Blasting process for hard rock multi-arch tunnel

A multi-arch tunnel and hard technology, which is applied in the field of hard rock multi-arch tunnel blasting technology, can solve the problems of difficulty in meeting precision requirements, difficulty in on-site implementation, and weak operability, and achieve easy operation, reduced blasting disturbance, and engineering The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

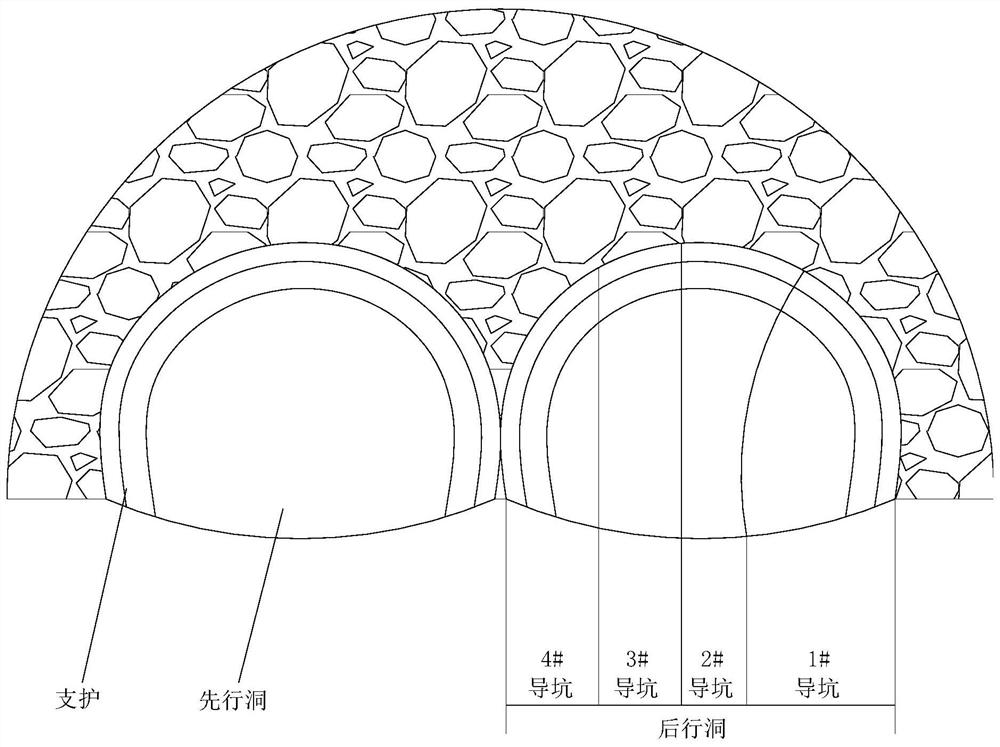

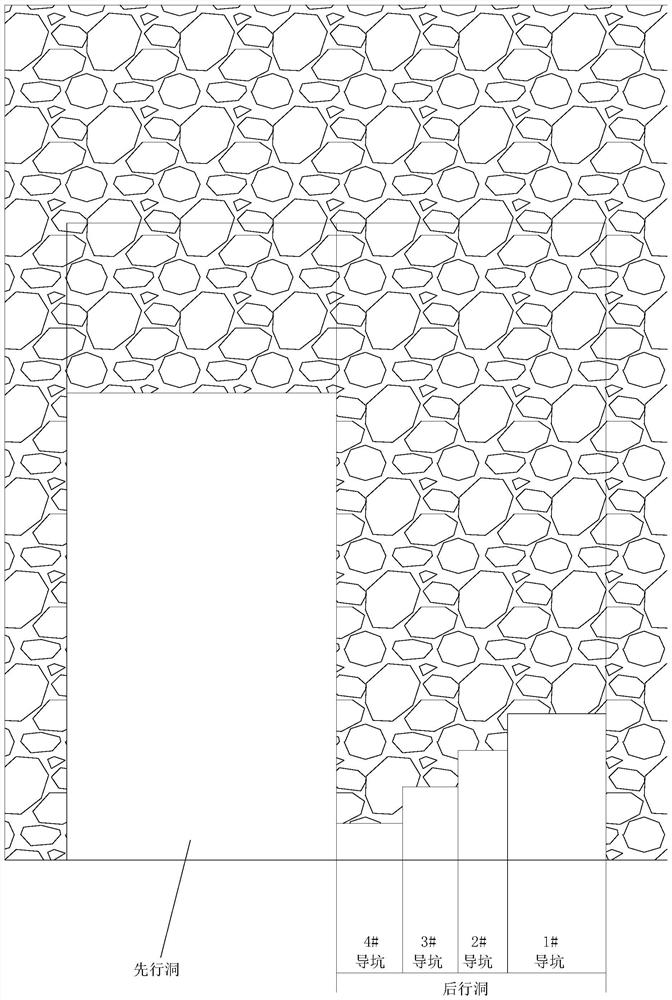

[0044] In order to make the object, technical scheme and advantages of the present invention more clearly understood, below in conjunction with embodiment and appended figure 1 And attached figure 2 , to further describe the present invention in detail. The exemplary embodiments and descriptions of the present invention are only used to explain the present invention, and are not intended to limit the present invention.

[0045] A blasting process for a hard rock multi-arch tunnel, comprising the following steps:

[0046] A. Blasting, tunneling, and supporting the advance hole until the depth reaches X m;

[0047] B. Divide the face of the back hole vertically into P areas. Along the direction close to the front hole, each area is defined as 1# area, 2# area, 3# area...P# area, P≥3;

[0048] C. Blasting and excavating the 1# area until the depth reaches Y m, forming the 1# pilot pit, Y<X;

[0049] D. According to the increasing order of P value, successively blast and excav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com