Combined tool clamp for automobile door ring laser tailor-welded plates

A technology of laser tailor welding and fixtures, which is applied in laser welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of affecting the mechanical properties of the weld, affecting the chemical composition of the weld metal, and not having adjustment, so as to shorten the production cycle , strong general purpose, the effect of meeting welding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

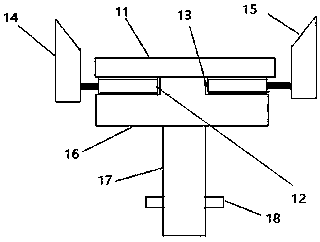

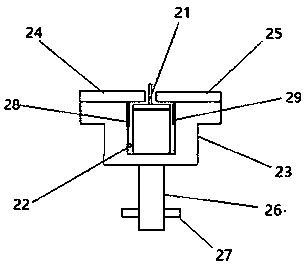

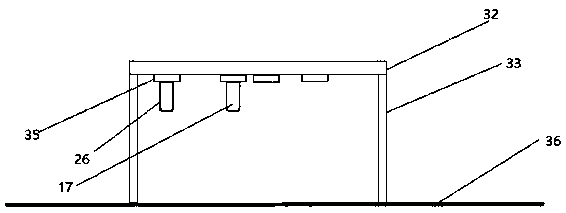

[0044] Please see attached figure 1 to attach Figure 5 , the automobile door knocker sheet material of present embodiment welding comprises the first steel plate 41 that thickness is 1.5mm, the second steel plate 42 that thickness is 1.8mm, the third steel plate 43 that thickness is 2.4mm, the fourth steel plate 44 that thickness is 1.4mm And the fifth steel plate 45 with a thickness of 1.1 mm, the steel plate is aluminum-silicon coated hot-formed steel; 9 sets of fixed chuck assemblies 10 and 5 sets of gap adjustment chuck assemblies 20 are used, and they are installed on the base plate 31 according to the positions of the round holes 34 , so that the fixed chuck assembly 10 is located at the two ends or the middle of the steel plate, and plays the role of fixing and positioning the steel plate. The gap adjustment chuck assembly 20 is located below the welding place of two adjacent steel plates, and the thickness is increased by the third cylinder 22. The 0.2mm gap adjustin...

Embodiment 2

[0047] Please see attached figure 1 to attach Figure 5 , the automobile door knocker sheet material of present embodiment welding comprises the first steel plate 41 that thickness is 1.5mm, the second steel plate 42 that thickness is 1.8mm, the third steel plate 43 that thickness is 2.4mm, the fourth steel plate 44 that thickness is 1.4mm And the fifth steel plate 45 with a thickness of 1.1 mm, the steel plate is aluminum-silicon coated hot-formed steel; 9 sets of fixed chuck assemblies 10 and 5 sets of gap adjustment chuck assemblies 20 are used, and they are installed on the base plate 31 according to the positions of the round holes 34 , so that the fixed chuck assembly 10 is located at the two ends or the middle of the steel plate, and plays the role of fixing and positioning the steel plate. The gap adjustment chuck assembly 20 is located below the welding place of two adjacent steel plates, and the thickness is increased by the third cylinder 22. The 0.3mm gap adjustin...

Embodiment 3

[0050] Please see attached figure 1 to attach Figure 5 , the automobile door knocker sheet material of present embodiment welding comprises the first steel plate 41 that thickness is 1.5mm, the second steel plate 42 that thickness is 1.8mm, the third steel plate 43 that thickness is 2.4mm, the fourth steel plate 44 that thickness is 1.4mm And the fifth steel plate 45 with a thickness of 1.1 mm, the steel plate is aluminum-silicon coated hot-formed steel; 9 sets of fixed chuck assemblies 10 and 5 sets of gap adjustment chuck assemblies 20 are used, and they are installed on the base plate 31 according to the positions of the round holes 34 , so that the fixed chuck assembly 10 is located at the two ends or the middle of the steel plate, and plays the role of fixing and positioning the steel plate. The gap adjustment chuck assembly 20 is located below the welding place of two adjacent steel plates, and the thickness is increased by the third cylinder 22. The 0.4mm gap adjustin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com