Super-large-section subsurface tunnel tall core soil dismounting method

A technology of extra-large section and core soil, which is applied in the field of demolition of tall core soil of extra-large section undercut tunnels, can solve the problems of high difficulty, high risk of demolition of tall core soil of tunnels, and difficulty in temporary support and demolition, so as to improve efficiency and solve construction traffic problems. The effect of convenient organization and construction transportation organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

[0034] A method for removing the tall core soil of an extra-large cross-section underground excavation tunnel, comprising the following steps:

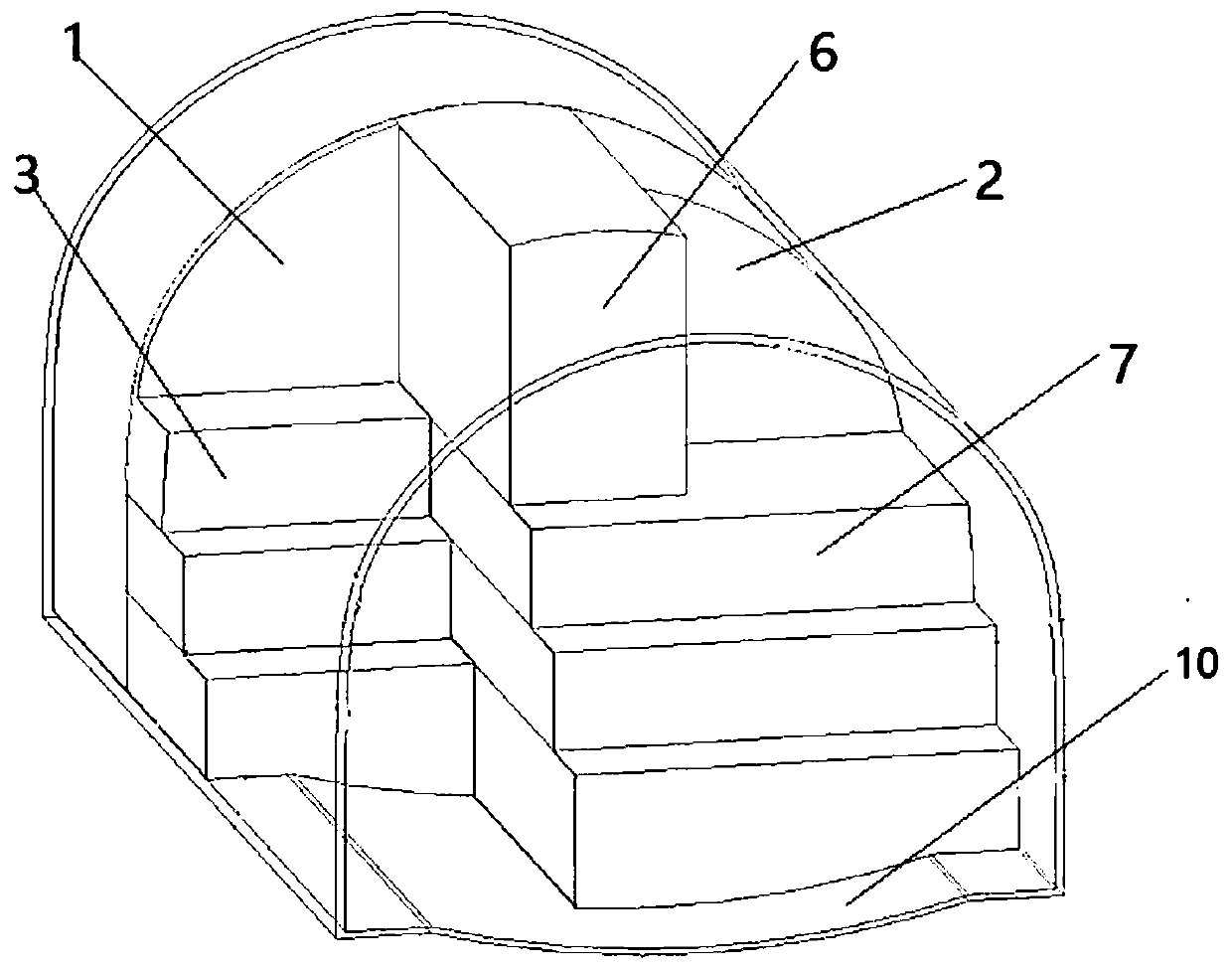

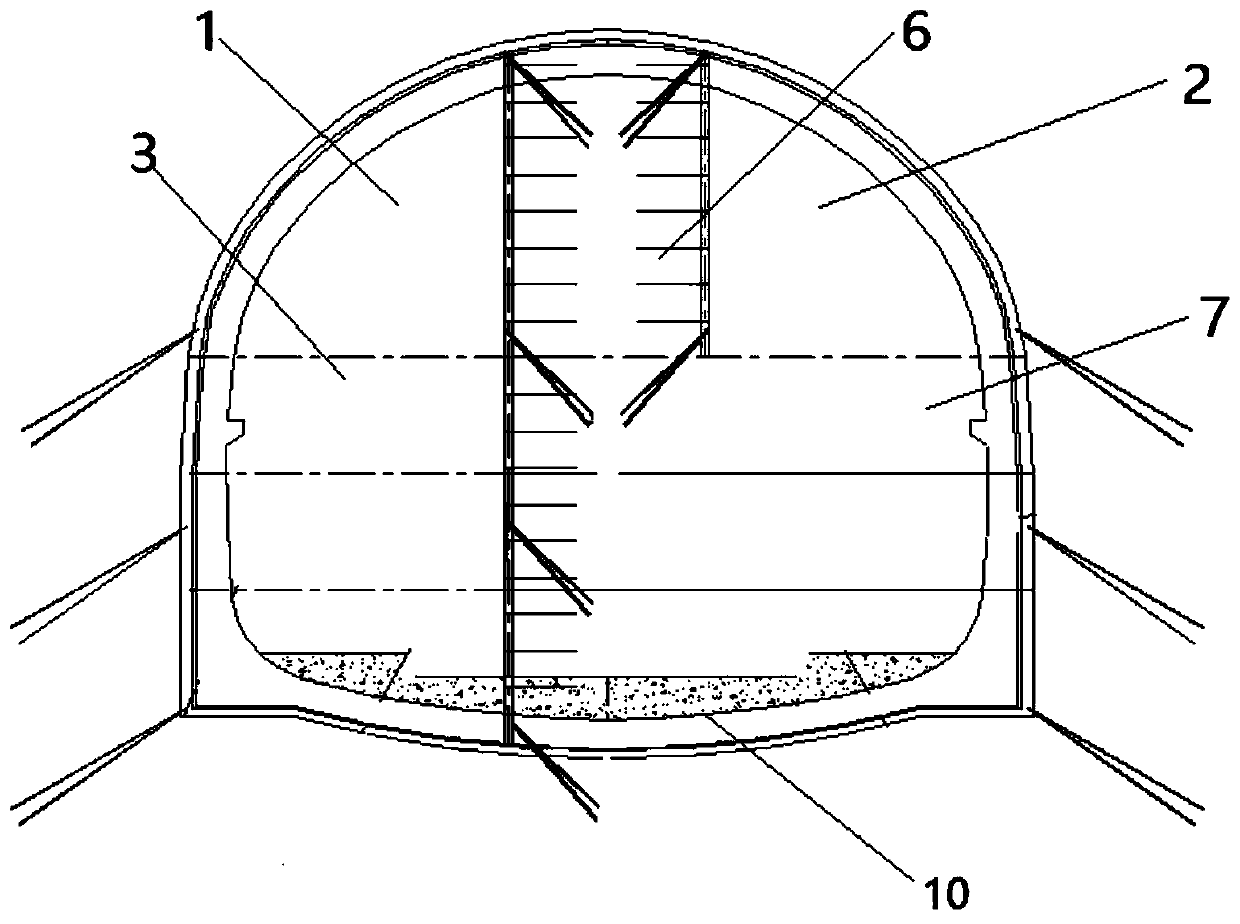

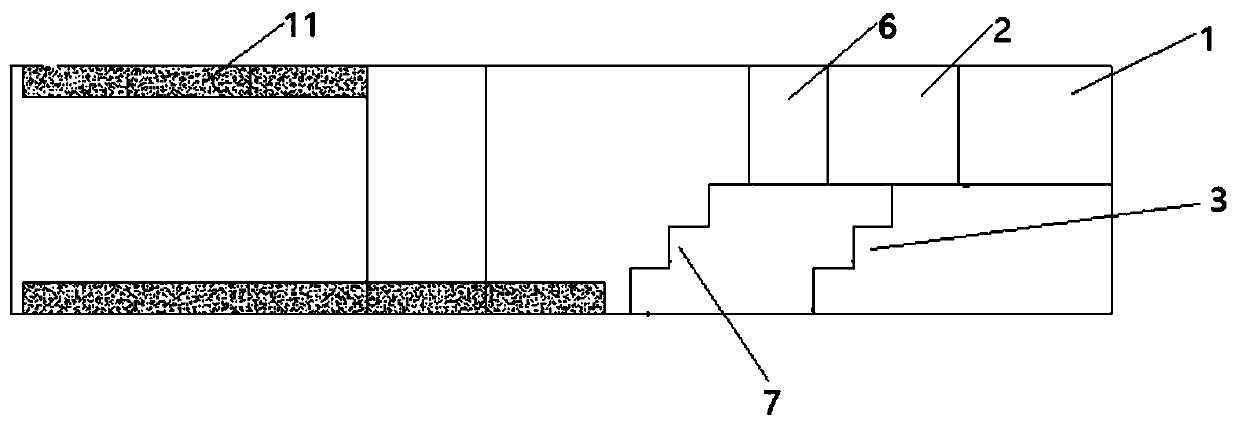

[0035] figure 1 It is a three-dimensional schematic diagram of the tunnel construction of the present invention; figure 2 It is a schematic diagram of the construction steps of the transverse section of the tunnel of the present invention; image 3 It is a schematic diagram of the facade of the tunnel excavation sequence of the present invention; Figure 4 A horizontal and longitudinal schematic diagram of rock pillars 12 reserved for the upper core soil 6 of the tunnel of the present invention; Figure 5 A schematic diagram of the longitudinal section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com