Method for lapped joint or anchoring of reinforcing bars in reinforced concrete member

A reinforced concrete and steel bar anchoring technology, which is applied in the direction of building structure, construction, etc., can solve the problems of complex construction, large lap (connection) length, difficulty, etc., to reduce the length of lap or anchorage, and reduce the problem of staggered lap , Improve the effect of anchoring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

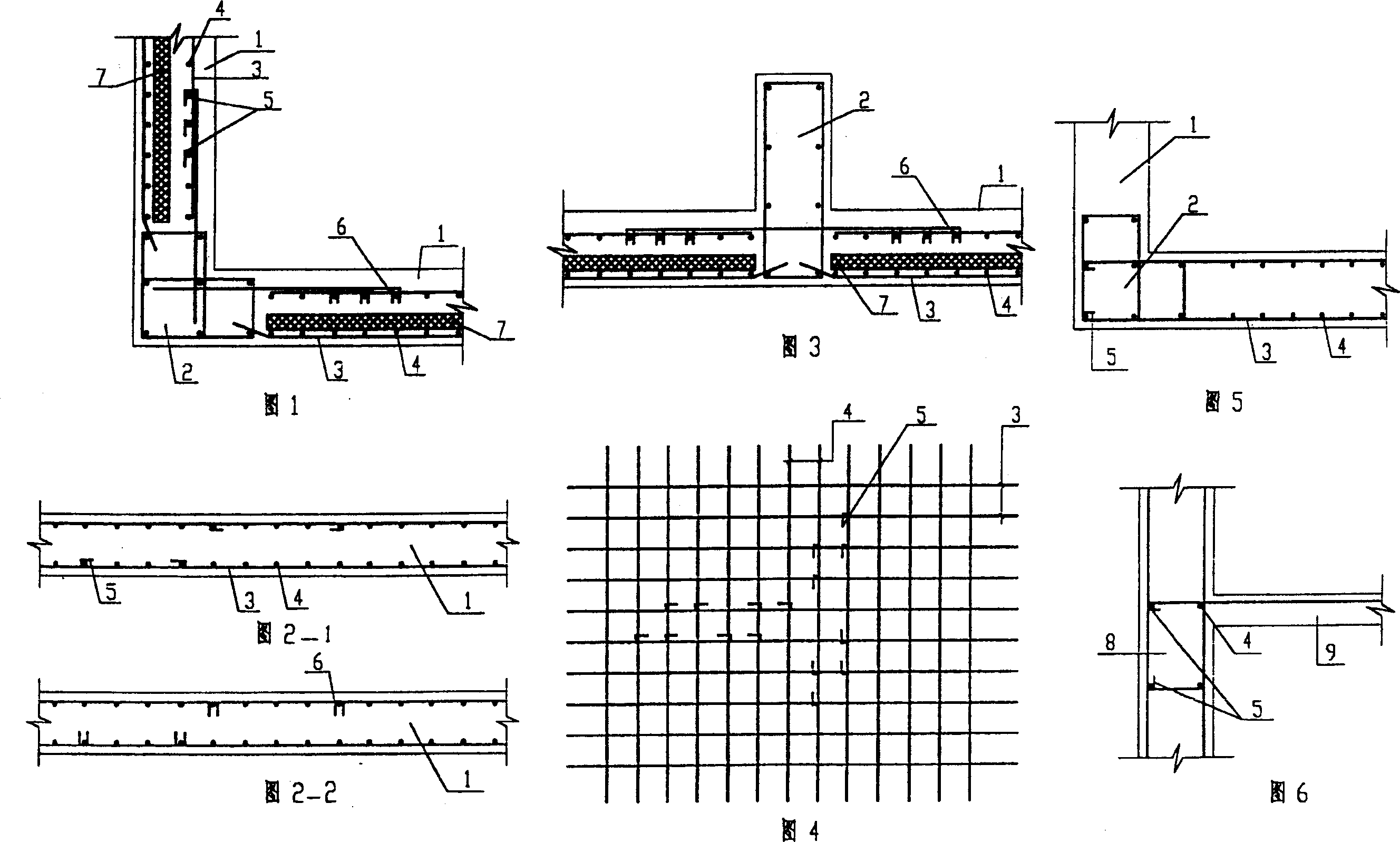

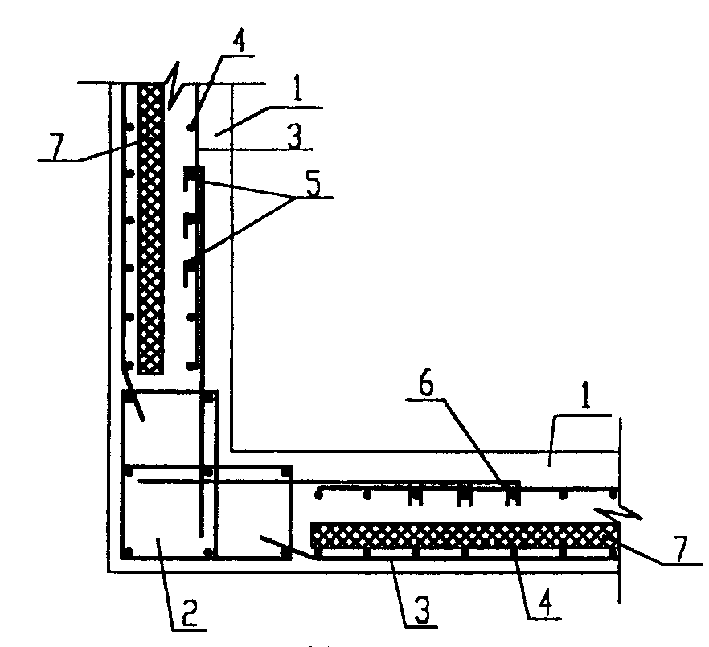

[0021] Embodiment 1: Using hooks or hooks to connect steel bars in reinforced concrete members (see Figures 1-4):

[0022] When the steel bars or steel wires in the reinforced concrete wall need lap joints, on the basis of the steel bar binding or welded mesh constructed earlier, use the lapped steel bars or steel wires with hooks or clips at the ends to hook or clamp the vertical longitudinal , horizontal steel bars or steel wires, so that the vertical and horizontal steel bars or steel wires are organically integrated.

[0023] When the steel bars are lapped, the overlapping steel bars with hooks or clips at the adjacent ends adopt the form of staggered lap joints.

[0024] The overlapping steel bars or steel wires with hooks or clips have 1-3 hooks or clips at the ends.

Embodiment 2

[0025] Embodiment 2: Adopting the method of anchoring the steel bar with a hook or clip in the reinforced concrete member (see Fig. 5, Fig. 6):

[0026] When the steel bar or steel wire in the reinforced concrete wall needs to be anchored in the beam or column, use the anchor steel bar or steel wire with hook or card at the end to hook or clamp the vertical steel bar in the beam, column or hidden beam, hidden column or Wires that integrate anchor bars or wires with vertical bars or wires in beams or columns.

[0027] An anchoring steel bar or steel wire with hooks or clips at the end, the number of hooks or clips at the end is 1-2.

Embodiment 3

[0028] Embodiment 3: In the reinforced concrete member, the method of combining the lap joint and anchorage of the hook or clamp is adopted, that is, when the steel bars in the reinforced concrete wall need lap joints, the lap joint method described in the invention is adopted. And when the steel bar in the reinforced concrete wall needs to be anchored in the beam or column, the anchoring method of the present invention is adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com