Ion-adsorption-type rare earth in-situ leaching method and leaching system thereof

An ion-adsorption, in-situ leaching technology, applied in the method and its leaching system, in the field of ion-adsorption rare earth in-situ leaching, can solve the problems of potential safety hazards, excessive discharge of slag, and reduced leaching efficiency. Achieve the effect of high degree of construction automation, reduce the discharge of waste soil, and improve the efficiency of ore leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

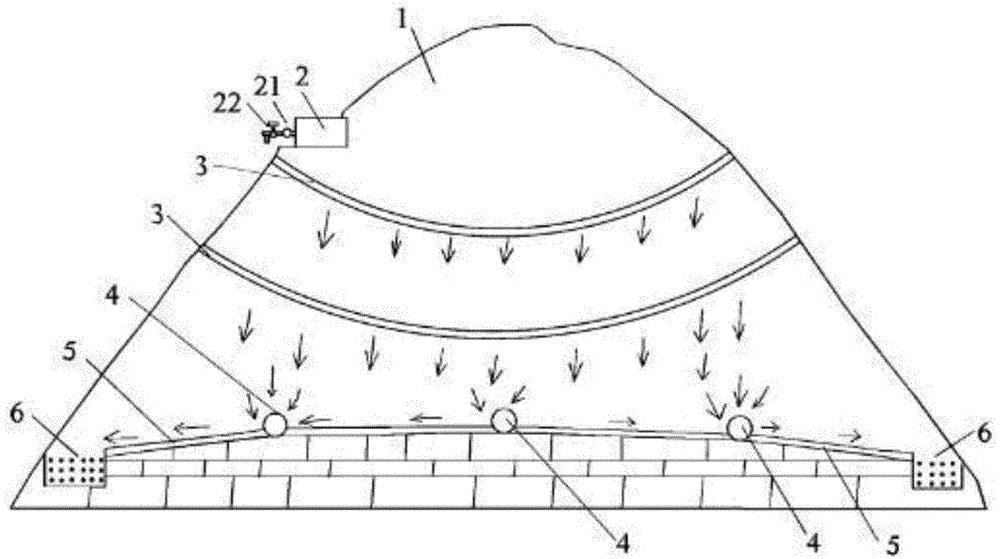

[0045] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0046] In the first step, a trenchless directional drilling machine is used to drill holes (liquid injection holes) in the ion-adsorption type rare earth mine 1 .

[0047] Drilling is carried out with a non-excavation directional drilling machine. The drilling is carried out with mud retaining wall and rotary drilling technology. The mud mix ratio is: water: bentonite: lubricant: Na 2 CO 3 =1:0.1:0.002:0.003 (weight ratio). In this embodiment, 2 boreholes (liquid injection holes) are arranged according to the burial conditions and scale of the ore body in the mine. The drilling trajectory line spacing is 6 meters.

[0048] Before drilling, put the probe into the probe box, then connect the guide bit to the drill pipe, install the receiver, etc., and the drilling angle is 25° 0 , Adjust the drilling machine and fix it well to prevent the horizontal di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com