Underwater rope saw cutting machine

A cutting machine and wire saw technology, applied in the field of underwater wire saw cutting machines, can solve the problems of uneven force on the feeding mechanism, limited underwater working depth, and unadjustable speed, and achieve strong practical value and safety guarantee. , moving simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

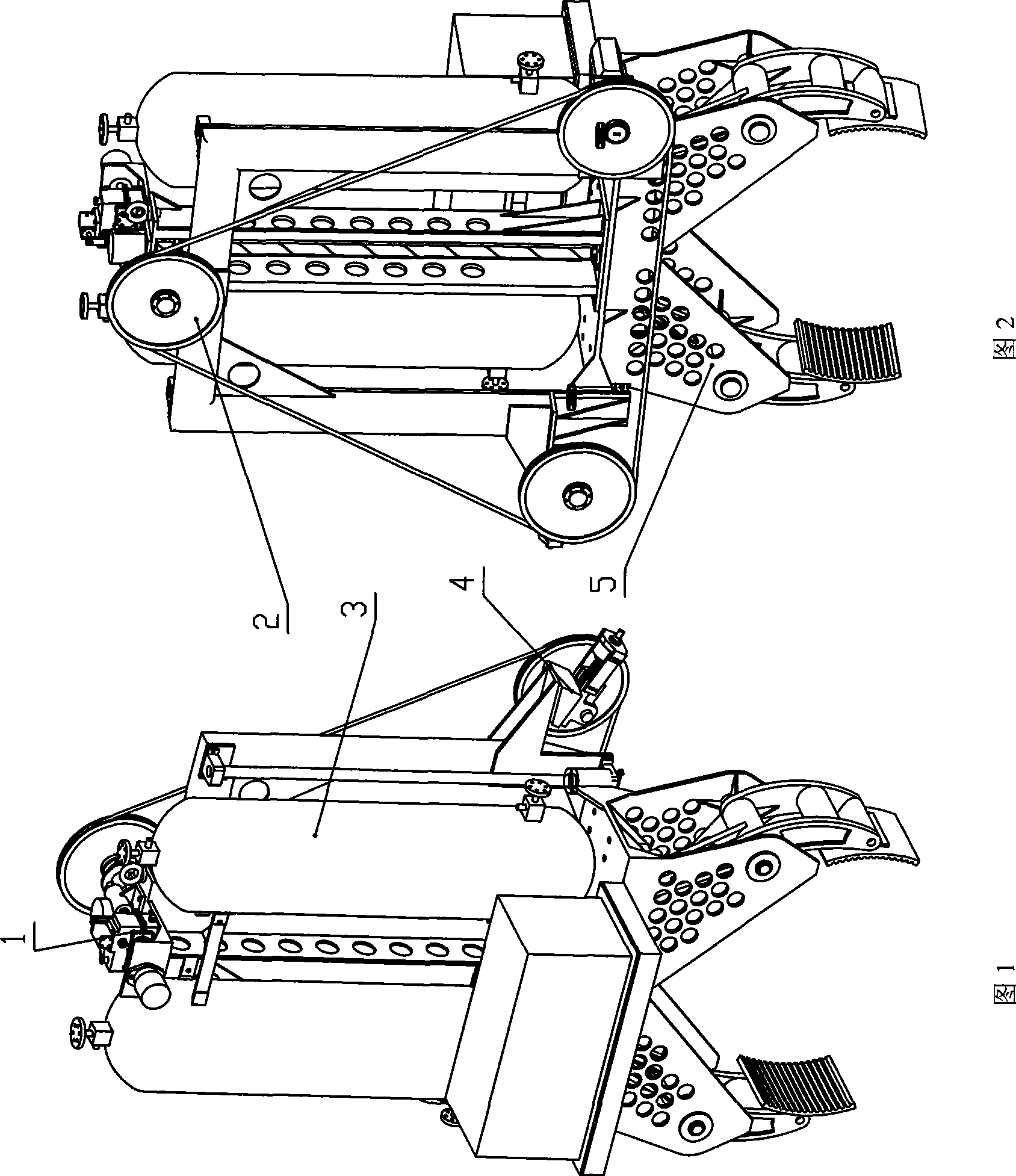

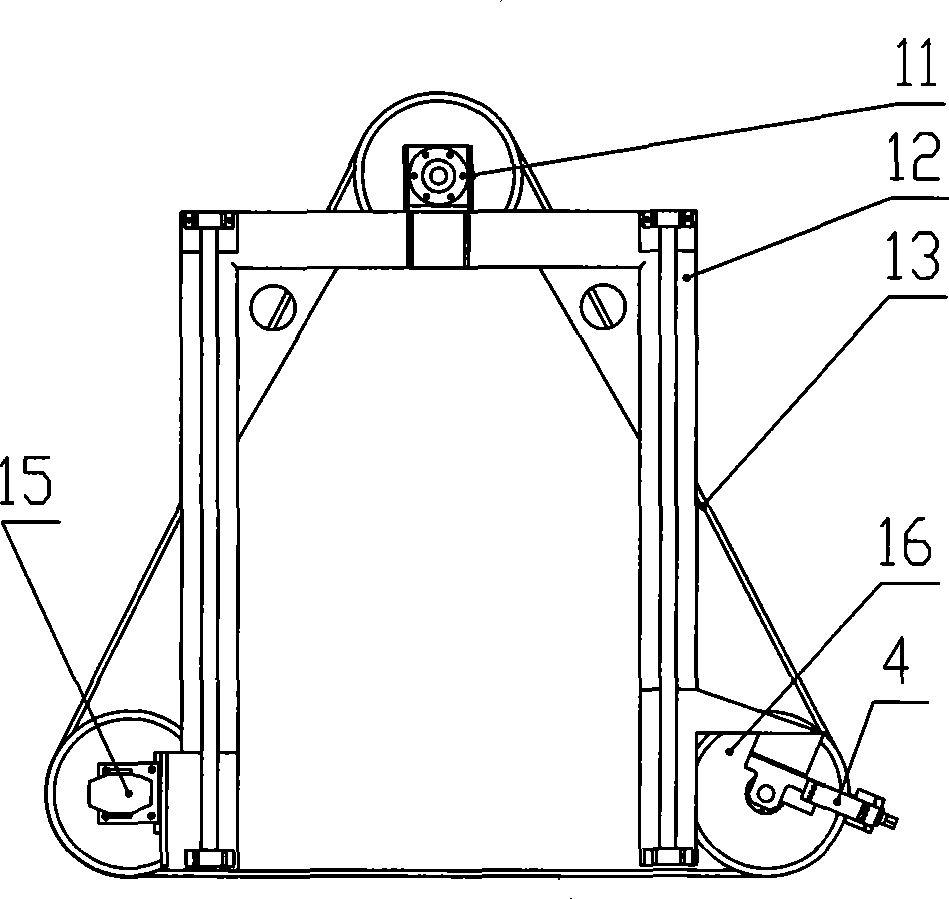

[0025] Combining Figure 1 and Figure 2, in the composition of the underwater wire saw cutting machine, 1 is the feeding device, 2 is the cutting mechanism, 3 is the buoy, 4 is the tensioning device, and 5 is the clamping device. When it works, the tensioning device 4 first tensions the diamond rope, and then the underwater pipeline is clamped by the clamping device 5. At this time, the feeding device 1 drives the cutting mechanism 2 to move downward until the entire pipeline is cut. Wherein the buoy 3 can carry out buoyancy adjustment by opening the valve and entering water.

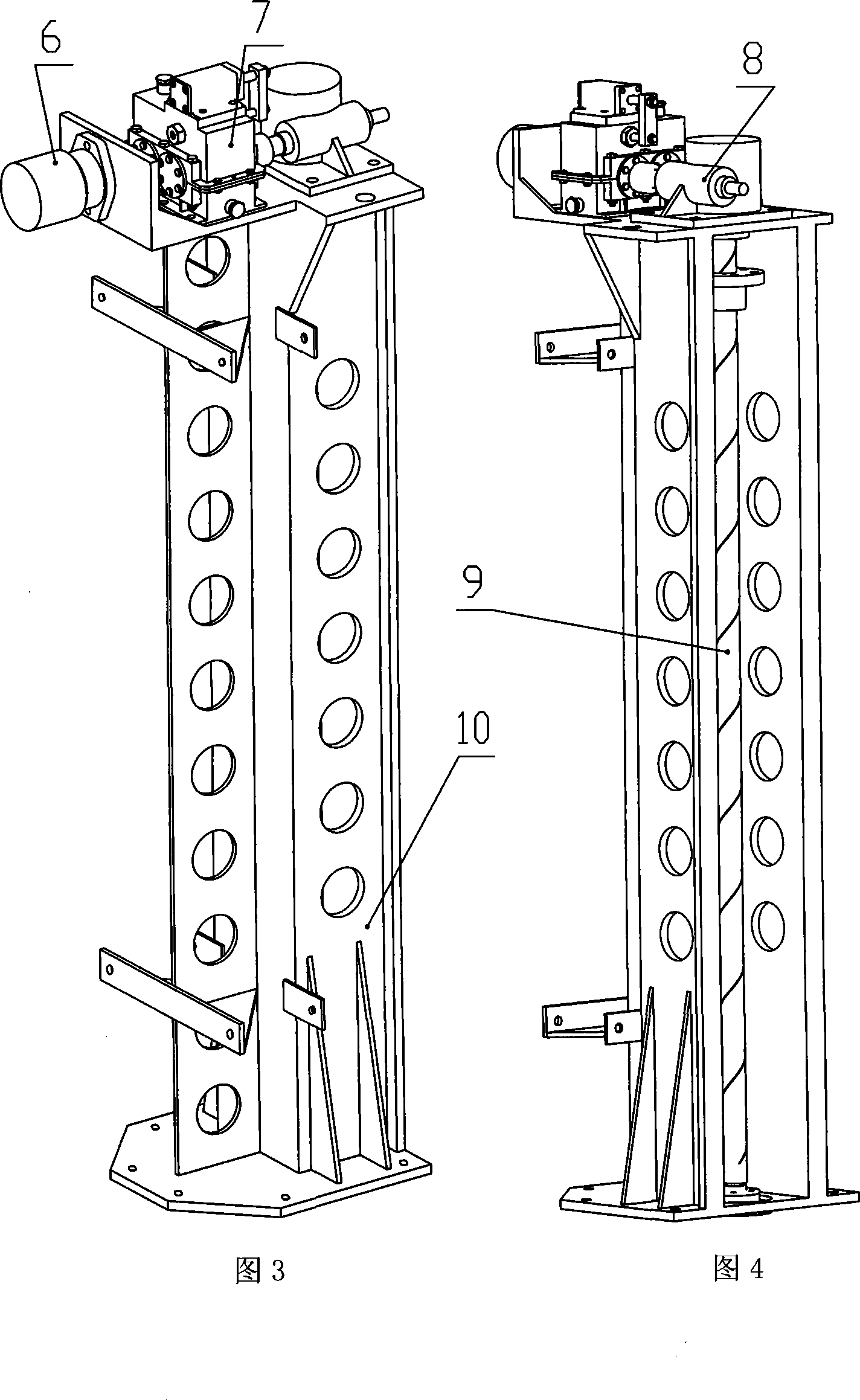

[0026] Combining 3 and Fig. 4, 6 is a hydraulic motor in the composition of the feeding device, 7 is a transmission, 8 is a worm gear screw lifter, 9 is a lead screw, and 10 is a fixed bracket. When it works, the hydraulic motor 6 rotates and outputs to the transmission 7 and then to the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com