CD-method construction method for improving loess tunnel with super-large cross section

A technology of loess tunnels and super large sections, which is applied in tunnels, tunnel linings, and earthwork drilling and mining, etc., can solve the problems of slow splicing of temporary supports in the upper and lower pilot pits, many temporary supports, and slow construction progress, and saves the bottom line. The effect of temporary pit support, simplified splicing and dismantling, and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

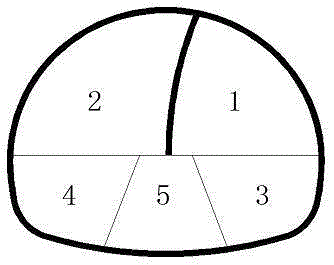

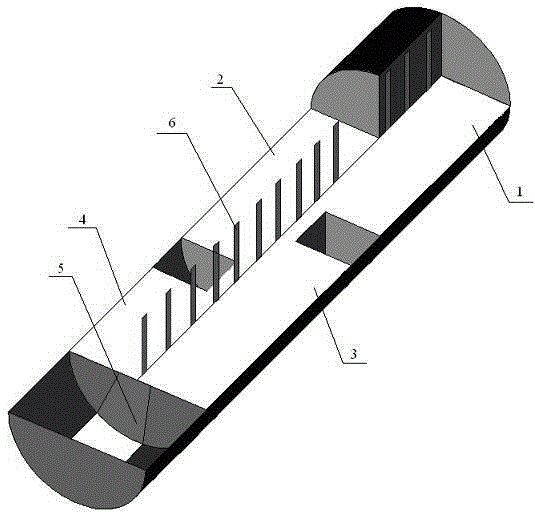

[0022] Such as figure 1 , figure 2 As shown, the improved CD method construction method for super-large-section loess tunnels includes the following steps:

[0023] ⑴Excavation firstly go up the pilot pit 1, apply initial support and temporary support 6, and excavate 1~2 times the arch frame spacing, depending on the surrounding rock conditions.

[0024] (2) After the excavation depth of the upper pilot pit 1 reaches 10m, proceed to the upper pilot pit 2 after excavation, and the excavation footage is 1~2 times the arch frame spacing, depending on the surrounding rock conditions. The distance between the leading upward pilot pit 1 and the subsequent upward pilot pit 2 is 10m~15m, so as to reduce the disturbance of the surrounding rock in the same area by the simultaneous excavation of the two pilot pits.

[0025] (3) Excavate the pilot pit 3 in advance, and excavate the arch frame spacing 3~4 times the footage, reserve the soil body of the middle soil column 5 for temporary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com