High-speed four-axis winding machine

A winder, high-speed technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of poor automation and low winding efficiency of the winding unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

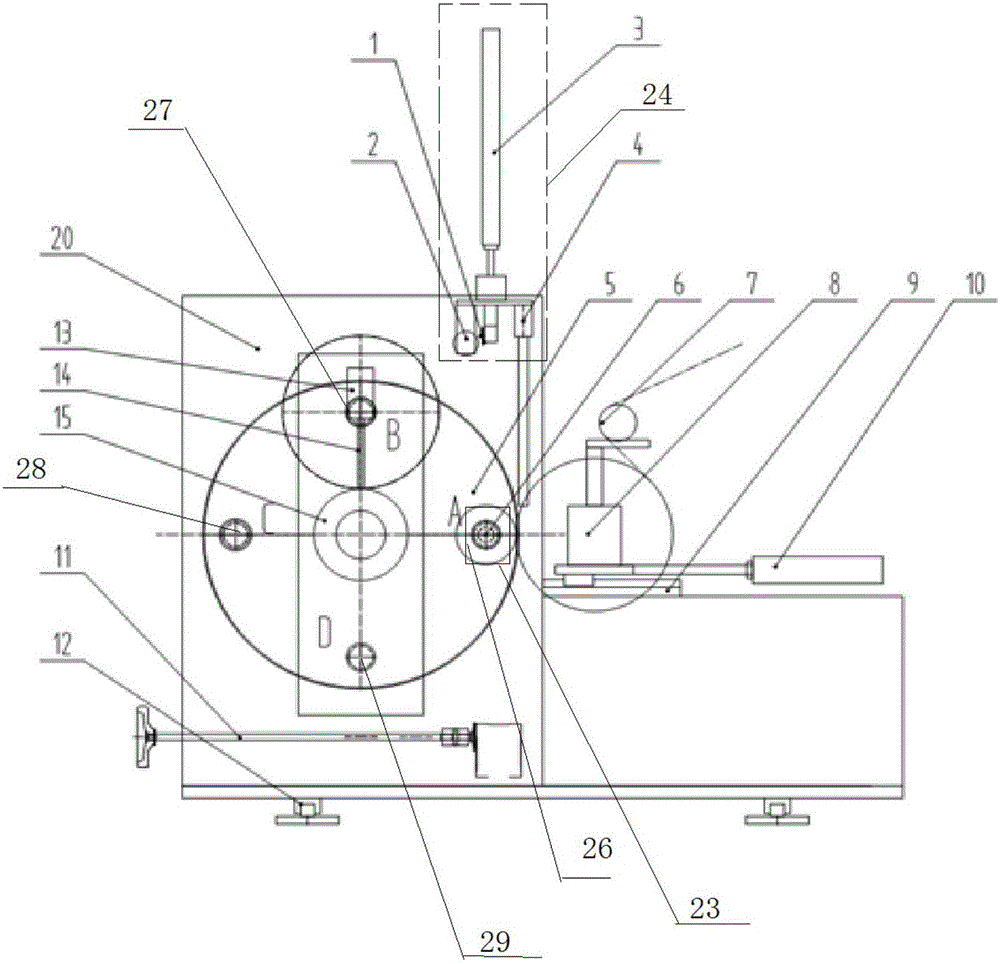

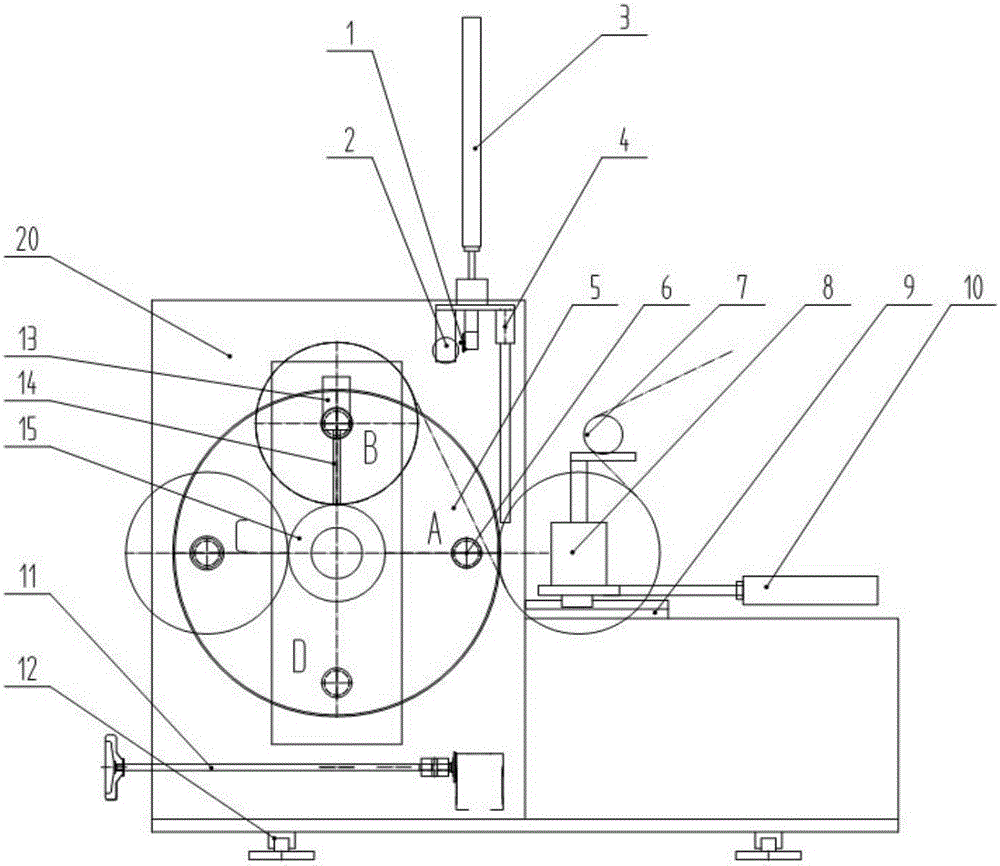

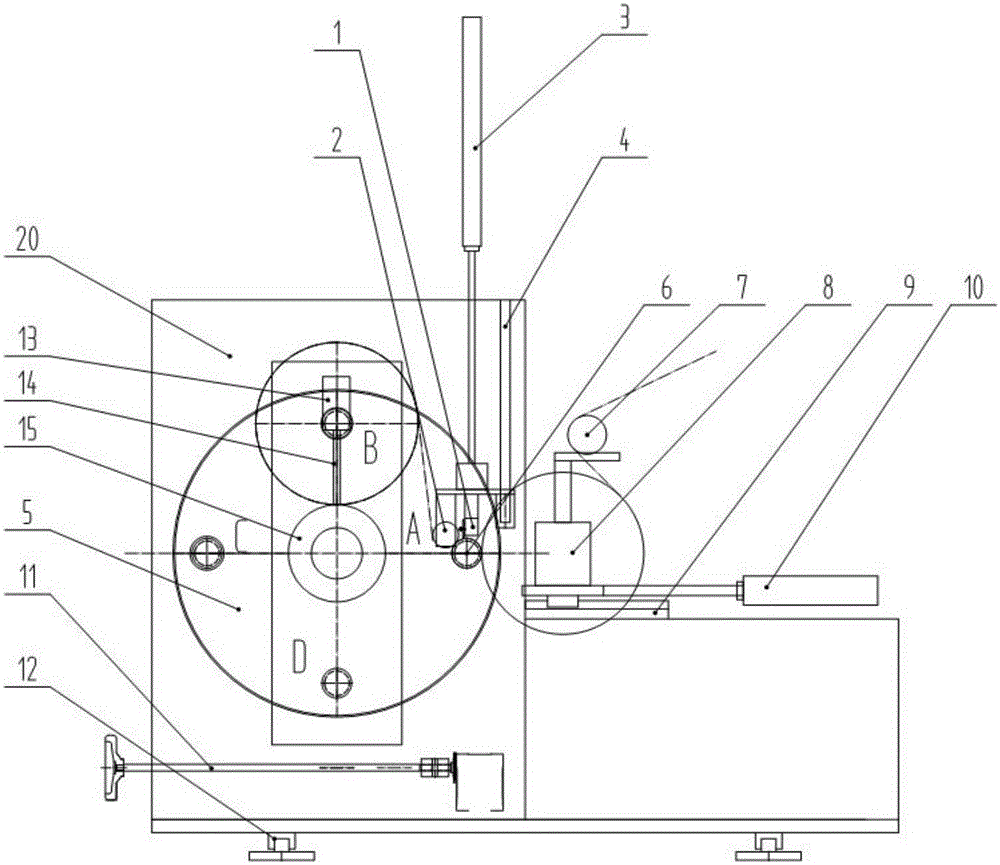

[0016] Combine below Attached picture The present invention will be described in detail with specific embodiments.

[0017] Book Invented a high-speed four-axis winder ,structure Such as figure 1 As shown, including frame 20, frame 20 is placed on frame slide rail 12, and frame 20 is provided with disk 5, and the center position of disk 5 is provided with positioning disk 15, and positioning disk 15 is provided with positioning disk 15. Mechanism 14, the positioning mechanism 14 can be driven by the positioning cylinder 13, cooperate with the positioning plate 15 for positioning, and the position near the edge of the disc 5 is also evenly equipped with A station 26, B station 27, and C station 28. D station 29, each station is also provided with a winding mechanism 23, and a driving rubber roller 8 is also arranged at the position of the frame 20 horizontally close to the A station 26, and the driving rubber roller 8 is placed on the rubber roller slide In the rail 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com