Assembled multi-groove reinforced composite floor slab

A superimposed floor slab, prefabricated technology, applied in the direction of floor slabs, building components, buildings, etc., can solve problems such as the inability to solve the problems of large-span and large-bay architectural design and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

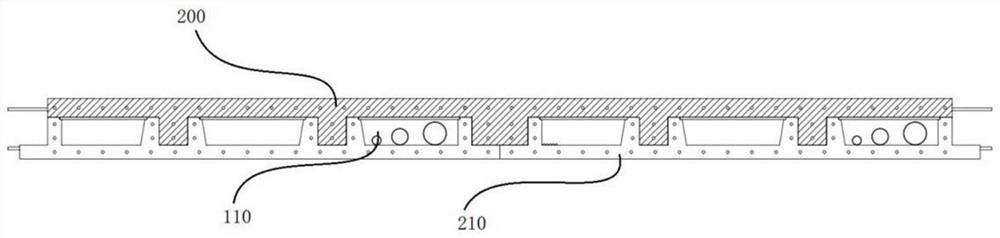

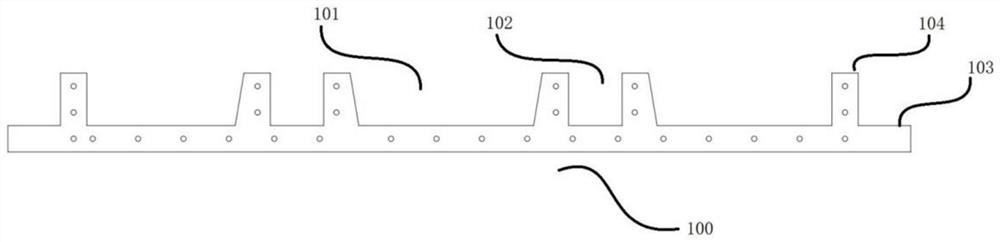

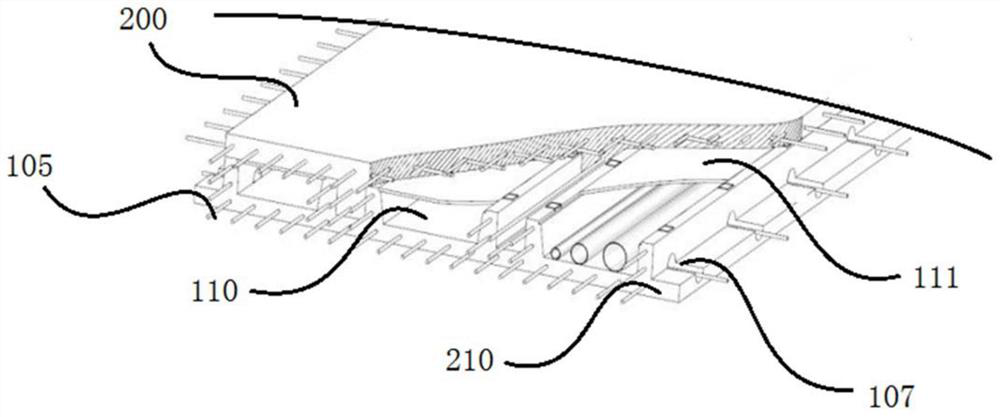

[0045] Such as Figure 1-Figure 4 A prefabricated multi-groove reinforced laminated floor slab is shown, including a form plate 210 and a cast-in-place concrete layer 200 poured on the form plate 210. The form plate 210 includes a bottom plate 100 and a reinforcing rib 104. The reinforcing rib 104 and the bottom plate 100 are Integral structure, the reinforcing ribs 104 are upwards straight to the bottom plate 100, structural intervals 102 and functional intervals 101 are formed between the reinforcing ribs 104, the functional intervals 101 and structural intervals 102 are distributed alternately, the functional intervals The upper end of the interval 101 is sealed with a cover plate 111 to form a cavity 110 or filled with functional materials. The bottom plate 100 has a pick-up edge 103, and there are butt joint reserved steel bars protruding from both sides of the bottom plate, and stressed steel bars 105 are evenly distributed inside the bottom plate. , the stressed steel b...

Embodiment 2

[0051] The difference from Embodiment 1 is that, as Figure 8-Figure 10 As shown, when the two ends of the base plate 10 are edge-sealed with reinforcing ribs, there is no overhanging edge. When the plurality of templates 21 are arranged horizontally, there is an interval between the outer edge reinforcing ribs 14 of each two base plates 10, and a hanging frame is installed in the interval. The mold 22 or the on-site mold support form the stressed rib beams between the formworks. The suspended mold 22 is bound with a stressed steel cage. The suspended mold 22 is suspended on the ribs 14 on both sides and parallel to the bottom plate 10. The ends are level with the two bottom plates 10. In addition, in this embodiment, the functional space 11 is filled with functional materials, which can be thermal insulation materials, sound insulation materials, and heat insulation materials. The hanging formwork is a permanent non-demolition bottom formwork and a temporary hanging formwork...

Embodiment 3

[0054] The difference between this embodiment and the first embodiment is that, if Figure 13-14 The surface of the reinforcing rib of the template shown in contact with the cast-in-place concrete layer is distributed with concave primary occlusal teeth 301 . When the bottom plate has a pick-up edge, secondary occlusal teeth 302 are distributed on the pick-up edge. When two adjacent panels are connected, the secondary occlusal teeth 302 on the pick-up edge correspond and are filled with cement. The concave area where the number of primary occlusal teeth / secondary occlusal teeth is greater than or equal to 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com