrication of concrete ribs to produce and prepare the box unit 1, the box unit and the box unit are connected and fixed by bolts to form a building mechanism, and the concrete ribs are used as the load-bearing wall 2 and the floor of the box unit 3. The load-bearing walls of the box unit are four walls or three walls.

[0024] figure 2 Shown is the connection between the wall body 2 and the floor 3 , which are connected by galvanized bolts 4 up and down, left and right.

[0025] The most important component of the box unit of the present invention is dense ribs (including wall panels and floor slabs). The dense ribs are designed according to the ultimate strength design method and are prefabricated in factories or on site. The concrete strength used in prefabrication is C35, the rib reinforcement adopts HRB335, and the reinforcement mesh adopts HPB235 or CRB550 welded reinforcement mesh. The width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com