Arch column method for building large-scale underground structure in shallow buried rock stratums

An underground structure and arch-column method, applied in underground chambers, mining equipment, earth-moving drilling, etc., can solve the problems of difficult deformation control, many excavation divisions, and large construction risks, so as to reduce construction risks and reduce construction risks. Small excavation span, the effect of avoiding the fall of the top arch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

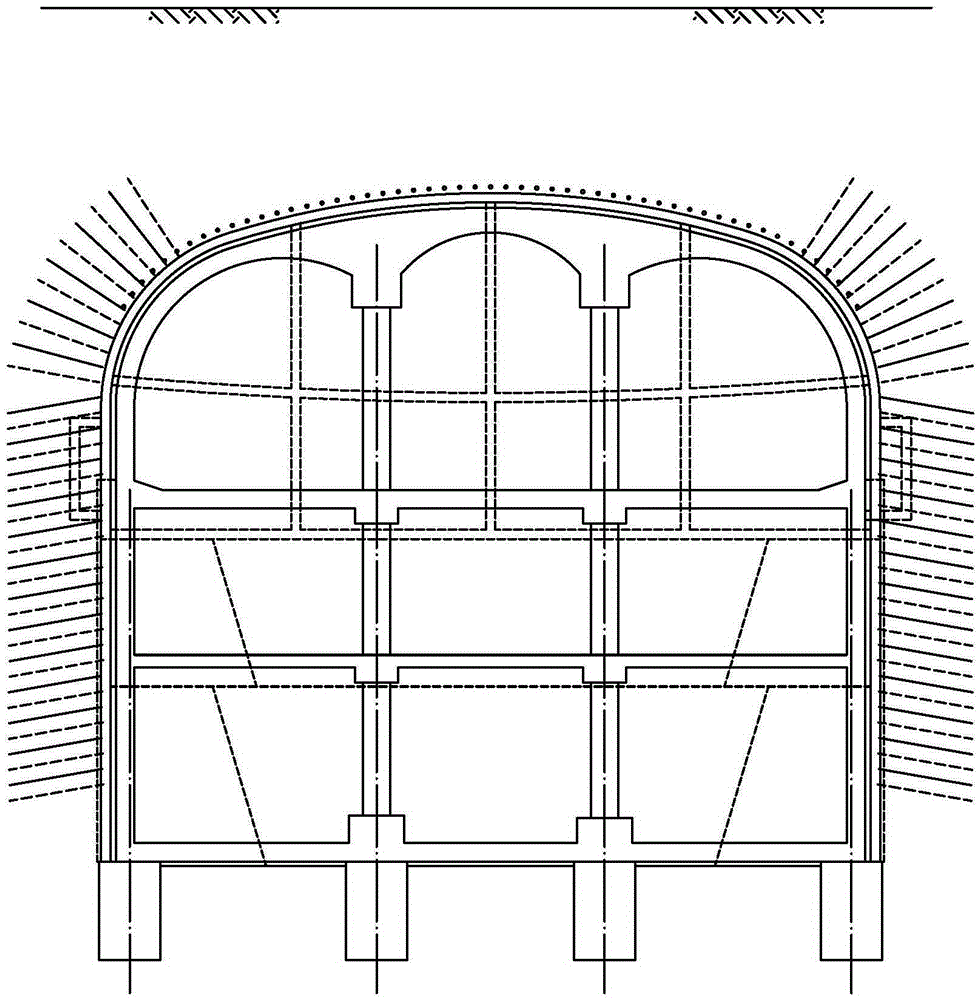

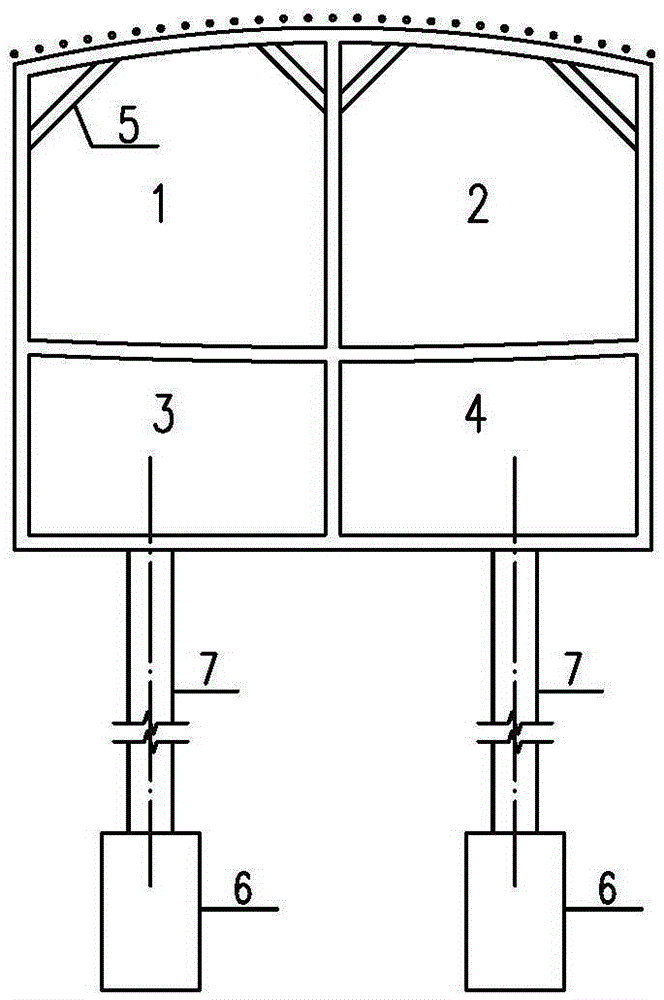

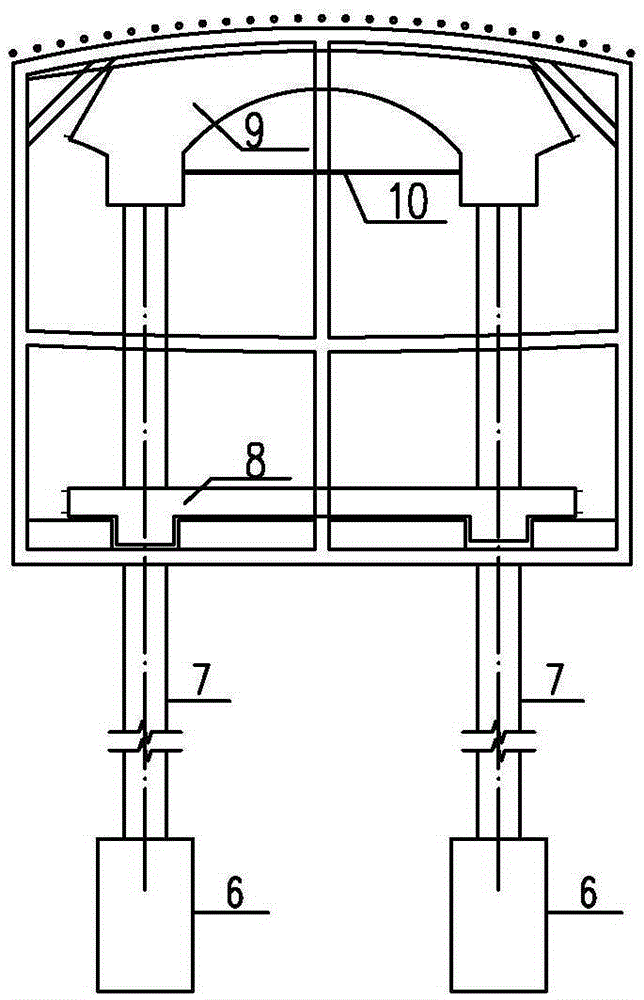

[0053] see Figure 1-Figure 7 Shown: implementation example 1, the construction steps are as follows:

[0054]1. Enter the basement floor from the upper guide hole of the construction cross passage, excavate the upper guide hole 1 and 2 (the distance between the left and right guide holes is staggered), set up advance support (when necessary) and anchor rods, and implement initial support , The top steel diagonal brace, after entering the pilot tunnel from the construction cross passage, excavate the lower pilot tunnel 3 and pilot tunnel 4 (the pilot tunnels are staggered), manually dig holes under the center column with water drill, pour the pile foundation, and place it above the pile foundation Steel pipe columns are installed in sections, the interior of the column is filled with micro-expansion concrete, and the exterior of the column is backfilled with fine sand, supplemented by grouting measures if necessary;

[0055] 2. Lay the floor formwork in the middle cave, pour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com