Wall with tie steel mesh structure

A tie-type, steel mesh technology, applied in structural elements, walls, building components, etc., can solve the problems of large dependence on power tools, waste of block materials, poor flexibility, etc., to simplify the joint joining process and reduce material consumption. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

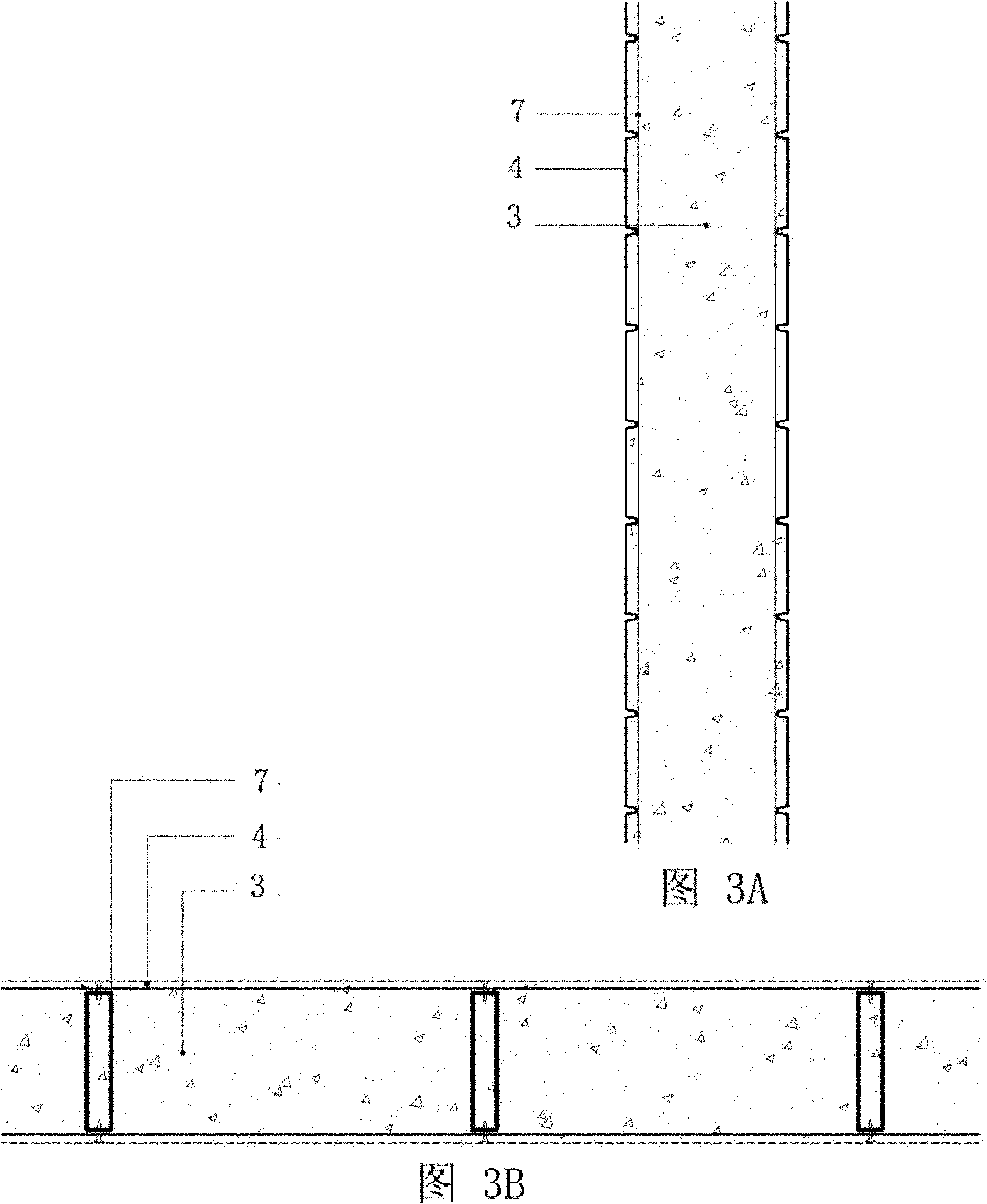

[0061] Figure 4A , 4B and Figure 5 Shown is a preferred embodiment of the present invention, and in this embodiment, the body of wall that is provided with tie-type steel mesh structure in China is made of transverse tension structure member 1, longitudinal positioning support member 2, filling layer 3 and have The rib expansion net 4 is composed of; the filling layer 3 is filled between the rib expansion net 4 on both sides, the rib expansion net 4 on both sides is fixedly connected with the longitudinal positioning support member 2, and the transverse tension member 1 passes through the filling layer 3 , its two ends are respectively fixed on the longitudinal positioning support member 2 that is fixedly connected with the rib expansion net 4 on both sides; the horizontal tension structure 1, the longitudinal positioning support member 2, the filling layer 3 and the rib expansion net 4 are integrated A wall with a tie-type steel mesh structure is formed.

[0062] In this...

Embodiment 2

[0067] Figure 7A and 7B Shown is the structural representation of the wall body that this embodiment is provided with pull-type steel mesh structure, wherein Figure 7A is the longitudinal section of the wall shown, Figure 7B is the cross section of the wall shown. The wall body provided with the tie-type steel mesh structure in this embodiment is composed of a transverse tension structure 1, a longitudinal positioning support member 2, a filling layer 3, a ribbed expansion net 4 and a painting layer 6, wherein the filling layer 3 is filled in Between the ribbed expansion nets 4 on both sides, the ribbed expansion nets 4 on both sides are fixedly connected to the longitudinal positioning support members 2, and the transverse tension member 1 passes through the filling layer 3, and its two ends are respectively fixed on the ribbed nets on both sides. The expansion mesh 4 is fixedly connected to the longitudinal positioning support member 2 . In order to make the wall with...

Embodiment 3

[0069] Figure 8A and 8B Shown is the structural representation of the wall body that this embodiment is provided with pull-type steel mesh structure, wherein Figure 8A is the longitudinal section of the wall shown, Figure 8B is the cross section of the wall shown. In this embodiment, on the basis of the embodiment 2, a waterproof and thermal insulation partition layer 5 is further arranged on the inner side of the ribbed expansion net 4 on the outer side of the outer wall. The waterproof and thermal insulation partition layer 5 has the function of waterproof and thermal insulation, and it is composed of a waterproof thermal insulation layer made of aluminum foil, linoleum or foam material.

[0070] The stucco layer and partition layer mentioned in the above embodiments can be designed according to the geographical factors and material factors of the construction site, and the design and combination of these components do not constitute a limitation of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com