Excavation method for subway shaft reinforcement in weak water-rich strata

A technology for water-rich formations and shafts, which is applied in shaft equipment, sinking, earthwork drilling and mining, etc. It can solve problems such as water gushing, mud inrush, large deformation, endangering the safety of structures and surrounding buildings, and failure to proceed smoothly in construction. Achieve the effect of saving temporary support, reducing construction risk, and convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

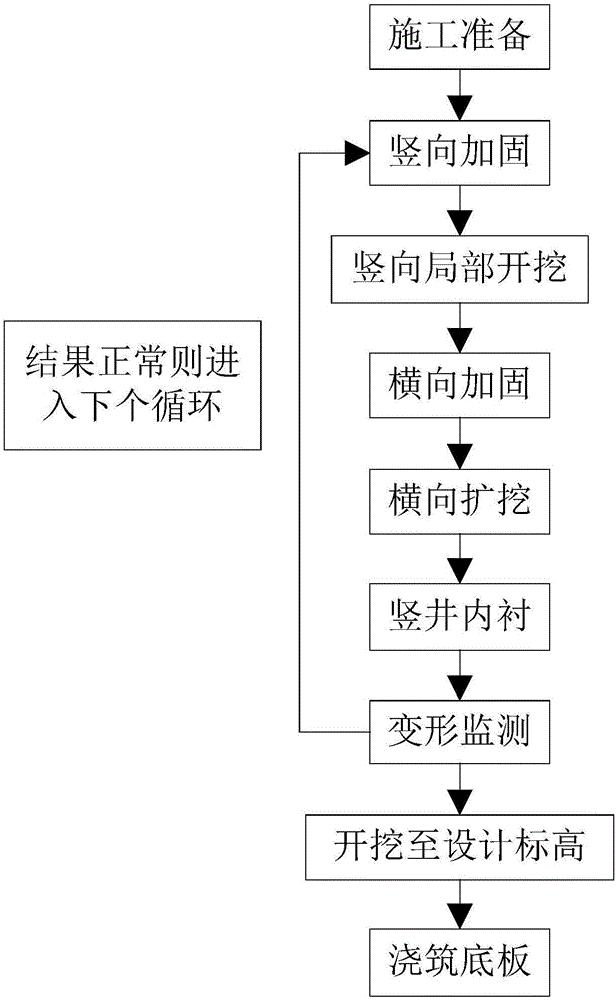

[0030] as attached figure 1 , to complete the reinforcement excavation of subway shafts in weak water-rich formations, mainly divided into seven steps: step 1), vertical reinforcement; step 2), vertical partial excavation; step 3), horizontal reinforcement; step 4), horizontal expansion Digging; step 5), shaft lining; step 6), deformation monitoring; step 7), repeating steps 1)-step 6), excavating to the design elevation; step 8), pouring the base plate. details as follows.

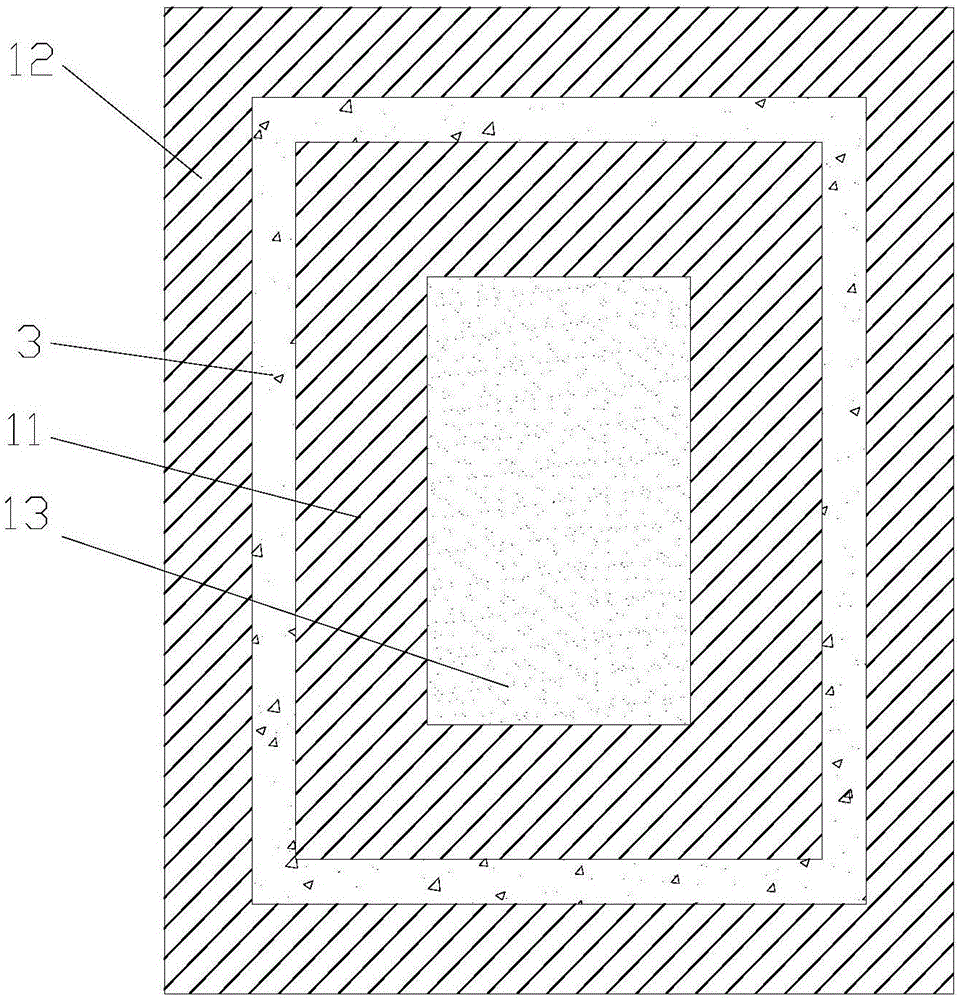

[0031] as attached image 3 As shown, step 1), vertical reinforcement, vertical reinforcement of the 1# reinforcement area 11 on the first floor, using three-axis mixing piles to grout the design size area of the shaft for about 3m to 4.5m;

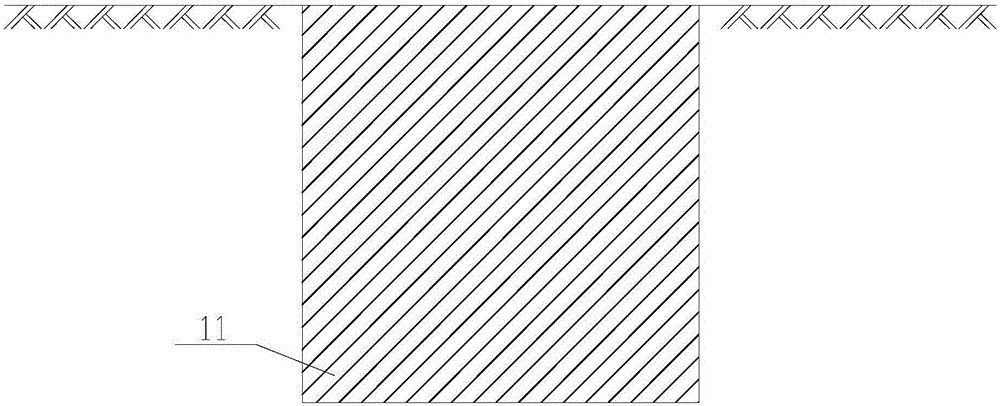

[0032] as attached Figure 4 , step 2), vertical partial excavation, and vertical excavation of the first layer 1# shaft I. At this stage, only the middle area is excavated, and the reinforced area with a thickness of about 1.5m to 2m is reserved around and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com