Foundation Pit Containment System and Construction Method Using Underground Diaphragm Wall as Vertical Cantilever Fulcrum

An underground diaphragm wall and foundation pit enclosure technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of increasing cooperation between the design department and the construction department, high construction precision requirements, and extended construction period, etc., to achieve The effect of shortening the construction period of earthwork, simplifying construction difficulty and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

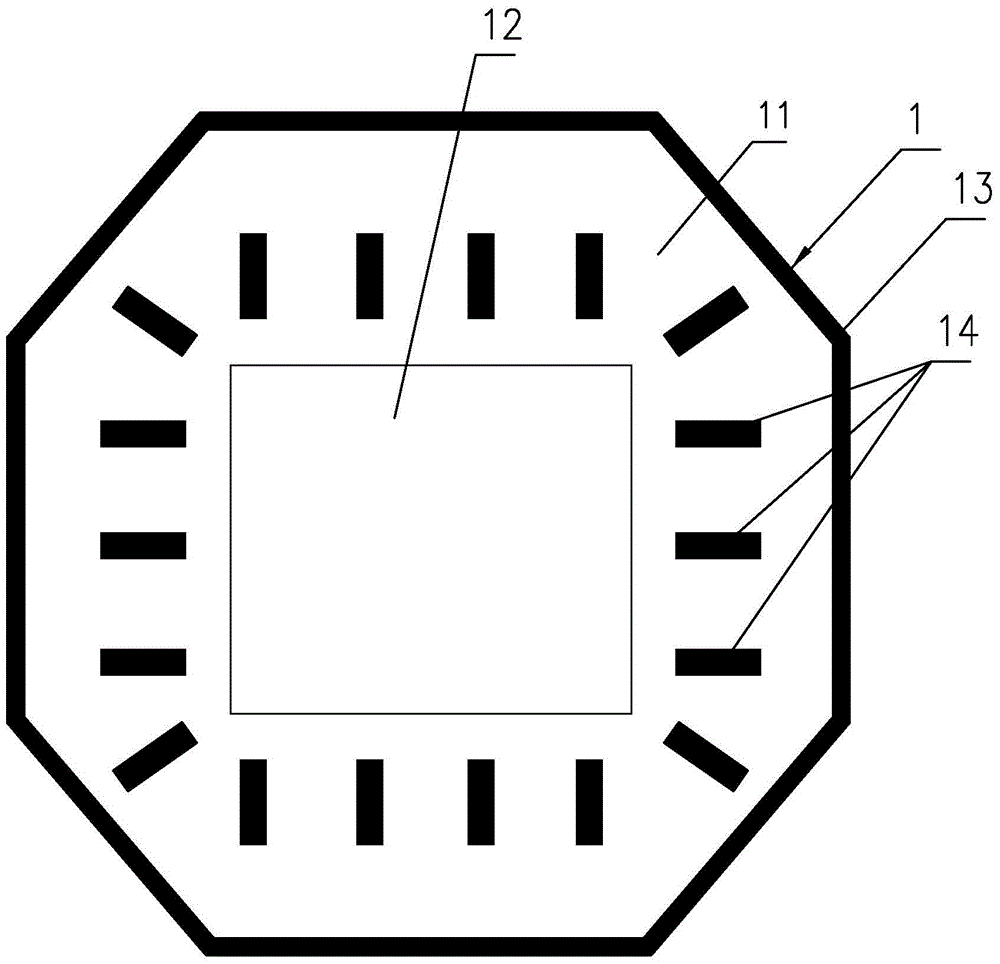

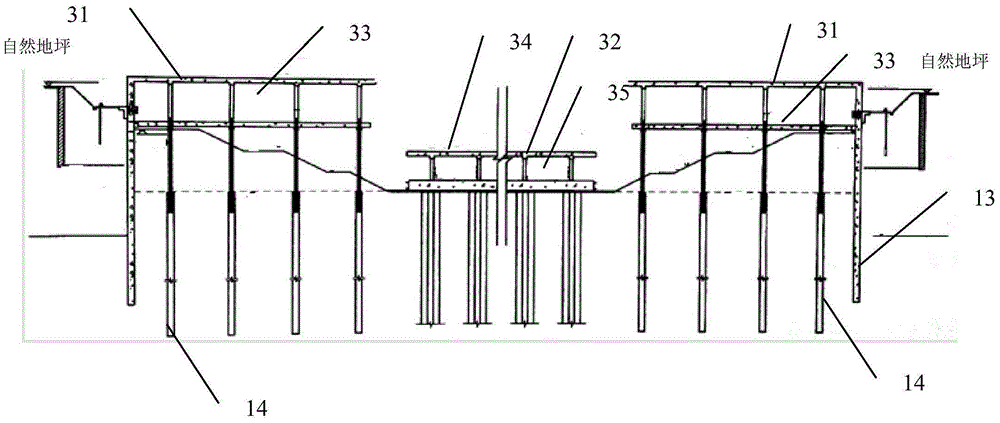

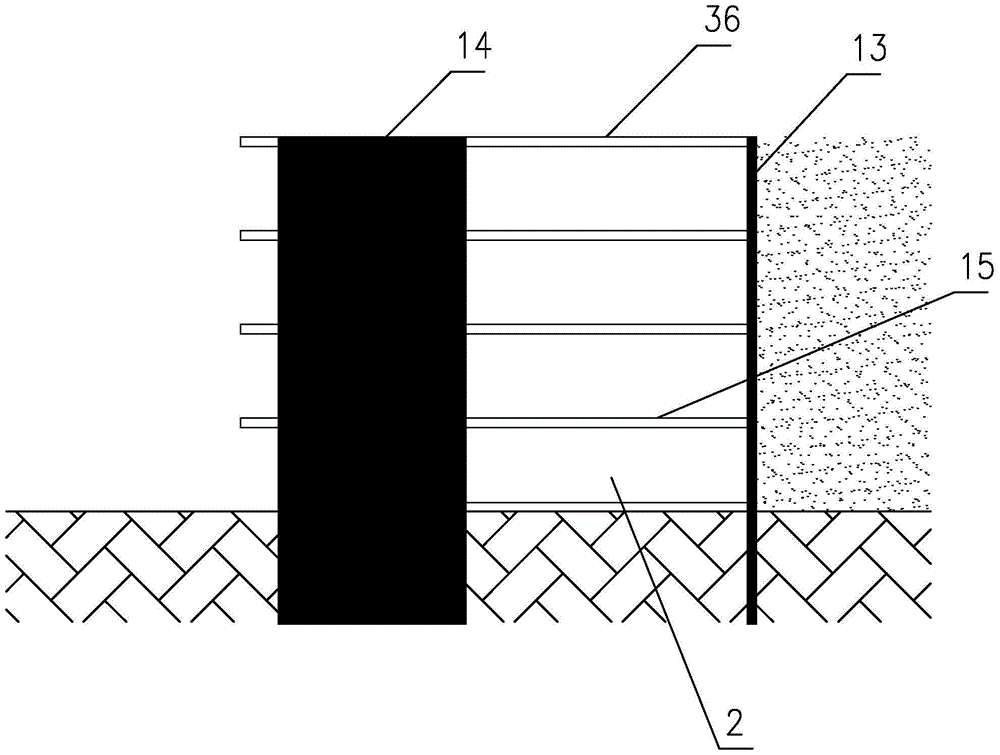

[0053] This embodiment is applicable to the situation that the area of the foundation pit is greater than or equal to 20,000 square meters, and the depth of the foundation pit is greater than or equal to 15 meters. Such as Figure 1~3 As shown, a foundation pit enclosure system with an underground continuous wall as a vertical cantilever fulcrum includes at least one layer of basement. The basement is formed by corresponding connection of respective floor slabs, wherein, the basement 31 located in the surrounding area 11 of the foundation pit is constructed by the reverse construction method, while the basement located in the remaining areas of the foundation pit 1 is constructed by the forward method, and the basement located in the surrounding area 11 of the foundation pit is constructed by the reverse method. The basement 31 comprises an underground diaphragm wall 13, a lateral shear wall 14 and a floor 15, and the underground diaphragm wall 13 is arranged along the inner...

Embodiment 2

[0070] In this embodiment, in response to the requirements of the construction party for the construction progress, one of the towers is constructed first. Therefore, the difference between this embodiment and Embodiment 1 is that the lateral shear resistance walls are distributed in the local area around the foundation pit.

[0071] The construction method of the foundation pit system of the present embodiment comprises the following steps:

[0072] (1) Excavate the pit for setting the underground diaphragm wall to below the floor of the basement along the building red line of the foundation pit, hoist the steel cage of the underground diaphragm wall in the pit, and then pour concrete into the pit to form the underground diaphragm wall ;

[0073] (2) Excavate multiple pits for setting lateral shear walls in the local area around the foundation pit to below the floor of the basement, hoist the reinforcement cages of lateral shear walls in the pits, and then place them in the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com