Excavation construction method of ultra-shallow buried uneven weathered stratum of tunnel

A construction method and tunnel technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as poor geology, uneven weathering, and shallow tunnel burial.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

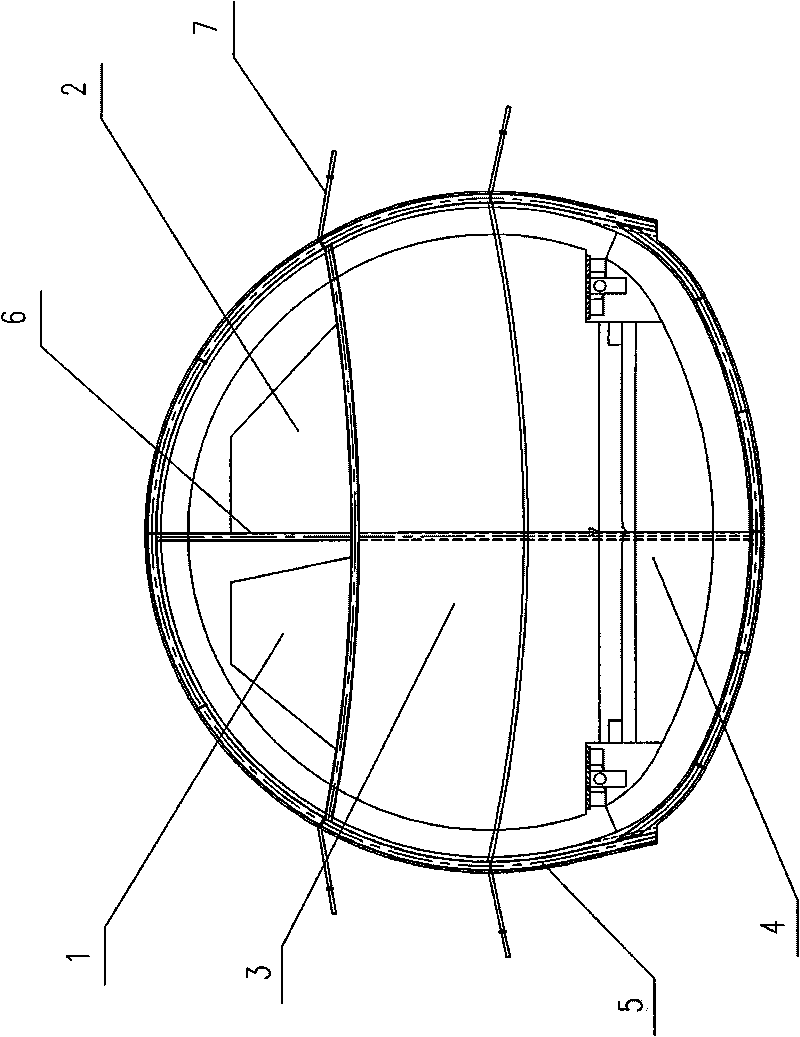

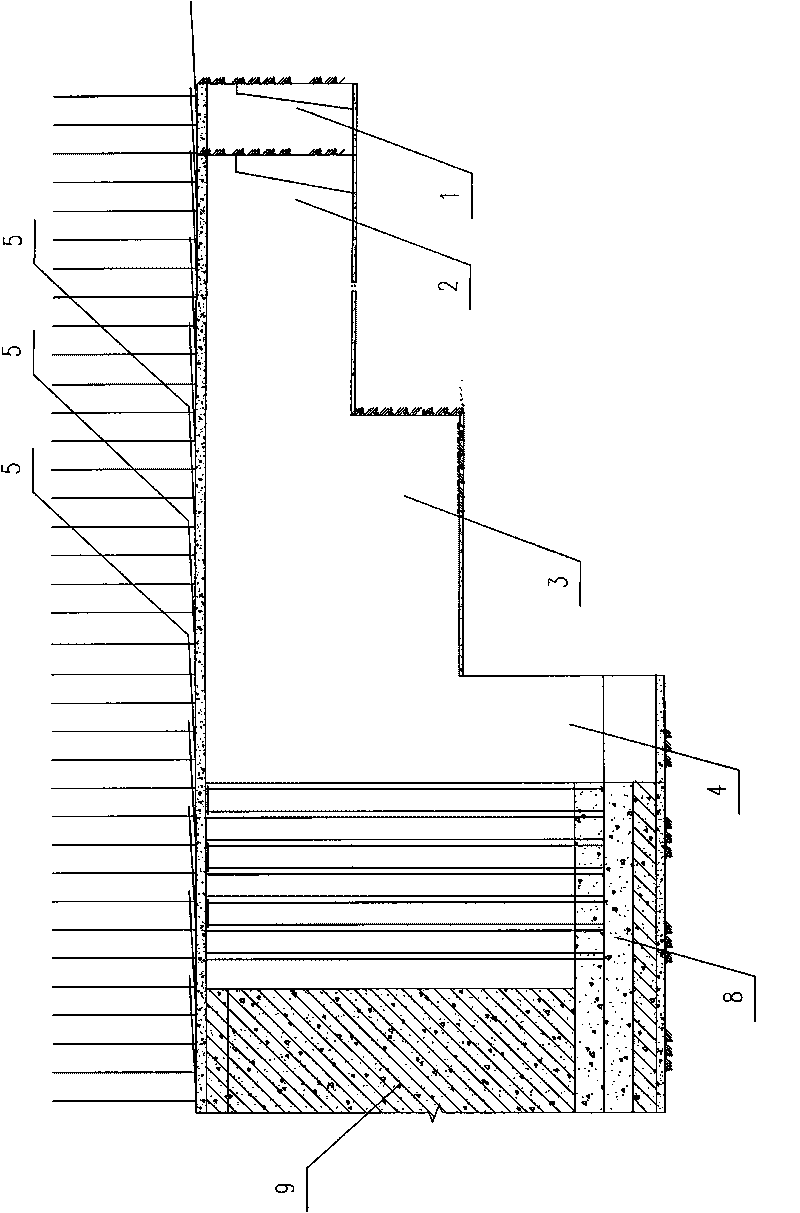

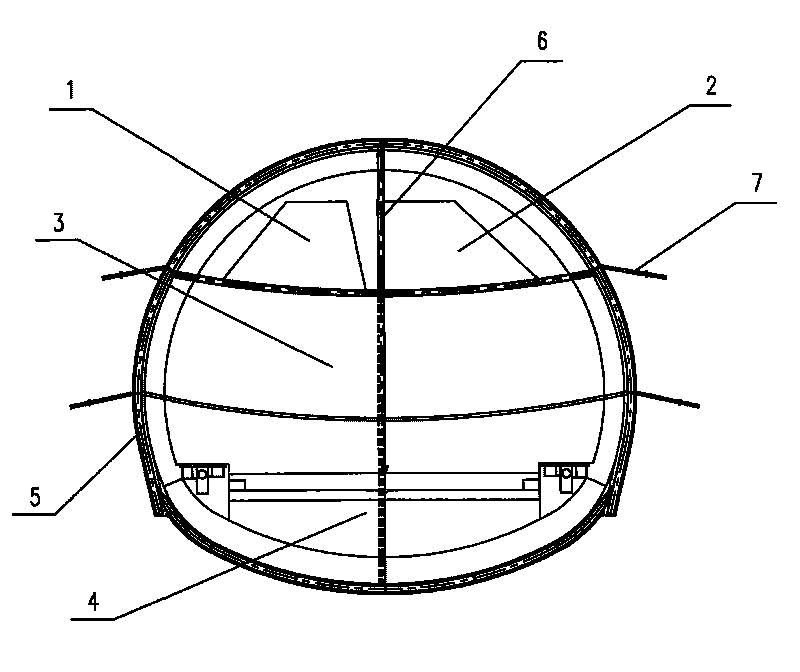

[0019] see figure 1 and figure 2 As shown, the excavation construction method of the present invention in the shallow buried uneven weathered stratum adopts the excavation construction method of the ultra-shallow buried uneven weathered stratum by entering the tunnel from the arch part. It adopts the sub-step method for construction. It is divided into four parts: the left side of the upper stage 1, the right side of the upper stage 2, the middle stage 3, and the lower stage 4; the specific construction steps are as follows:

[0020] 1), advance support of arch 5 (φ108 pipe shed advance pre-reinforcement):

[0021] In the 140° range of the tunnel arch, dense advanced 108 long tube sheds are adopted, with a length of 20-40m and a circumferential spacing of 40cm. The long tube sheds overlap 4-5m between cycles. The excavation is supplemented by a 1.5m ring of 3.5m-long encrypted φ42 advanced small conduit. The long tube shed is laid horizontally in advance, the guide wall is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com