Beam column connecting piece and construction method of wall

A technology of beam-column connection and construction method, which is applied in the direction of building components, building reinforcements, buildings, etc., can solve the problems that the end steel bars are easy to occupy each other, increase the space of connection nodes, and it is difficult to position accurately, so as to achieve convenient The connection is fixed, it is convenient for installation and leveling, and the effect of construction speed block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

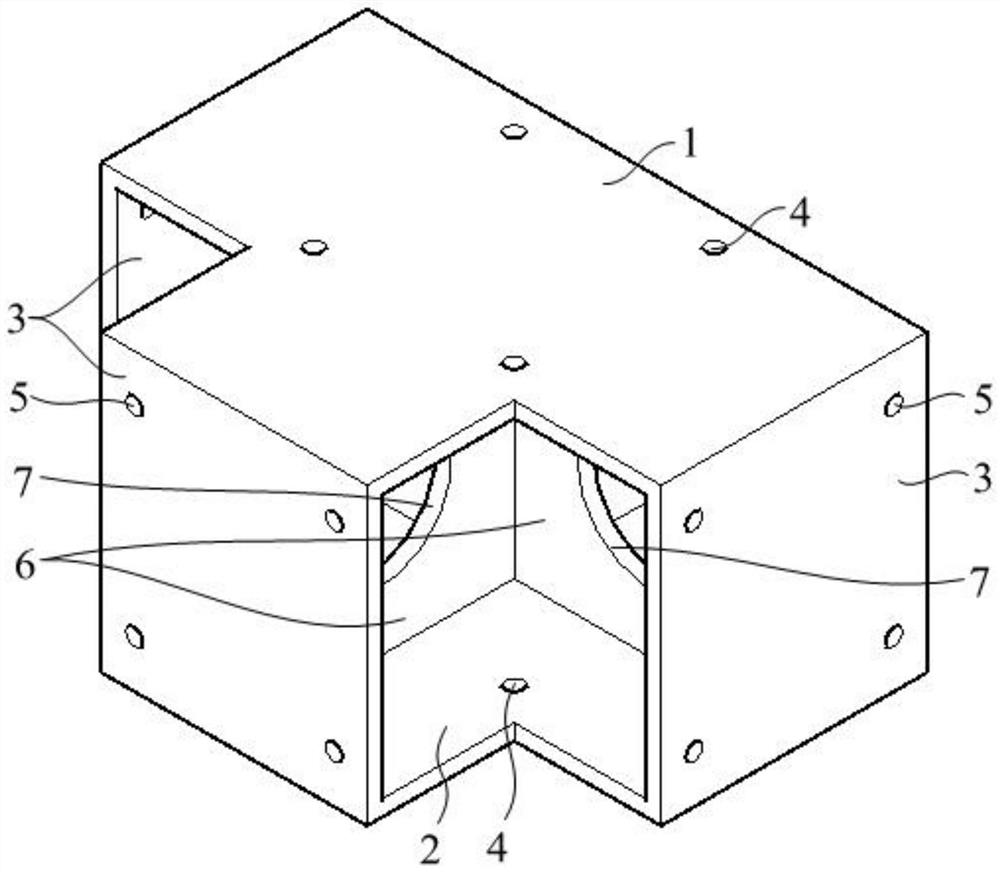

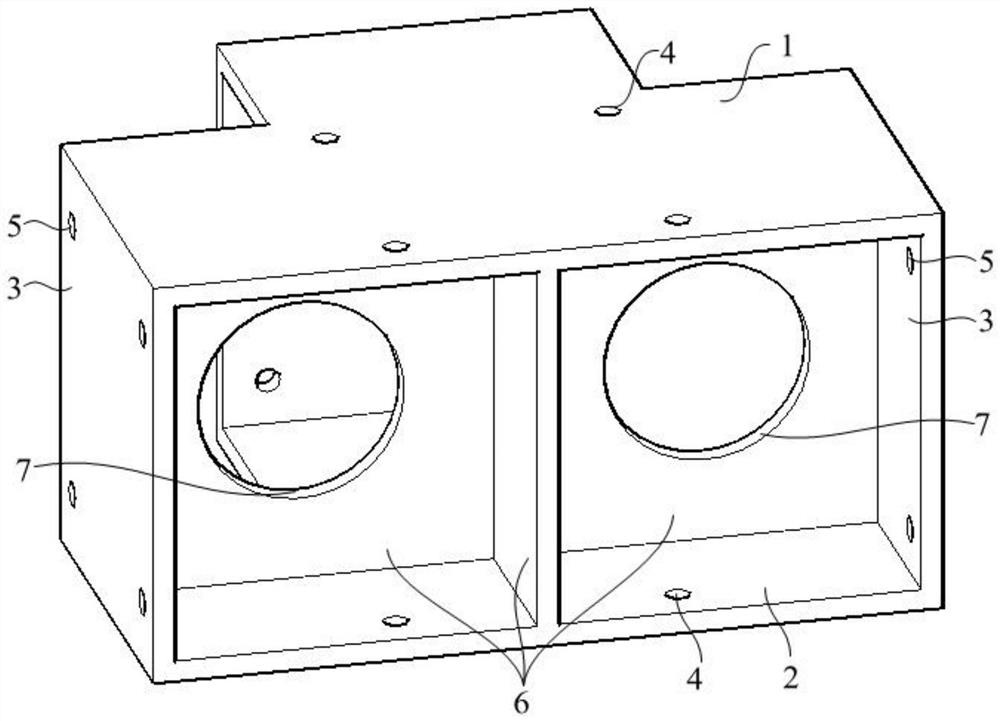

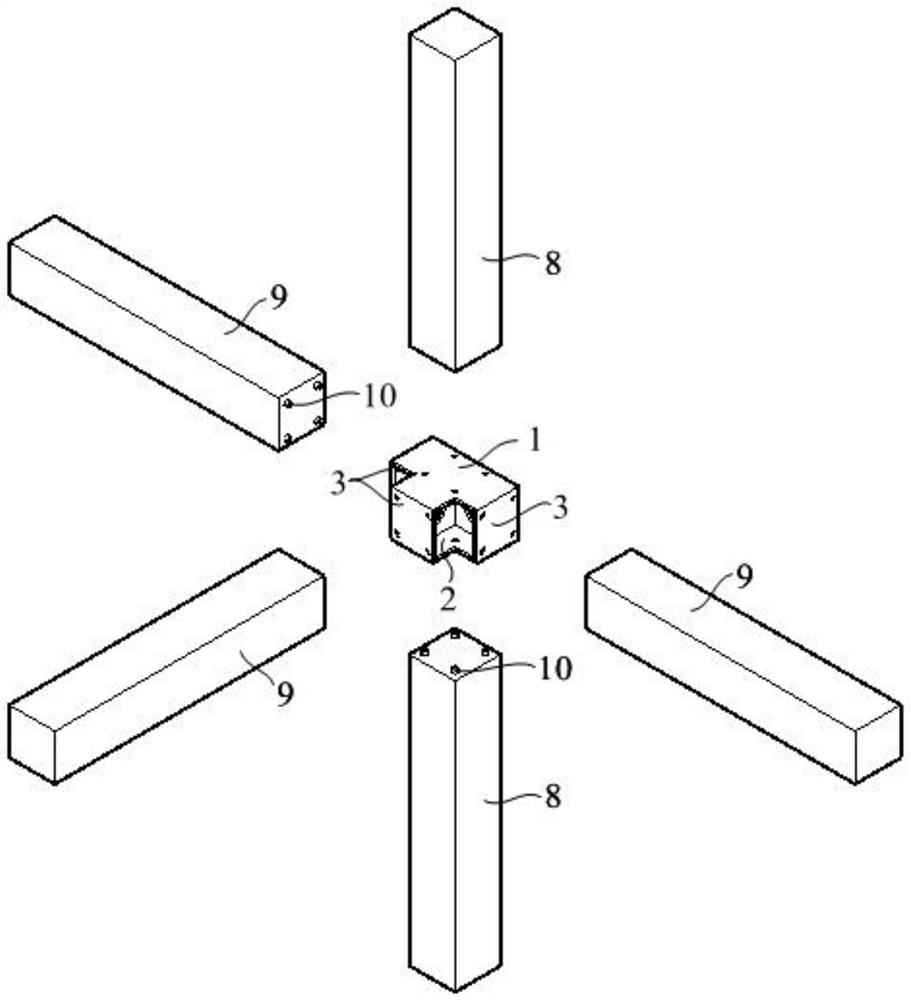

[0069] like figure 1 , Figure 4 and Figure 7 As shown, a beam-column connector of the present invention includes an upper connecting plate 1 and a lower connecting plate 2, a side connecting plate 3 is connected between the upper connecting plate 1 and the lower connecting plate 2, and the upper connecting plate 1 and the lower connecting plate 2 are provided with at least two through holes 1 4, the side connecting plate 3 is provided with at least two through holes 2 5, the through holes 1 4 are used for fixing the connecting bars 10 of the structural columns 8, and the through holes 2 5 are used for fixing the ring beam. 9 or the connecting bars 10 of the ground beam 17.

[0070] In this embodiment, the beam-column connector is a steel structure. Since the structural column 8, the ground beam 17 and the ring beam 9 are usually prefabricated with four pre-embedded steel bars, the corresponding connecting bars 10 extending from the end face are also Four, and the four con...

Embodiment 2

[0083] A construction method for a wall of the present invention, using the beam-column connector as described in Embodiment 1 for wall construction, includes the following steps:

[0084] A: Use beam-column connectors to connect the structural column 8 and the ring beam 9 to form a wall skeleton and fix it to the floor;

[0085] B: Assemble and fix the wall panels 16 in sequence in the wall skeleton, fill the beam-column connectors with mortar, and complete the construction of the wall.

[0086] In this embodiment, as Figure 10 As shown, the object of construction is a single-sided wall, and the wall skeleton is formed by four structural columns 8, a ring beam 9 and a ground beam 17. The wall skeleton is divided into a bottom layer and a top layer. Each layer is filled with five prefabricated wall panels 16 by horizontal assembly. The ring beam 9 and the wall panel 16 are clamped and fixed through the structure of grooved convex ribs, and the connecting surface of the ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com