'Drip shaped' radial monolayer steel pipe reticulated shell block and installation method

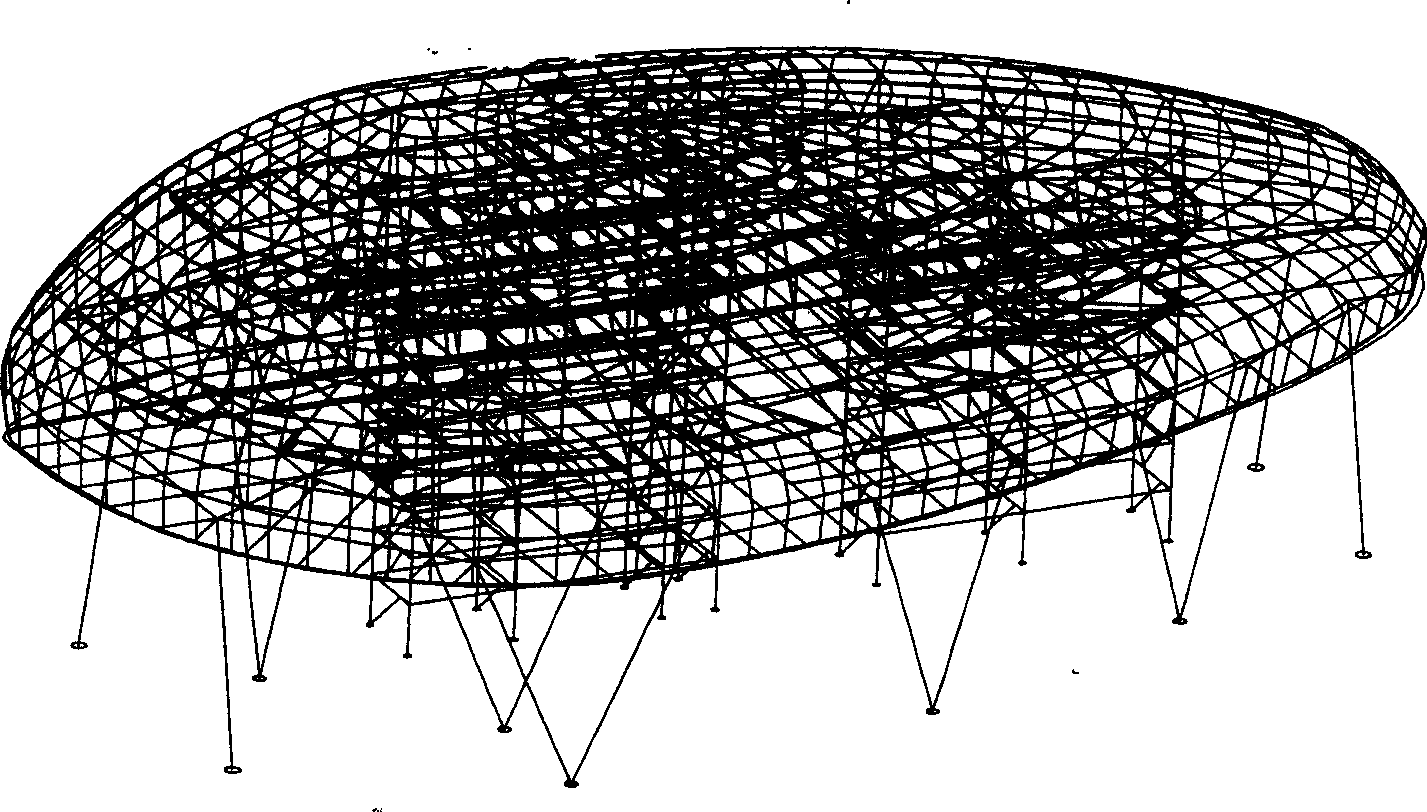

A technology of single-layer steel pipe and installation method, which is applied in the direction of arch structure, dome roof structure, building components, etc., can solve the problems of poor rigidity and different shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

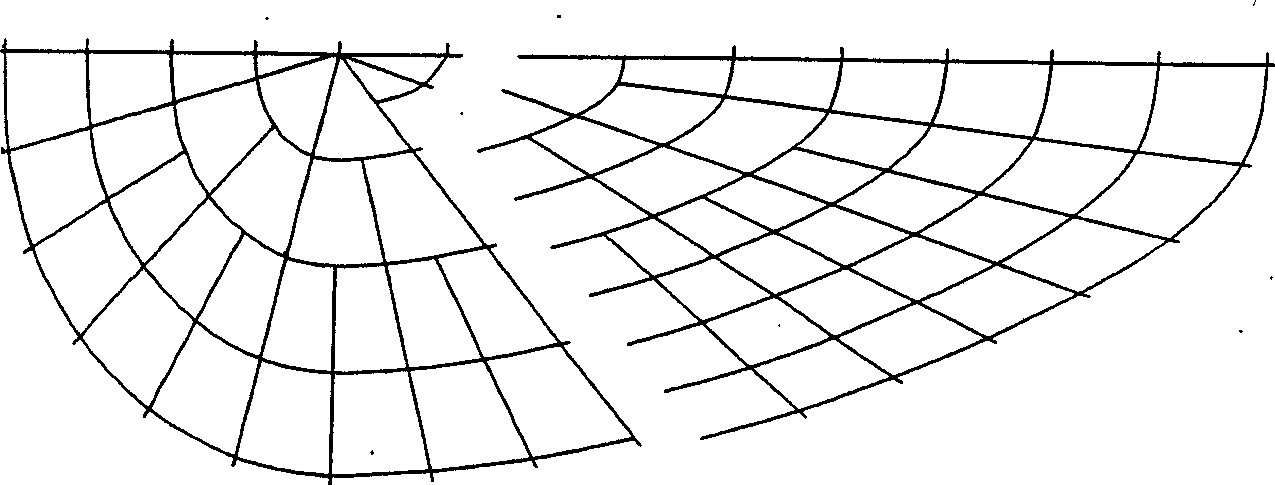

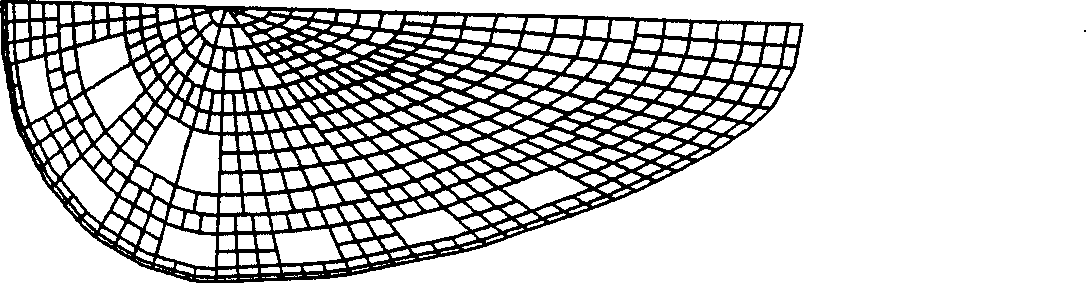

[0010] The idea of dividing the reticulated shell into blocks:

[0011] (1) The form of block-combining the position and axis of the support point,

[0012] From the appearance of the reticulated shell, there are no rules, but in terms of its structural form, the main pipe is used for the steel pipes that radiate to the main axis on the south side, and the secondary pipes are used for the pipe fittings between the main axes. The angle between each axis gradually changes from east to west. Decrease, the length of the projection axis gradually increases; the ring direction is divided by several contour main pipes; the bottom of the reticulated shell is placed on the ring beam of the bottom layer of the structure. If this is simply divided into several pieces according to the vertical and horizontal axis for hoisting, it will be more difficult to eliminate the cumulative error of the reticulated shells and solve the effects of mutual reticulated shell lifting and electric welding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com