Large-section tunnel excavation method based on double-side-wall pilot tunnel method

A technology for double-sided pilot pits and tunnel excavation, which is applied in tunnels, tunnel linings, earth-moving drilling and mining, etc. It can solve the problem of neglecting progress control and cost control, the inability to construct left and right pilot holes at the same time, and it is not difficult to find repeated workloads, etc. problems, to achieve the effect of saving temporary support, facilitating mechanized construction, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

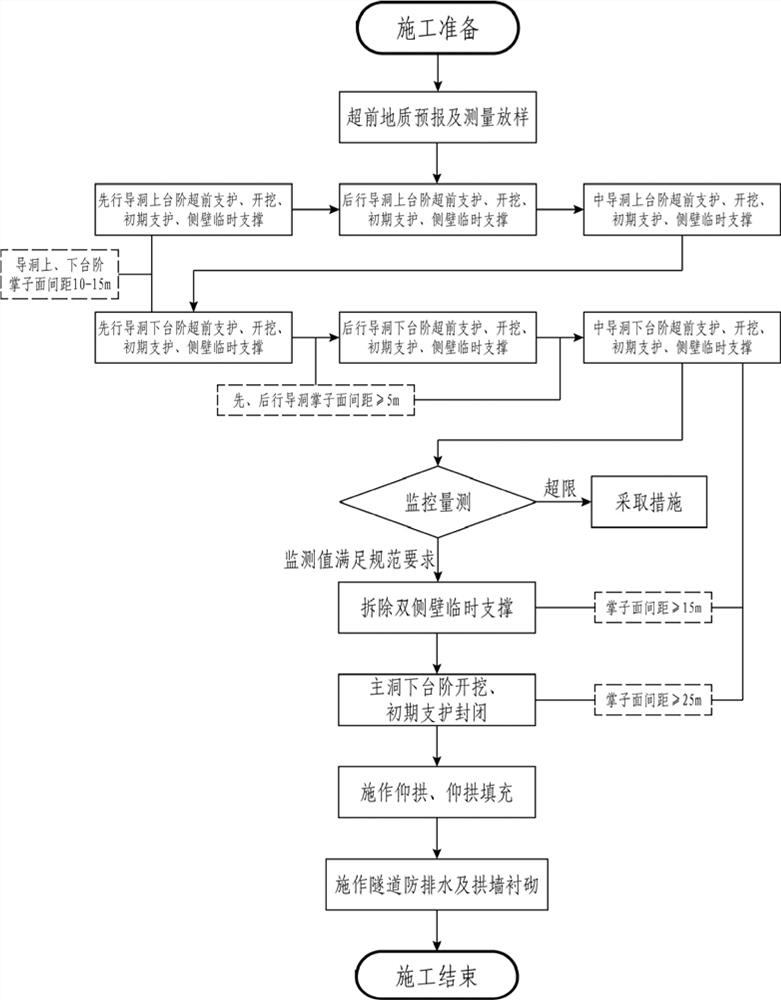

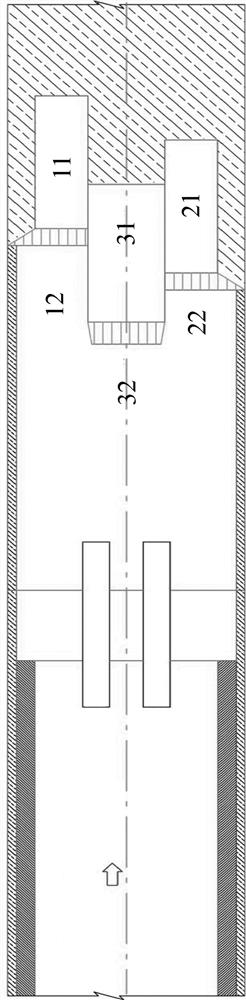

[0038] A large-section tunnel excavation method based on the double-side-wall pilot pit method, such as figure 1 and figure 2 As shown, follow the steps below:

[0039] Step 1. Construction preparation: including advanced geological forecast and survey and stakeout;

[0040] Step 2. Construction of the upper step 11 of the leading pilot tunnel: advanced support, excavation, initial support, and temporary support of the side wall of the upper step 11 of the leading pilot tunnel;

[0041] Step 3. Construction of the upper step 21 of the backward guide tunnel: advanced support, excavation, initial support, and temporary support of the side wall of the upper step 21 of the rear guide tunnel;

[0042] Step 4: Construction of the upper step 31 of the intermediate pilot tunnel: advanced support, excavation, initial support, and temporary support of the side wall of the upper step 31 of the intermediate pilot tunnel;

[0043] Step 5. Construction of the lower step 12 of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com