Construction technology of step temporary support and partial double side walls

A technology of temporary support and construction technology, applied in temporary shields, mining equipment, earthwork drilling and mining, etc., can solve the problems of low efficiency of personnel and machinery use, potential safety hazards, high cost, etc. Construction space, the effect of speeding up the progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Describe in detail below in conjunction with accompanying drawing:

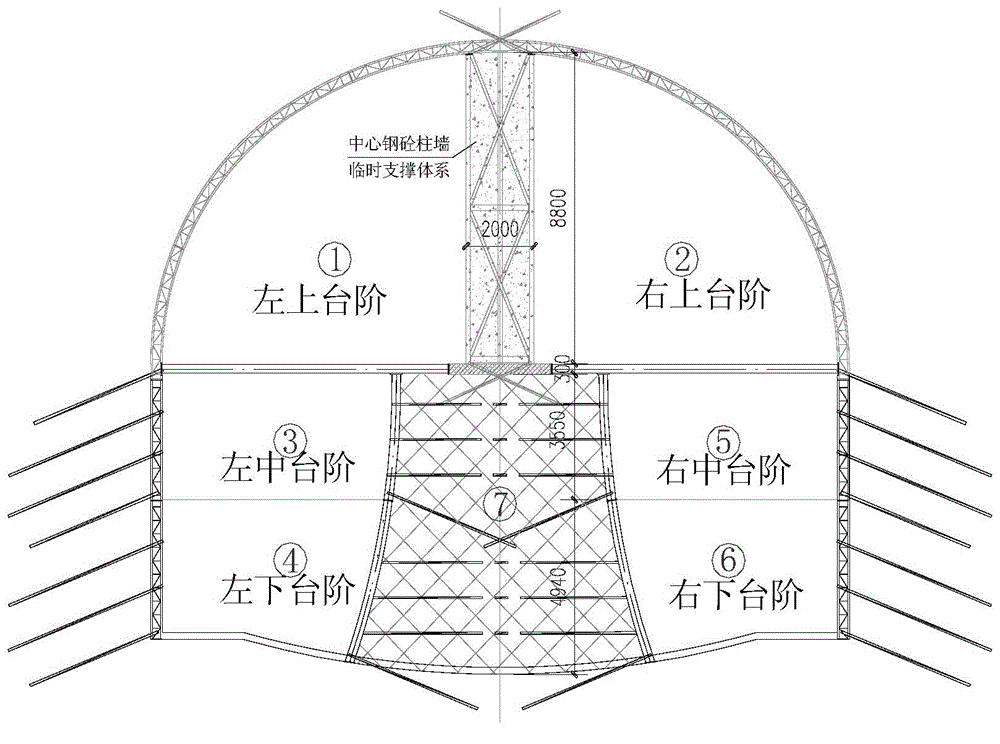

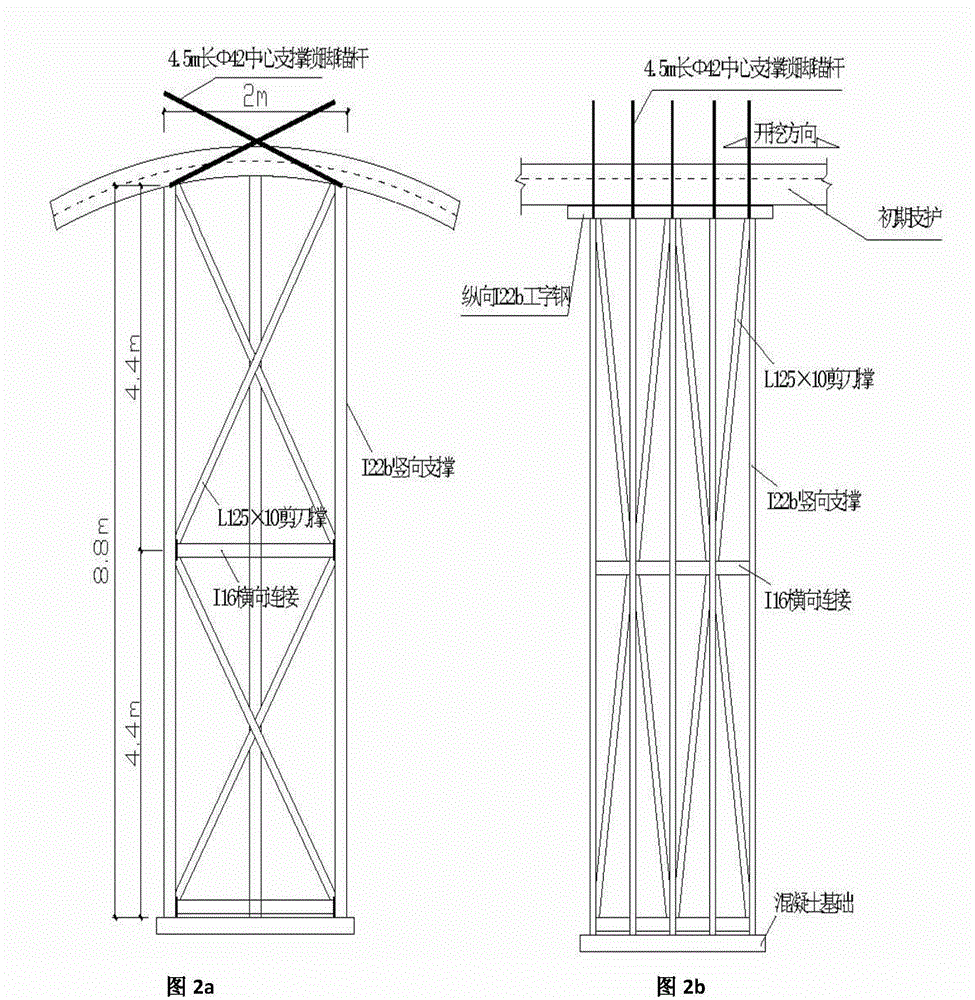

[0028] like figure 1 As shown, the step temporary support of the present invention adds the construction technology of partial double side wall, and the specific construction process steps are:

[0029] The first step: Excavation, support and horizontal steel support construction of the upper left step of the upper half section. The excavation height is 7.5-8.8m, and the width is controlled at 1 / 2 of the hole width. Advance support shall be implemented before excavation, and initial support and horizontal steel support shall be constructed in time after excavation.

[0030] The second step: Excavation, support and horizontal steel support construction of the upper right step of the upper half section. The distance between the left and right parallel steps is controlled at 10-15m. The excavation height, footage length and other parameters are consistent with the left steps. After the excavation, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com