Patents

Literature

57results about How to "No tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

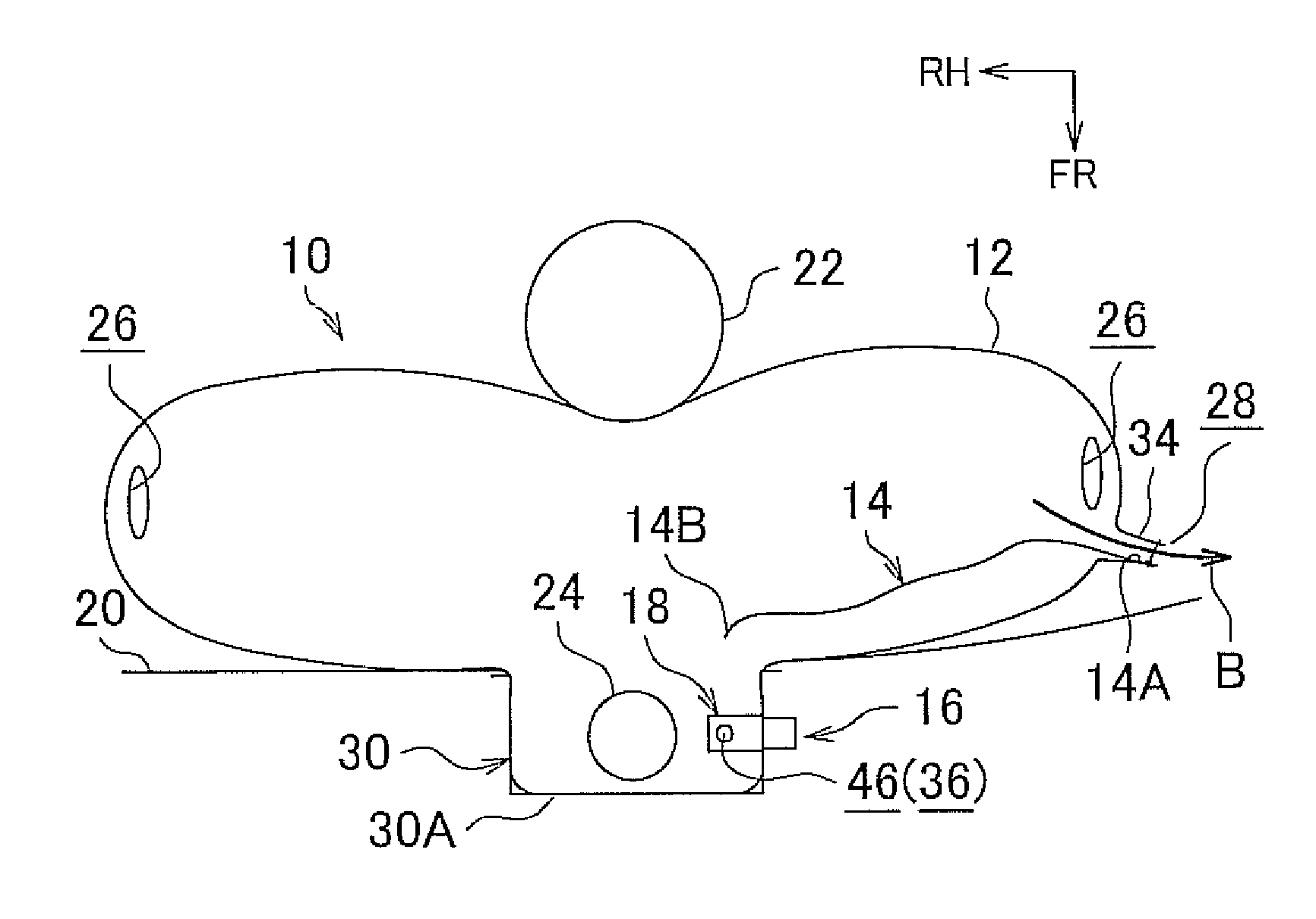

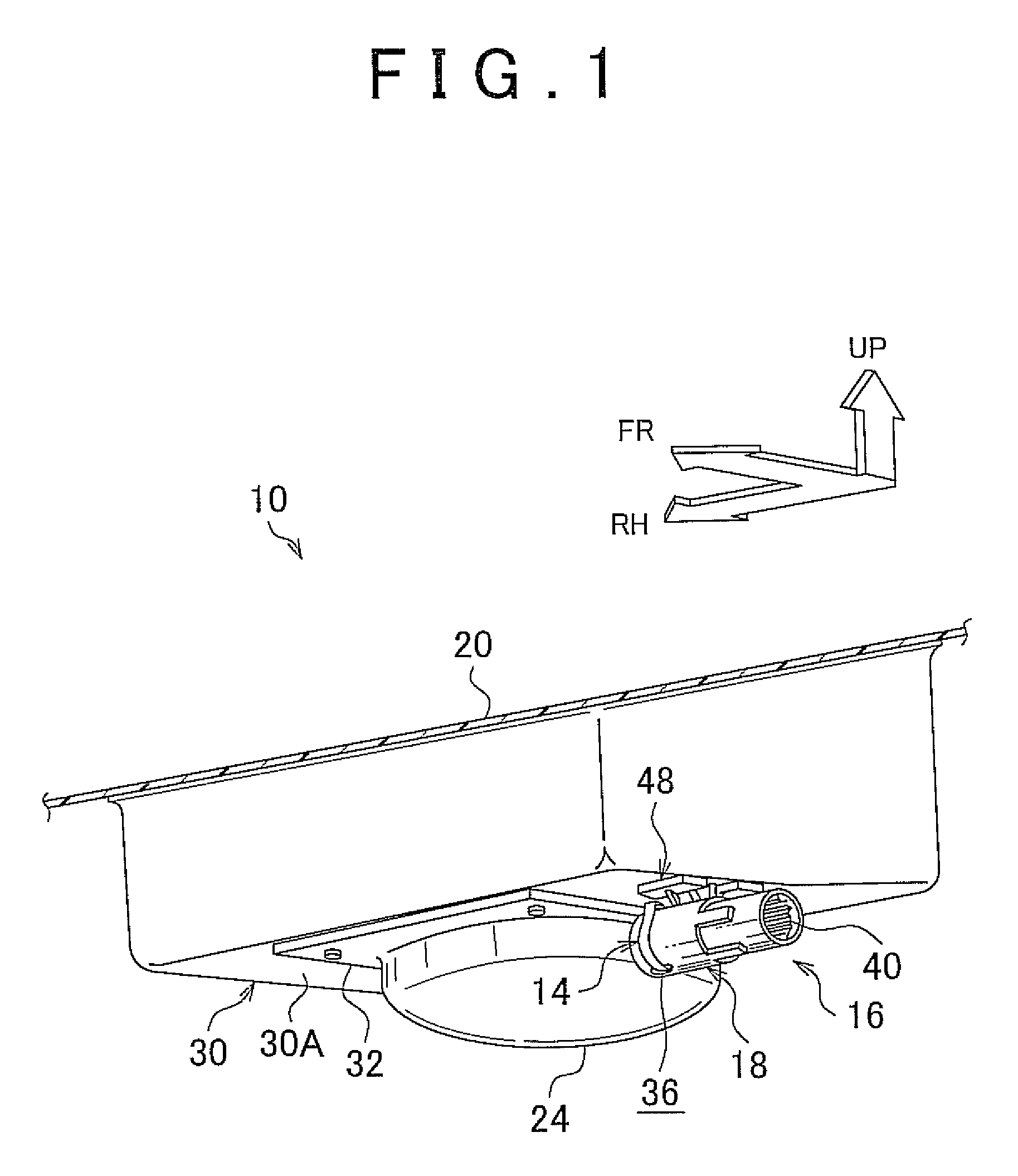

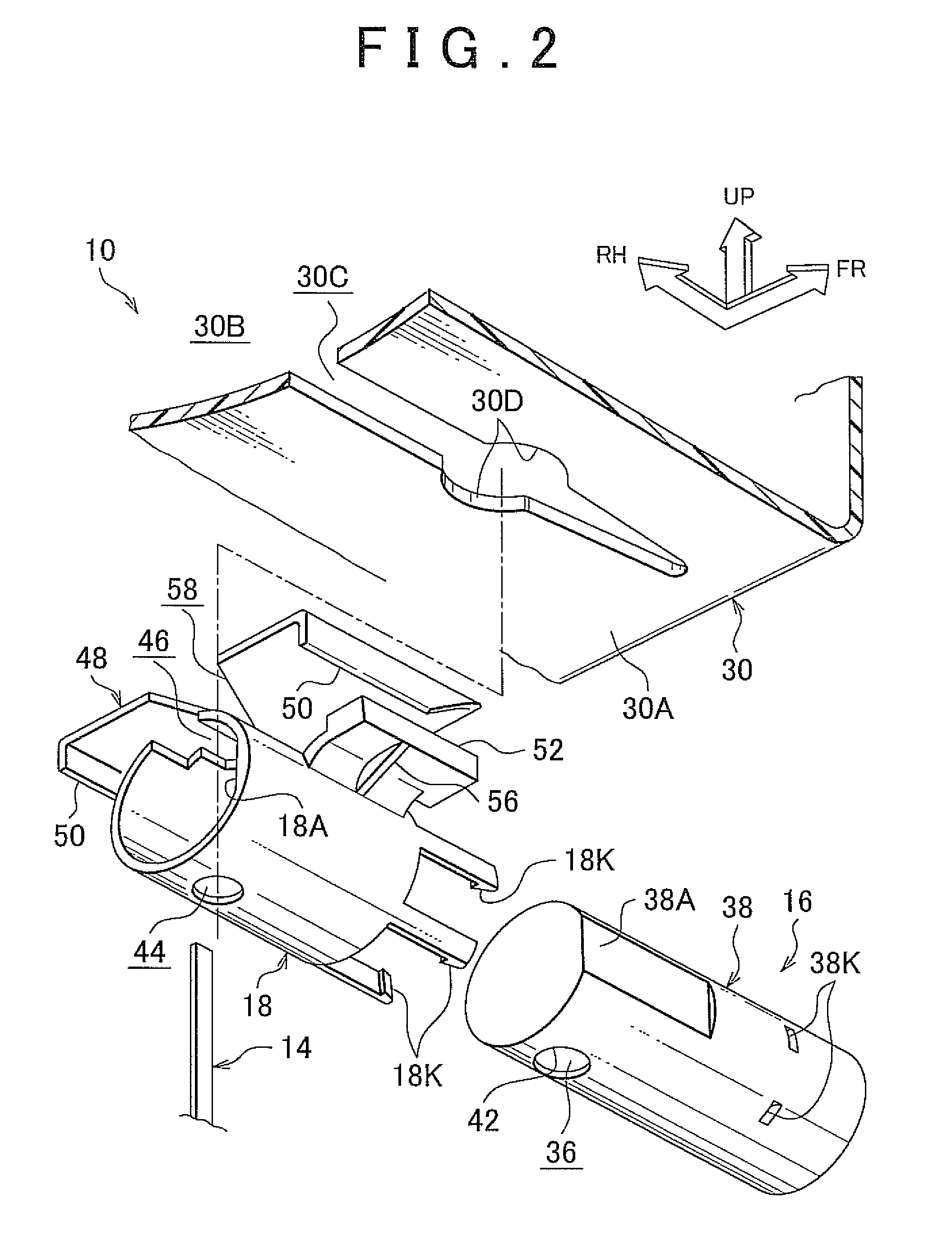

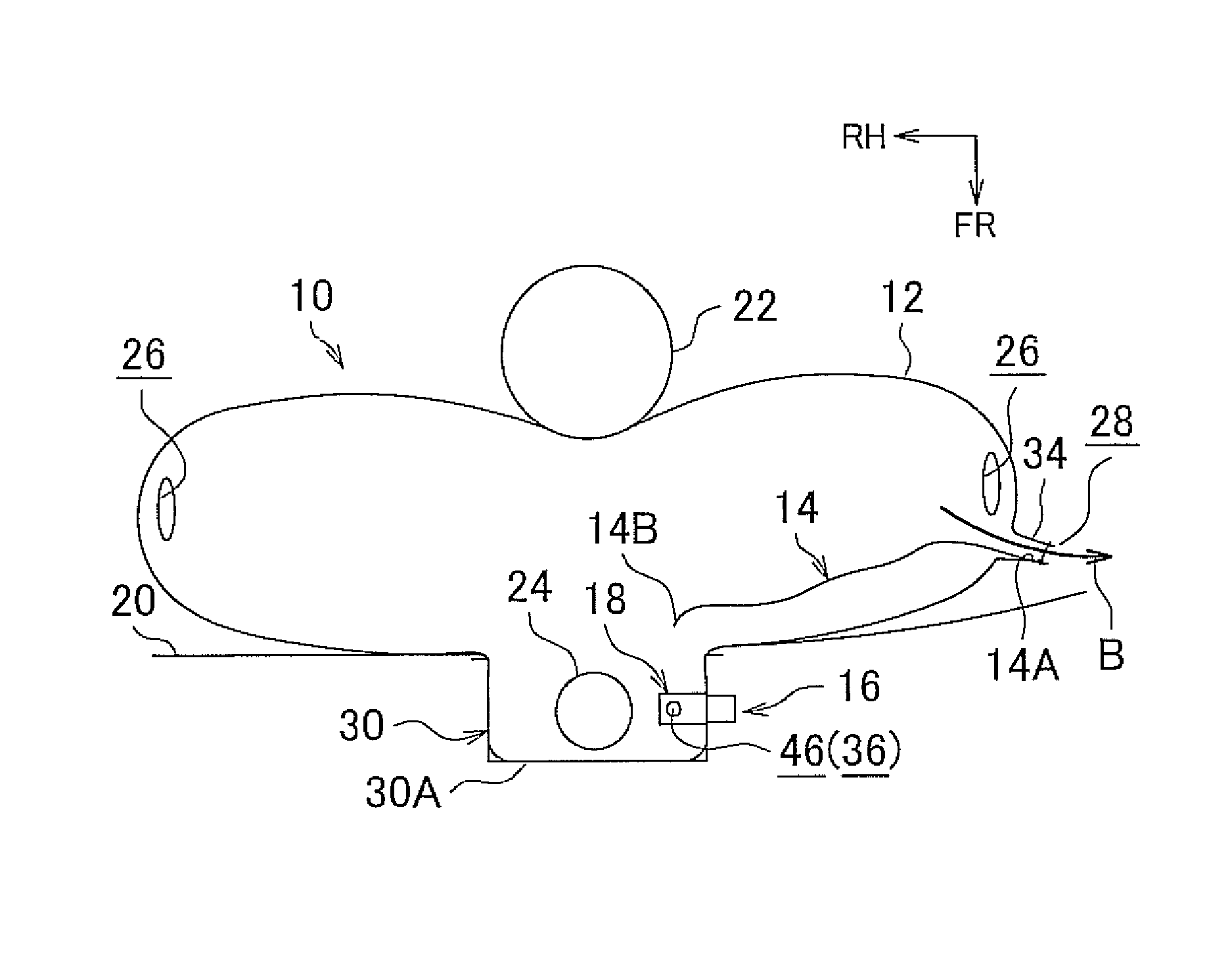

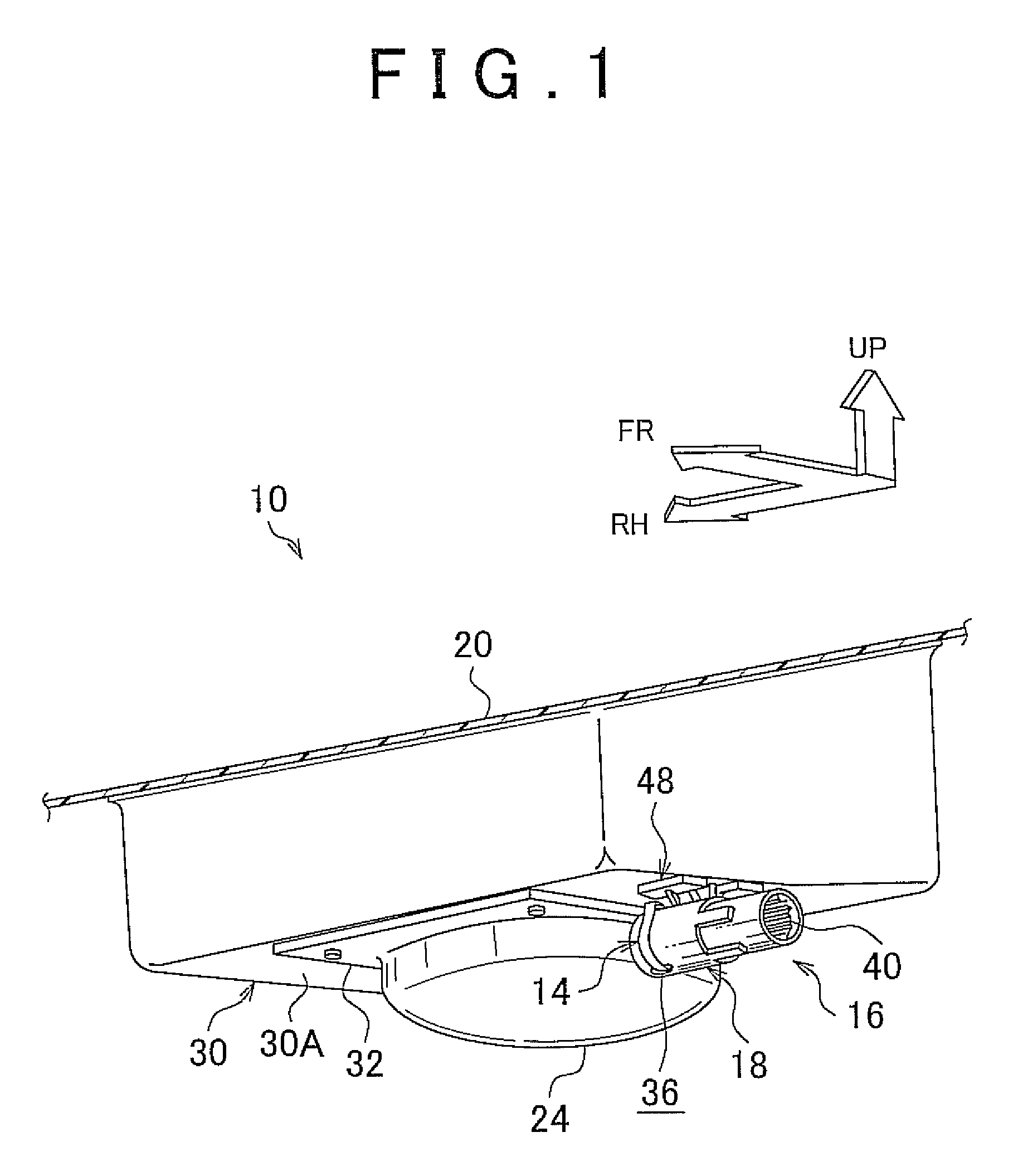

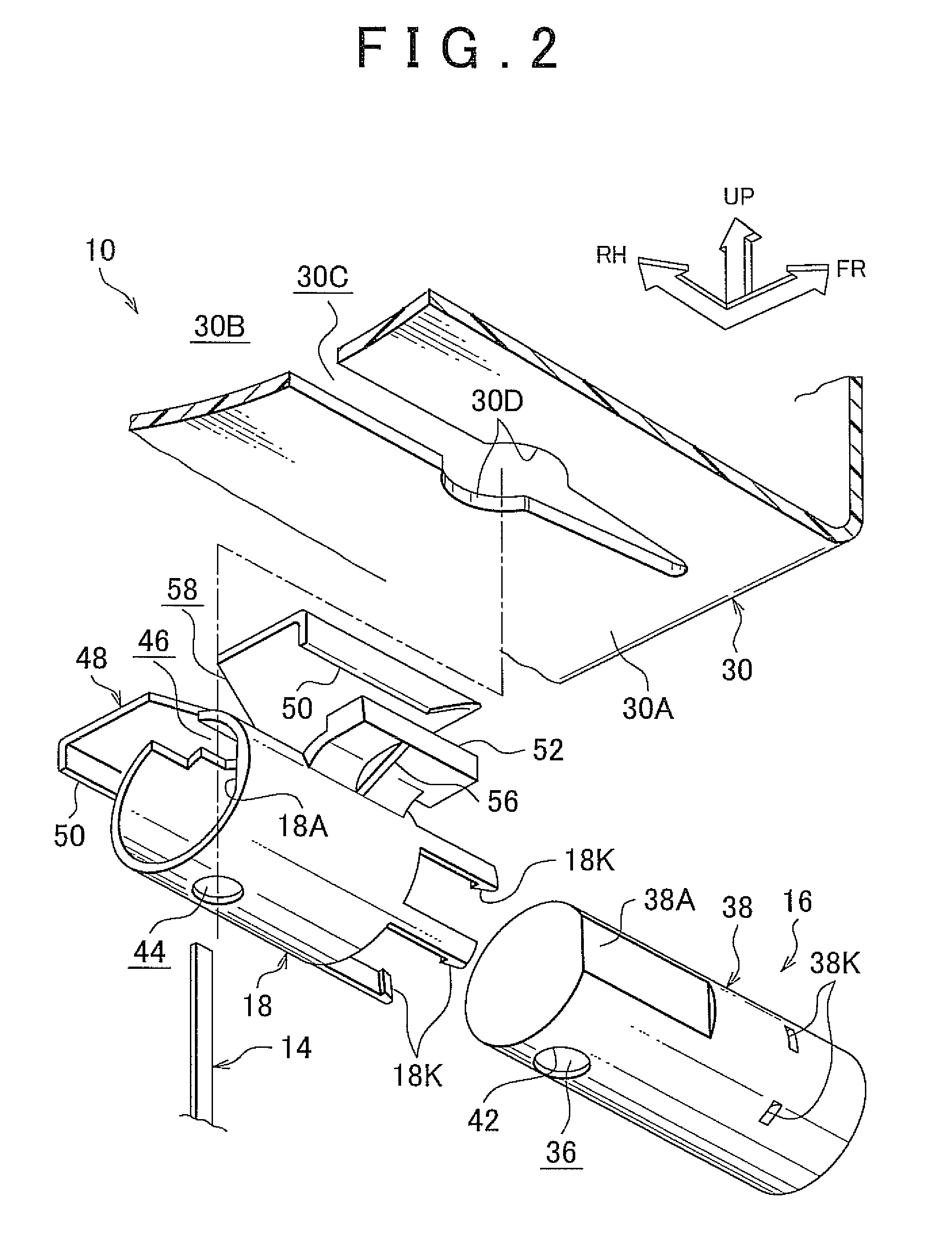

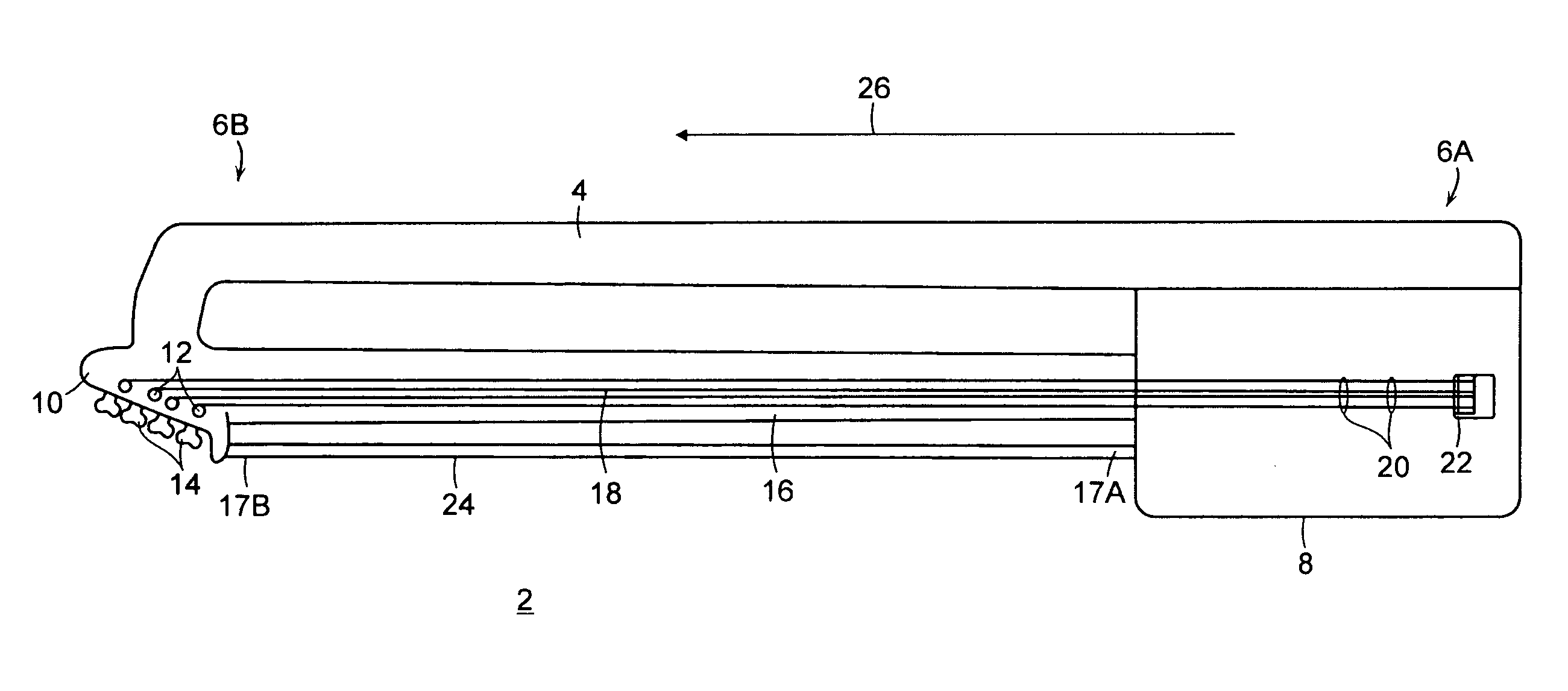

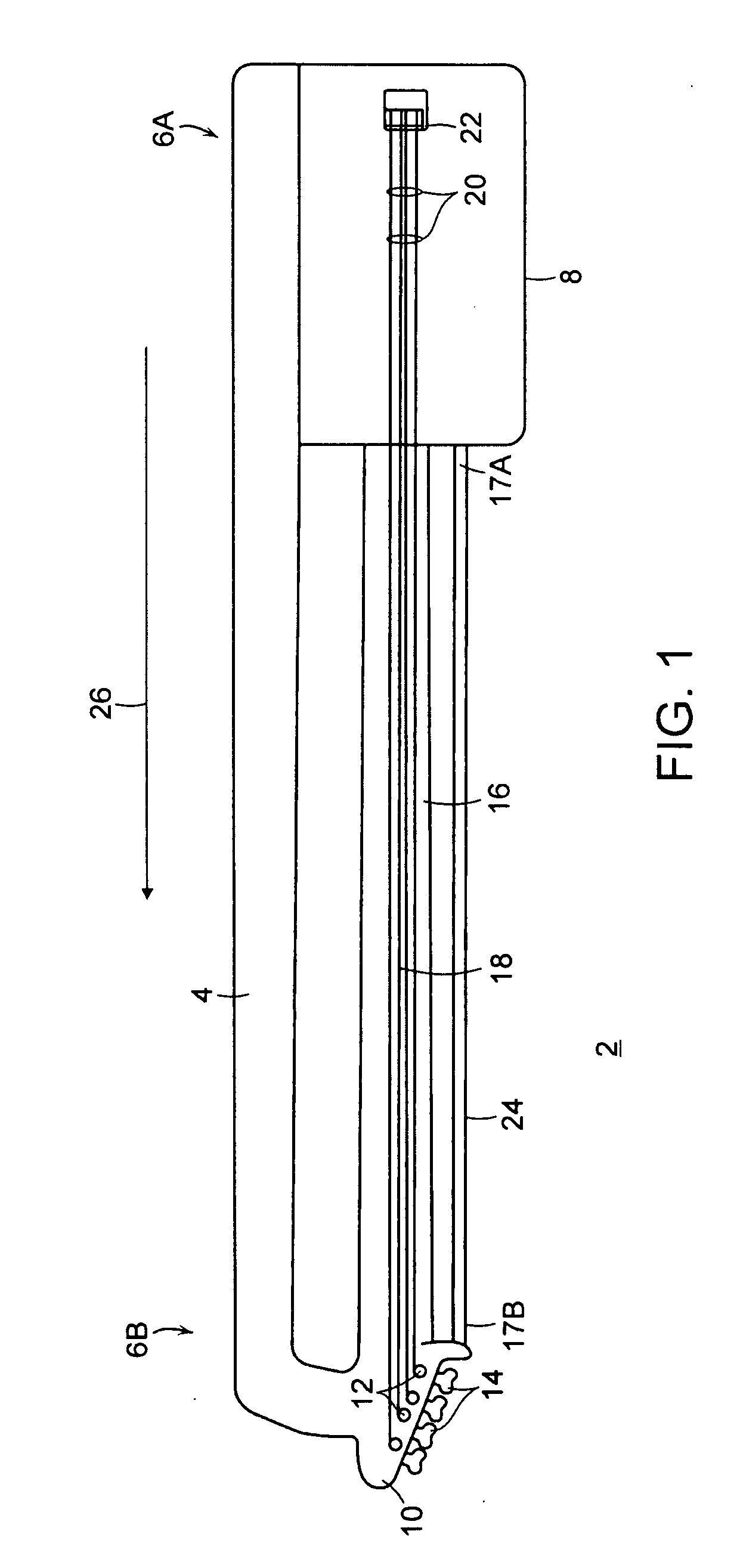

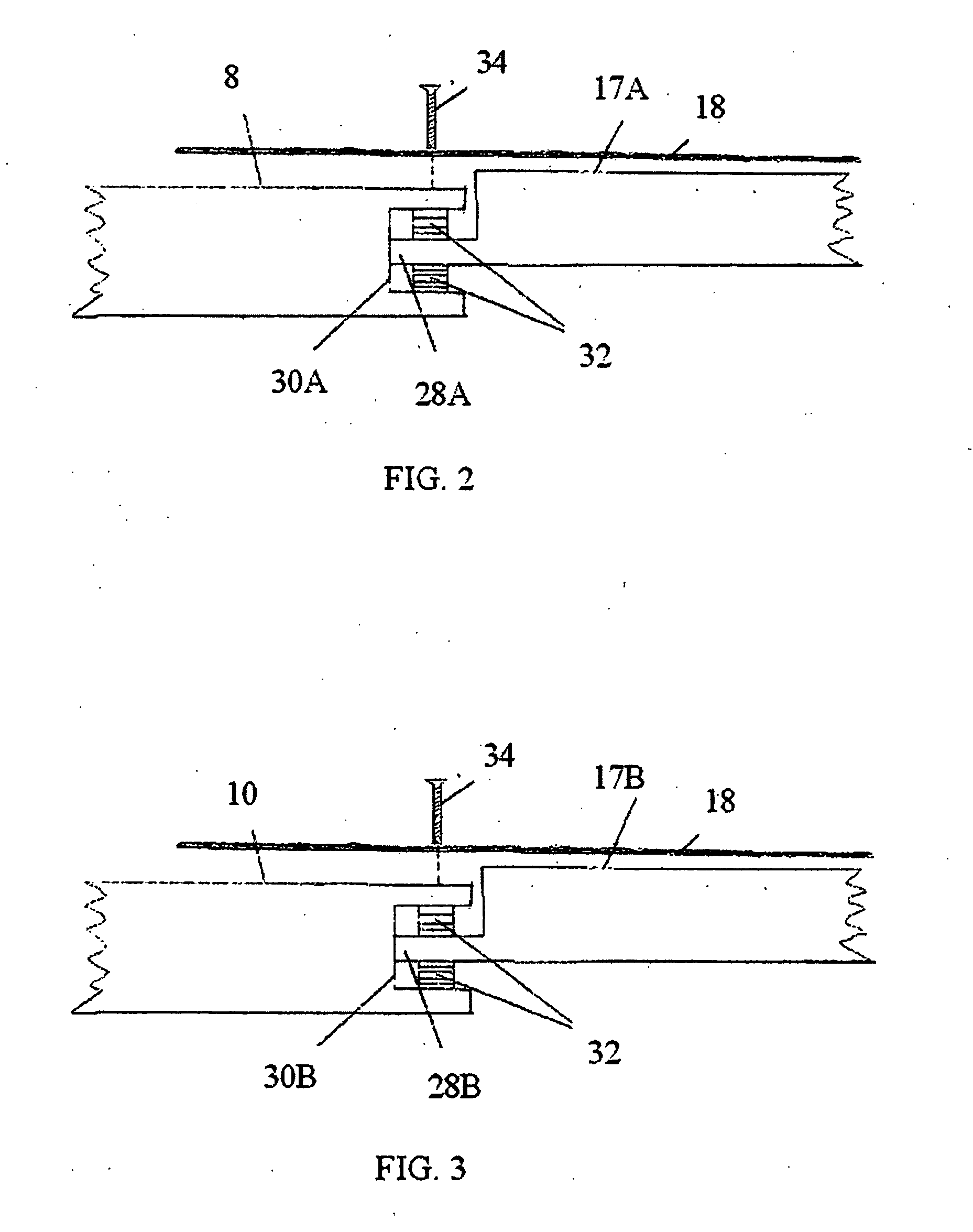

Passenger seat airbag apparatus

ActiveUS20100078924A1Direct contact guaranteeNo tensionPedestrian/occupant safety arrangementAirbagActuator

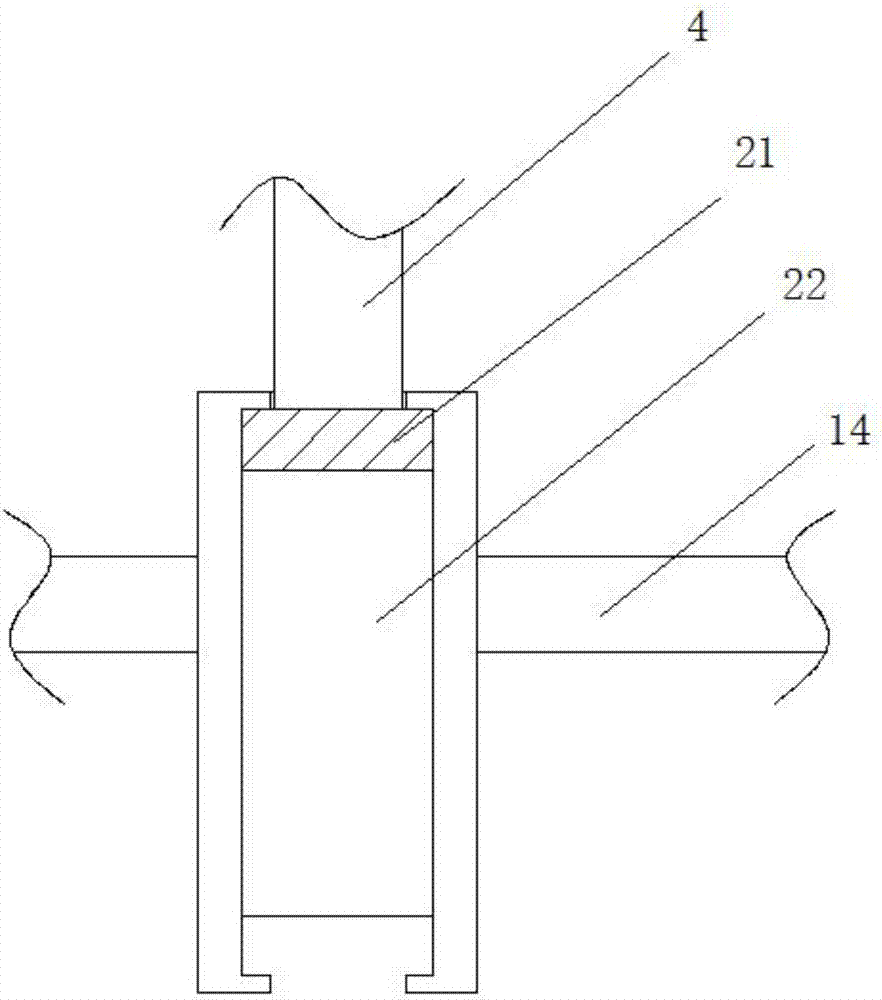

A passenger seat airbag apparatus includes: an airbag which is housed in a folded state inside an instrument panel, and which inflates toward a passenger with a supply of gas during a frontal collision of a vehicle, and which has a vent hole that can be opened and closed; a tether whose first end is linked to a periphery of the vent hole in the airbag, and which closes the vent hole due to tension that is caused when the airbag inflates; an actuator which has a first hole that a second end of the tether is passed through, and which discontinues a linked state of the tether by cutting the tether if a predetermined condition is satisfied; and a protective member that is attached to the actuator so as to cover at least an edge portion of the first hole, and that is interposed between the edge portion and the tether.

Owner:TOYOTA JIDOSHA KK +1

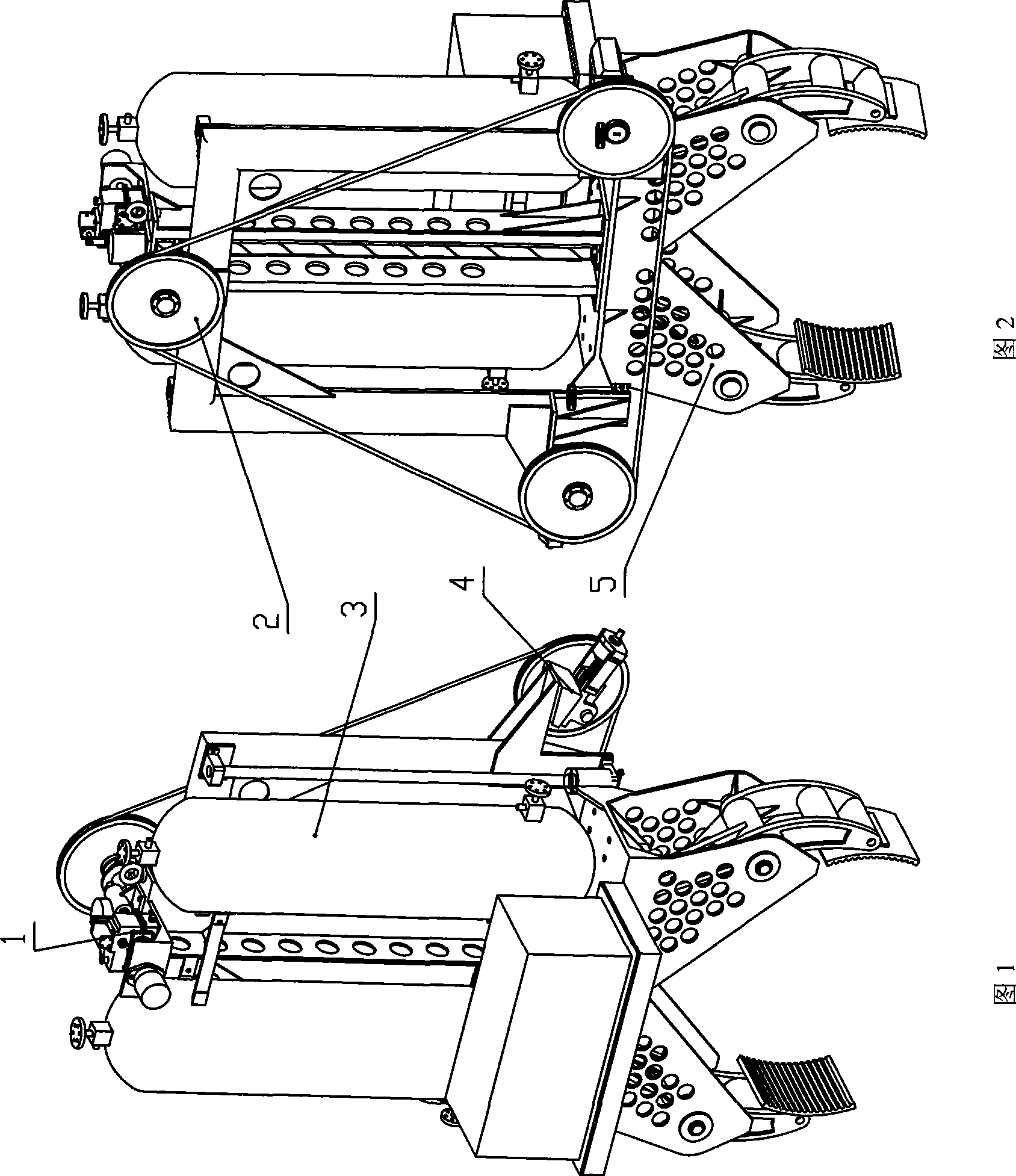

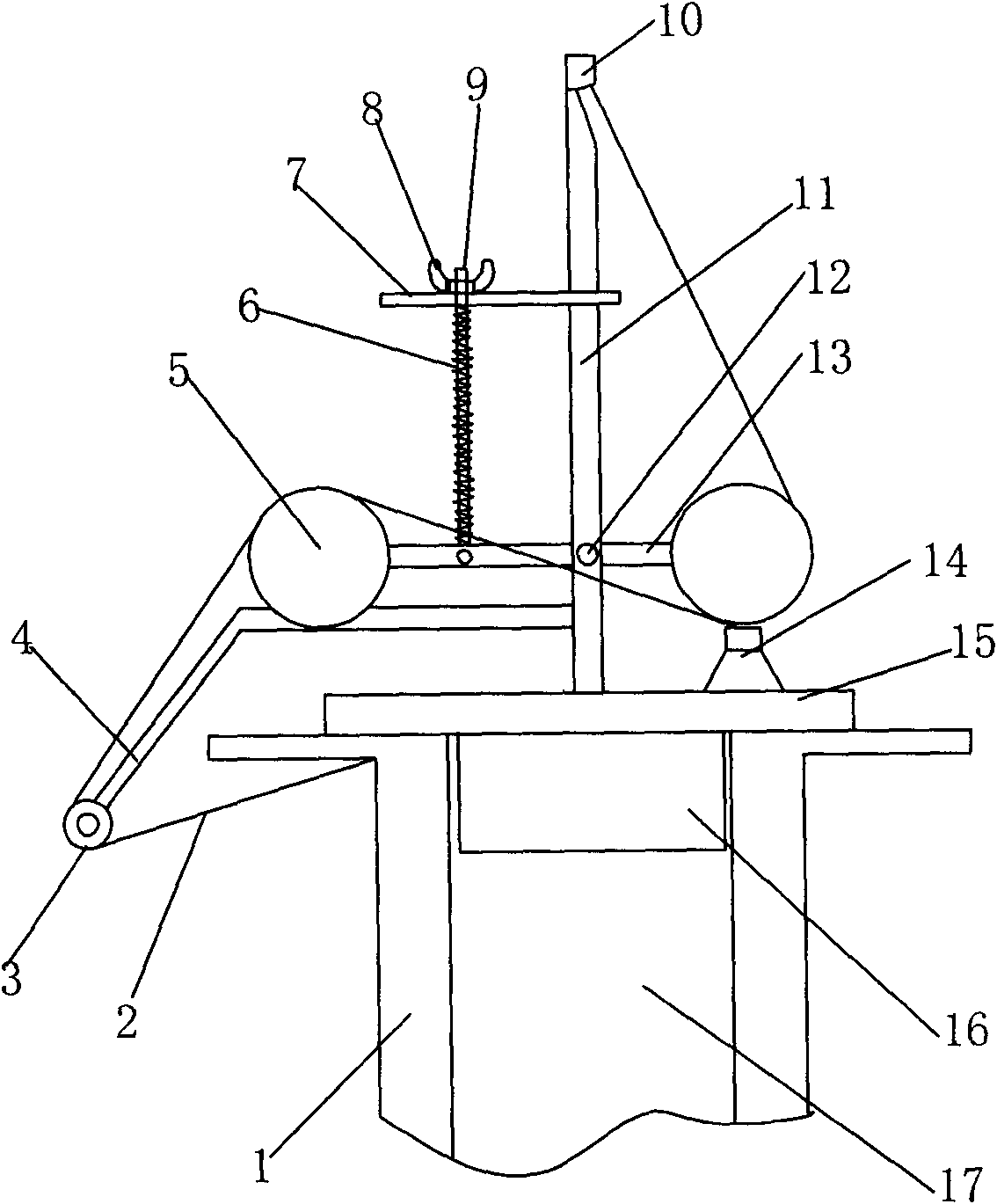

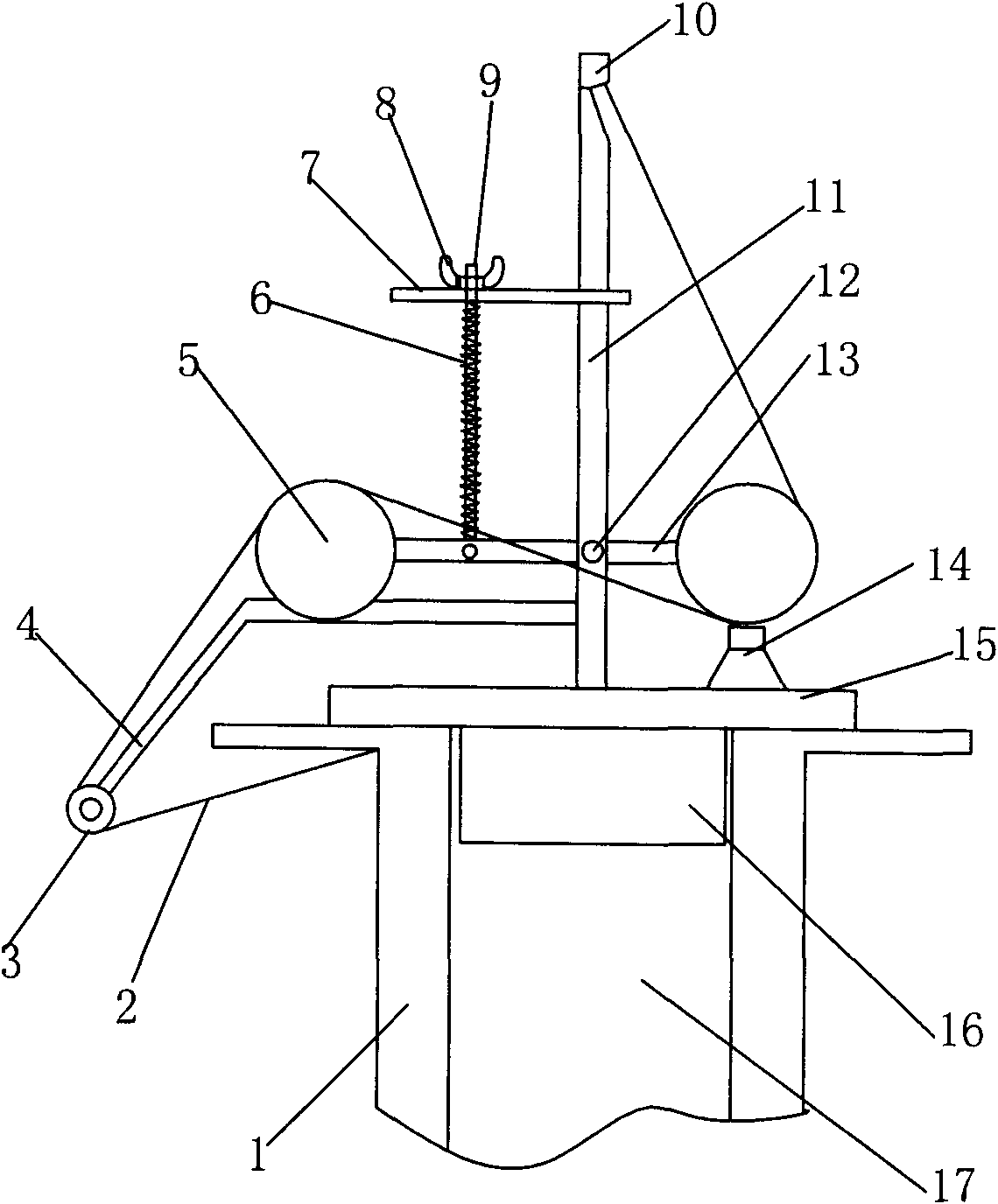

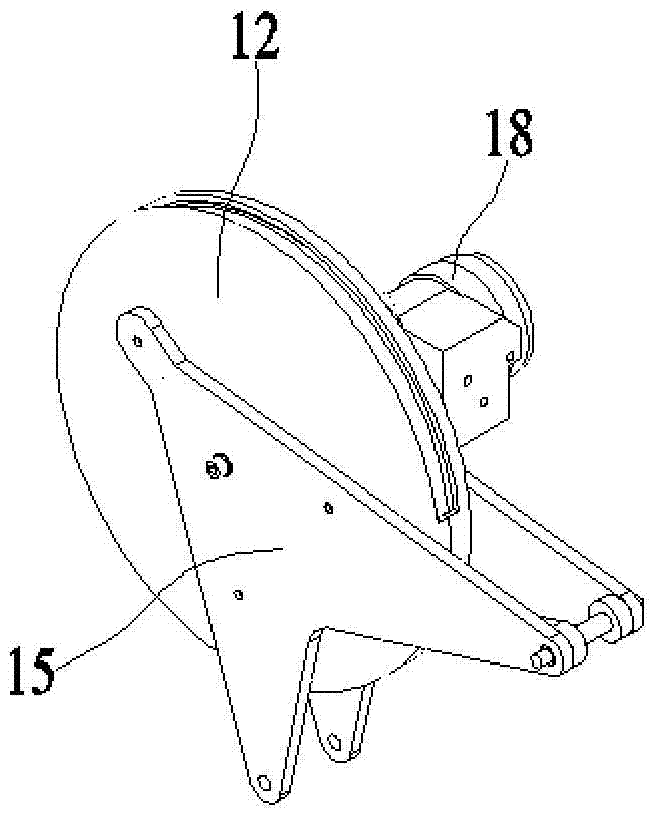

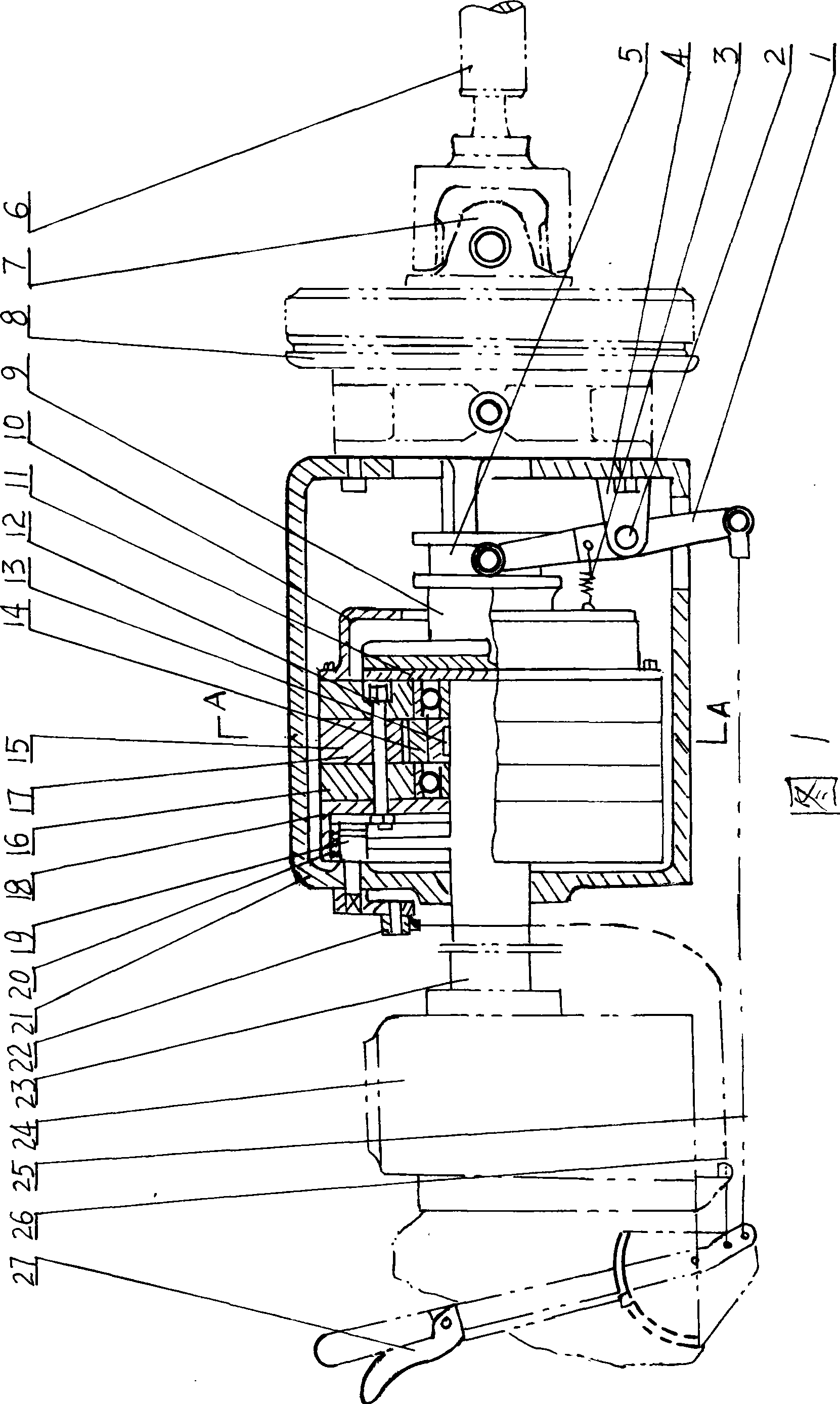

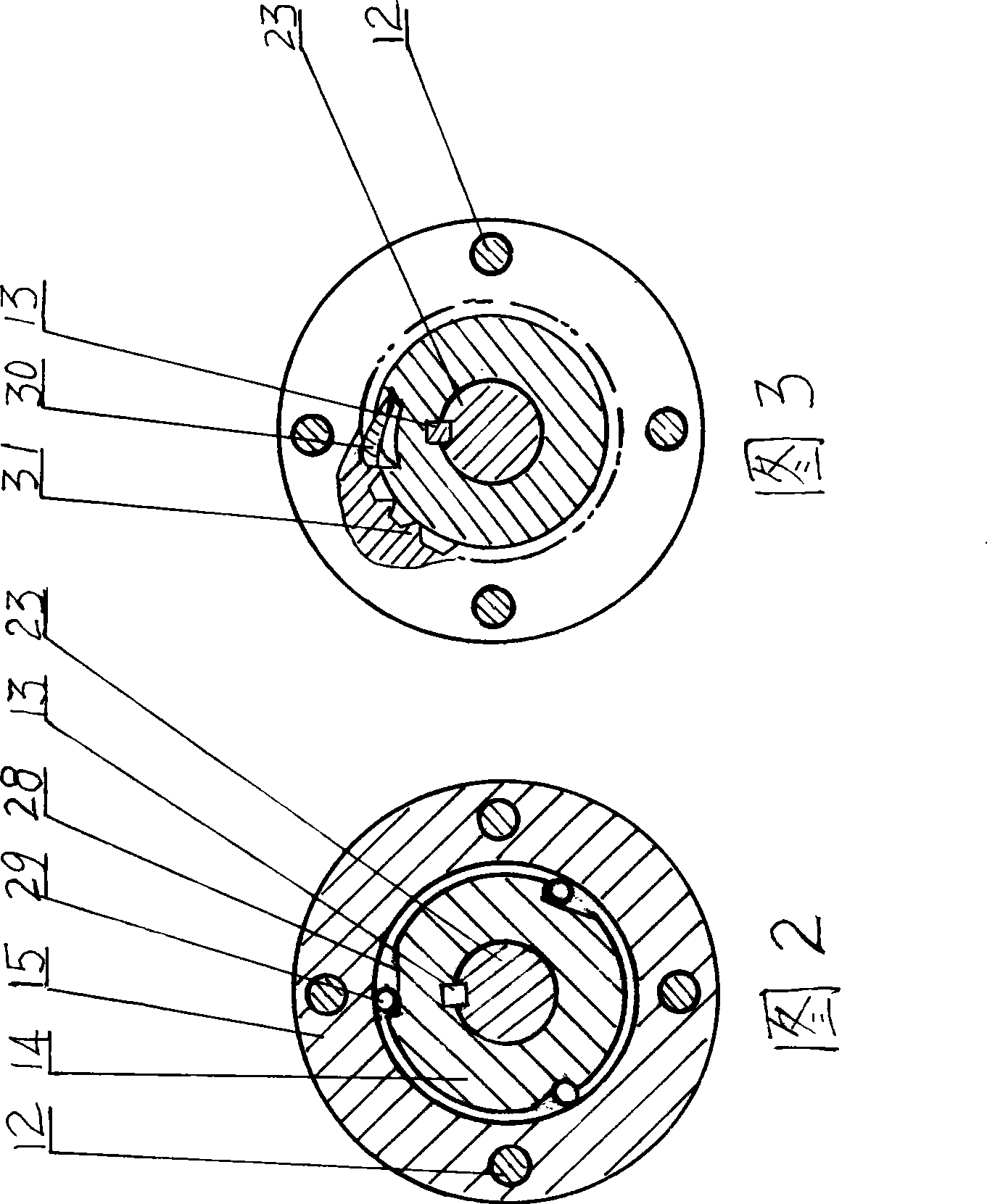

Underwater rope saw cutting machine

InactiveCN101444921AVersatile and strongEasy to operateMetal working apparatusStone-like material working toolsMechanical engineeringForce sensor

The invention provides an underwater rope saw cutting machine which comprises a feeding mechanism, a clamping mechanism arranged at the lower part of the feeding mechanism, and a cutting mechanism arranged on the feeding mechanism. Compared with various rope saw cutting machines in the prior art, the rope saw cutting machine of the invention has the most remarkable advantages that the underwater rope saw cutting machine utilizes the triangularly fixed feeding mechanism, thus enhancing working stability, measuring a tensioning mechanism of resultant force and changing buoyancy under the water by a pontoon, cutting away a damaged submarine pipeline in a manner of speed changing, being adapted to the requirements of various pipelines and causing the rope saw cutting machine to be more universal and operable; meanwhile, due to the adoption of a tensioning device of a force sensor, the tensioning force can be adjusted, no tensioning insufficiency or over-tensioning happens, and the safety is also ensured.

Owner:HARBIN ENG UNIV

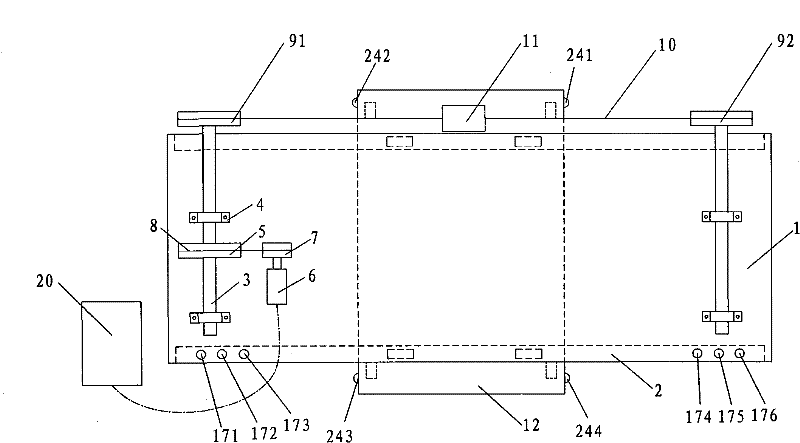

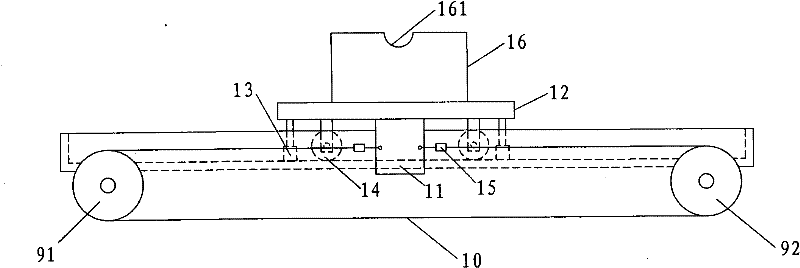

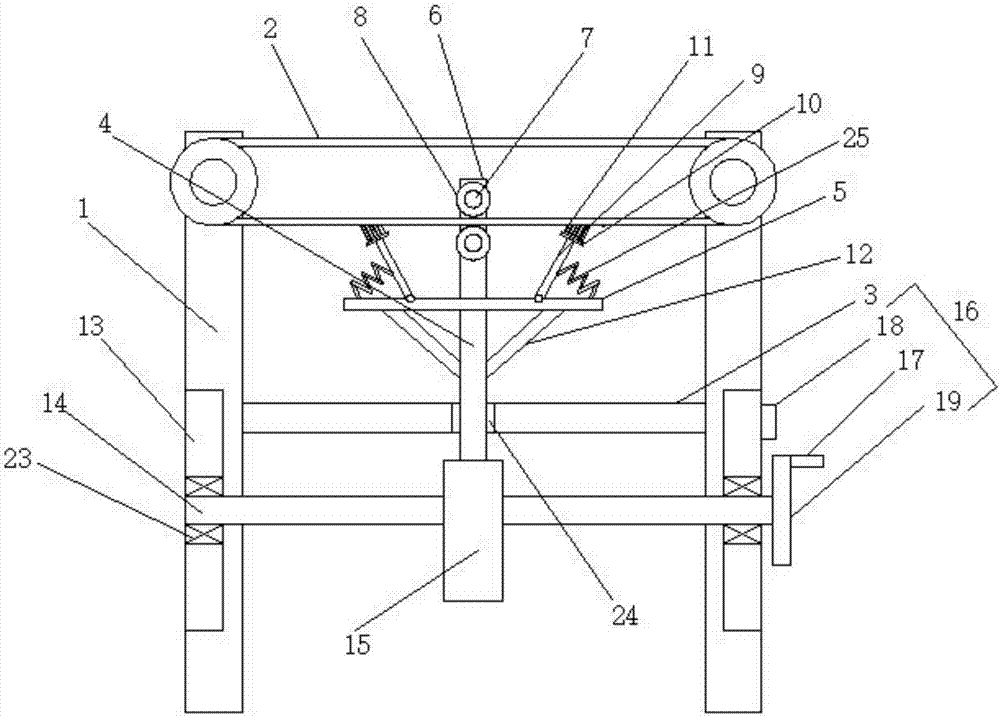

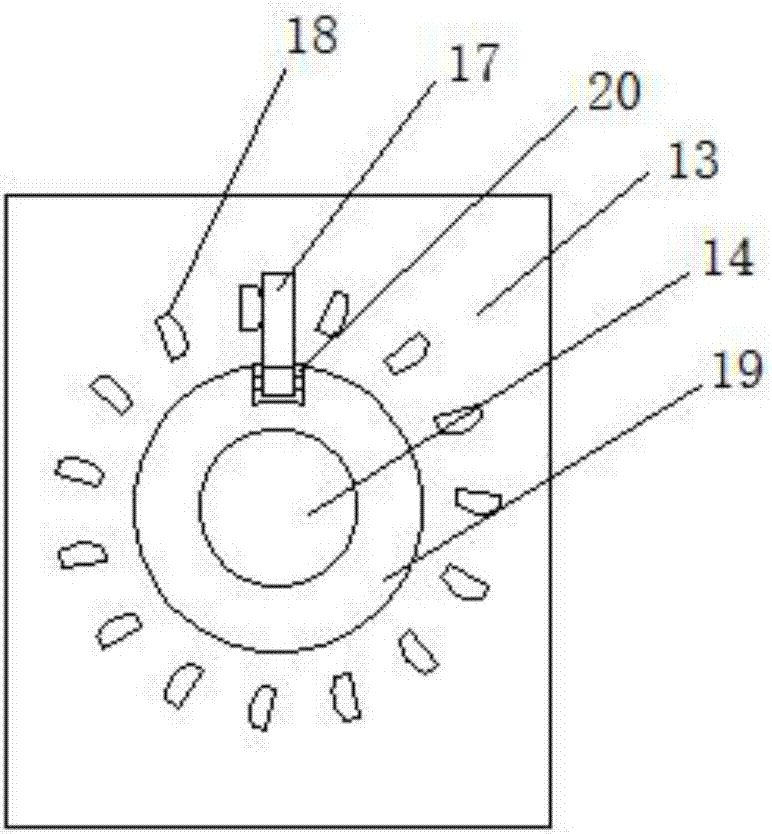

Automatic cloth paving device

ActiveCN102190205AReduce manufacturing costSimple structureUnfolding thin materialsEngineeringProcess control

The invention discloses an automatic cloth paving device designed mainly for providing an automatic cloth paving device which has the advantages of simple structure and tension generation in a cloth paving process. The automatic cloth paving device comprises a control unit, a transmission unit and a cloth paving unit, wherein the control unit outputs a control instruction to the transmission unit according to a pre-set process control program; the control instruction input end of the transmission unit is connected with the control instruction output end of the control unit, and the transmission unit outputs linear power outwards according to the control instruction output by the control unit; the cloth paving unit is composed of a working board and a moving trolley capable of moving relative to the working board; and the moving trolley is connected with the linear power output end of the transmission unit directly or through a connecting piece.

Owner:JIHUA 3543 KNITTING CLOTHING

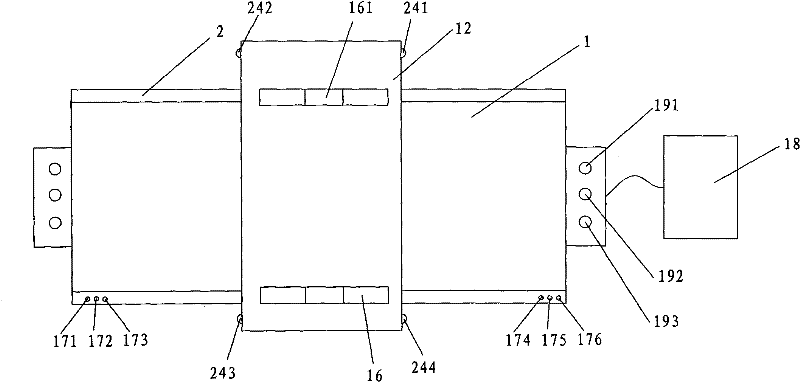

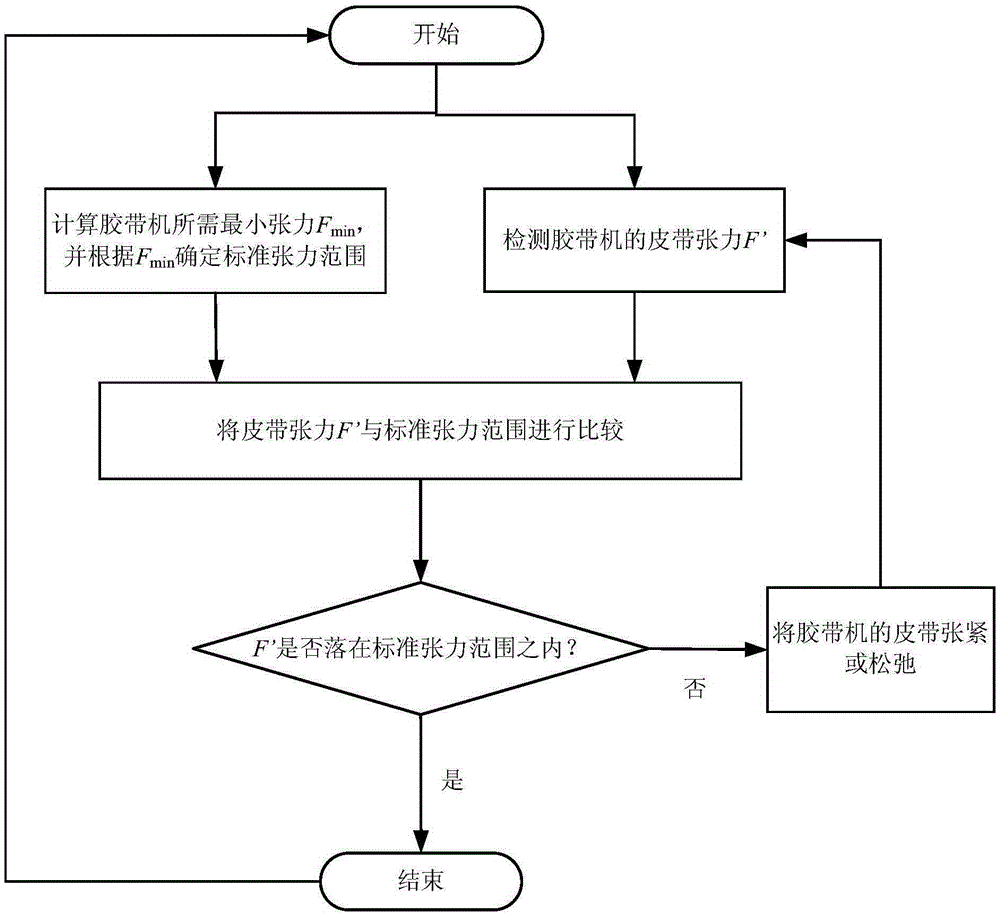

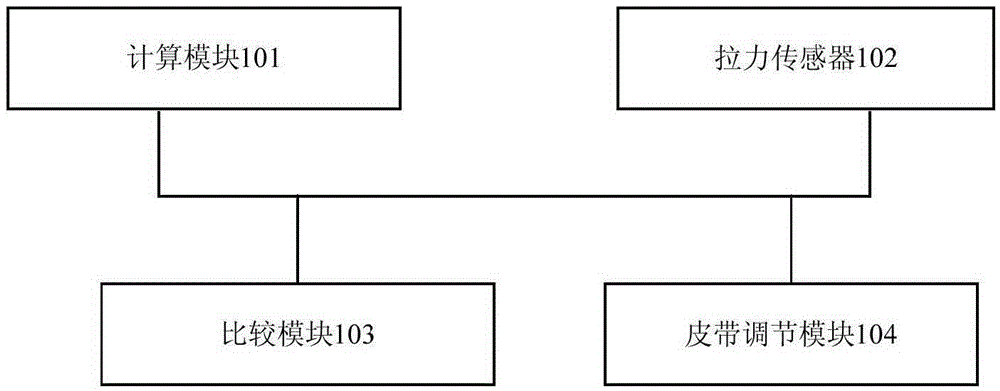

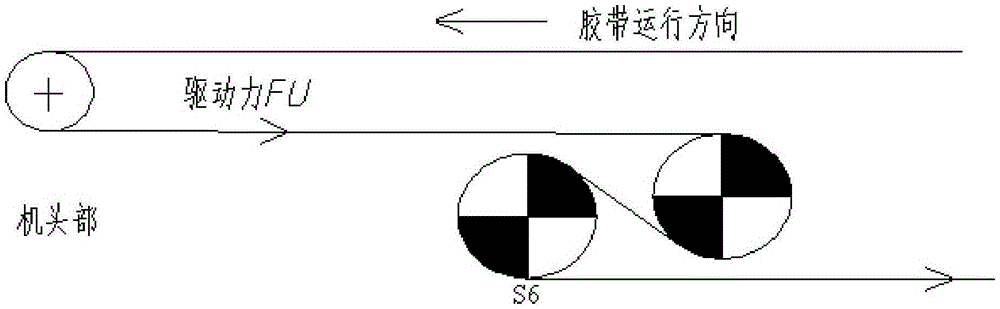

Full-automatic tensioning control system and method used for rubber belt machine

ActiveCN105417014AHigh degree of automationAccurate tension valueConveyorsControl devices for conveyorsControl systemStructural engineering

The invention discloses a full-automatic tensioning control method used for a rubber belt machine. The full-automatic tensioning control method includes the steps of in the starting or stopping or running process of the rubber belt machine, calculating the minimum tension F<min> required by the rubber belt machine, and determining a standard tension range according to the F<min>; detecting the belt tension F' of the rubber belt machine; and comparing the detected belt tension F' with the standard tension range, and if the F' is out of the standard tension range, tensioning or loosening a belt of the rubber belt machine till the detected belt tension F' is within the standard tension range. By means of the full-automatic tensioning control method, the tension of the belt can be adjusted in real time in the starting or stopping or running process of the rubber belt machine.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Passenger seat airbag apparatus

ActiveUS8388021B2Direct contact guaranteeNo tensionPedestrian/occupant safety arrangementEngineeringAirbag

A passenger seat airbag apparatus includes: an airbag which is housed in a folded state inside an instrument panel, and which inflates toward a passenger with a supply of gas during a frontal collision of a vehicle, and which has a vent hole that can be opened and closed; a tether whose first end is linked to a periphery of the vent hole in the airbag, and which closes the vent hole due to tension that is caused when the airbag inflates; an actuator which has a first hole that a second end of the tether is passed through, and which discontinues a linked state of the tether by cutting the tether if a predetermined condition is satisfied; and a protective member that is attached to the actuator so as to cover at least an edge portion of the first hole, and that is interposed between the edge portion and the tether.

Owner:TOYOTA JIDOSHA KK +1

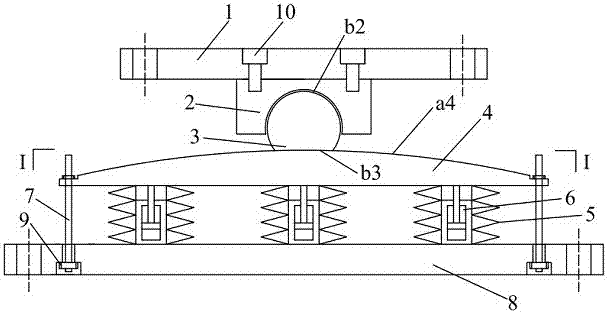

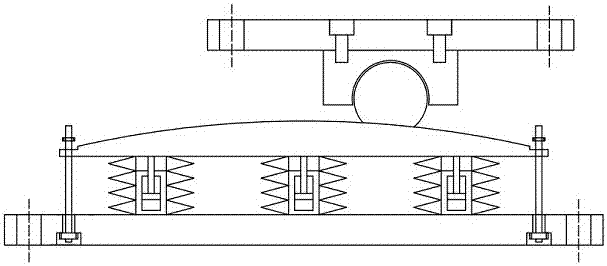

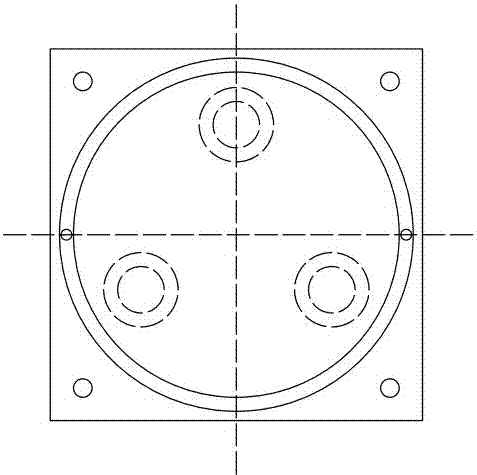

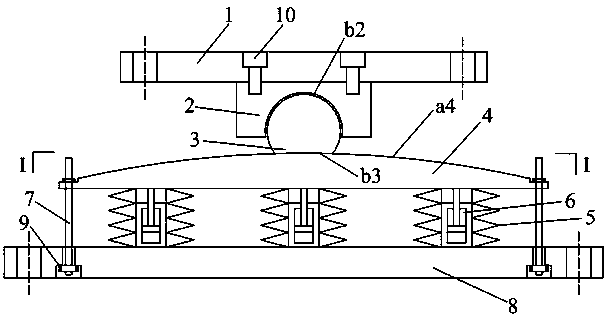

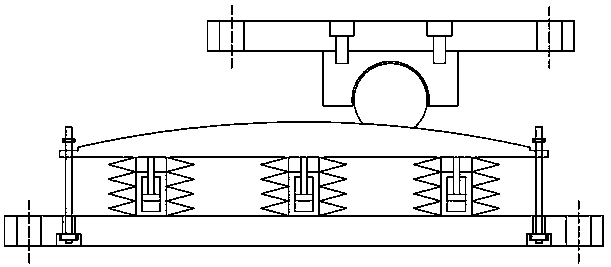

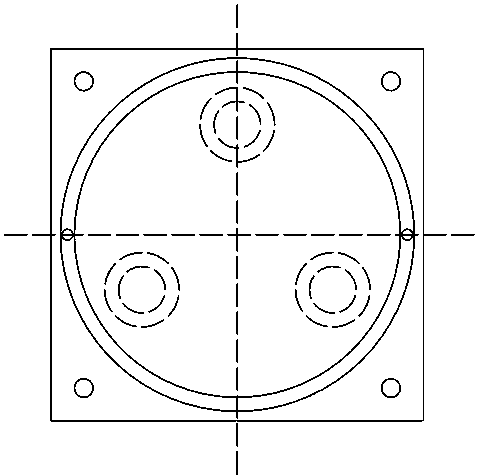

Horizontal negative stiffness device with vertical damping function

ActiveCN106968499AChange negative stiffnessMeet different design needsProtective buildings/sheltersShock proofingDamping functionNegative stiffness

The invention relates to a horizontal negative stiffness device with a vertical damping function. The horizontal negative stiffness device comprises a spherical hinge upper connecting plate, a spherical hinge lower connecting plate, a spherical hinge, an arched spherical face, pre-pressing disc springs, viscous dampers, limiting rods, a bearing base, nuts and inside hexagonal bolts; the spherical hinge upper connecting plate and the spherical hinge lower connecting plate are fixedly connected through the inside hexagonal bolts, and the spherical hinge is embedded into the spherical hinge lower connecting plate for fixation and makes contact with the arched spherical face in a pressure-bearing mode; the upper portions of the pre-pressing disc springs are in welding connection with the arched spherical face, and the lower portions of the pre-pressing disc springs are in welding connection with the bearing base. The viscous dampers are arranged at the internal diameters of the pre-pressing disc springs, the upper portions of the viscous dampers are in welding connection with the arched spherical face, and the lower portions of the viscous dampers are in welding connection with the bearing base. The viscous dampers and the pre-pressing disc springs cooperatively work, and meanwhile negative stiffness and damping force are generated; and the limiting rods are connected with the arched spherical face and the bearing base through the nuts, the pre-pressing states of the disc springs are achieved, and the limiting rods are symmetrically arranged on the two sides of the arched spherical face.

Owner:SHANGHAI UNIV

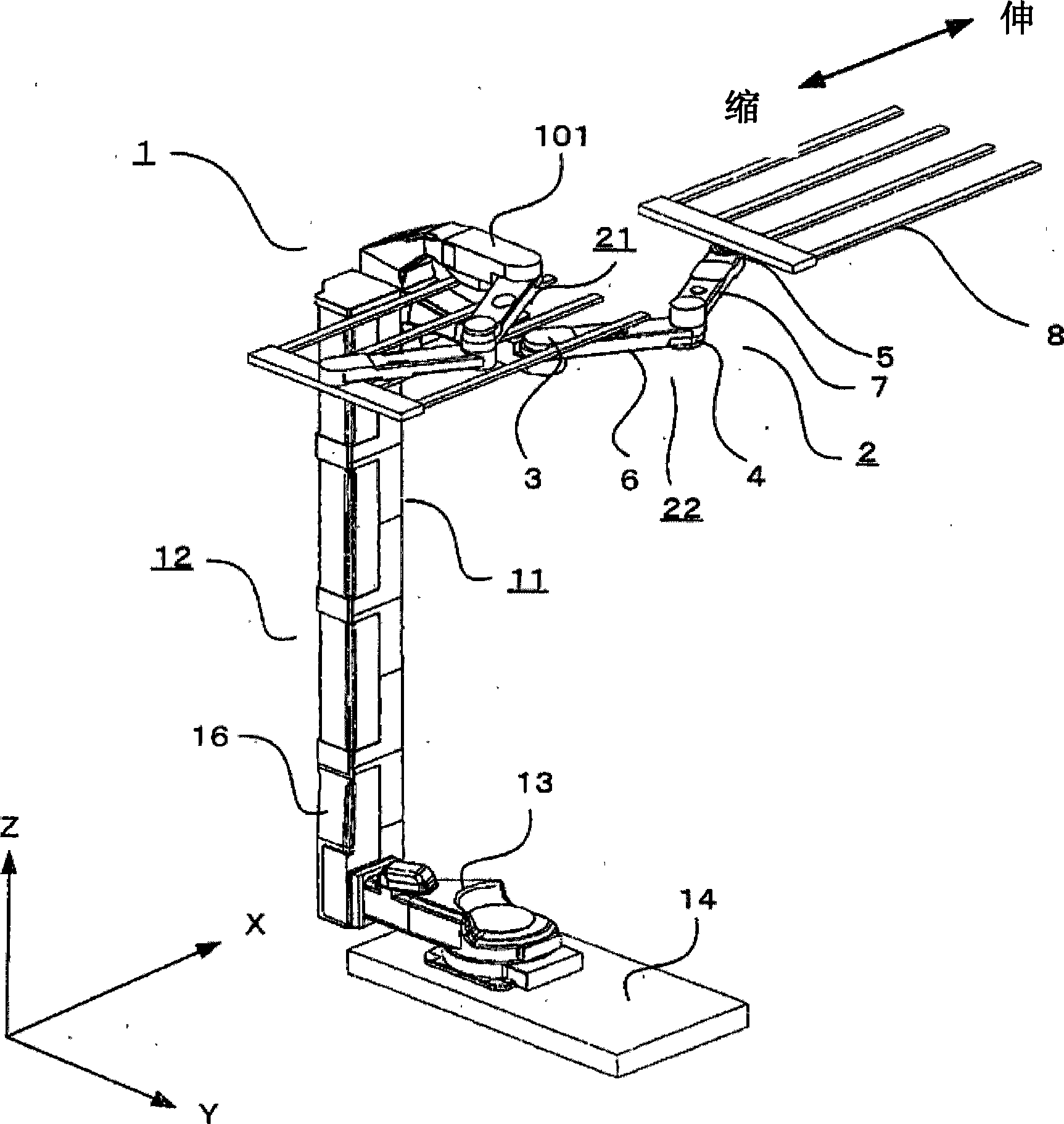

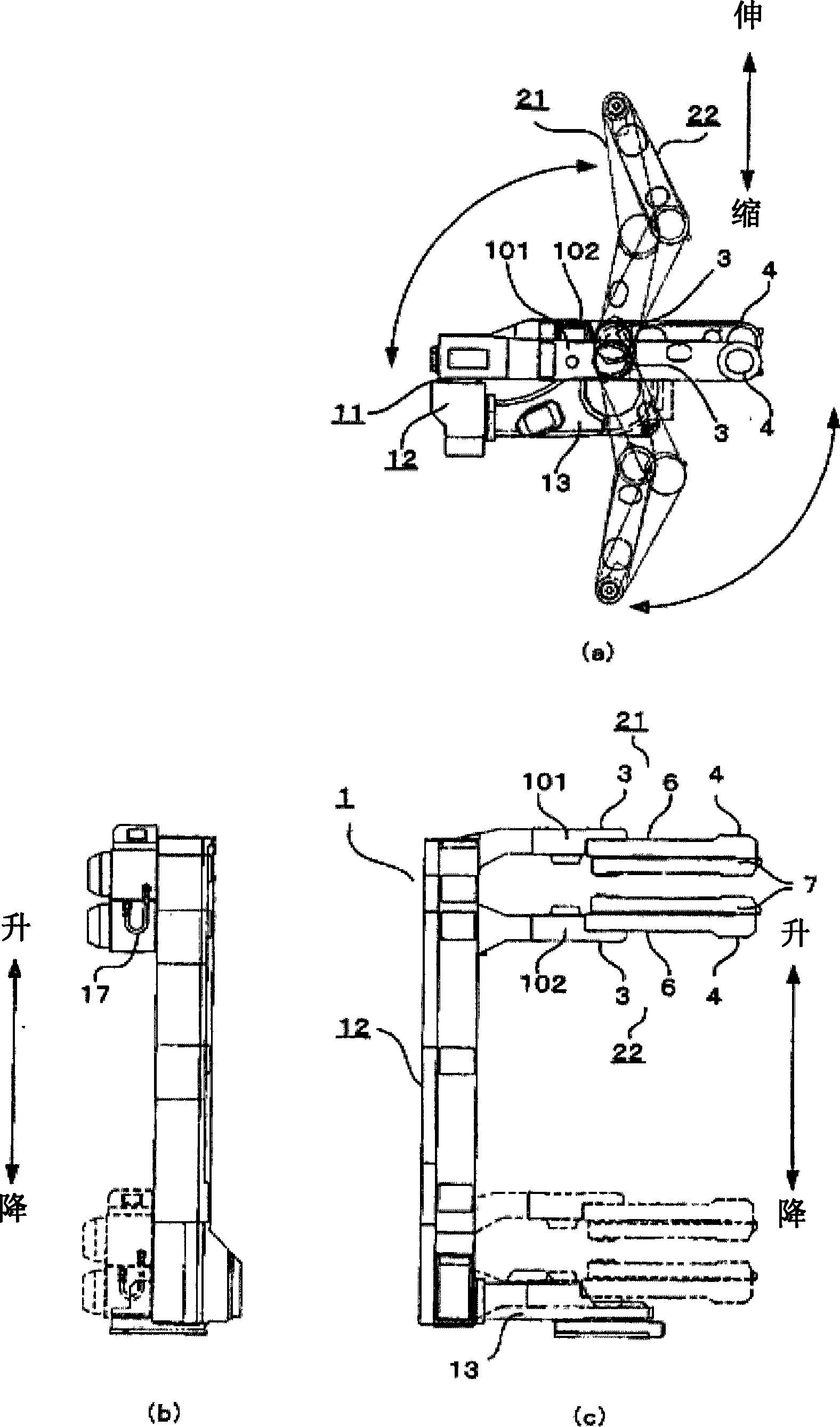

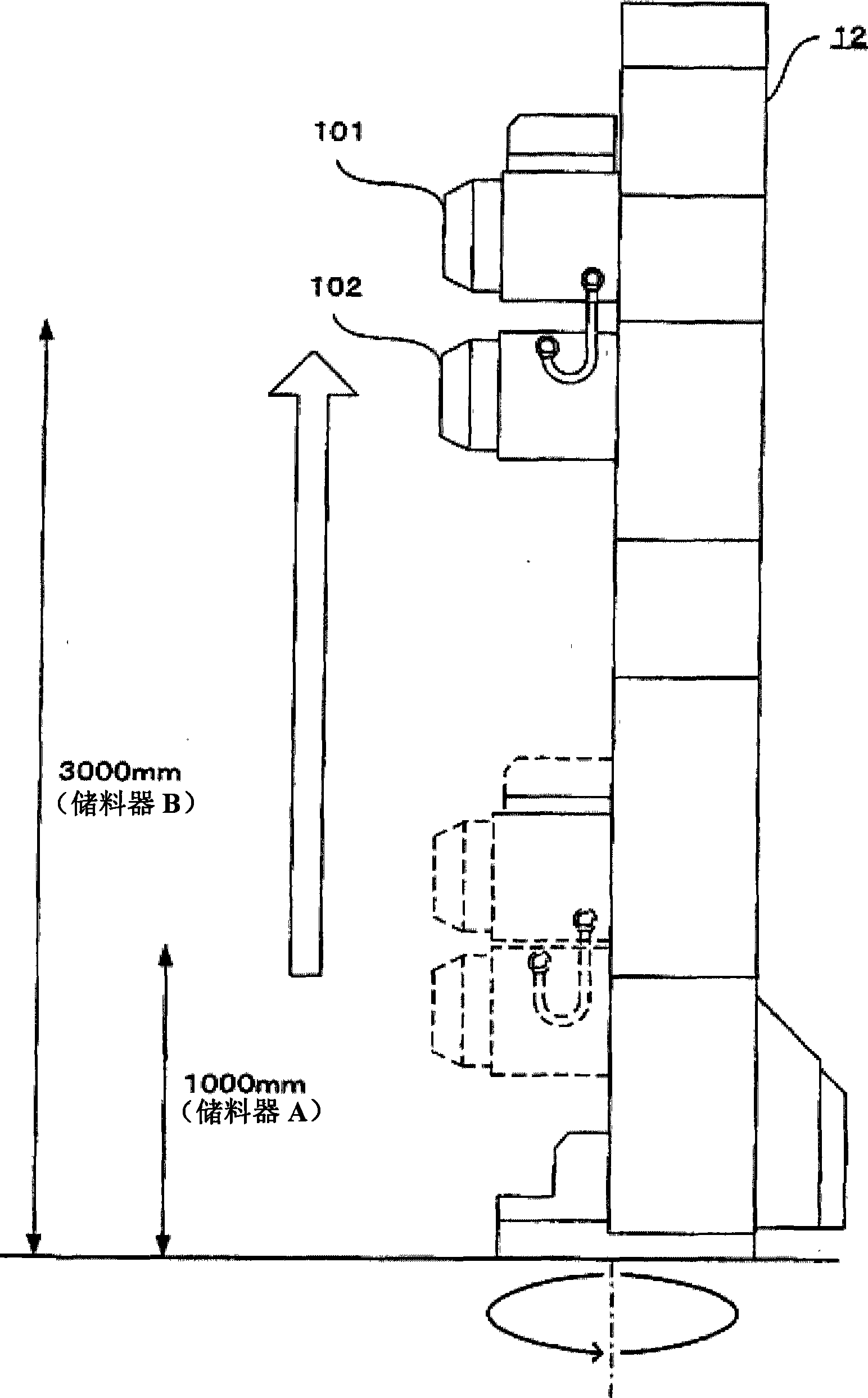

Double arm robot

ActiveCN101506963AImprove handling efficiencyReduce vibrationProgramme-controlled manipulatorCharge manipulationMechanical engineeringRADIUS

A double arm robot having double arms vertically movable independent of each other, having a compact column achieved by controlling the distance between upper and lower support members to an appropriate range, having a reduced installation area and swing radius, and in which adverse effect to a workpiece by operation of the upper and lower members is minimized. The double arm robot (1) has two support members (101, 102) for individually supporting two multi-joint arms arranged in a top- bottom relationship and also has a movement mechanism (11) for connecting the two support members so that they are independently movable in the top-bottom direction along the column (12). When either or both of the two support members (101, 102) move up and down, the distance between the two support members (101, 102) in the top-bottom direction is increased, and when the distance reaches a first predetermined value, the up-down movement of the two support members (101, 102) is stopped.

Owner:YASKAWA DENKI KK

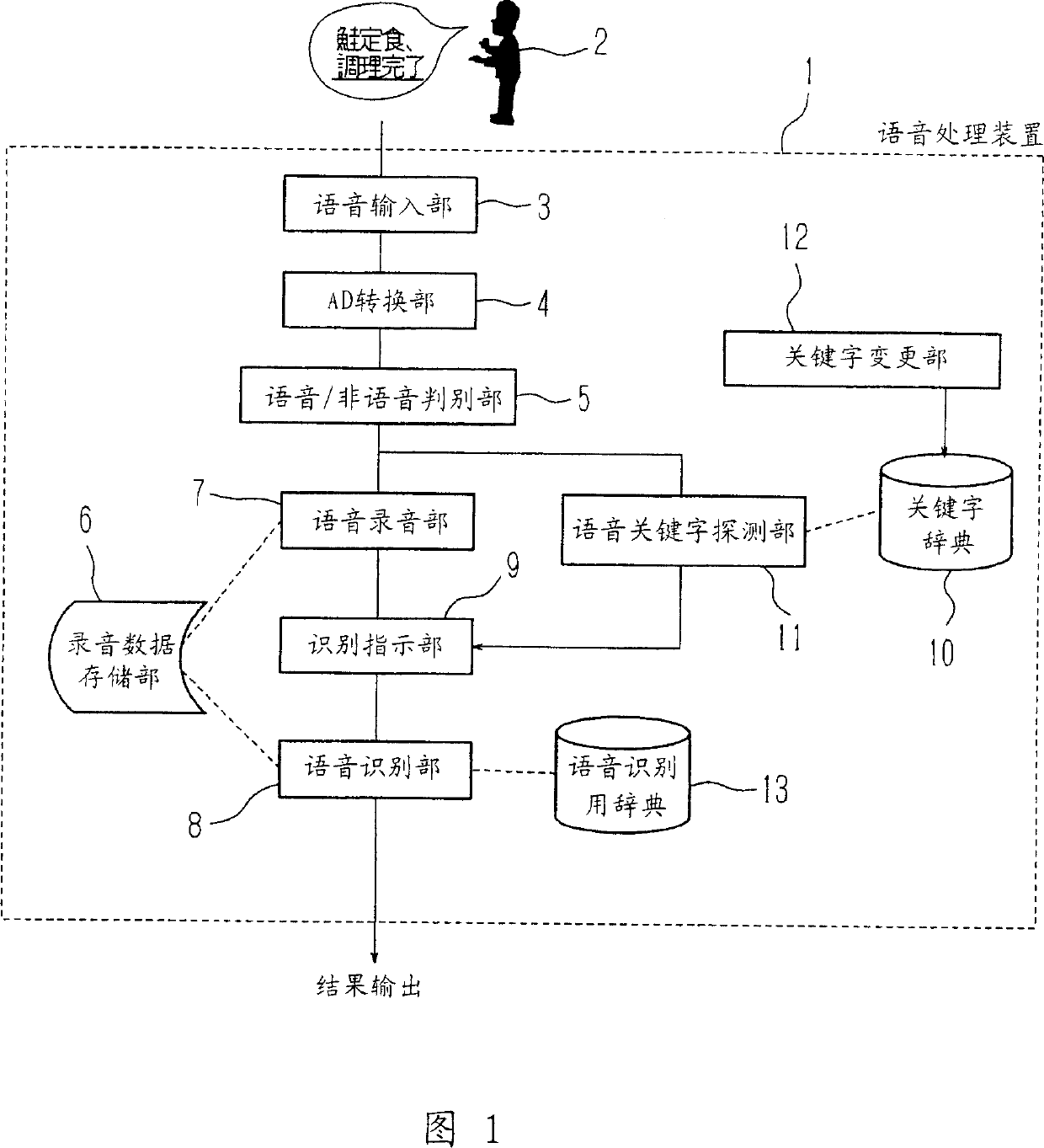

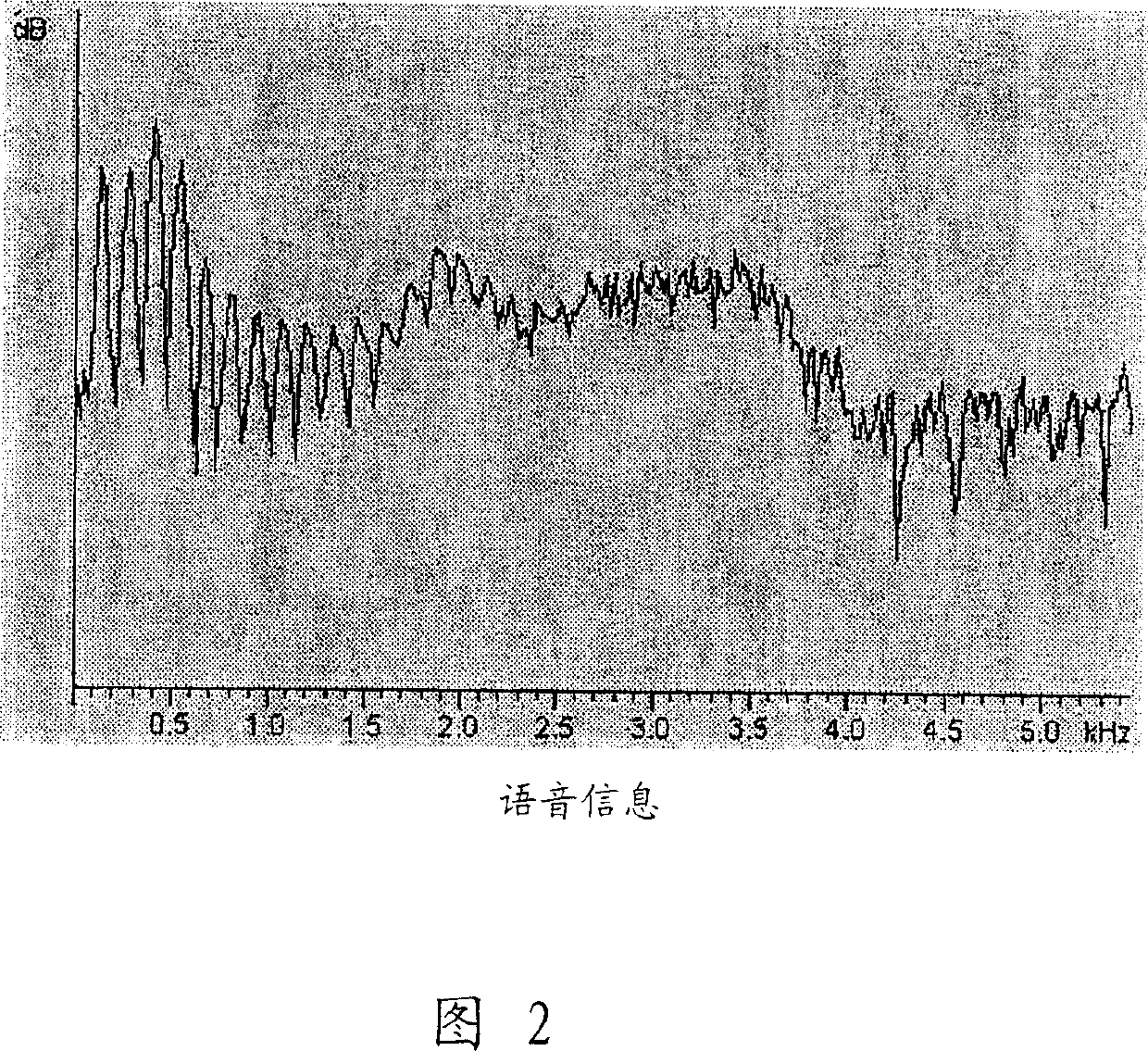

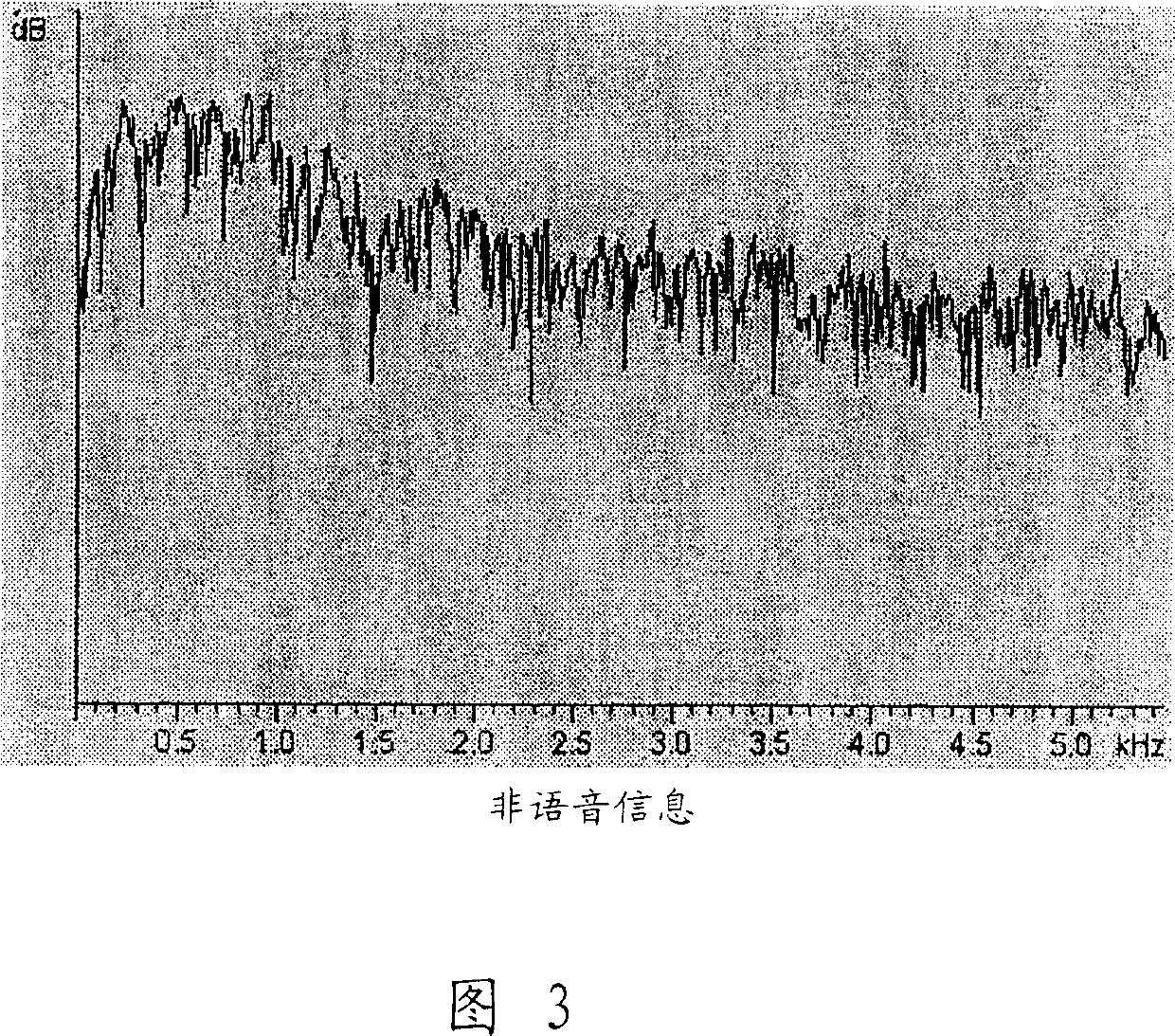

Speech processing device

InactiveCN1819016ANo tensionVoice recognition is reliableSpeech recognitionSpeech identificationSpeech discrimination

To ensure that speech recognition is performed without being accompanied by operation of a forward trigger. The system includes a speech / non-speech discrimination section 5 which discriminates whether the sound inputted from a speech input section 3 is speech or non-speech, a keyword dictionary 10, a dictionary 13 for speech recognition, a speech recognition section 8 which performs speech recognition based on the dictionary 13 for speech recognition, a speech keyword detection section 11 which detects whether the sound judged to be the speech in the speech / non-speech discrimination section 5 is a word previously registered in the keyword dictionary 10 or not, and a recognition instruction section 9 which emits the instruction to perform the speech recognition of the sound inputted at the time the sound inputted from the speech input section 3 is detected to be the sound including a word registered in the keyword dictionary 10 to the speech recognition section 8. The speech recognition is performed using the specific utterance after the user utters a desired word as a trigger.

Owner:TOSHIBA TEC KK

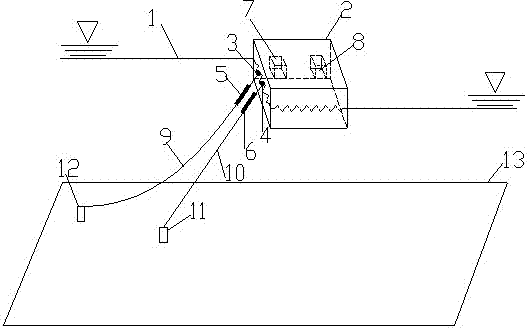

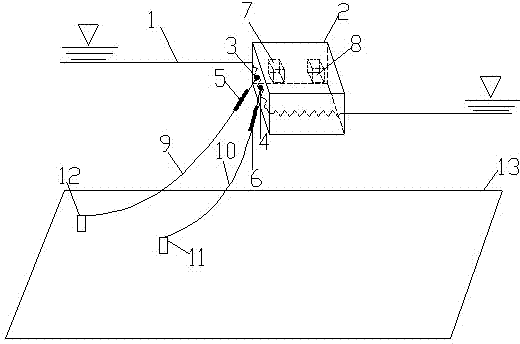

Hybrid mooring system for ultra-deepwater floating structures and mooring method

ActiveCN103482026ALength relaxationLength shrinkageAnchoring arrangementsMarine terraceMooring system

The invention discloses a hybrid mooring system for ultra-deepwater floating structures and a mooring method in the field of marine engineering oil and gas development. The mooring method includes: recording a motion response value of an ocean platform in real time by a GPS (global position system), when the motion response value is lower than a preset reasonable response value, judging the current ocean condition to be the ordinary ocean condition, and otherwise the limit ocean condition; when in the limit ocean condition, straining a tension-type mooring line, and transmitting tension A on a catenary-type mooring line and tension B on the tension-type mooring line to a control module by a second tension sensor and a first tension sensor respectively; calculating a value C through a formula by the control module, if the value C is smaller than a preset reasonable difference, keeping the tension-type mooring line constant in length, otherwise comparing the tension A with the tension B, if A is smaller than B, loosening the tension-type mooring line in length, and if A is larger than B, shrinking the tension-type mooring line in length. By the mooring method, intelligent switching between a single set of catenary-type mooring line system and the hybrid mooring system can be automatically completed, and the mooring method is simple and convenient and rapid.

Owner:佛山市榕岸海洋工程装备有限公司

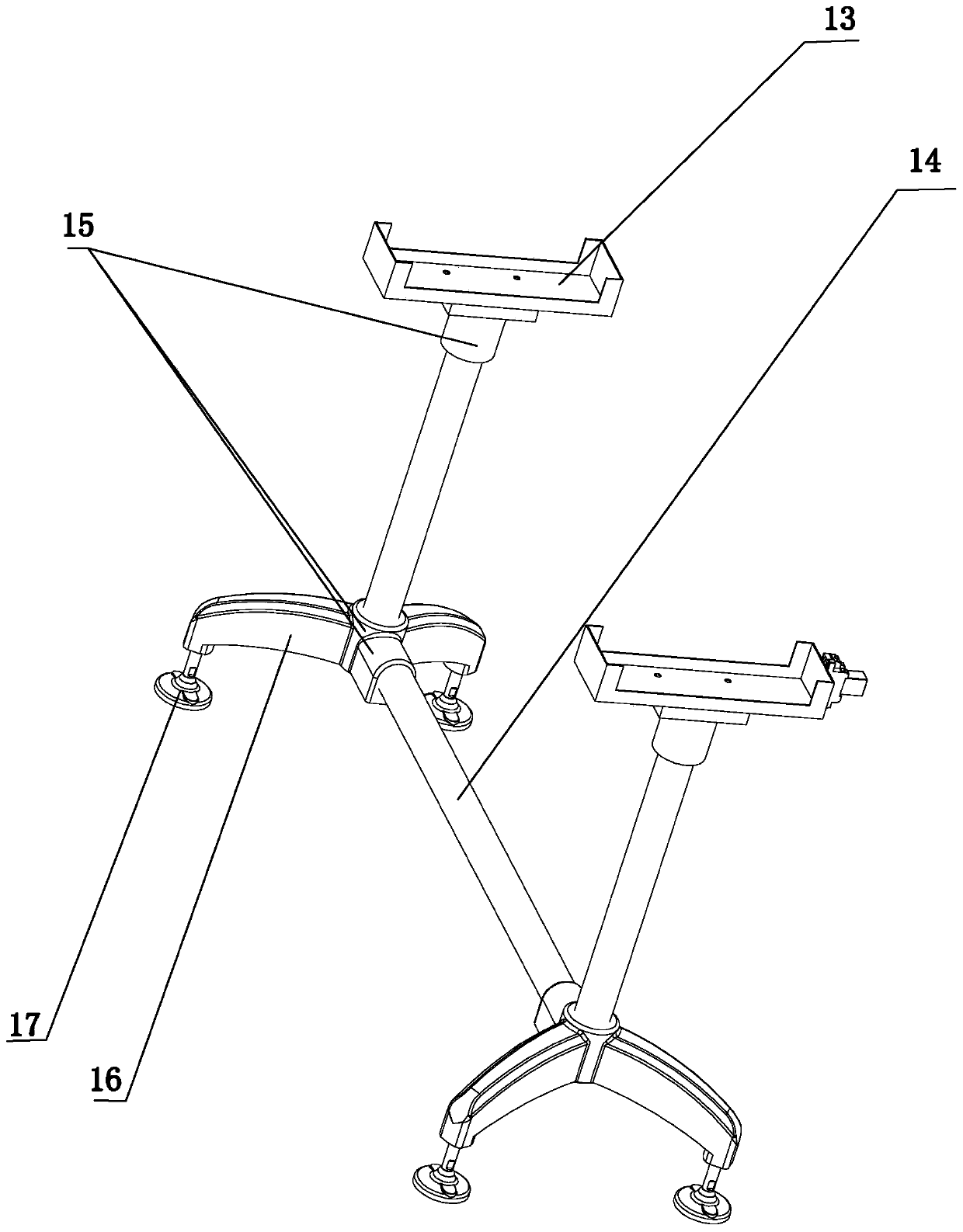

High-speed copper line wire drawing machine uncoiling device

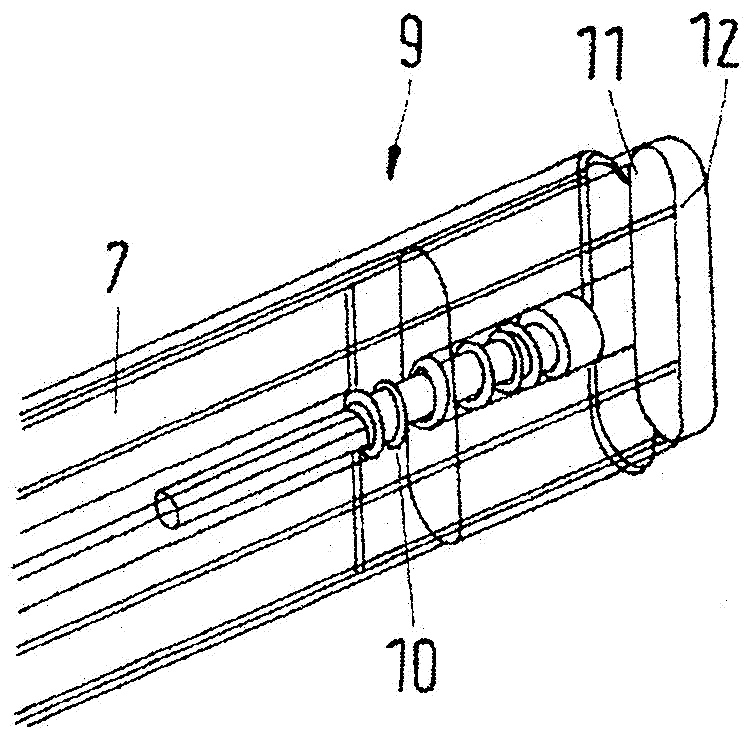

The invention discloses a high-speed copper line wire drawing machine uncoiling device, comprising a base [15], a rotating shaft [11], a lever [13] and a line guide rod [4], wherein, a round table [16] is arranged below the base [15]; a porcelain sleeve [10] is fixed on the upper end of the rotating shaft [11]; the lever [13] is connected on the rotating shaft [11], and the two ends of the lever [13] are respectively connected with line guide wheels [5]; one end of the line guide rod [4] is fixedly connected with the rotating shaft [11], and the other end of the line guide rod [4] is connected with a guide sleeve [3]; the rotating shaft [11] is horizontally fixedly connected with a horizontal shaft [7]; a screw [9] is arranged between the horizontal shaft [7] and the lever [13]; the end part of the screw is provided with a butterfly nut [8]; a tension spring [6] is sheathed on the screw; and a friction plate [14] is arranged below the line guide wheel at the right side of the rotating shaft [11], so as to lead a copper line [2] to generate friction force when in moving. The device of the invention can not damage the copper line when in uncoiling; and tension exists on the copper line all the time, thus copper line does not collide with other equipment even under the action of centripetal force.

Owner:TONGLING CHANG JIANG COPPER IND

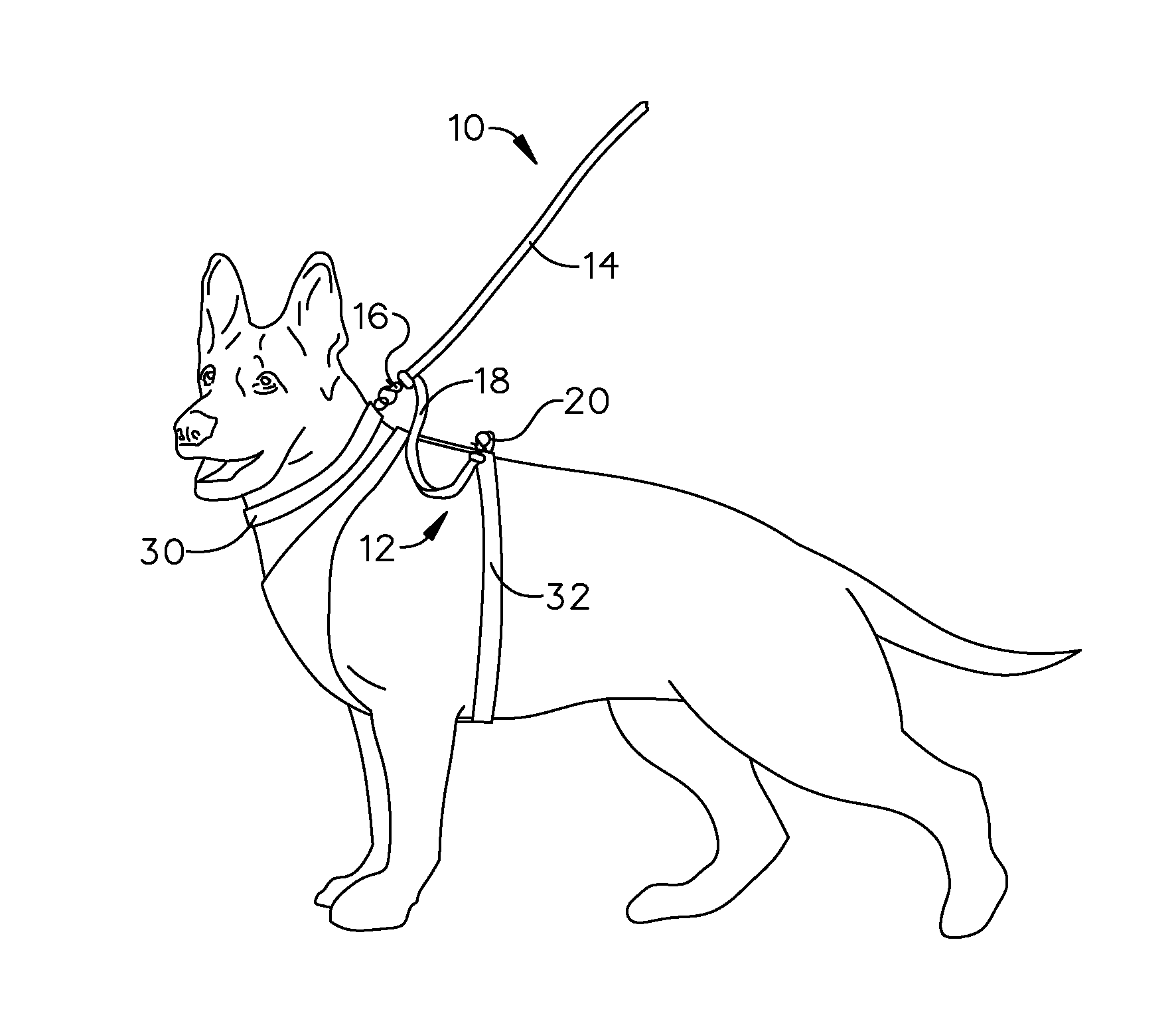

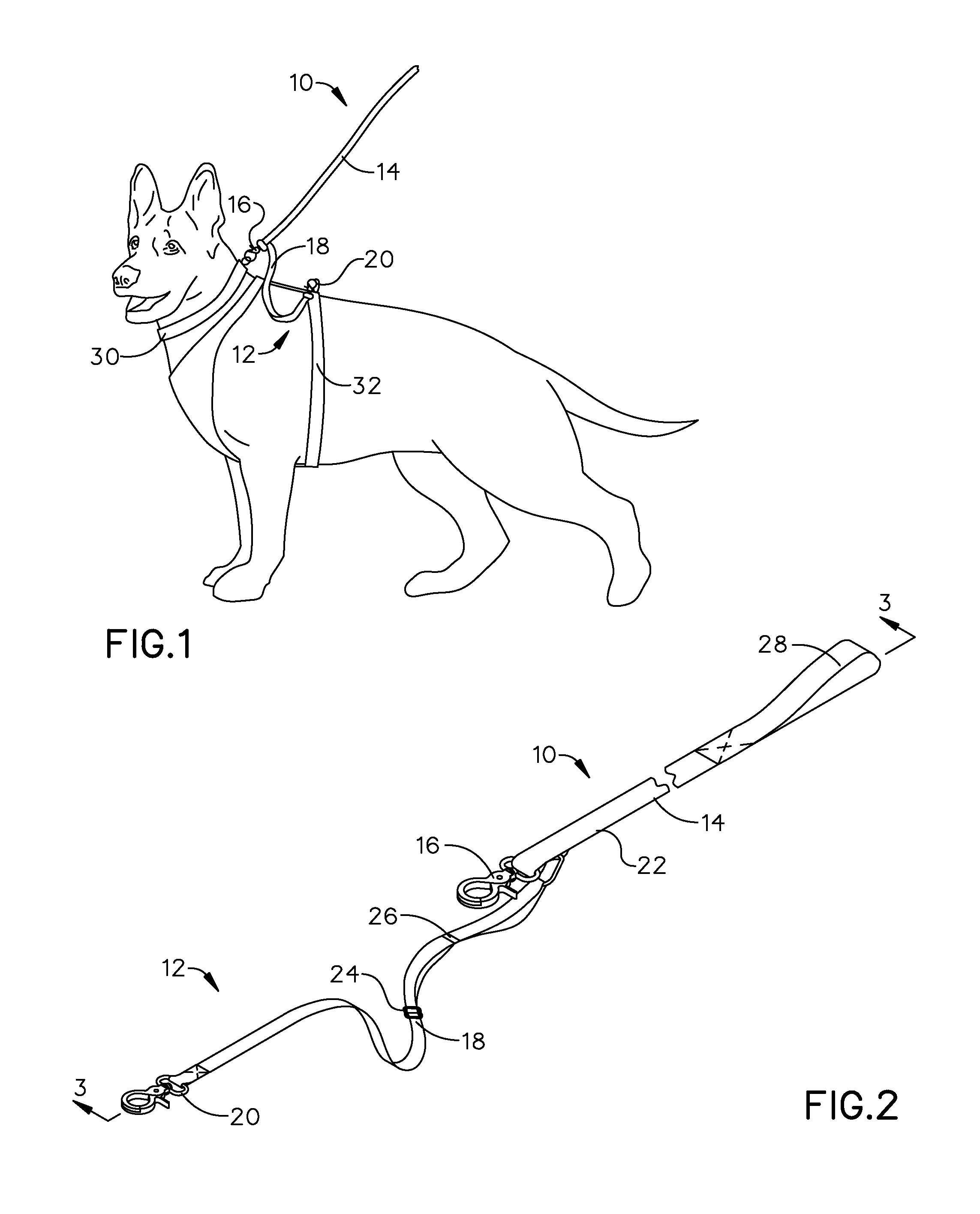

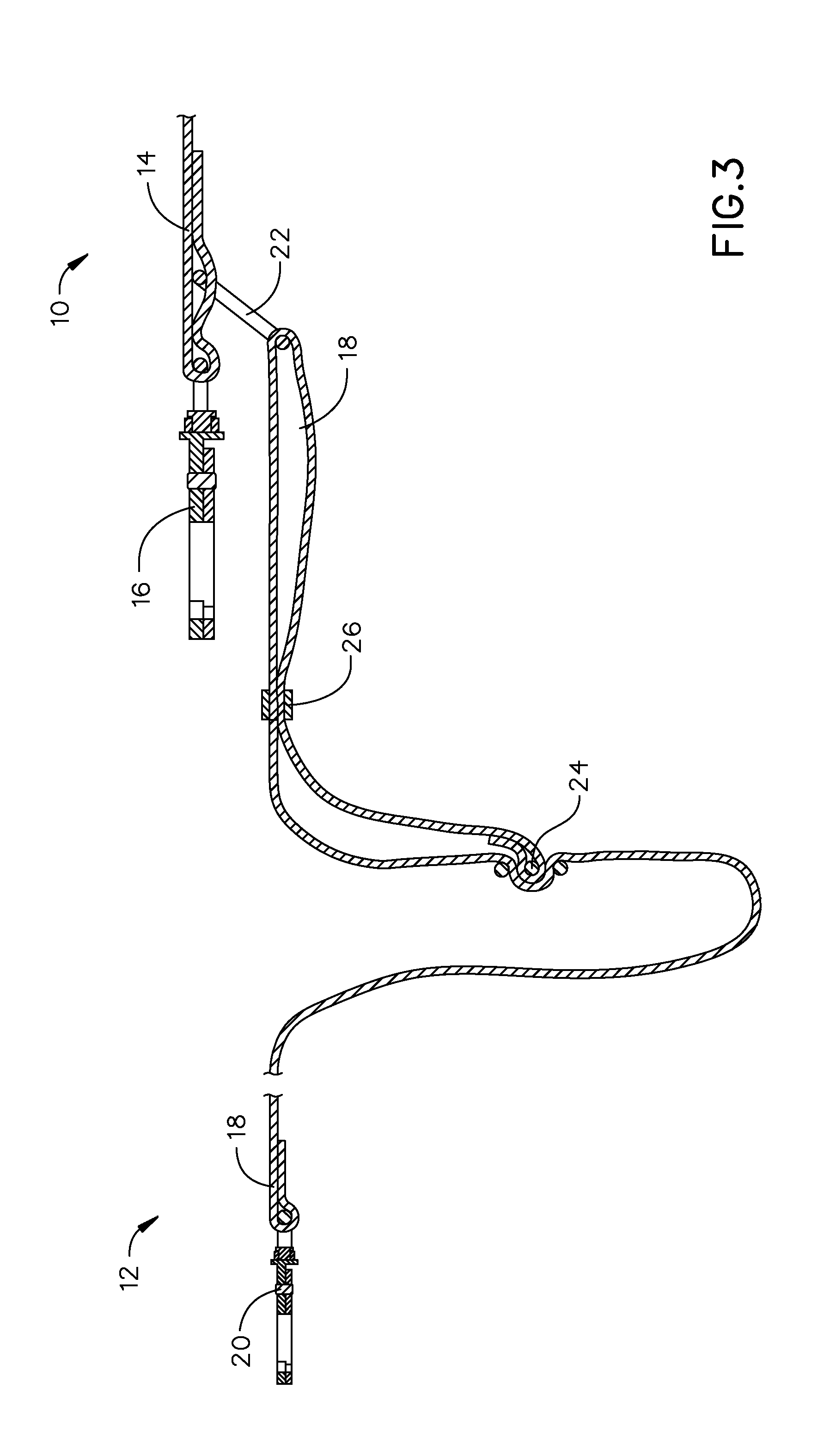

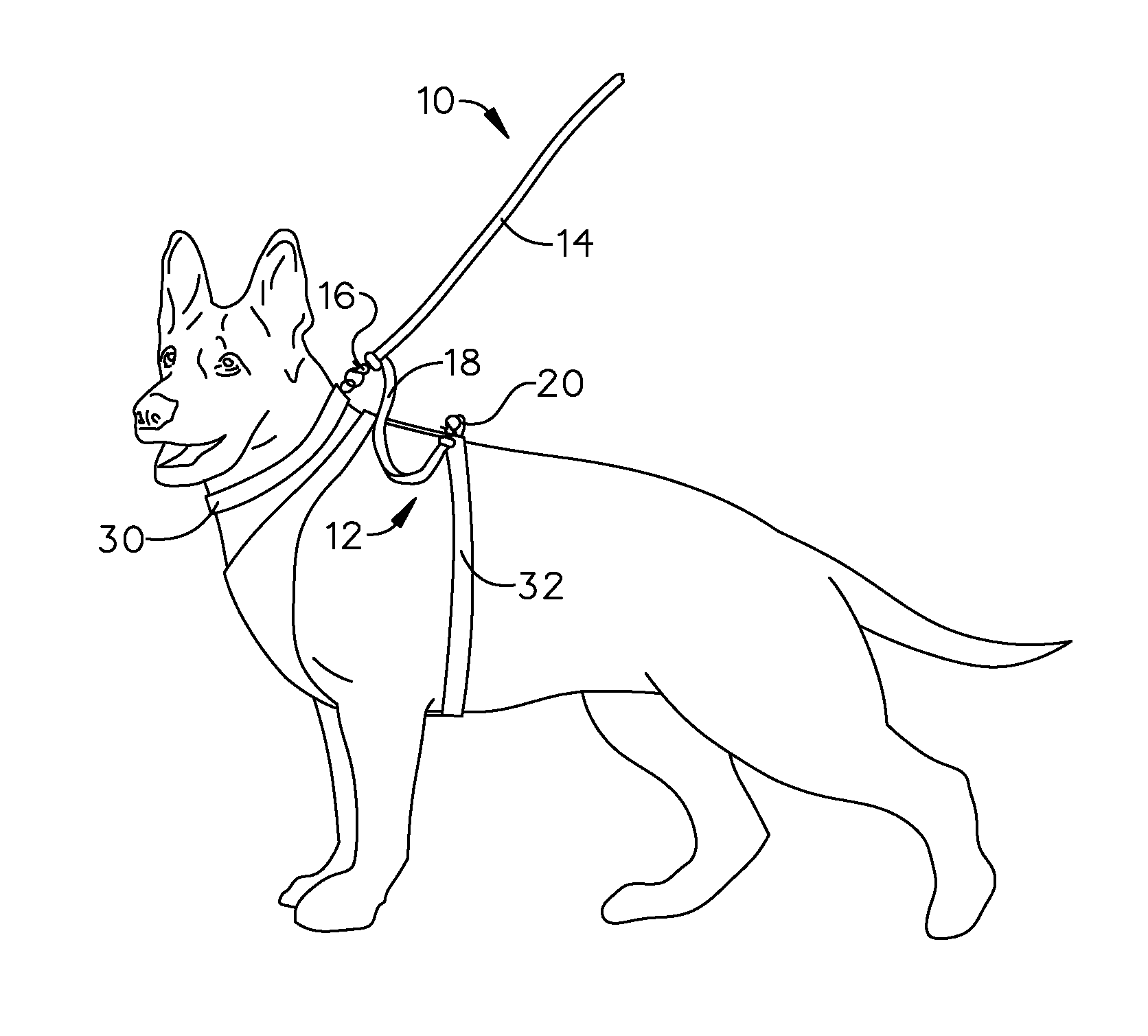

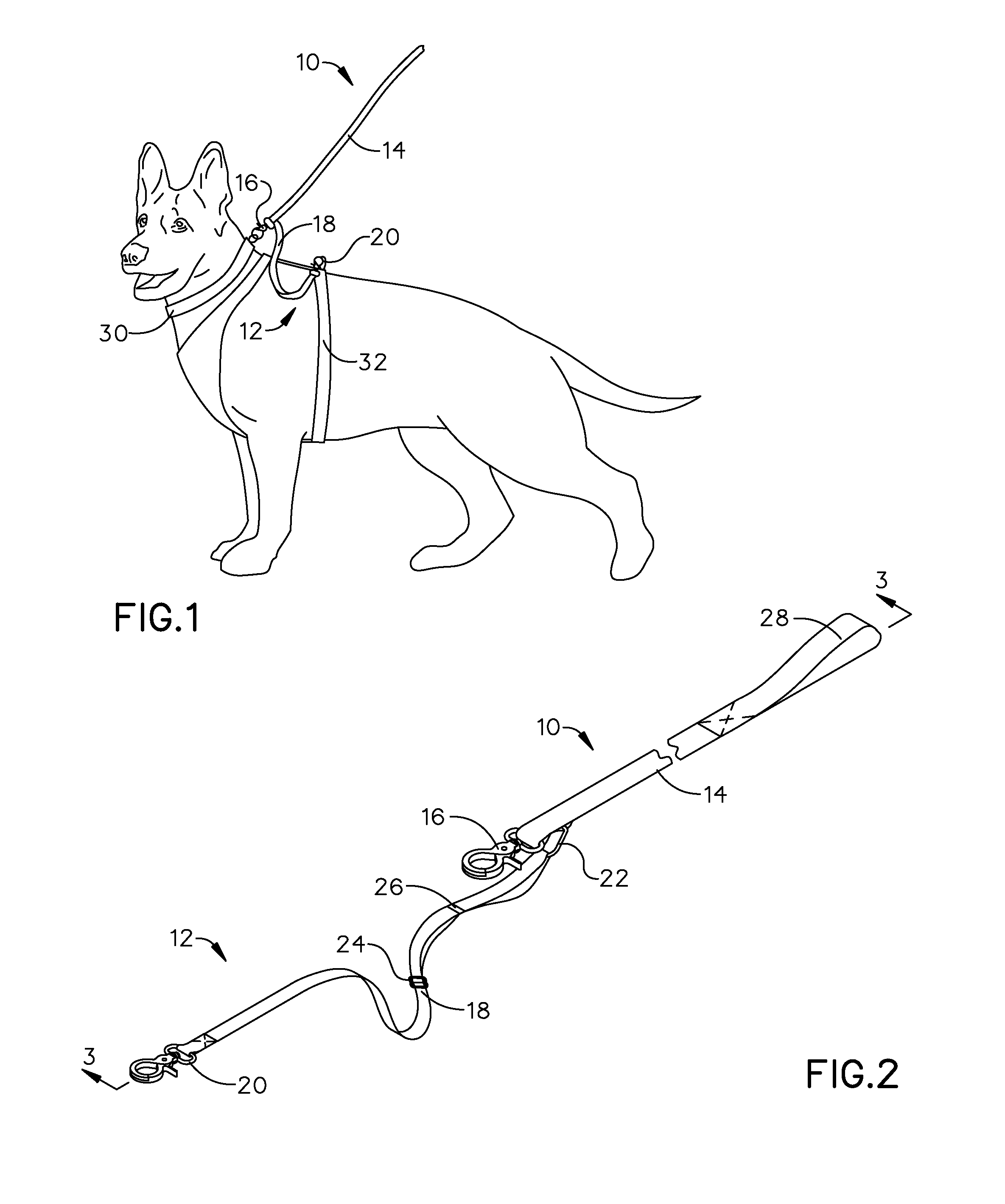

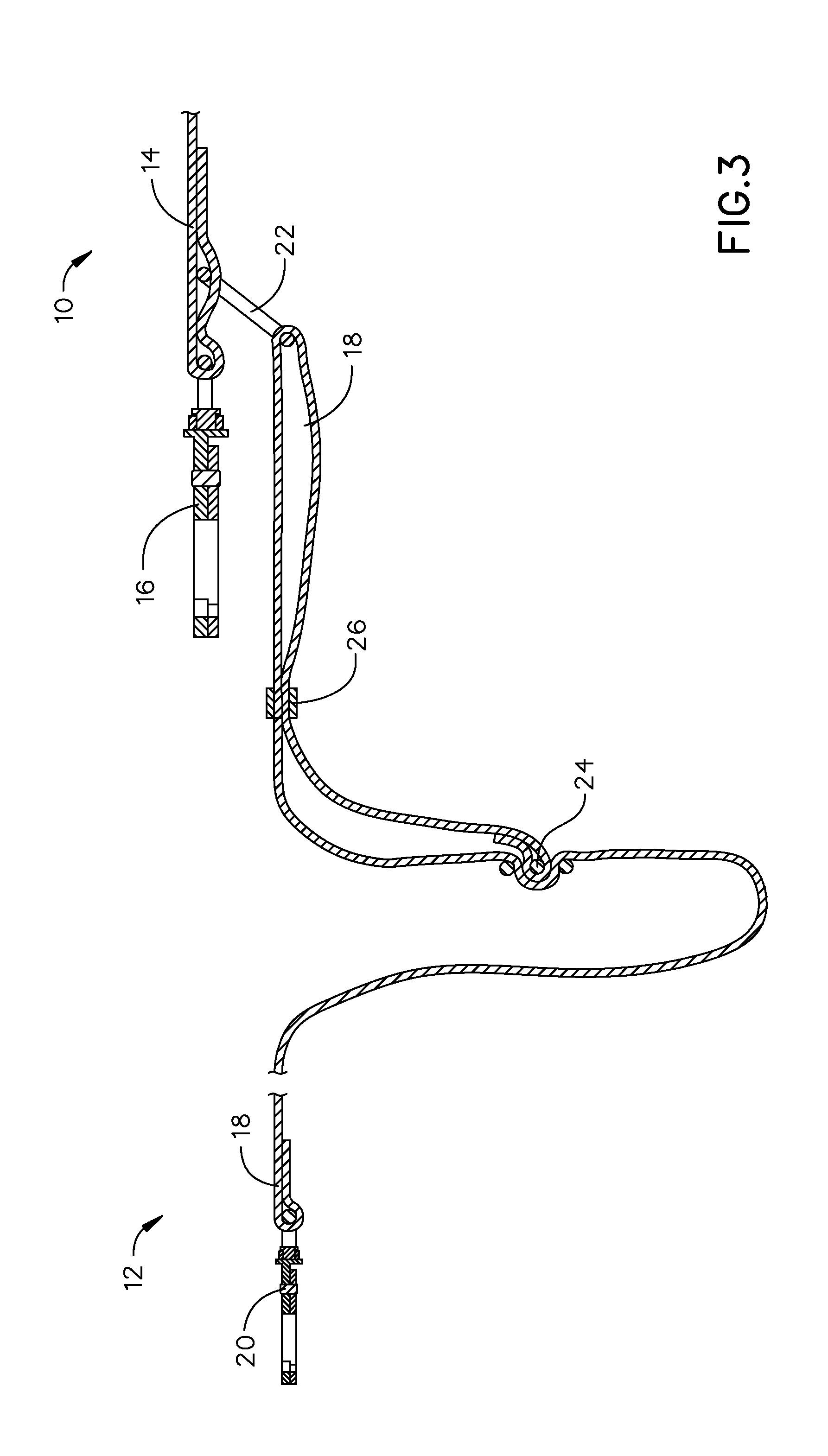

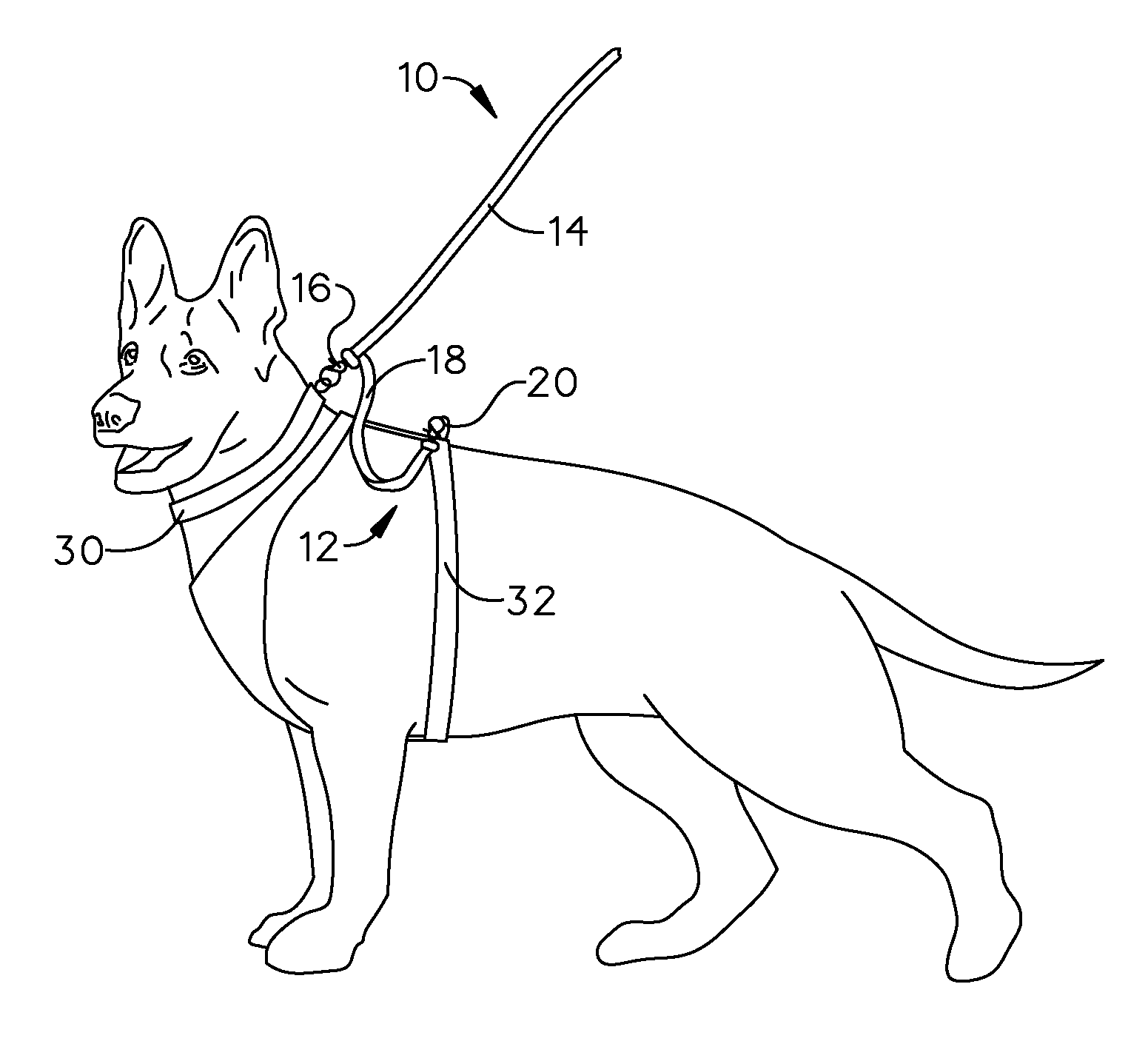

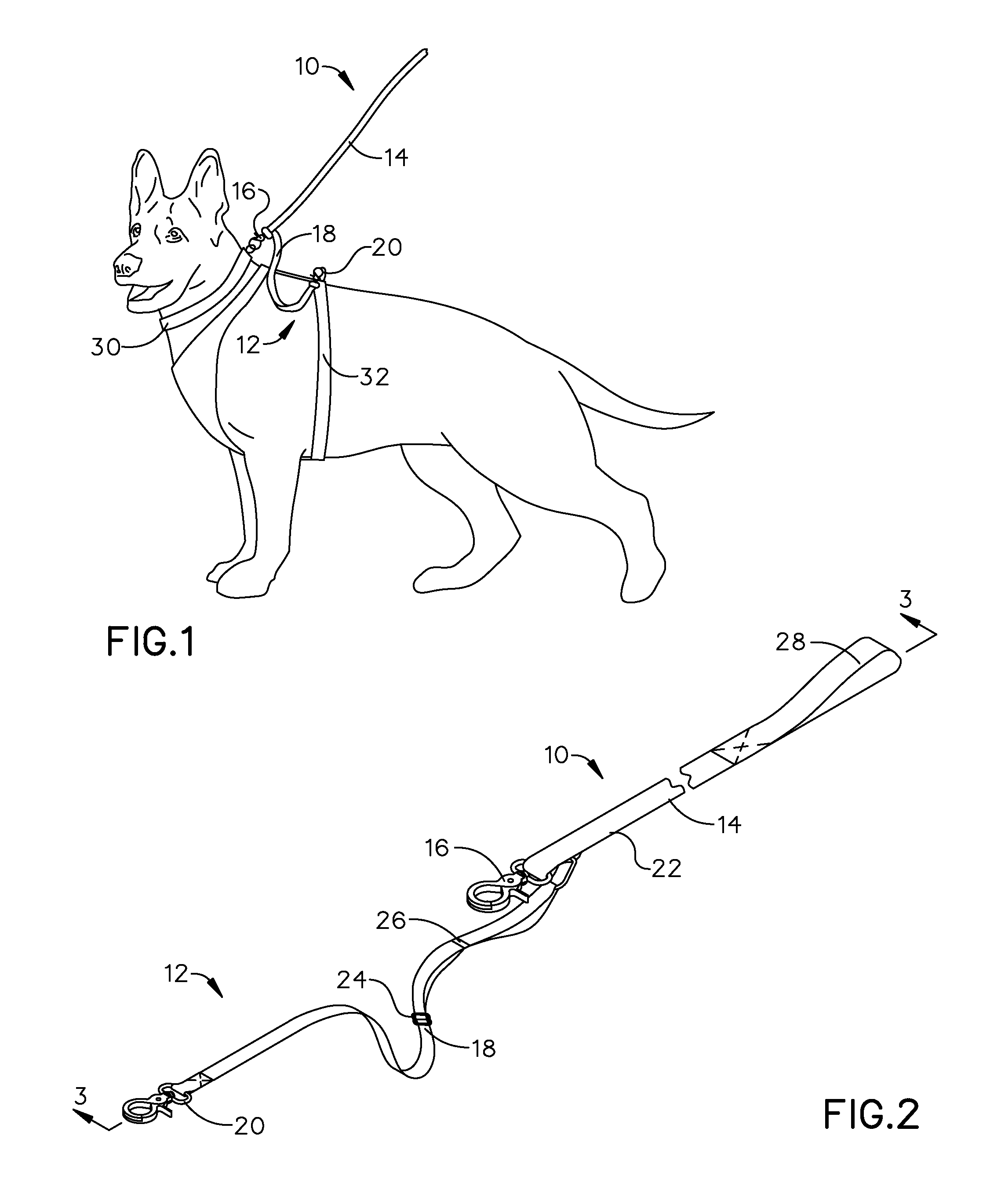

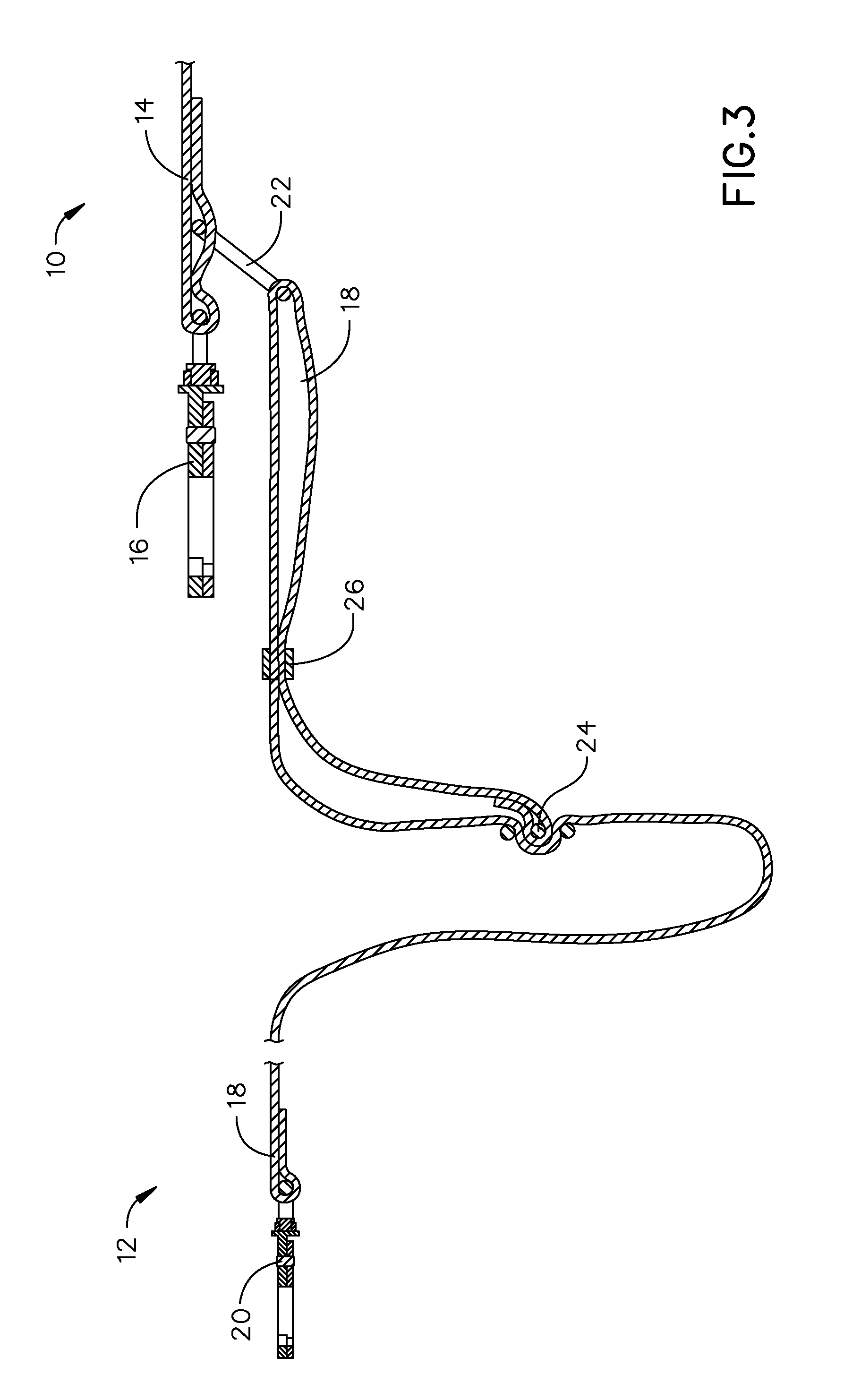

Pet leash with adjustable security extension

ActiveUS20150150221A1Adjustable lengthNo tensionTaming and training devicesEngineeringCompanion animal

Owner:BELT N SUSPENDERS

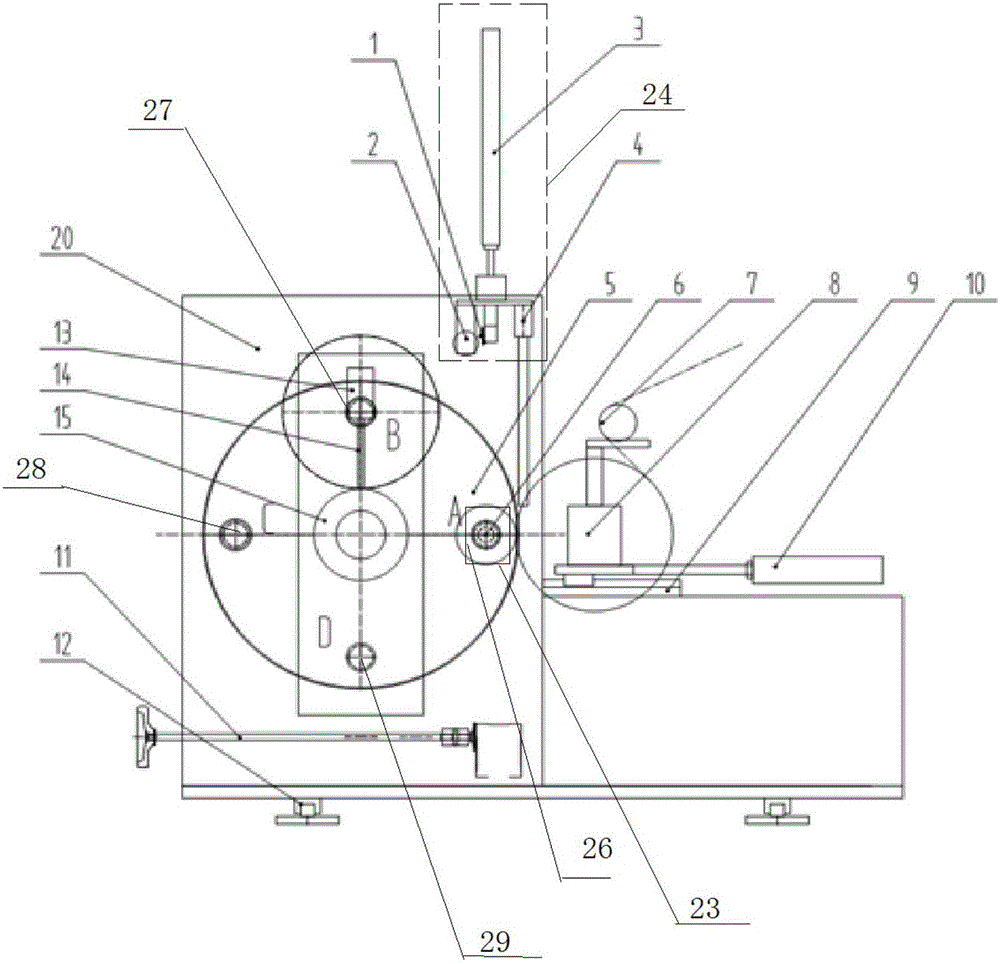

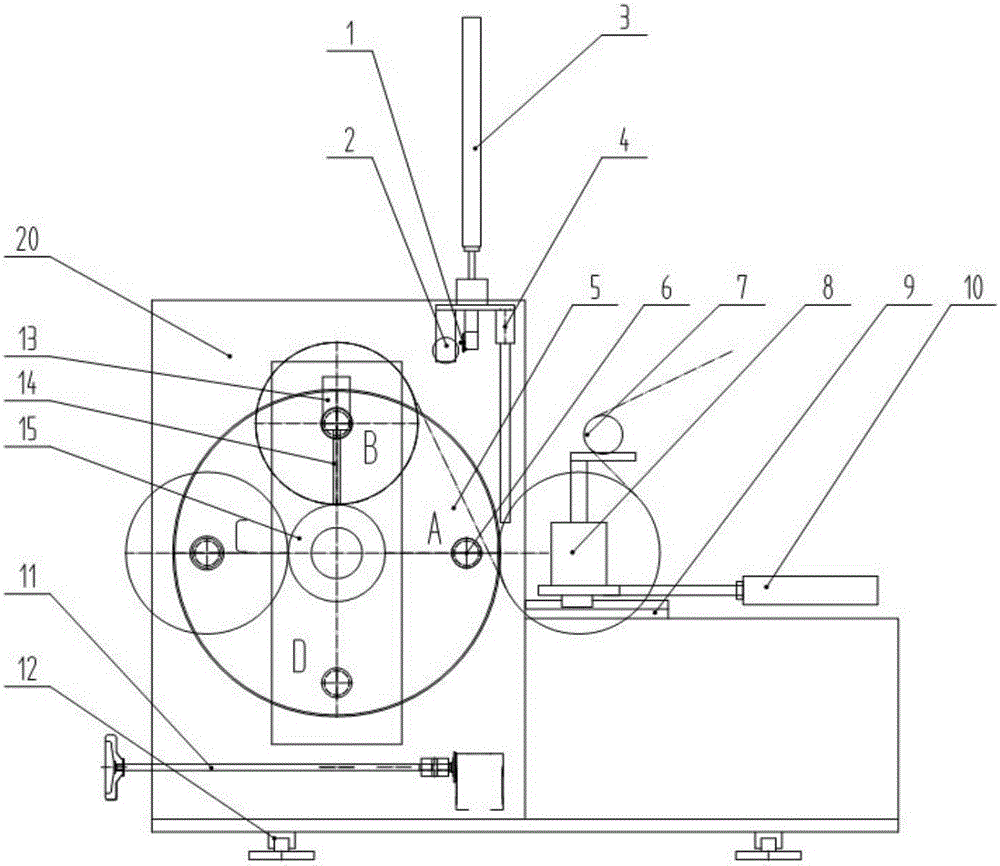

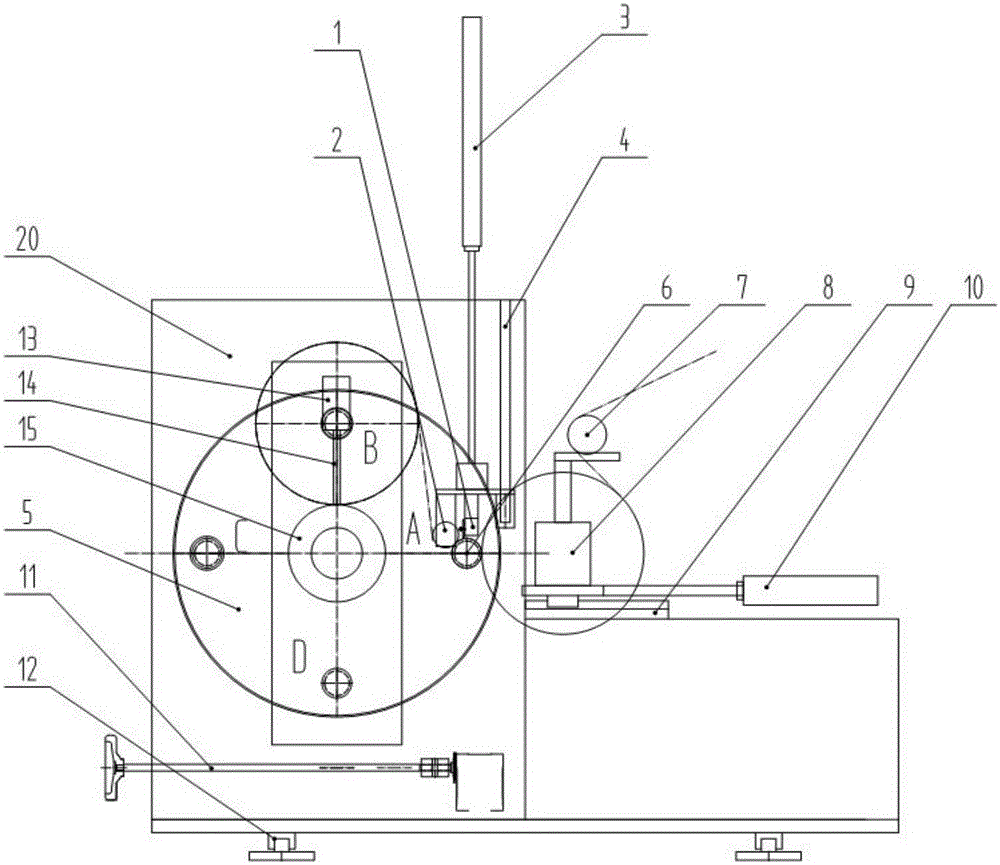

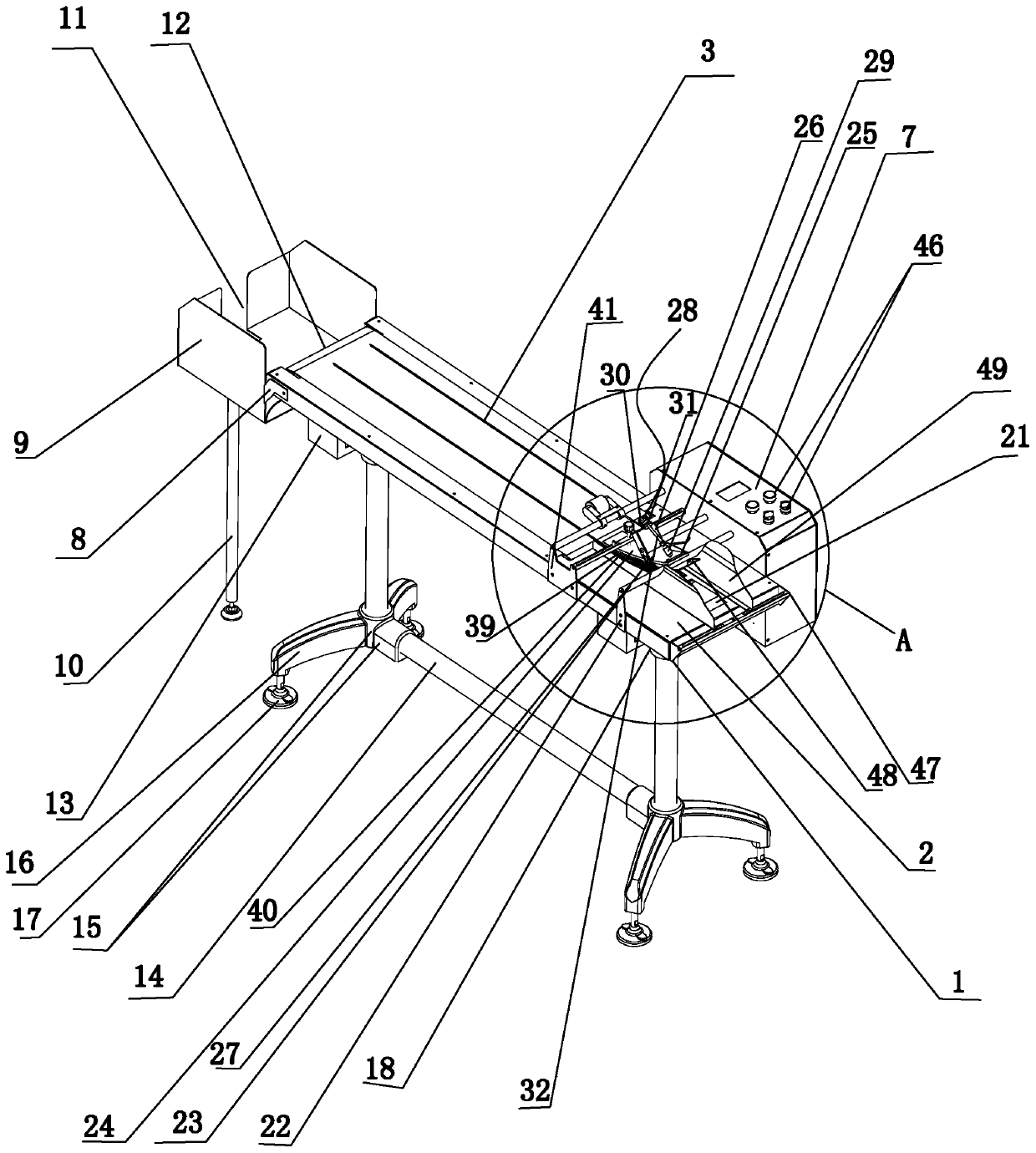

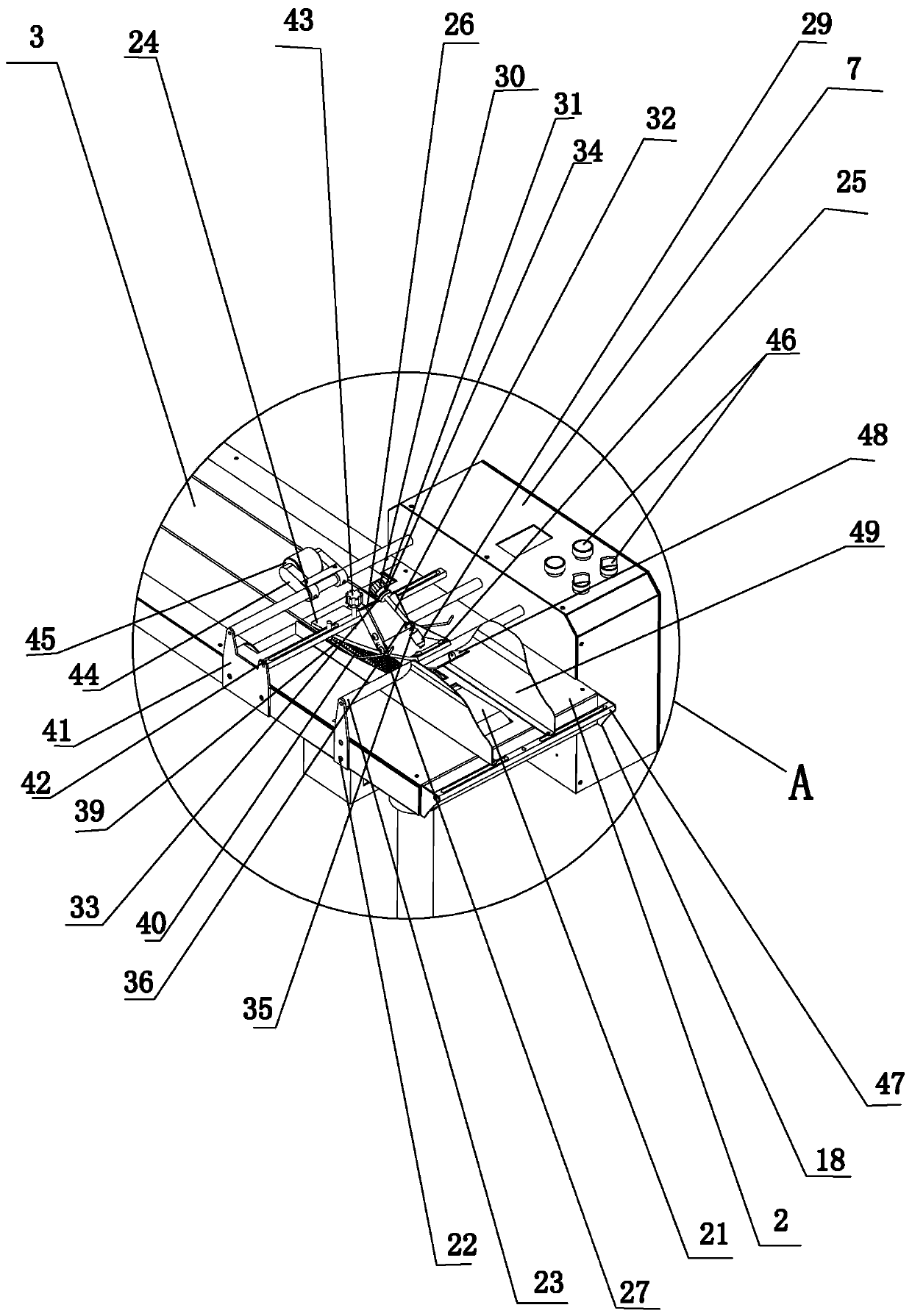

High-speed four-axis winding machine

The invention discloses a high-speed four-axis winding machine. The high-speed four-axis winding machine comprises a machine frame arranged on a machine frame slide rail. A disc is arranged on the machine frame. A positioning disc is arranged at the central position of the disc. A positioning mechanism is arranged on the positioning disc and is driven by a positioning cylinder to be matched with the positioning disc for positioning. A station A , a station B, a station C and a station D are evenly arranged on the portions, close to the position of the edge of the disc, on the disc. A winding mechanism is arranged on each station. A driving rubber covered roller is arranged at the position, horizontally close to the station A, of the machine frame and is arranged in a rubber covered roller slide rail. The driving rubber covered roller slides in the rubber covered roller slide rail under the driving of a rubber covered roller cylinder connected with the driving rubber covered roller. An arc-shaped roller is arranged on the upper portion of the driving rubber covered roller. A cutter mechanism is arranged at the position, corresponding to the upper portion of the station A, on the machine frame and slides up and down in a cutter slide rail. The cutter slide rail is fixed to the machine frame. The problems that in the prior art, winding units are low in winding efficiency and poor in automation degree are solved.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

Pet leash with adjustable security extension

InactiveUS20150150222A1No tensionAdjustable lengthMetal working apparatusTaming and training devicesEngineeringIndividual animal

Owner:SCHLOSSER JOANNA FRANCES

Pet leash with adjustable security extension

InactiveUS9119378B2No tensionAdjustable lengthTaming and training devicesEngineeringCanis lupus familiaris

Owner:BELT N SUSPENDERS

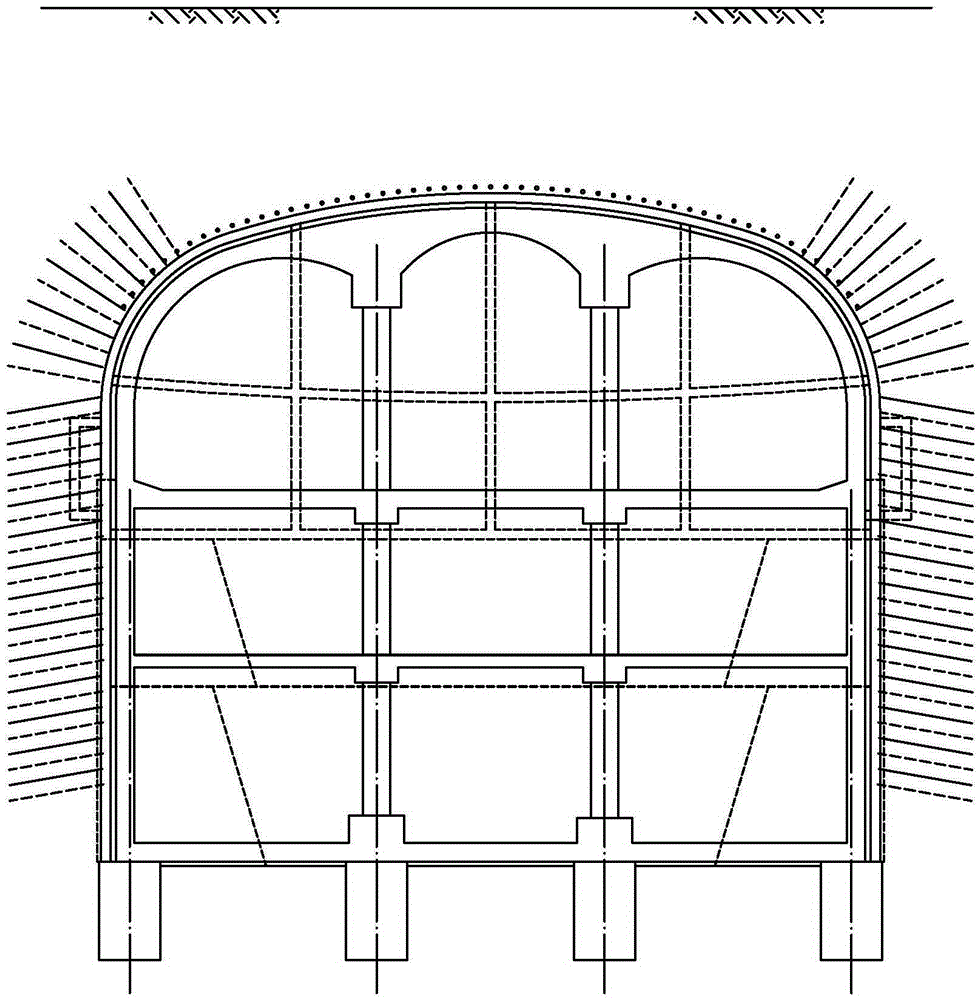

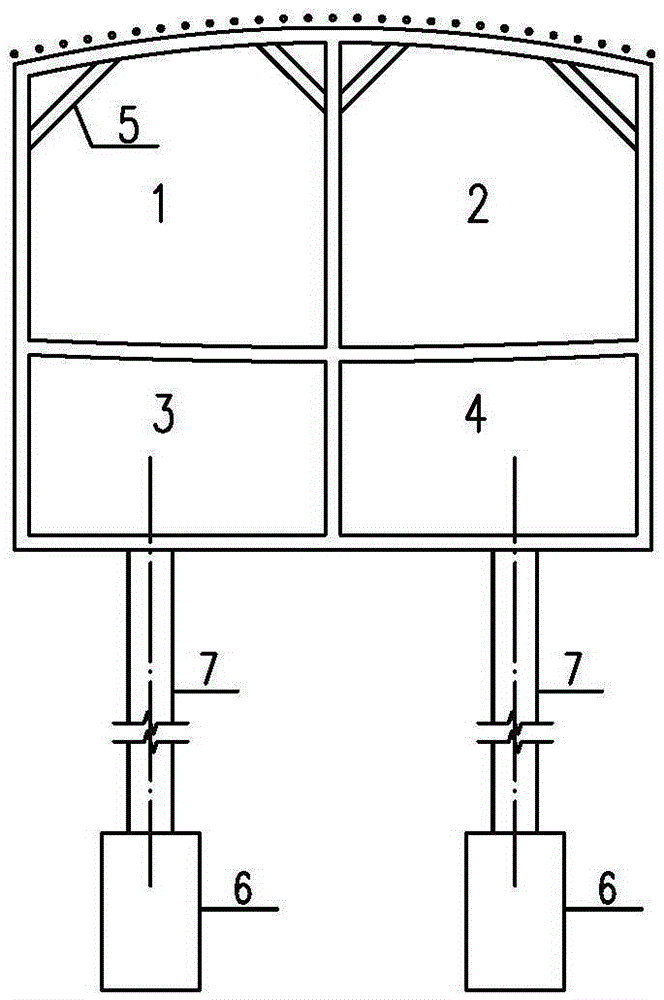

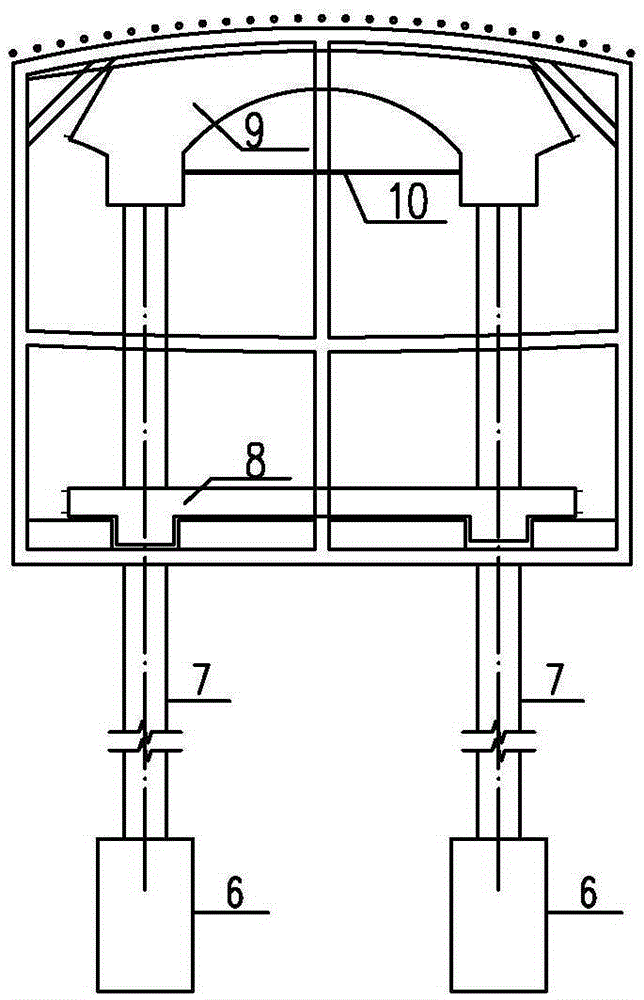

Arch column method for building large-scale underground structure in shallow buried rock stratums

ActiveCN105386779ALow costShorten the construction periodUnderground chambersStructure of the EarthDeformation control

The invention relates to an arch column method for building a large-scale underground structure in shallow buried rock stratums. The method comprises the following steps of: 1, separately excavating underground one-storey middle pilot tunnels, constructing primary supports, and constructing pile foundations and steel pipe columns at the positions of middle columns; 2, constructing secondary linings including underground one-storey floors, steel pipe columns, roof timbers, roof arches and the like, and waterproof layers in middle tunnels; 3, symmetrically excavating underground one-storey two-side pilot tunnels, constructing primary supports, and constructing pile foundations and side columns under side walls; 4, constructing secondary linings including floors, vertical walls, edge arches and the like in side tunnels and waterproof layers, and disassembling temporary supports; 5, under the protection of underground one-storey structures, downwards excavating an underground second-storey structure with large-scale machinery, besides, constructing side wall bolt spray supports or slab rib type anchored bolt retaining wall supports, and pouring underground second-storey floors, side walls and waterproof layers; and 6, sequentially downwards excavating a plurality of underground storeys, besides, constructing side wall supports, and pouring floors, side walls and waterproof layers of corresponding storeys. The method disclosed by the invention is convenient to construct, high in efficiency, small in construction risks, good in stratum deformation control, and low in building cost.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

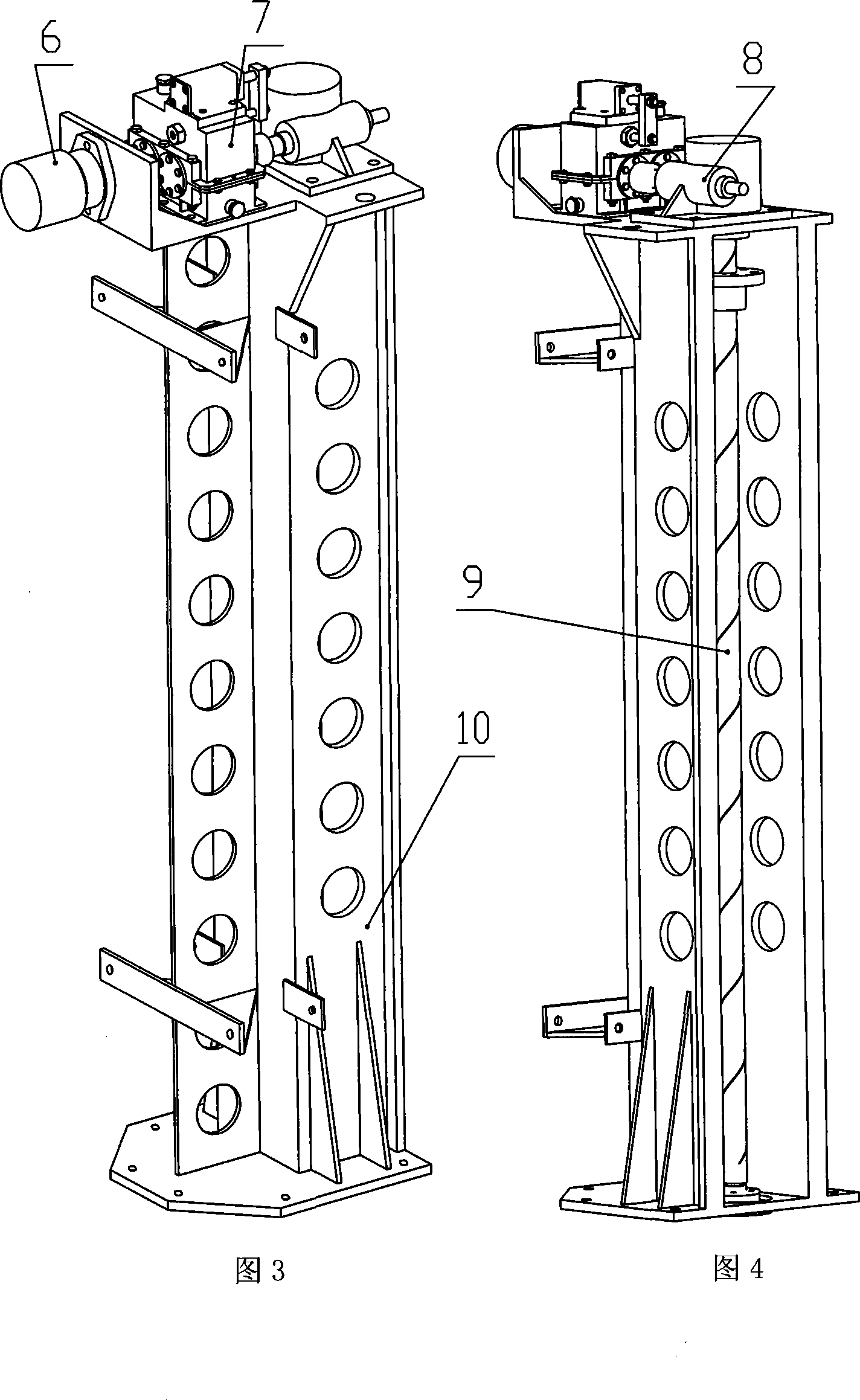

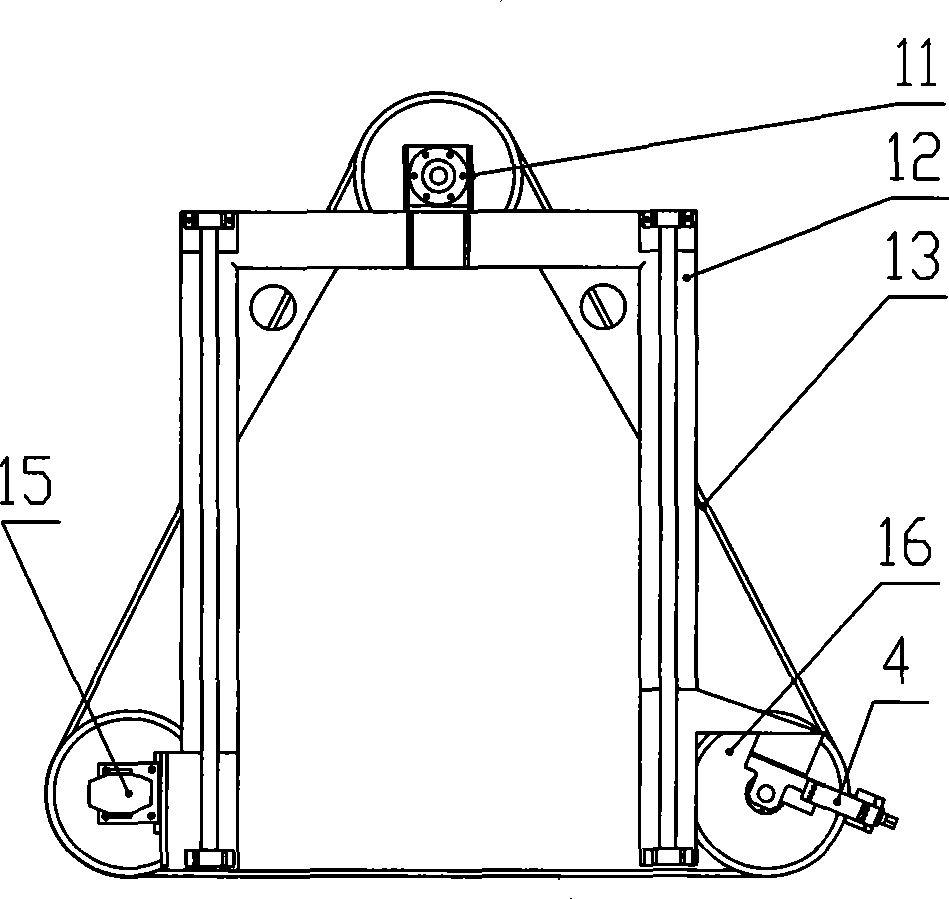

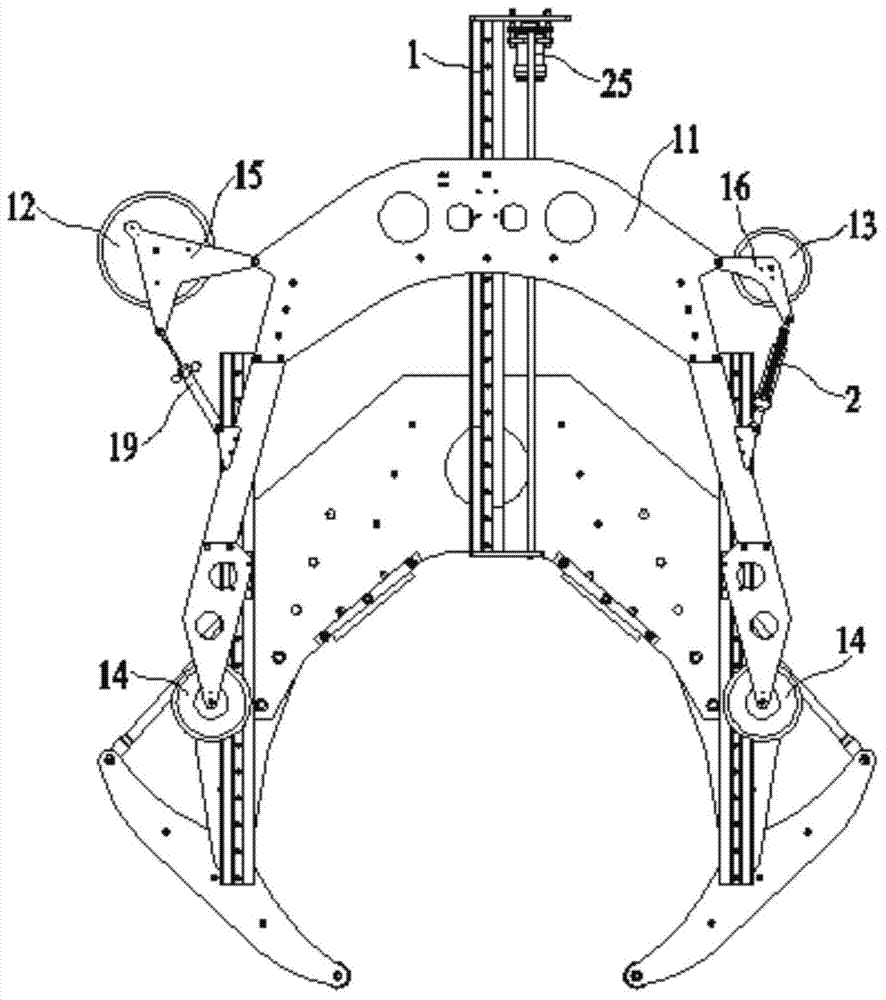

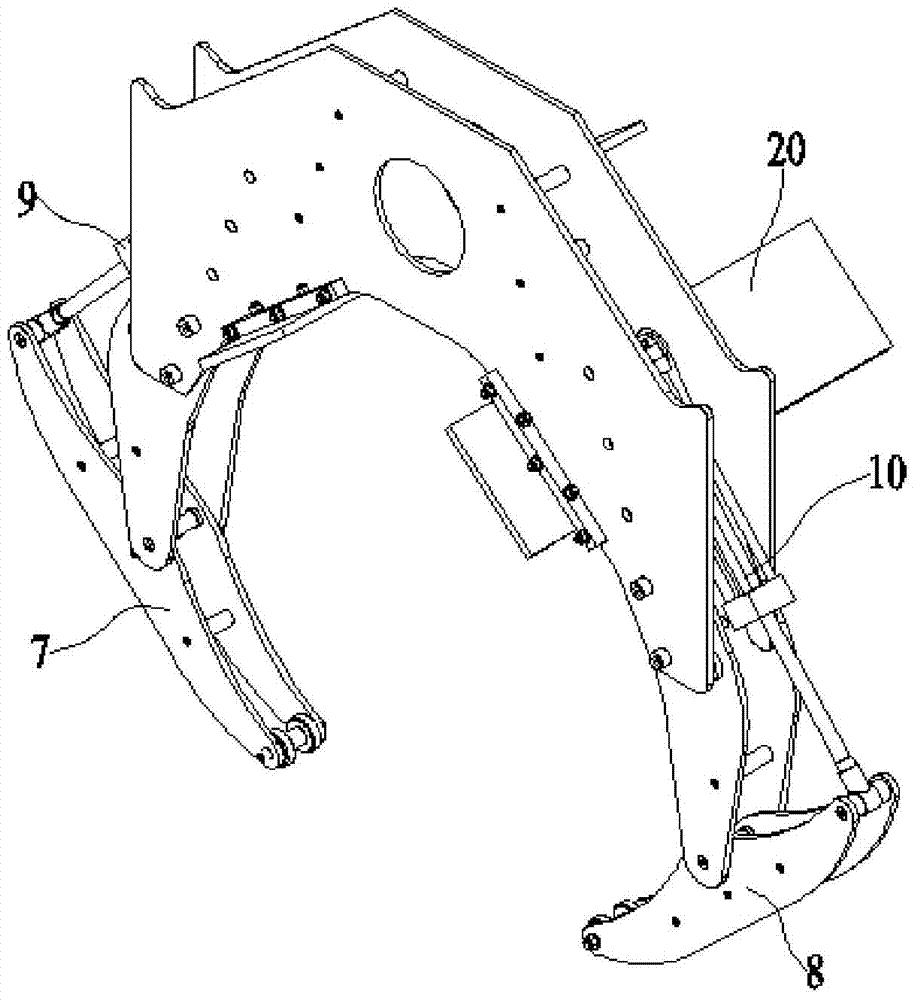

Wire saw for cutting pipelines

InactiveCN104842008AImprove reliabilityImprove stabilityMetal sawing devicesMetal sawing accessoriesHydraulic cylinderOperability

The invention discloses a wire saw for cutting pipelines. The wire saw comprises a support frame, a tension self-adaptation adjusting mechanism, a cutting mechanism and a clamping mechanism, wherein the cutting mechanism and the clamping mechanism are respectively disposed on two sides of the support frame; the clamping mechanism comprises a front clamp plate, a rear clamp plate, a left clamping jaw, a right clamping jaw, a left air cylinder and a right air cylinder, and the left air cylinder and the right air cylinder are mounted between the front clamp plate and the rear clamp plate; the cutting mechanism comprises a frame body, a drive wheel, a tension wheel and two driven wheels, the drive wheel, the tension wheel and the two driven wheels are respectively located at four corners of the frame body, an adjusting telescopic support rod is disposed between the other end corner of a main support and the frame body, and the tension self-adaptation adjusting mechanism is disposed between the other end corner of a driven support and the frame body; the tension self-adaptation adjusting mechanism further comprises a connecting shaft sleeve, a movable pin, a connecting plate, a slide plate, a hydraulic cylinder and loop bar, and a spring sleeves the loop bar. The wire saw has the advantages that the wire saw is high in reliability, stability, safety and universality and simple to operate, work stability is increased, the requirements of various pipelines can be met, the universality and operability of the wire saw are increased.

Owner:苏州博合雅工程材料科技有限公司

String instruments

A stringed instrument including an arm extending besides the strings from the body to the headstock such that said arm supports the tensions of the tuned strings, thereby eliminating the need for a neck to support this tension, and allowing for the use of fingerboards of a wide range of shapes which greatly improves ergonomic properties of the instrument.

Owner:STARR JONATHAN

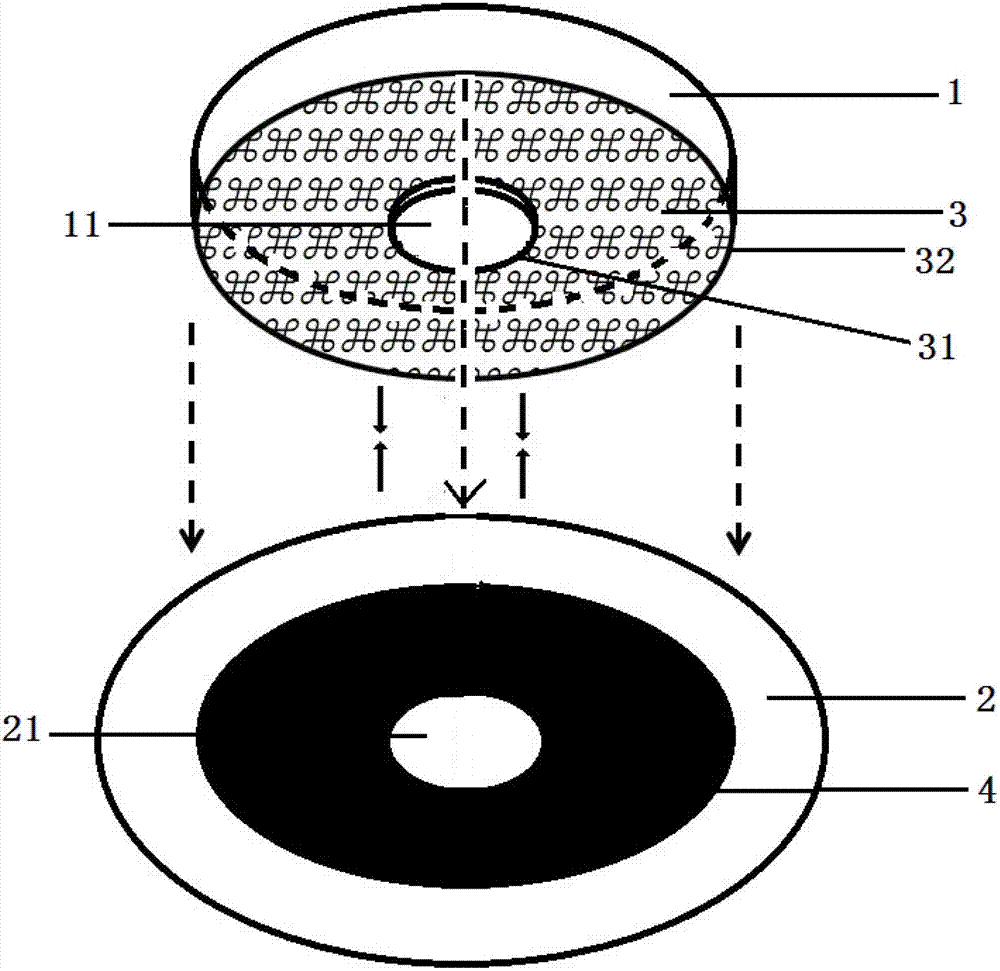

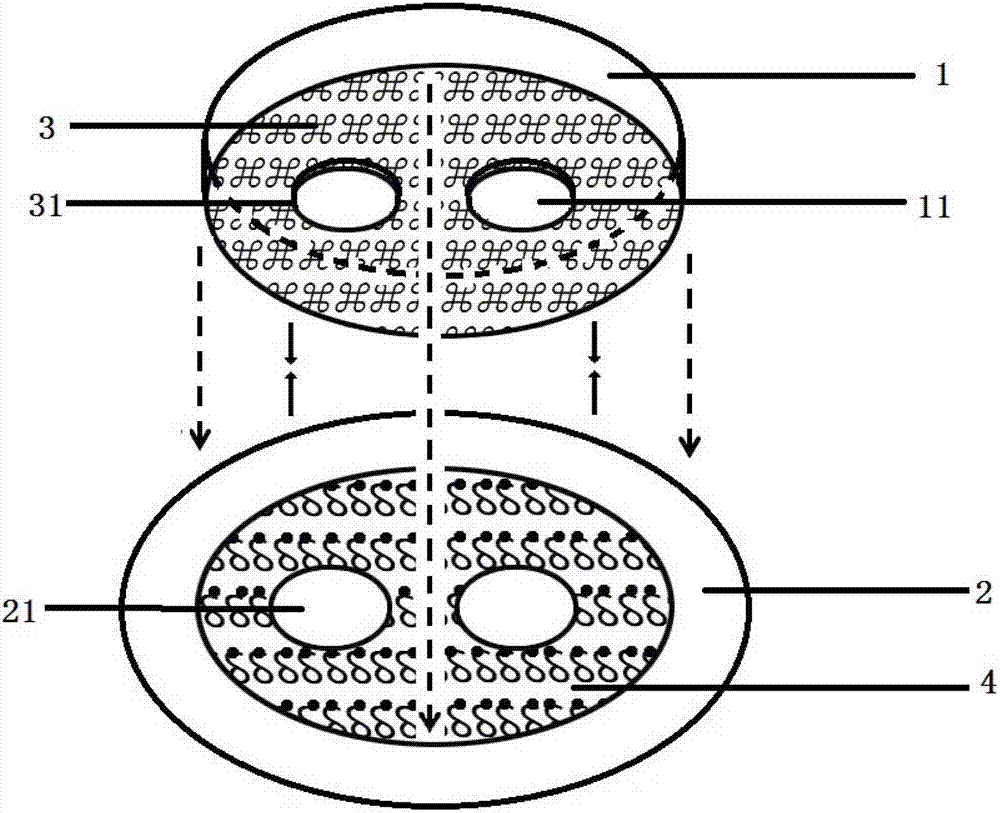

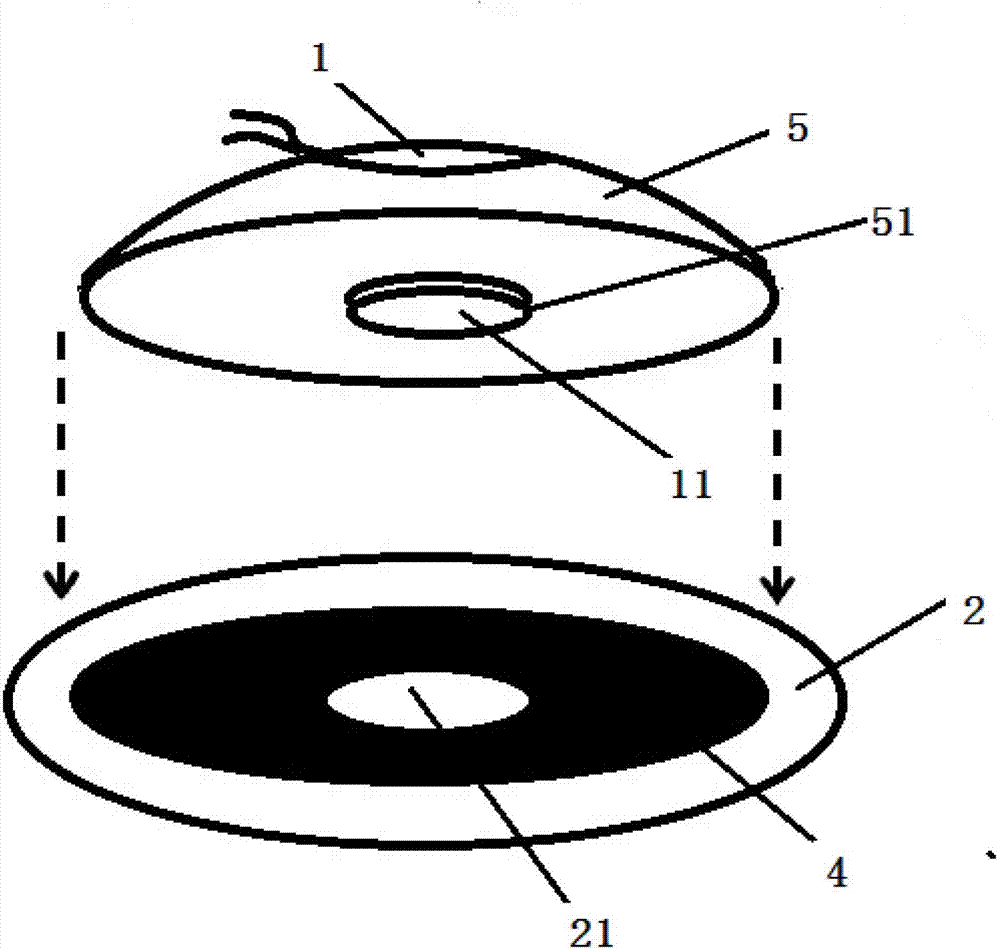

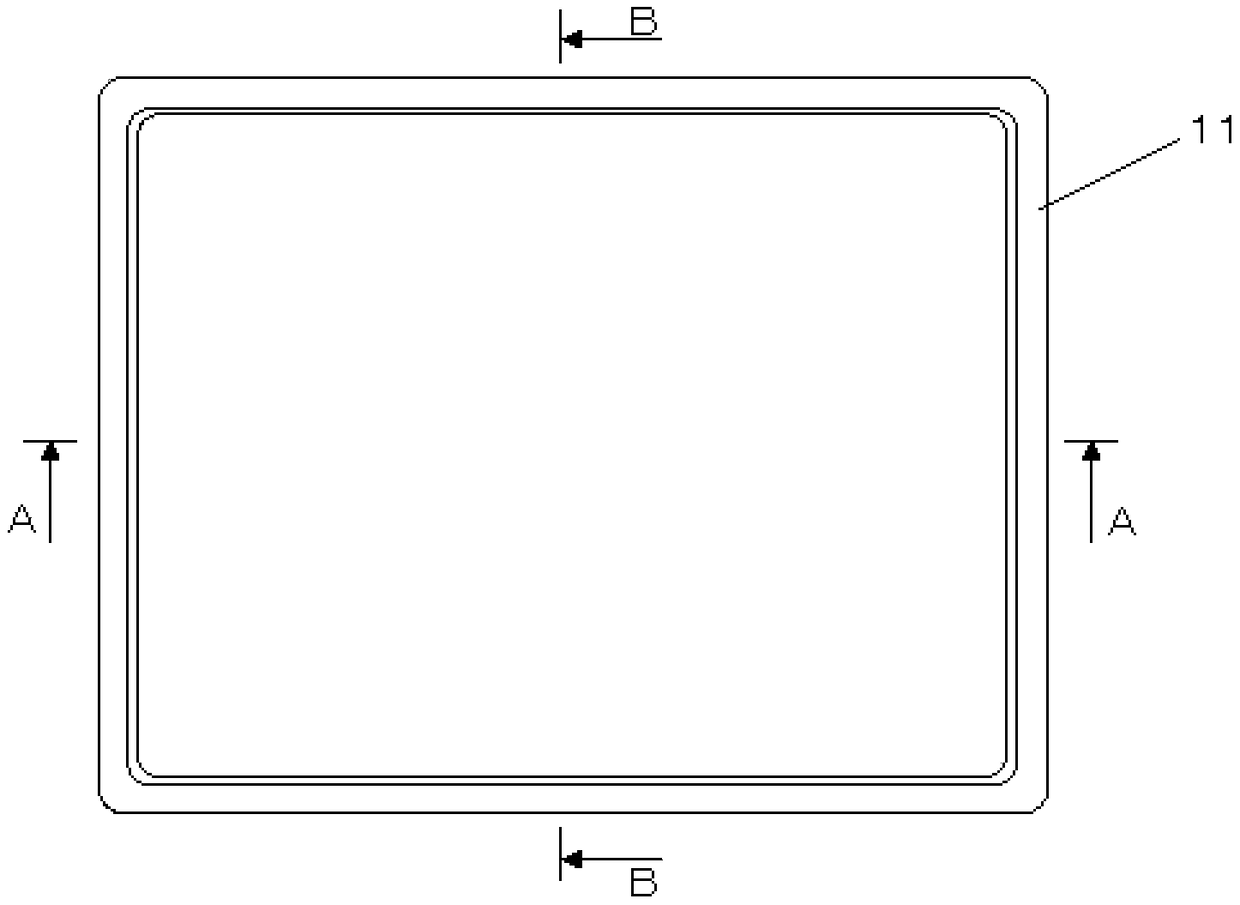

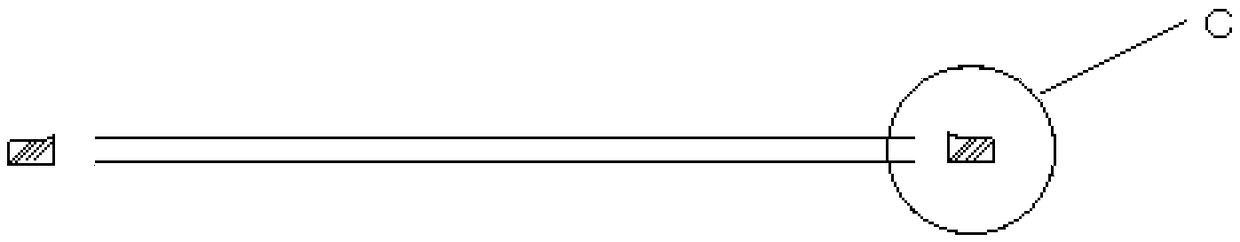

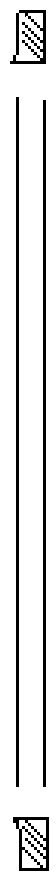

Pellicle member frame and pellicle member

PendingCN109388017ANo tensionGood lookingOriginals for photomechanical treatmentEngineeringMechanical engineering

An object of the present invention to provide a pellicle member frame capable of preventing a pellicle from being tightened due to the fact that an inner edge portion of an adhesive layer on the pellicle member frame is a curved surface when viewed from a cross section, and a pellicle member having a pellicle with an excellent appearance and without tightening. The present invention relates to a frame-shaped pellicle member frame which is arranged on a surface of the pellicle and has an inclined surface that descends from an inner edge side to an outer edge side, wherein a flat surface is arranged from an outer edge side end of the inclined surface to an outer edge of a surface provided with a pellicle. Further, the present invention provides a pellicle member, wherein an adhesive layer isarranged on the inclined surface and the flat surface on a surface provided with the pellicle on the pellicle member frame, and the pellicle is arranged on the adhesive layer.

Owner:SHIN ETSU CHEM IND CO LTD

A horizontal negative stiffness device with vertical shock absorption function

ActiveCN106968499BIncrease stiffnessReduce stiffnessProtective buildings/sheltersShock proofingDamping functionNegative stiffness

The invention relates to a horizontal negative stiffness device with a vertical damping function. The horizontal negative stiffness device comprises a spherical hinge upper connecting plate, a spherical hinge lower connecting plate, a spherical hinge, an arched spherical face, pre-pressing disc springs, viscous dampers, limiting rods, a bearing base, nuts and inside hexagonal bolts; the spherical hinge upper connecting plate and the spherical hinge lower connecting plate are fixedly connected through the inside hexagonal bolts, and the spherical hinge is embedded into the spherical hinge lower connecting plate for fixation and makes contact with the arched spherical face in a pressure-bearing mode; the upper portions of the pre-pressing disc springs are in welding connection with the arched spherical face, and the lower portions of the pre-pressing disc springs are in welding connection with the bearing base. The viscous dampers are arranged at the internal diameters of the pre-pressing disc springs, the upper portions of the viscous dampers are in welding connection with the arched spherical face, and the lower portions of the viscous dampers are in welding connection with the bearing base. The viscous dampers and the pre-pressing disc springs cooperatively work, and meanwhile negative stiffness and damping force are generated; and the limiting rods are connected with the arched spherical face and the bearing base through the nuts, the pre-pressing states of the disc springs are achieved, and the limiting rods are symmetrically arranged on the two sides of the arched spherical face.

Owner:SHANGHAI UNIV

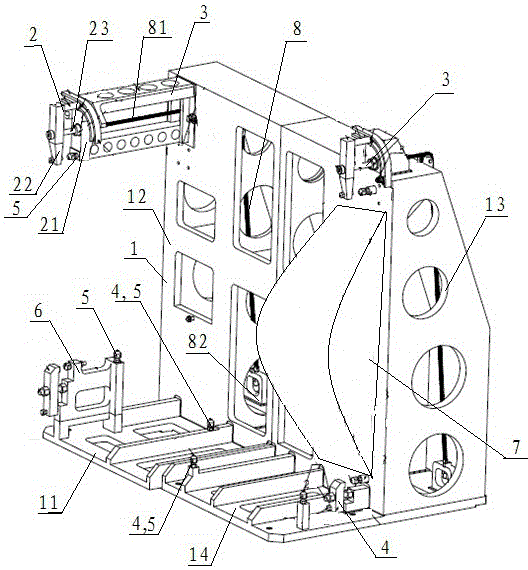

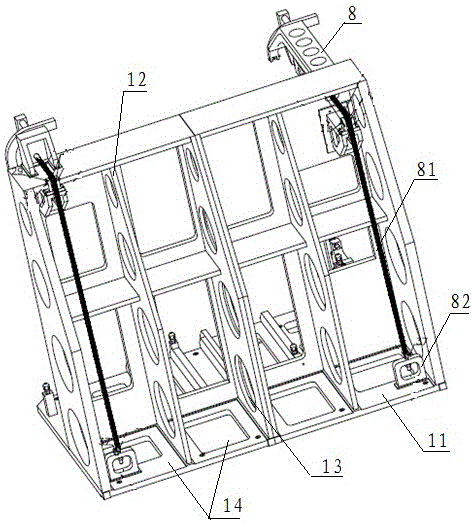

Multi-hole, multi-plane and same-direction finish machining fixture for large castings

ActiveCN105058081AEasy to adjustHigh degree of automationPositioning apparatusMetal-working holdersMachined surfaceEngineering

The invention discloses a multi-hole, multi-plane and same-direction finish machining fixture for large castings. The fixture comprises multiple L-shaped brackets connected in parallel, wherein the horizontal parts of all the L-shaped brackets are connected, and are provided with upward horizontal support projections; the vertical parts of all the L-shaped brackets are backwards projected to form vertical reinforcing ribs; multiple lower and upper support bases are respectively arranged on the horizontal projections of the L-shaped brackets and the vertical reinforcing ribs near the top positions; each lower support base is connected with parts to be machined through a net-shaped bracket; each upper support base is connected with the parts to be machined through a clamping device; at least one clamping device is connected with a single linkage clamping mechanism; and each single linkage clamping mechanism comprises chains for tensioning and transmission. The fixture is accurate in positioning, improves the workpiece machined surface smoothness, the machining size precision and the automation degree, and shortens the machining period.

Owner:ANHUI YONGCHENG MACHINERY

Processing method for instant green tea powder

InactiveCN106035809AReduce usageLow costPre-extraction tea treatmentTea extractionNutrient solutionGreen tea

The invention relates to the field of agriculture product processing and specifically relates to a processing method for instant green tea powder. The method comprises the following steps: (1) preparing materials; (2) integrally killing out and crushing; (3) extracting a nutrient solution; (4) filtering; (5) concentrating; (6) forming; and (7) drying. The processing method provided by the invention has a good crushing effect and has the effect of keeping the original tea taste.

Owner:GUIZHOU PROVINCE FENGGANG COUNTY WANWU AGRI TECH DEV CO LTD

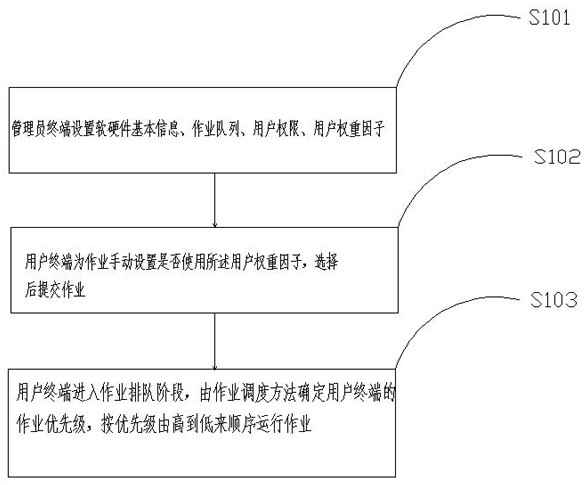

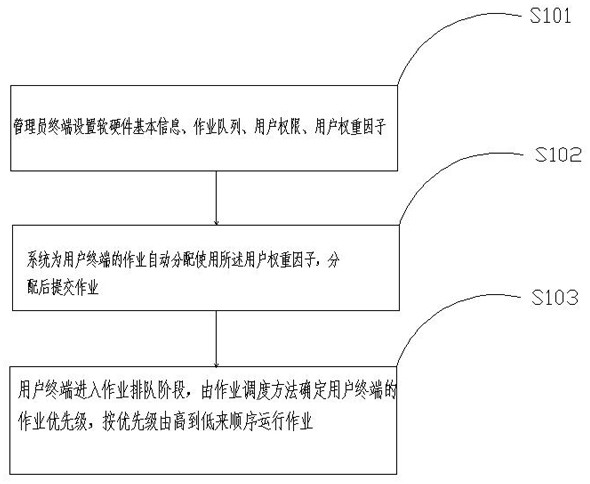

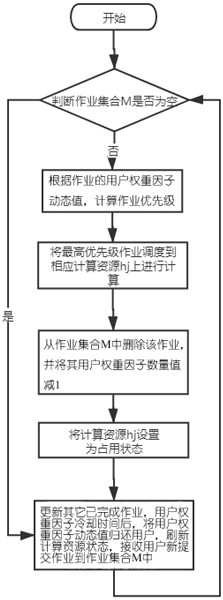

Job scheduling method and system based on high response ratio, terminal and storage medium

ActiveCN113254179ANo tensionAvoid repeated useProgram initiation/switchingOperation schedulingDistributed computing

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

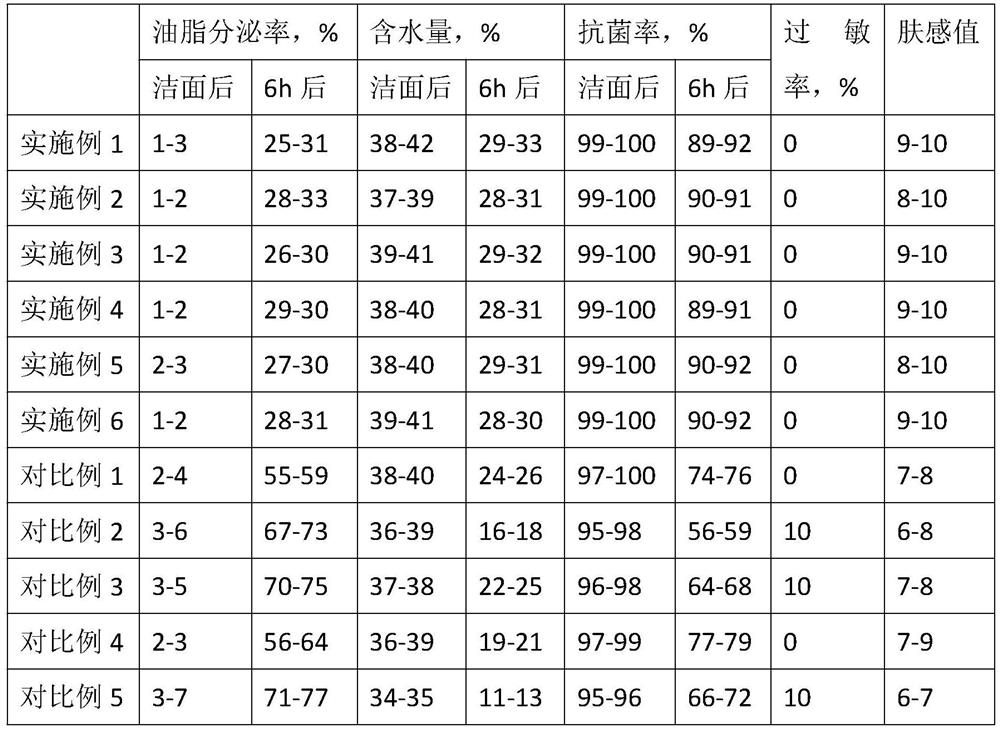

Antibacterial facial cleanser with strong oil control and preparation method thereof

InactiveCN112022770AStrong coating stabilityStrong cleaning effectCosmetic preparationsToilet preparationsUreaGlycerol

The invention provides an antibacterial facial cleanser with strong oil control and a preparation method thereof. The facial cleanser comprises the following components in percentage by mass: 3.5-5% of plant source doped modified mesoporous particles, 15-25% of cyclodextrin doped nano silica sol, 3-8% of glycerin, 2-4% of octadecanol, 0.5-1% of urea, 0.5-1% of lecithin, 0.5-0.8% of chitosan oligosaccharide and the balance distilled water. According to the antibacterial facial cleanser with strong oil control and the preparation method thereof, the raw materials are reasonably selected and matched, the compatibility is optimized, the active ingredients are pretreated, activated and loaded, and an outer permeation layer is flexibly coated, so that the skin-friendly and oil-removing effects during face cleaning are effectively guaranteed, the formed cream is high in loading and coating stability, the effective rate of adsorption and carrying of grease and dust is remarkably improved except the water-soluble release of the effective ingredients, the cleaning and nursing effects on the skin are high, and the comprehensive cost performance is high.

Owner:南京宜薇安化妆品科技有限公司

Automatic paper sheet paging device for teaching

InactiveCN110950114AGuaranteed stability and firmnessSimple structureArticle separationPaper sheetControl trunk

The invention discloses an automatic paper sheet paging device for teaching. The automatic paper sheet paging device for teaching comprises a machine frame, a paging mechanism and a transporting mechanism, wherein the paging mechanism comprises an operating platform, a rolling module which is arranged on the operating platform and used for enabling paper sheets to move at a uniform speed on the operating platform, and a speed adjusting module which is arranged on the operating platform and used for enabling the paper sheets to move at a variable speed on the operating platform; the transporting mechanism comprises a transporting platform which is connected with the operating platform, wherein the transporting platform comprises a driving pulley and a driven pulley which are located at twoends of the transporting platform, and a conveyor belt which is arranged on the external peripheral walls of the driving pulley and the driven pulley in a sleeving manner; a material collecting assembly which is used for collecting paper sheets is arranged at one end of the transporting platform; a supporting assembly which is used for supporting the transporting platform and the operating platform is arranged at the lower end of the transporting platform; and a control box which is used for controlling the paging mechanism and the transporting mechanism is arranged on the operating platform.The automatic paper sheet paging device for teaching disclosed by the invention is simple in structure, convenient to use and high in paging efficiency, and a paper sheet repeating phenomenon cannotappear.

Owner:上栗县金山镇中学

Brake

InactiveCN101434232AEasy to operateNo tensionBraking element arrangementsHand actuated initiationsEngineeringCam

A brake relates to the structure improvement of automobile brakes and aims at replacing the imperfect structure of the existing manual brakes of automobiles. The main structural feature of the invention lies in that a brake drum (18) which is arranged in a box body (21) and provided with the diameter corresponding to an output shaft (23) of a gear box (24), a bearing frame (16), an isolator (17), the bearing frame (16) and a shield cover (10) are connected sequentially and fixed through bolts (12); a stop hoof (20) of the brake drum (18) corresponds to a cam (19) on a crank (22) of the box body (21); the crank is provided with a flexible shaft (26) which can be connected with a control lever (27); a clutch (9) is arranged on the side of the bearing frame (16) under the shield cover (10); a transmission fork (1) is arranged between a chute (5) of the clutch (9) and a bracket (4) of the box (21) and a spring (3) is arranged between the transmission fork (1) and the shield cover (10); and the other end of the transmission fork (1) is provided with a pull wire (25) which can be connected with the control lever (27).

Owner:沈阳昂立信息技术有限公司

Conveying belt tensioning device used for workshop and having sweeping function

The invention discloses a conveyor belt tensioning device for belt cleaning in a workshop, which comprises a conveyor belt and two conveying support rods, a vertical rod perpendicular to it is arranged on the middle part of the horizontal plate, and a support plate is arranged on the top of the vertical rod , the end surface of the support plate is provided with a tensioning bracket, and the tensioning bracket is provided with two horizontal shafts, the two horizontal shafts are respectively located on both sides of the conveyor belt, and tensioning wheels are installed on the two horizontal shafts, so Two symmetrical cleaning rods are also arranged on the end surface of the support plate, a mounting plate is arranged on the top of the cleaning rod, a cleaning brush is arranged on the mounting plate, a rotating shaft is arranged between the two side plates, and a rotating shaft is arranged on the rotating shaft. A cam is installed, and the vertical rod passes through the through hole on the horizontal plate and is connected with the edge of the cam through a sliding mechanism, and one end of the rotating shaft is provided with a rotating mechanism. The invention has a simple structure, can clean the conveyor belt while tensioning the conveyor belt, has simple operation, is driven without power, can save energy, and has strong practicability.

Owner:金波

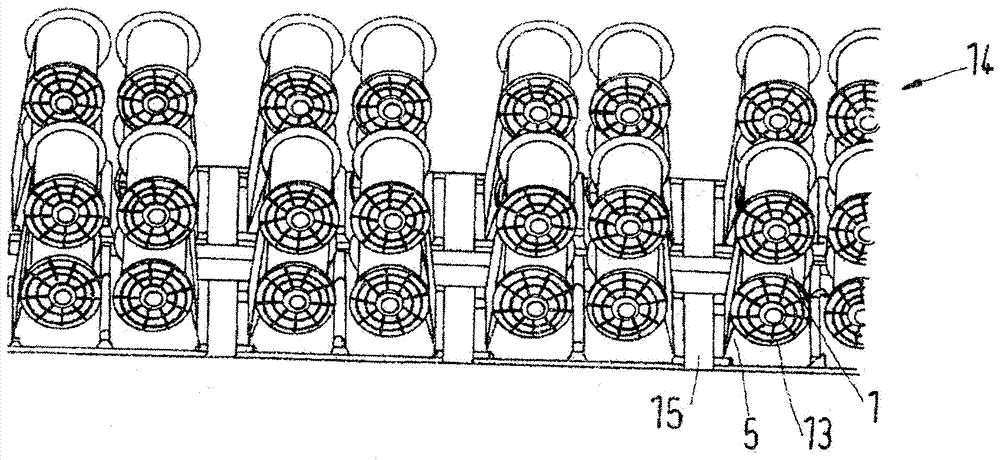

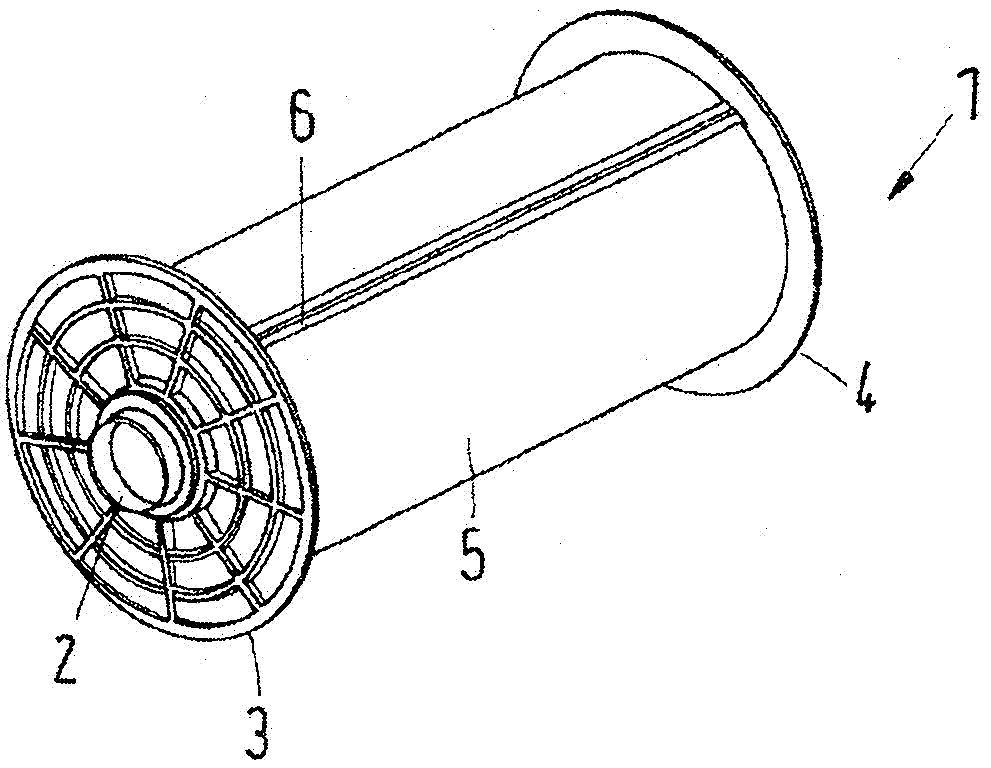

Sectional warp beam and creel of assembling device

ActiveCN106978660ASimple structureEasy to operateFilament handlingCreelsEngineeringMechanical engineering

Owner:KARL MAYER ROTAL SRL

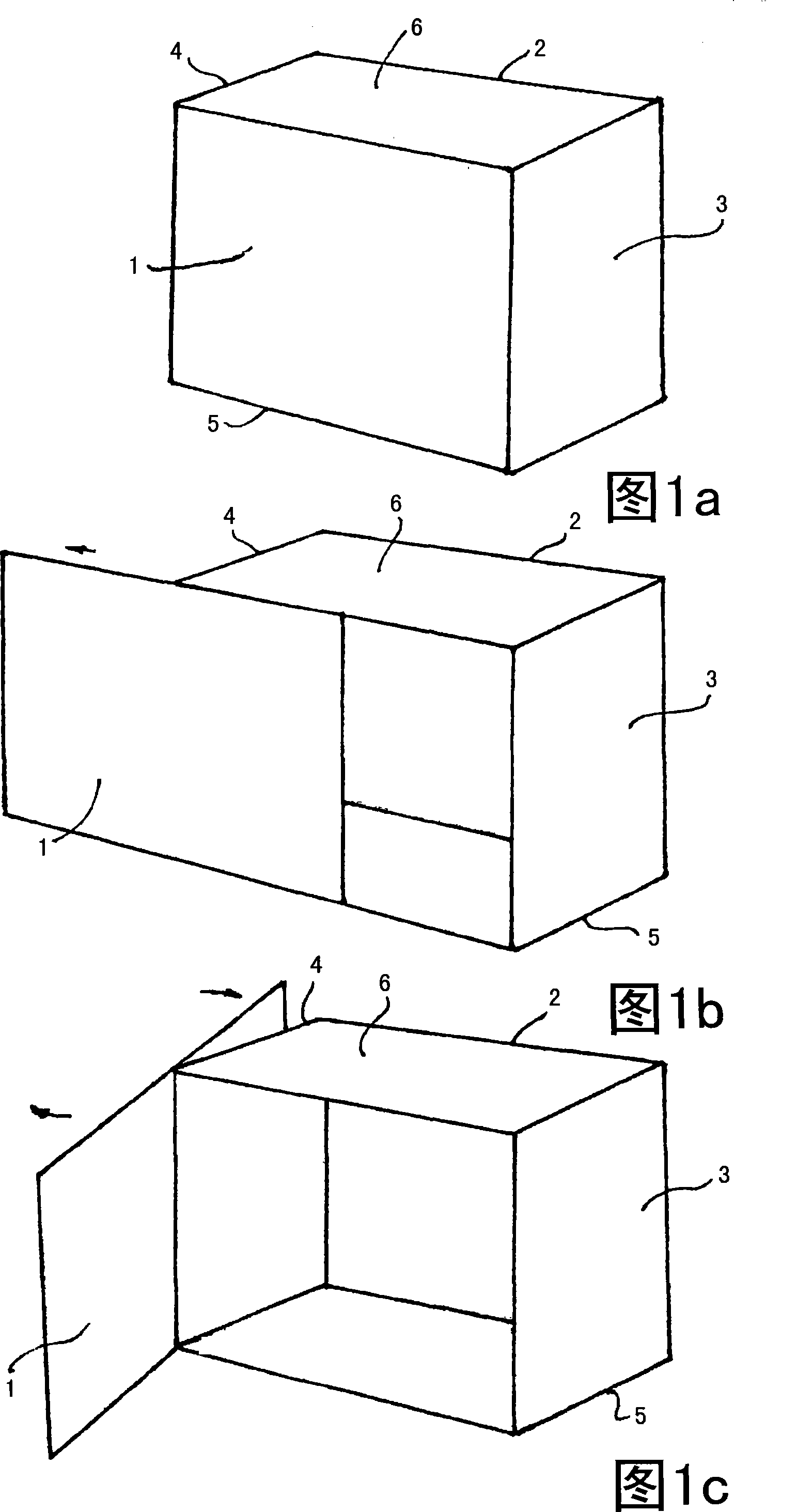

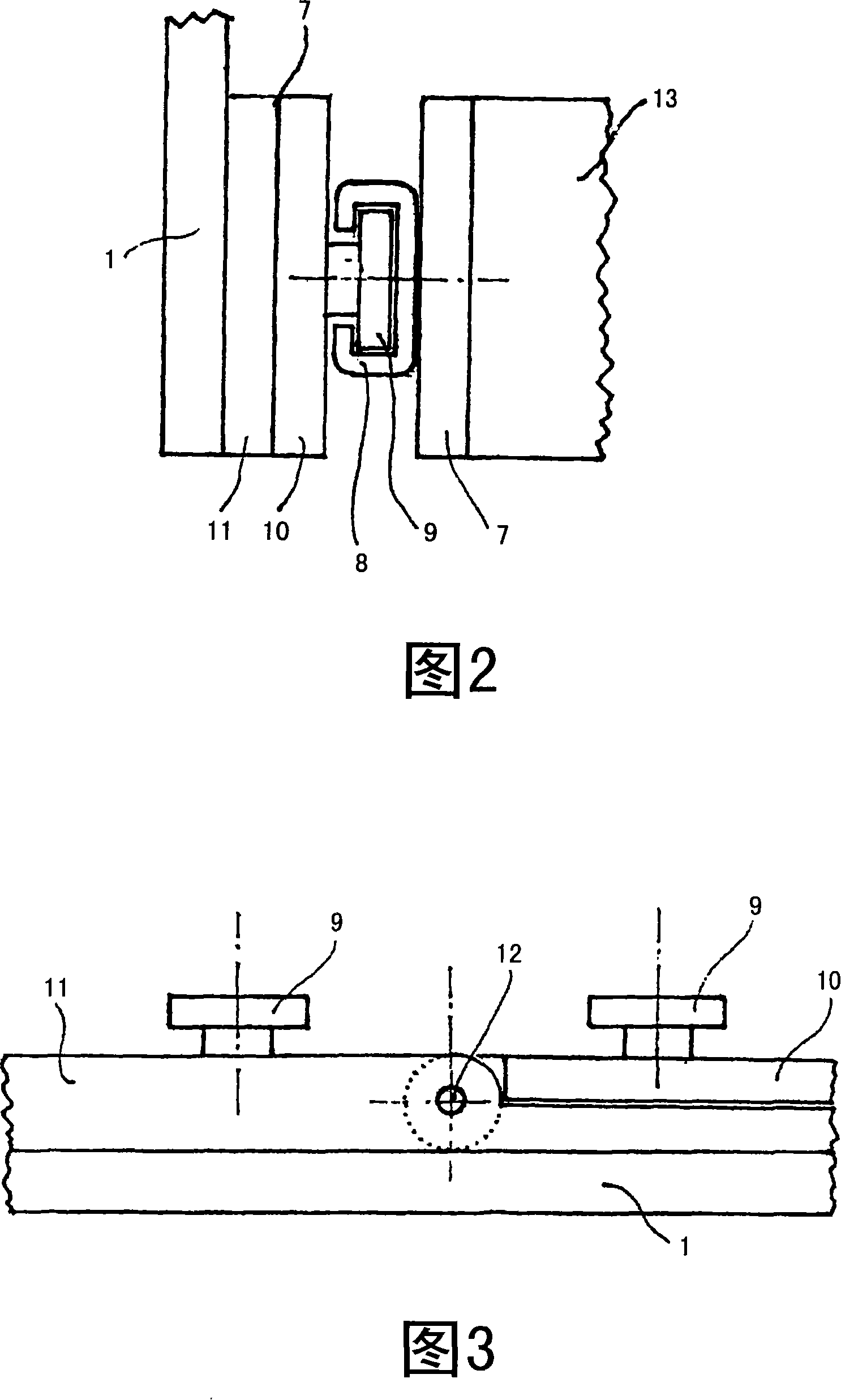

Glass cabinet for storage and/or display of objects

InactiveCN101166448BReduce layoutNo stability issuesShow cabinetsWing suspension devicesEngineeringDisplay cabinet

The display cabinet has a door (1) which is mounted on rollers (9). These slide in C-profile rails at the top and bottom and the door is fitted with hinges (12) which allow it to swivel so that it rests against the side of the cabinet when it reaches its end position.

Owner:GLASBAU HAHN

Moisturizing and nourishing smoothing toner for pregnant women and preparation method thereof

InactiveCN108451831AIncrease supplementGood moisturizing effectCosmetic preparationsToilet preparationsFacial skinWrinkle skin

The invention discloses moisturizing and nourishing smoothing toner for pregnant women. The moisturizing and nourishing smoothing toner is prepared from the following raw materials in parts by weight:1 to 8 parts of dipropylene glycol, 0.1 to 1 part of a tamarind seed extract, 0 to 10 parts of glycerinum, 0.02 to 0.6 part of allantoin, 0.2 to 4 parts of lubrajel oil, 0.1 to 8 parts of a purslaneextract, 0.02 to 0.6 part of dipotassium glycyrrhizinate, totally 0.4 to 3 parts of octyl hydroxime acid, 1,2-hexanediol and 1,3-propanediol and 80 to 98 parts of water. The moisturizing and nourishing smoothing toner has the beneficial effects that the product does not contain alcohol; a strong moisturizing substance is added into the smoothing toner, so that the skin moisture can be quickly supplemented to achieve an extremely good effect of moisturizing the facial skin; the smoothing toner has effects of smoothing wrinkles on the skin, enhancing the elasticity of the skin, eliminating skintoxins and activating the skin, is irritant to the facial skin, and does not cause rubbing and tensing phenomena and the like. The product can further decompose greasy dirt on the face to prevent fatgranules and the like.

Owner:SHANDONG ZHUSHI PHARMA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com