Device for automatic material stripping and automatic Bin splitting for serial flaky LEDs

An automatic, flaky technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as error-prone, low efficiency, poor equipment compatibility, etc., and achieve the effect of reducing process requirements, improving efficiency, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

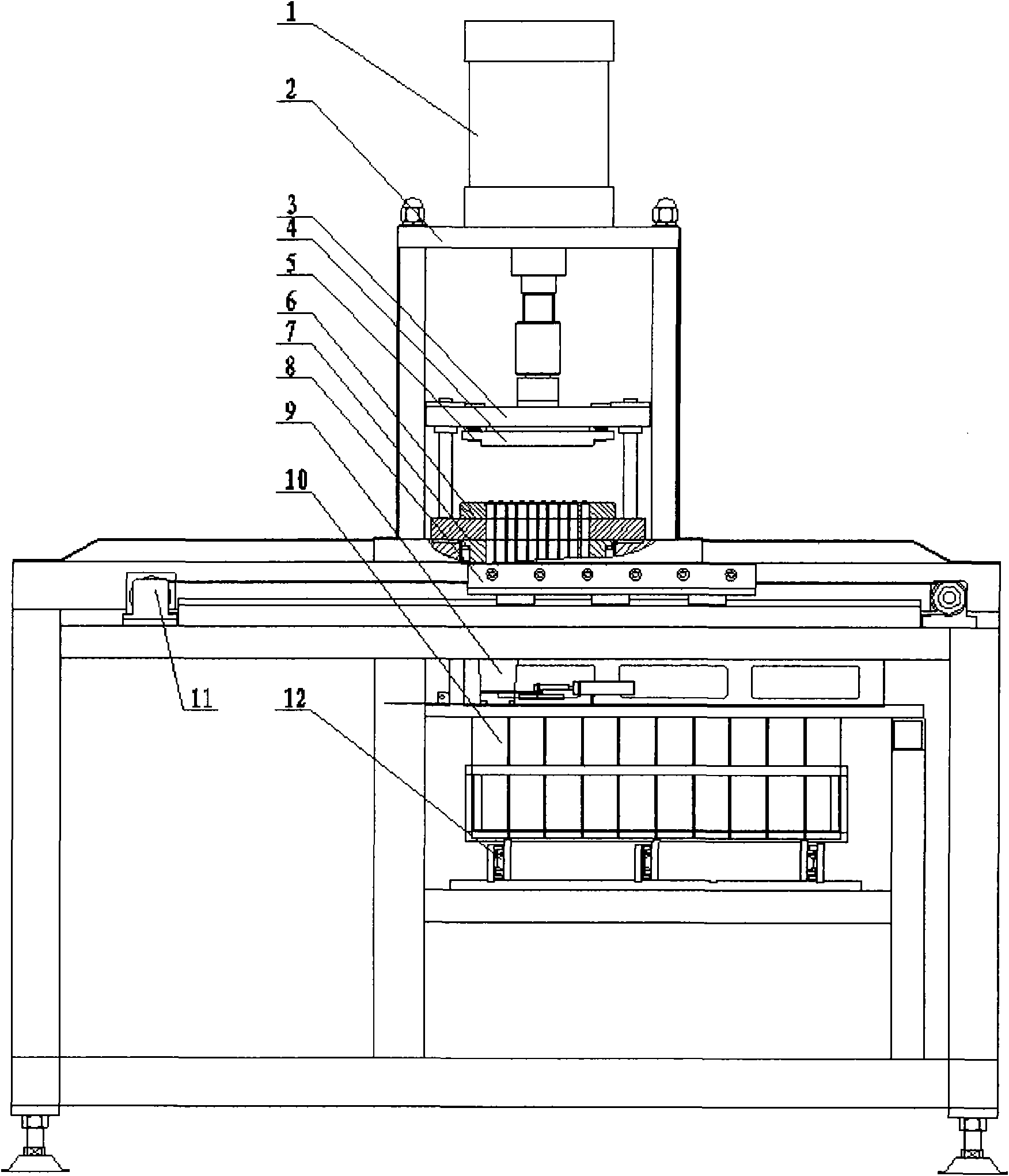

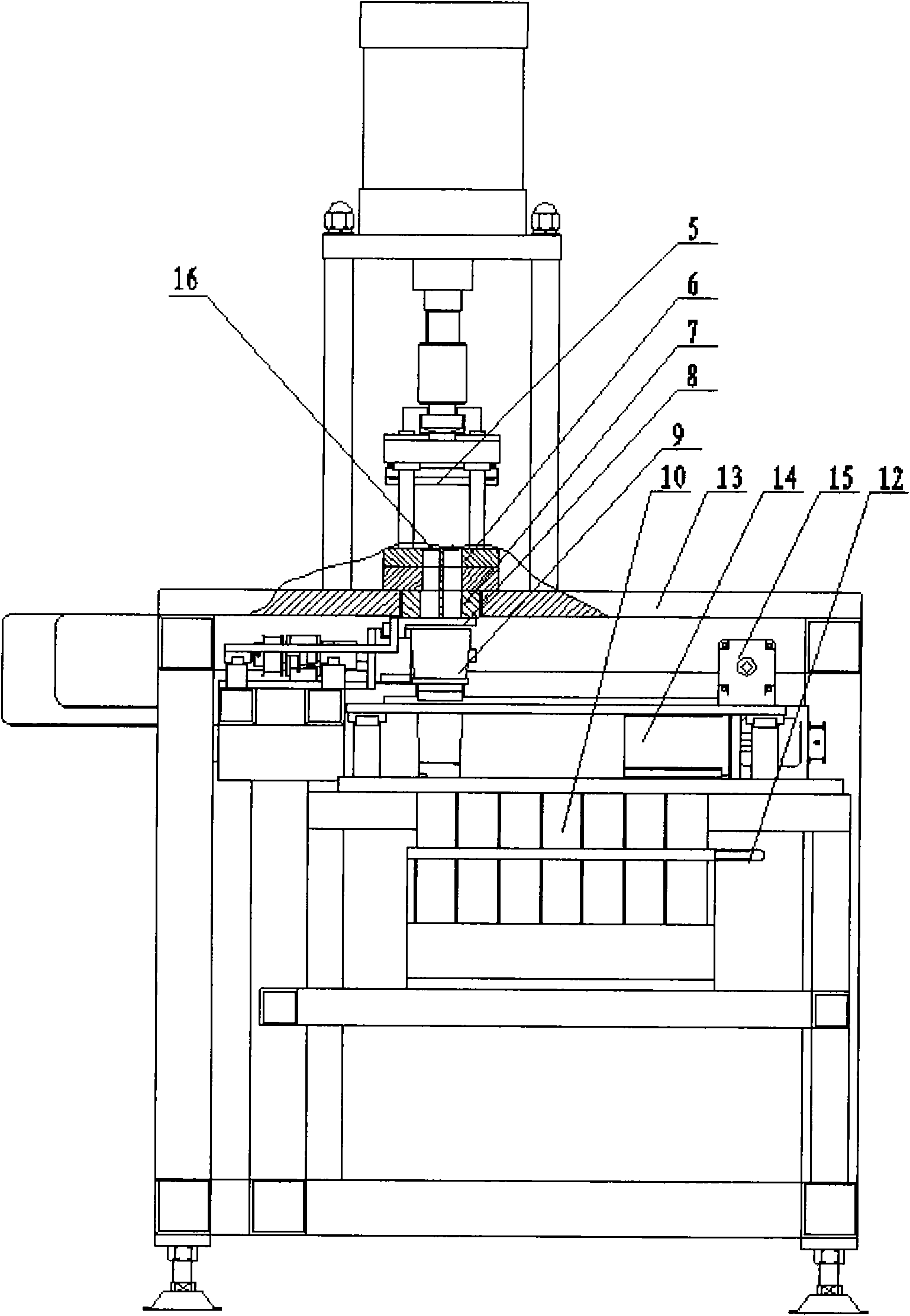

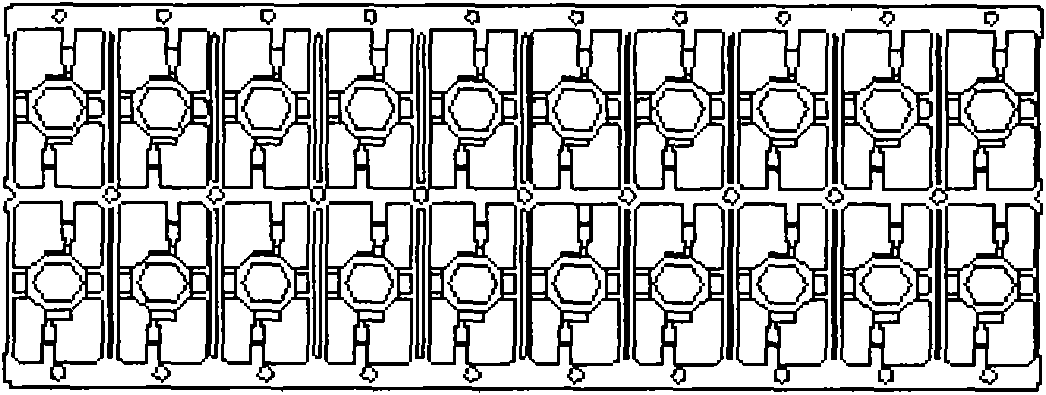

[0021] Such as figure 1 , figure 2 As shown in the structure, the row-by-row chip LED automatic stripping and binning equipment is composed of four major parts: automatic stripping mechanism, sequential discharging escapement mechanism, X / Y automatic material shifting mechanism, and sorting and collecting mechanism; pressure cylinder 1 is installed On the pressure cylinder bracket 2, the piston rod of the pressure cylinder 1 is connected with the four guide post mold base 3 through threads, the punch 4 and the blank holder 5 are located on the upper template of the mold base 3, and the die 6 is positioned on the lower side of the mold base 3 On the template, the transitional separation mold 7 is fastened to the bottom of the die 6, and the corresponding positions of the die 6, the lower formwork, and the transitional separation mold 7 are all opened with small square holes, the number of rows of small square holes and the number of holes in each row The number is determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com