Fabricated wallboard and fabricated station building

A prefabricated, wall panel technology, applied in building components, buildings, building structures, etc., can solve the problems of general sound insulation and fireproof performance, poor environmental protection and energy saving, and cannot be reused, avoiding long maintenance, improving bending resistance, Avoid the effect of welding and auxiliary support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

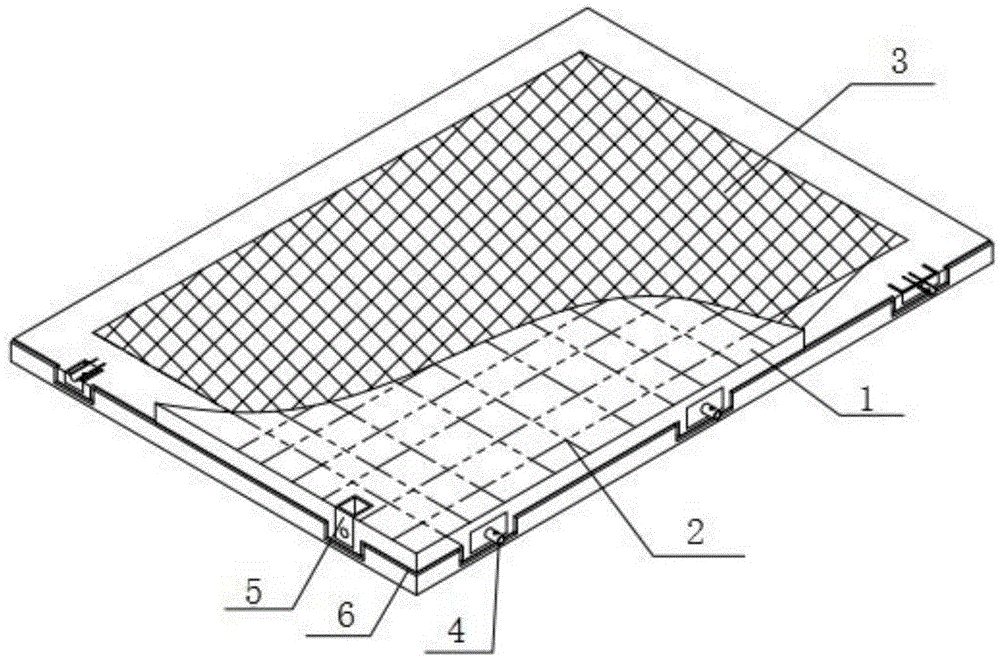

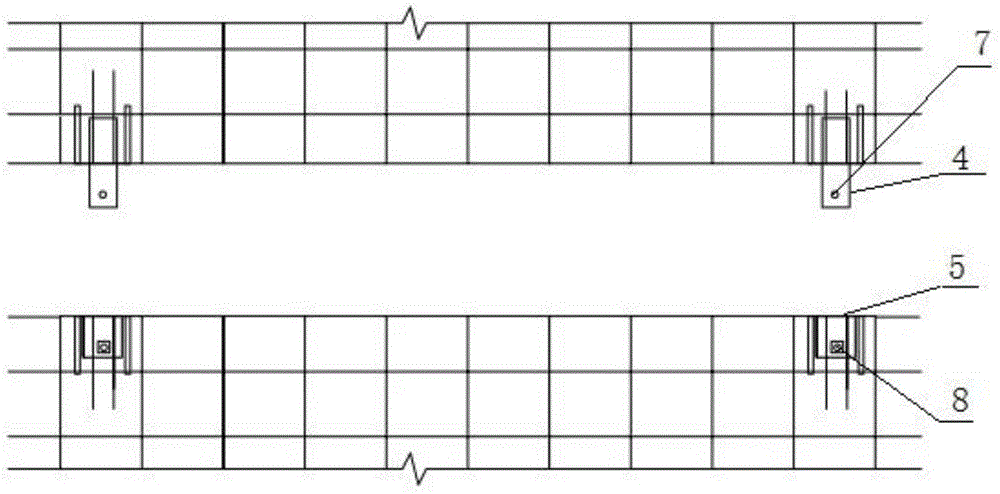

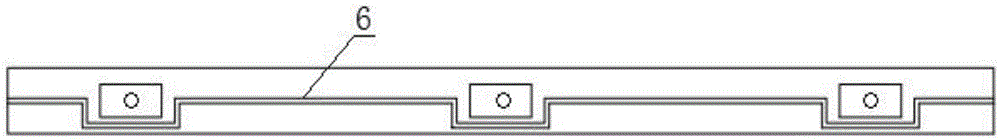

[0022] Such as figure 1 Shown is a schematic structural view of a prefabricated wall panel according to a preferred embodiment of the present invention. Generally, wall panels can be divided into wall panels used as house walls, bottom panels used as floors, roof panels used as roofs and wall panels with other functions according to the division of composition functions. The basic structure of each wall panel is the same. The difference lies in the corresponding functional parts included to realize the corresponding functions (such as wall panels containing doors and windows, usually with embedded parts such as doors and windows) and the number of connecting parts set on the connecting surface. For the convenience of the following description, no distinction will be made. For the above several forms of wall panels, only the general form of wall panels is used as the main body of explanation.

[0023] The prefabricated wall panel provided by the present invention includes an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com