Tunnel excavation method in shallow-buried bias-pressure toppling-deformation bulk solid and strong-unloading rock structure

A technology of rock unloading and tunnel excavation, applied in tunnels, temporary shields, mining equipment, etc., can solve problems such as engineering safety, quality, progress and economic losses, tunnel shallow buried bias, waste of construction time, etc., to achieve The effect of preventing excessive deformation and collapse of the tunnel, saving the cost of temporary support measures, and enhancing the self-stabilization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

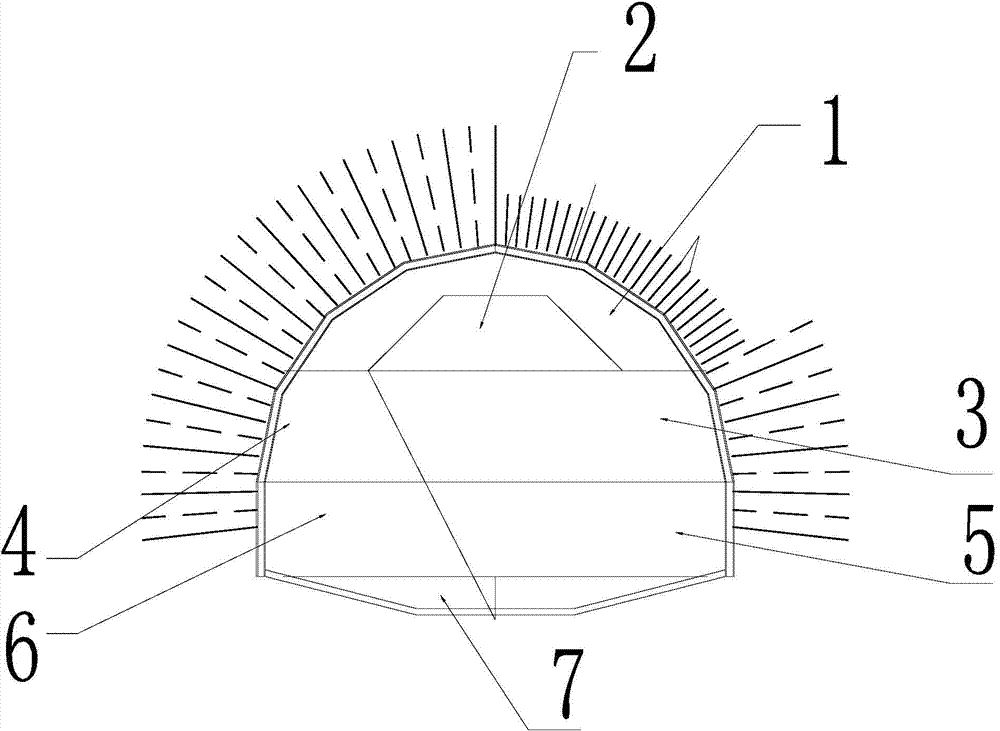

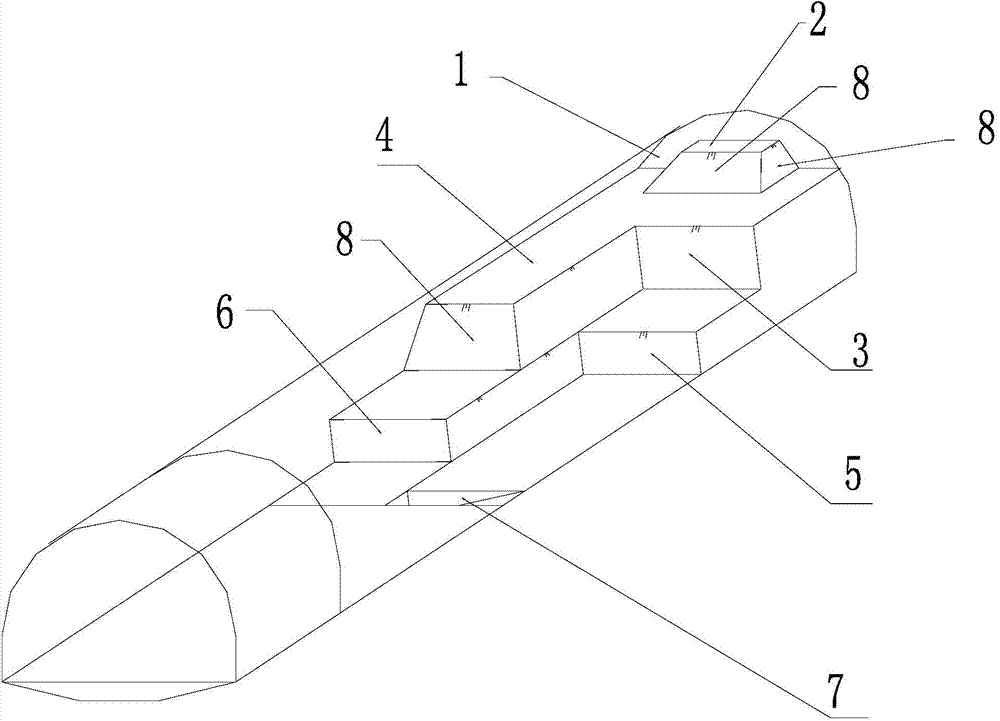

[0024] like figure 1 and figure 2 As shown, in order to solve the above-mentioned technical problems, the tunnel excavation method in the shallow buried partial pressure dumping deformed bulk and the strong unloading rock structure that the present invention adopts comprises the following steps:

[0025] a. With the steel frame joint as the boundary, divide the tunnel to be dug into four parts: upper step, middle step, lower step and inverted arch;

[0026] b. Excavate the upper steps and support the excavated part during the excavation process;

[0027] c. Excavate the middle steps, and support the excavated part during the excavation process;

[0028] d. Excavate the lower steps and support the excavated part during the excavation process;

[0029] e. Excavate the inverted arch part 7, and support the excavated part during the excavation process.

[0030] The excava...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com