Dry and wet mixed connection method of fabricated shear wall

A hybrid connection and shear wall technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of difficult to guarantee the forming quality of reserved holes, difficult to guarantee welding quality, and difficult to guarantee the quality of grouting, so as to avoid welding operations and Auxiliary support, convenient on-site construction, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

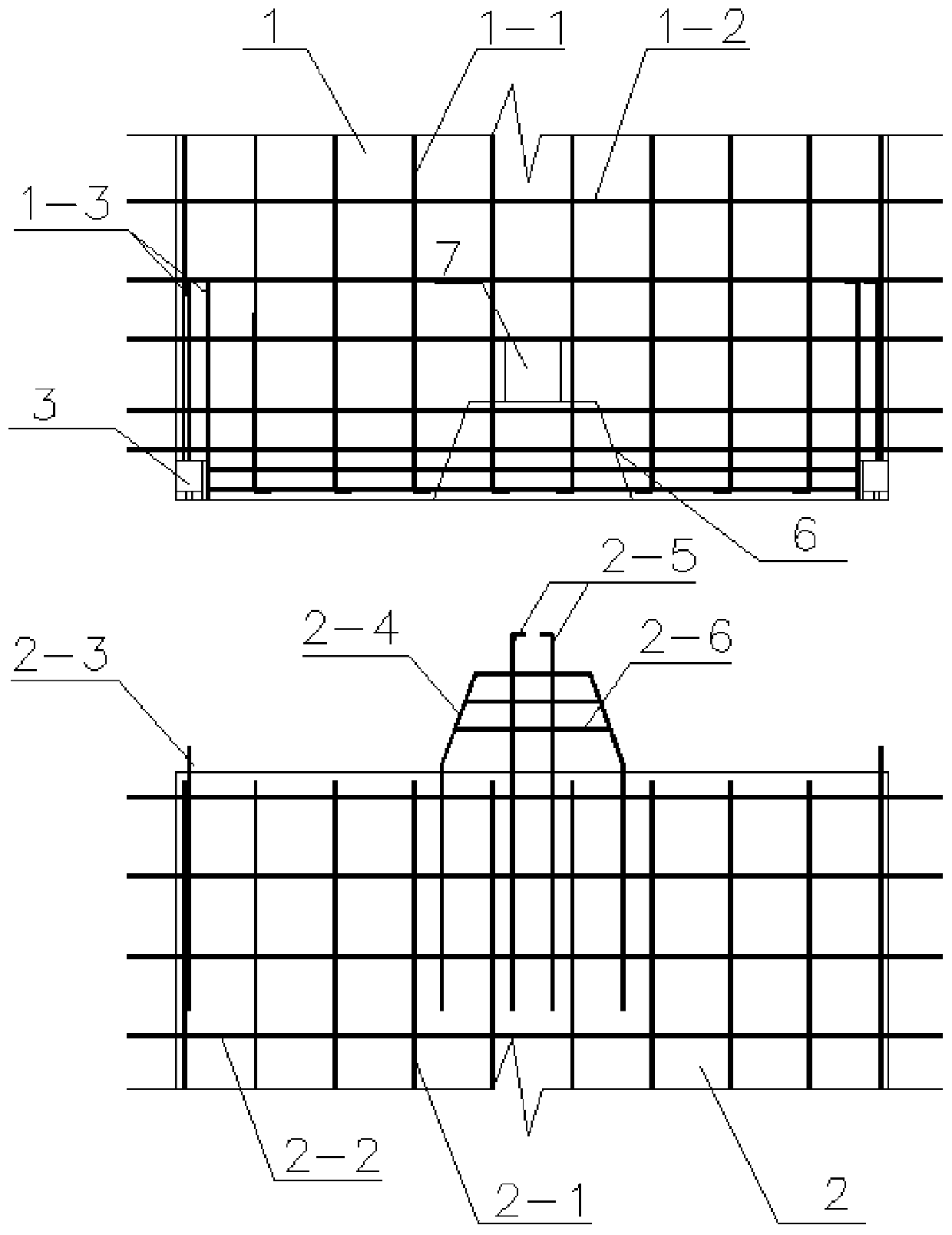

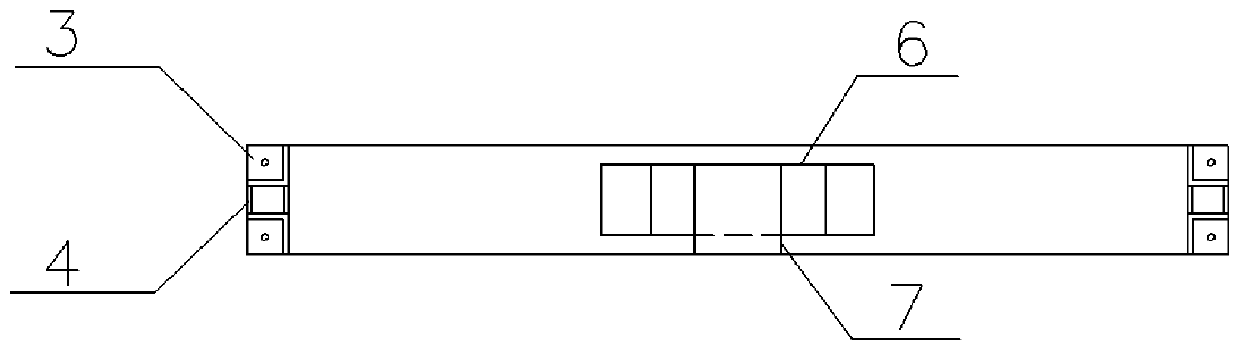

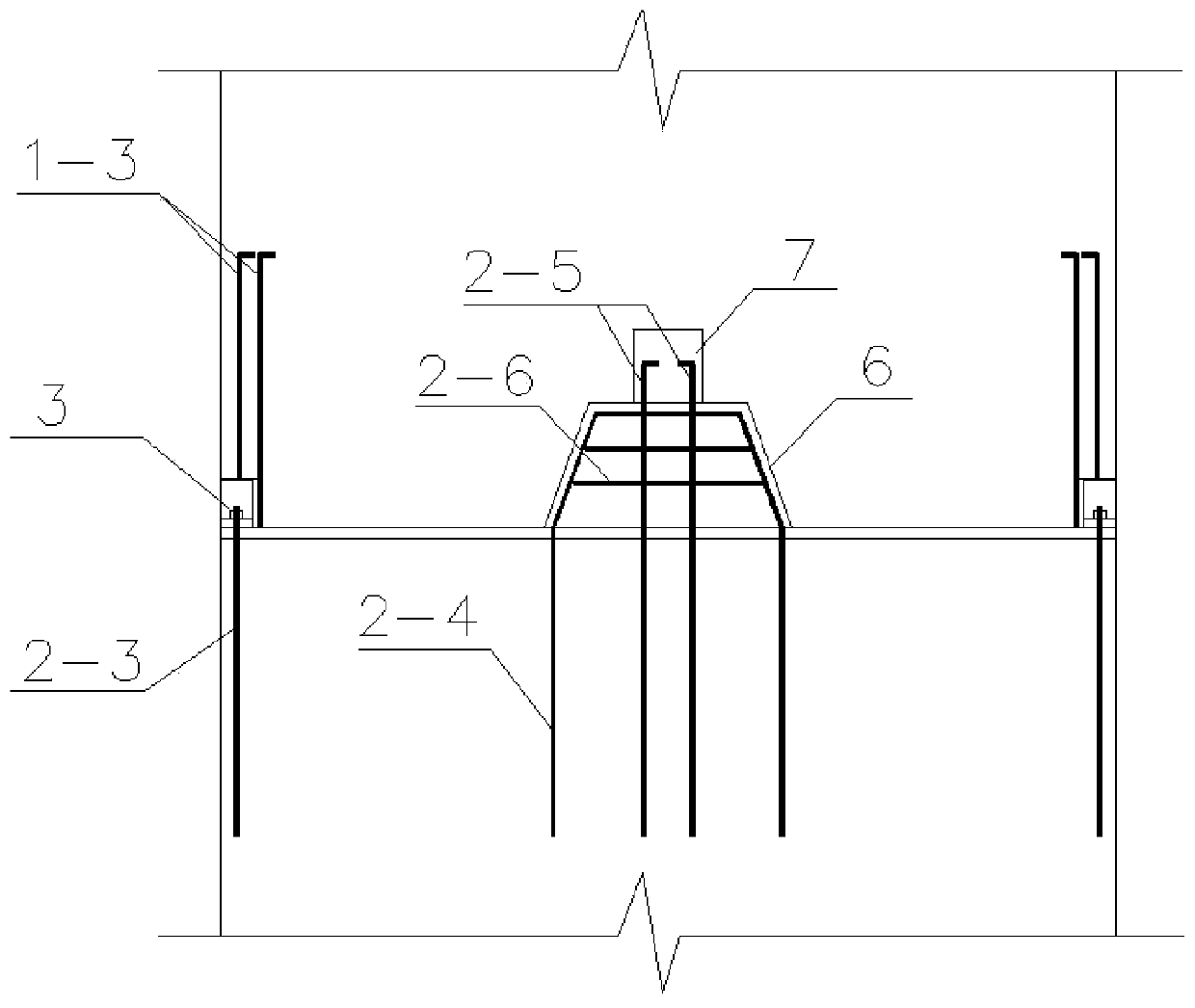

[0027] see Figure 1 to Figure 8 , a dry-wet hybrid connection method for prefabricated shear walls, in which a missing corner structure is provided at the four bottom corners of the upper prefabricated wall panel 1, and a steel bar connector 3 matching it is fixed in the missing corner structure, The steel bar connector 3 is provided with a vertically arranged angle steel section 3-1, and a horizontally arranged connecting bottom plate 3-2 is fixed on the bottom of the angle steel section 3-1, and the connecting bottom plate 3-2 is connected to the upper layer The bottom surface of the prefabricated wallboard 1 is flush, and bolt holes are provided on the connecting bottom plate 3-2. The middle position of the bottom of the bottom is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com