Sectional warp beam and creel of assembling device

A technology of section warping and creel, which is applied in the direction of creel, warping machine, transportation and packaging, etc. It can solve the problems of unusable yarn, relative force and time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

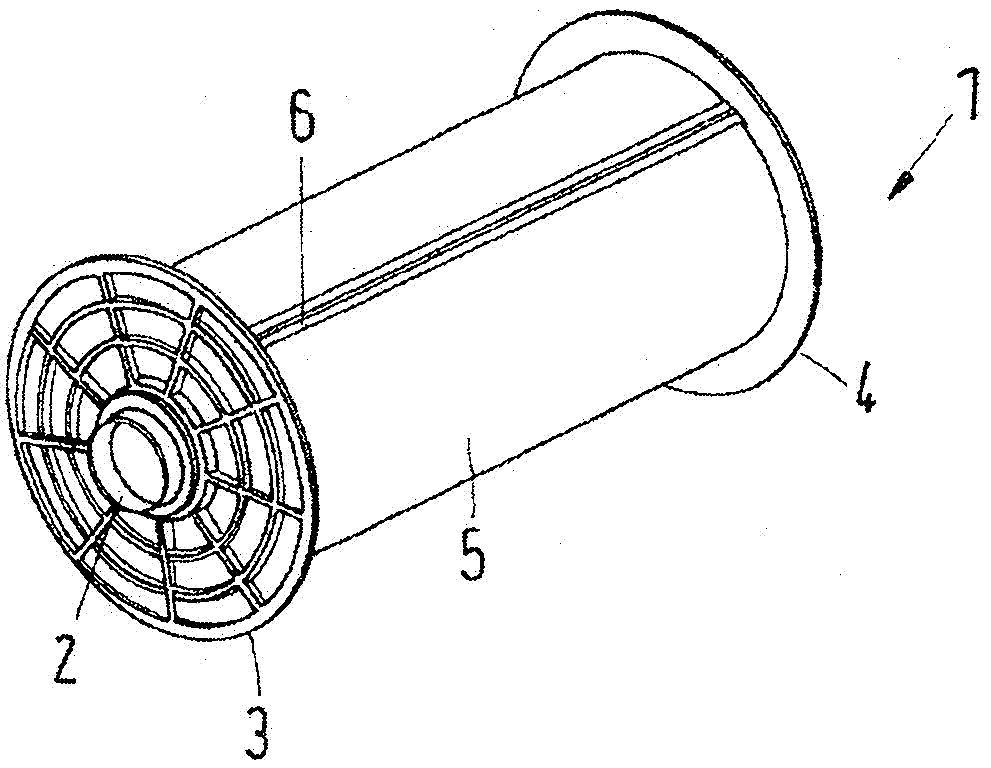

[0030] figure 1 A section warp beam 1 is shown with a core 2 and two side disks 3 , 4 at both ends of said core 2 . A yarn sheet 5 is wound on said core 2 . The yarn sheets consist of a plurality of yarns arranged side by side in the longitudinal direction of the core 2 and running in parallel.

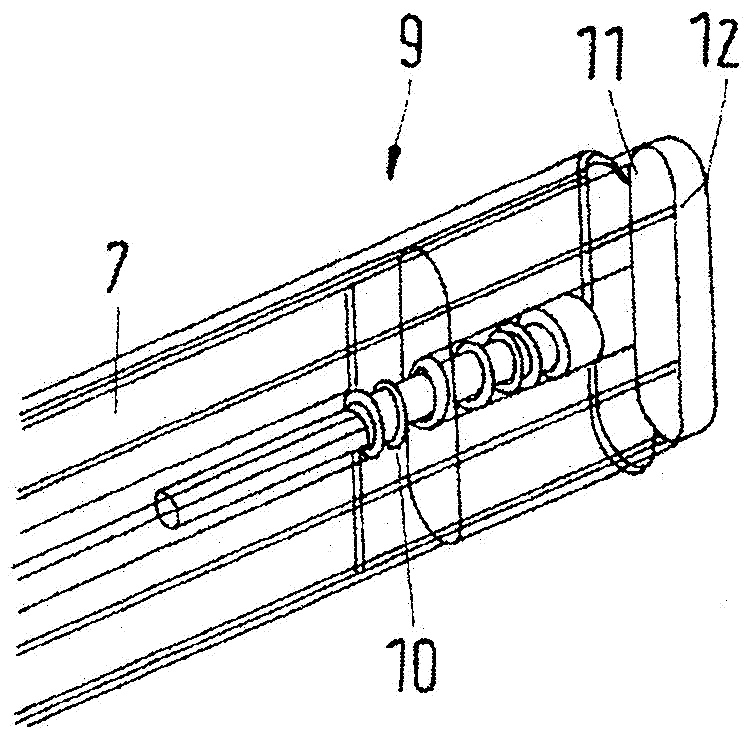

[0031] Clamps 6 extend parallel to said core 2 . The clamp 6 (which is in figure 2 shown in more detail in ) holds the yarns side by side along the width direction of the section warp beam 1 at the ends and acts equally on all yarns. To this end, the tongs 6 have a tong core 7 and a clip 8 . The yarns of the yarn sheet 5 are guided in a U-shape around the clamping core 7 and are then fixed on the clamping core 7 with the clamps 8 . This fixing is enough to reliably fix and maintain the yarn of the yarn sheet 5 at the clamp 6 .

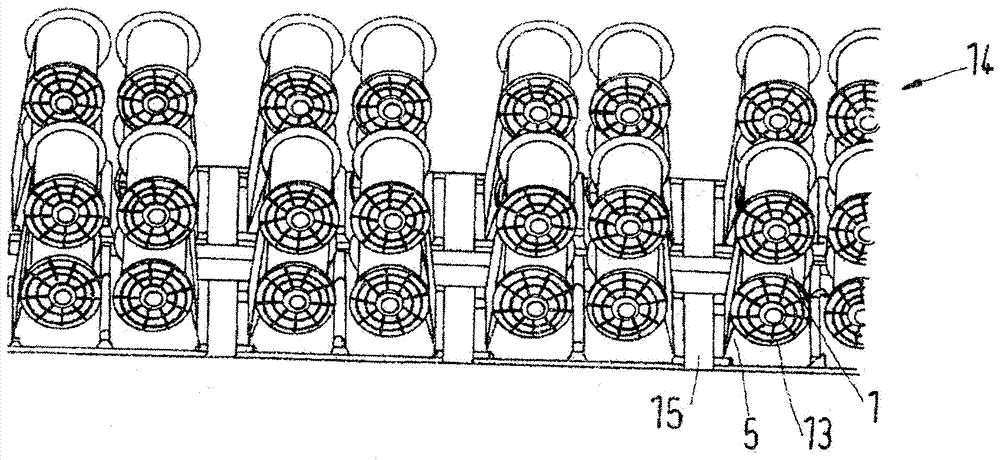

[0032] if possible in figure 1 As can be seen in , the clamp 6 is fixed between the side disks 3, 4 of the section beam. For this use in image 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com