Prefabricated superimposed shear wall mounting system and method

A technology of stacking shear walls and installation systems, which is applied in the treatment of walls and building materials, construction, etc., can solve problems such as unfavorable construction operations by workers, difficult fixing of pads, labor-consuming and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

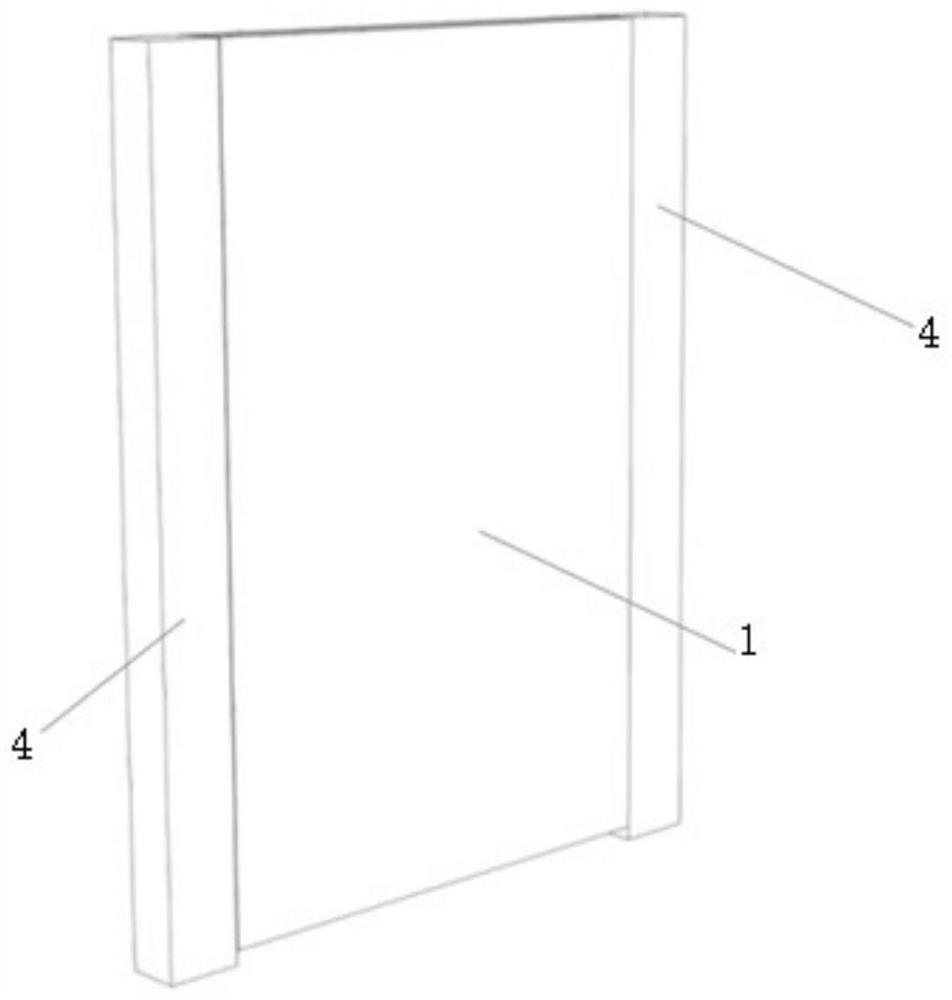

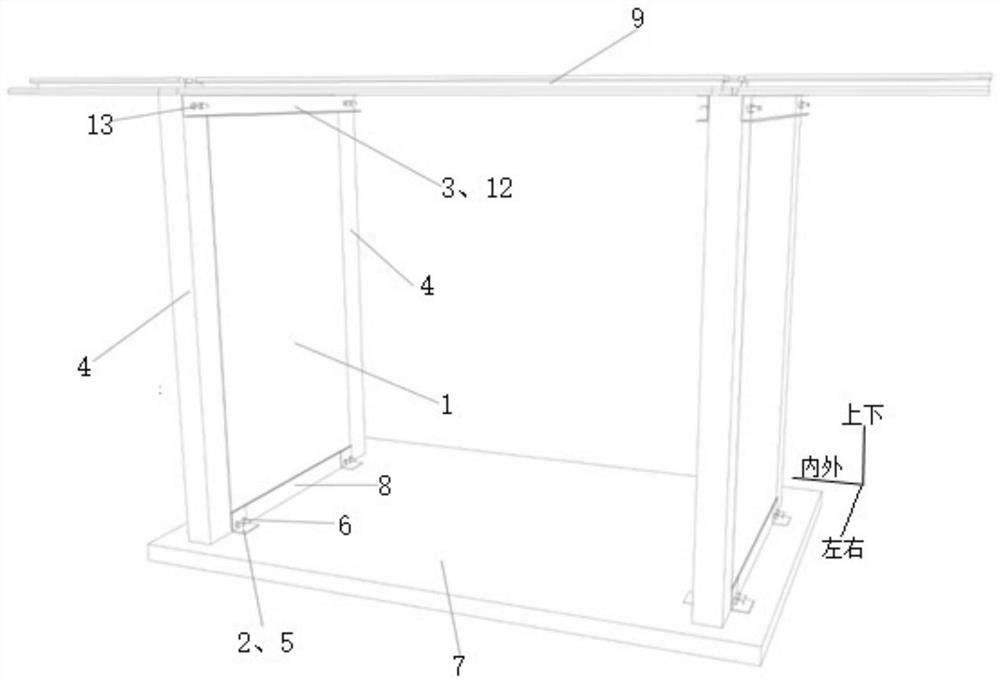

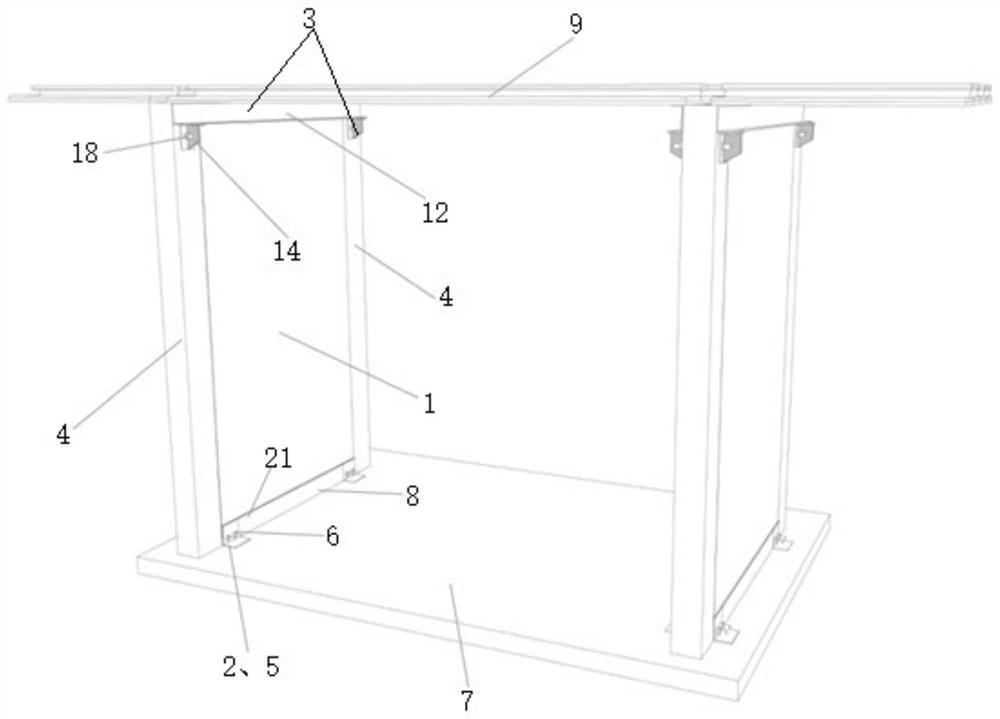

[0040] An embodiment of the present invention provides a prefabricated laminated shear wall installation system, such as Figure 1-6 As shown, the system includes a prefabricated laminated shear wall 1, a bottom support 2 and a top support 3, where:

[0041] Steel pipe edge constraining members 4 are respectively arranged on the left and right sides of the prefabricated laminated shear wall 1; there are multiple bottom supports 2, and each bottom support 2 includes two unit parts 5, and the distance between the two unit parts 5 from the bottom surface A first group of horizontal bolt holes is opened at a certain height, and the two unit parts 5 are connected together by a first group of penetrating bolts 6 passing through the first group of bolt holes and a certain distance is kept between the two unit parts 5 .

[0042] The bottom support 3 is placed on the top surface of the lower concrete floor 7, the bottom of the prefabricated laminated shear wall 1 is placed between the ...

Embodiment 2

[0056] The embodiment of the present invention provides the installation method of the prefabricated laminated shear wall installation system described in Embodiment 1, the method comprising:

[0057] S1: Install steel pipe edge restraint members on the left and right sides of the prefabricated laminated shear wall.

[0058] S2: Assemble the bottom support and place the bottom support on the top surface of the lower concrete floor, wherein the two unit parts of each bottom support are connected together by the first set of through bolts and keep the two unit parts at a certain distance distance.

[0059] Taking the two unit parts as angle steel as an example, a pair of angle steel is assembled into a temporary support through the first set of cross bolts and a space for installing a prefabricated laminated shear wall is reserved.

[0060] S3: hoist the prefabricated laminated shear wall in place, place the bottom of the prefabricated laminated shear wall between the two unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com