Assembled shear wall post-pouring ring beam template and plate support integrated design and construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

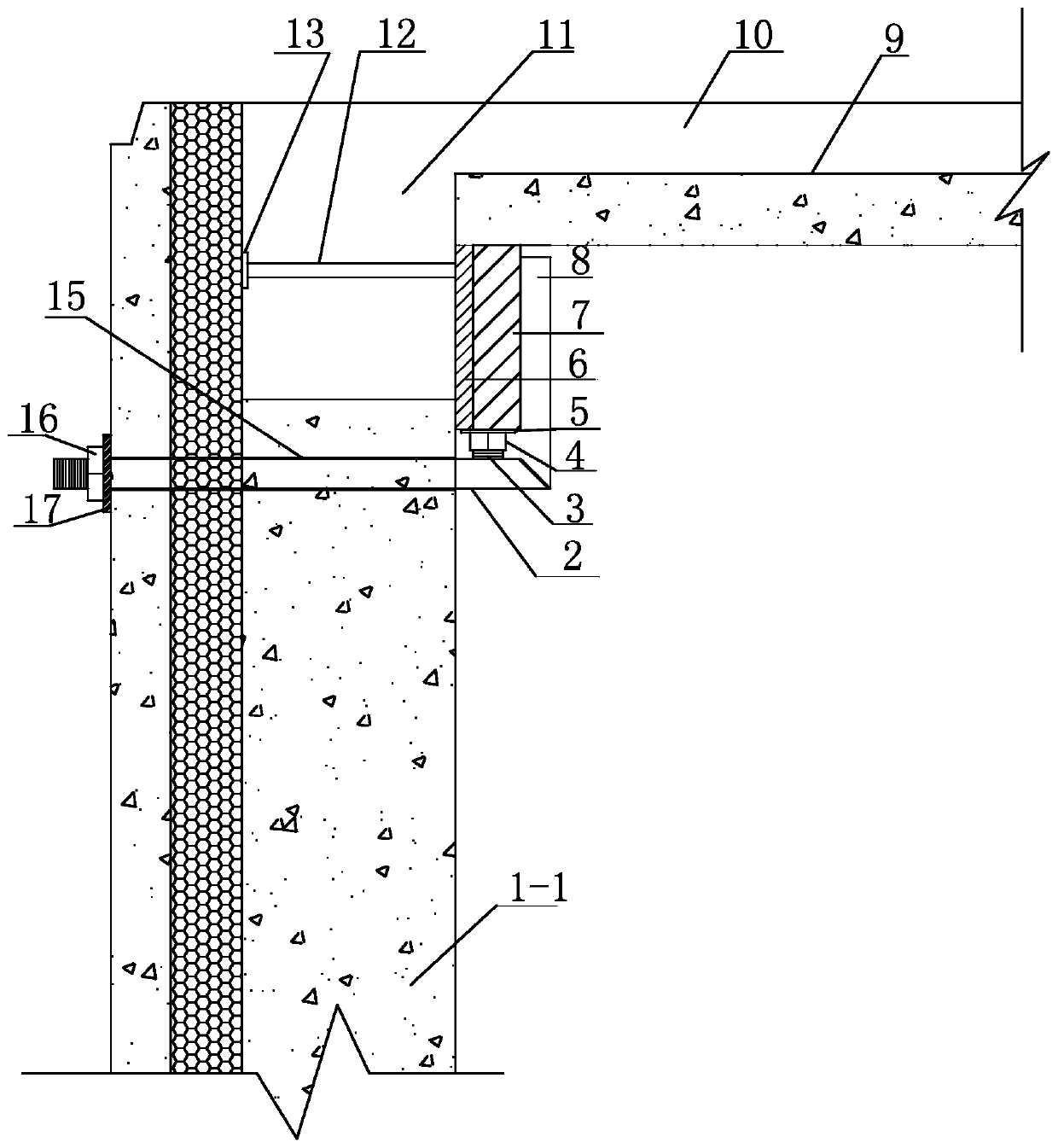

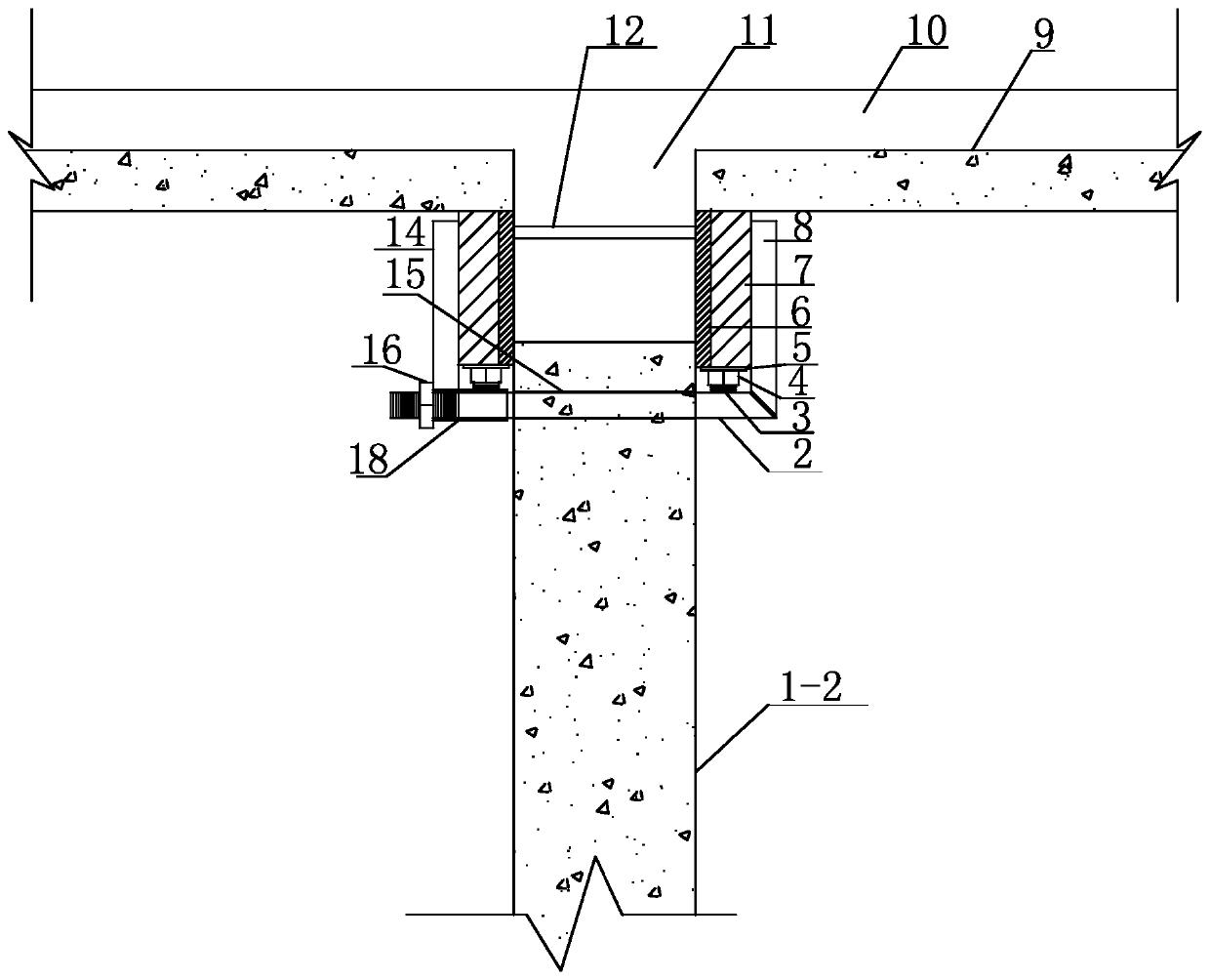

[0199] Such as Figure 1-2 As shown, the integrated design and construction method of the assembled shear wall rear pouring ring beam template and slab support of the present invention adopts the following steps:

[0200] 1. Determine the calculation model of the template system:

[0201] 1.1. Determine the template calculation model:

[0202] The template is supported by the backing 14 and the vertical rod 8, and the template calculation model is determined according to the three-span continuous beam;

[0203] 1.2. Determine the corrugated beam calculation model:

[0204] 1) The post-cast ring beam template of the external precast shear wall 1-1 uses the vertical rod 8 as the corrugated beam, and the corrugated beam calculation model is determined according to the cantilever beam;

[0205] 2) The post-cast ring beam template of the inner prefabricated shear wall 1-2 uses the vertical rod 8 and the back corrugation 14 as corrugated beams, and the corrugated beam calculation model is det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com