Hybrid mooring system for ultra-deepwater floating structures and mooring method

A mooring system and water-floating technology, applied in the field of offshore oil and gas development, can solve the problems of high cost, heavy weight and complex technology, and achieve the effects of light weight, weight reduction and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

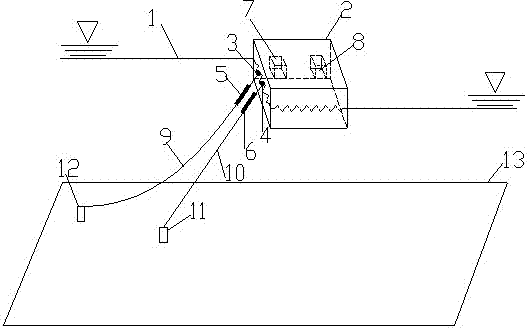

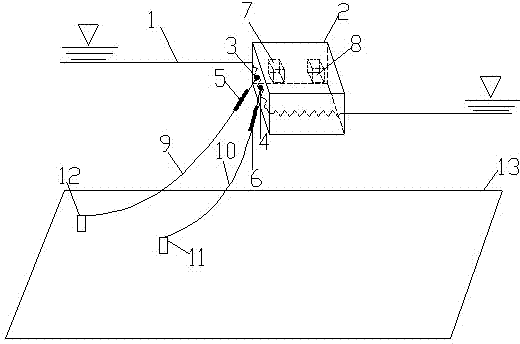

[0023] see figure 1 and figure 2 As shown, the present invention includes an ocean platform 2 floating on the sea level 1, and a control module 7, a GPS 8, a support 3, and a winch 4 are installed on the ocean platform 2. One end of the tensioned mooring cable 10 is fixed to the seabed 13 through the first seabed anchor 11 , and the other end is connected to the winch 4 of the offshore platform 2 . A first tension sensor 6 is installed on the tensioned tether 10 . One end of the catenary type mooring cable 9 is fixed on the seabed 13 by the second seabed anchor 12, and the other end is connected on the support 3, and the second tension sensor 5 is housed on the catenary type mooring cable 9.

[0024] The control module 7 is respectively connected with the GPS 8 , the first tension sensor 6 , the second tension sensor 5 and controls the action of the winch 4 . The GPS 8 is used to measure the real-time motion response value of the ocean platform 2 , and the control module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com