Epoxy resin dipping fibre high voltage insulation core body

An epoxy resin fiber, high-voltage insulation technology, applied in the direction of insulators, transformer/inductor coils/windings/connections, etc., can solve the problems of high material prices, cable head explosion, carbon powder falling, etc., to improve the yield and Effect of service life, good electrical properties, good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

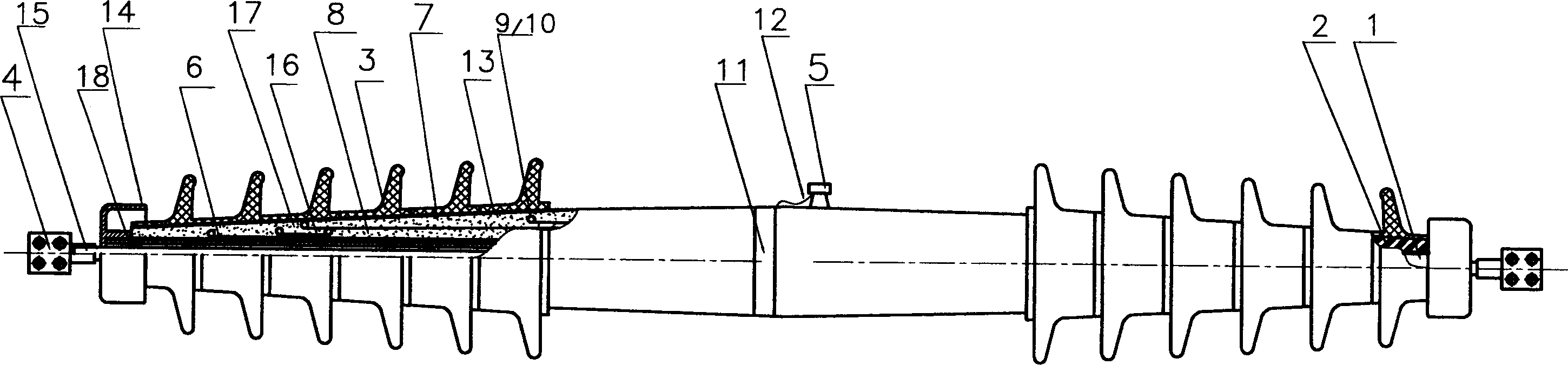

[0038] Taking the high-voltage insulating core body of 110kV, 1000A wall bushing as an example, the manufacturing steps of the epoxy resin fiber-impregnated high-voltage insulating core body of the present invention are illustrated:

[0039] a. Select a conductive rod with a diameter of φ30 and put it into a high-resistance metal tube with an outer diameter of φ49 and an inner diameter of φ42. One end is fixed with a metal conductive ring, and the other end is fixed with a spacer made of insulating material;

[0040] b. Heat-shrink the semi-conductive heat-shrinkable tube outside the metal tube or wrap the semi-conductive self-adhesive tape;

[0041] c. The above-mentioned workpieces are mounted on automatic special machine tools;

[0042] d. Automatically wrap the glass fiber layer with a thickness of about 3mm impregnated with epoxy resin in a clean room or in a vacuum state;

[0043] e. Wrap the capacitor plate with a thickness of about 0.15mm in the purification room. The...

example 2

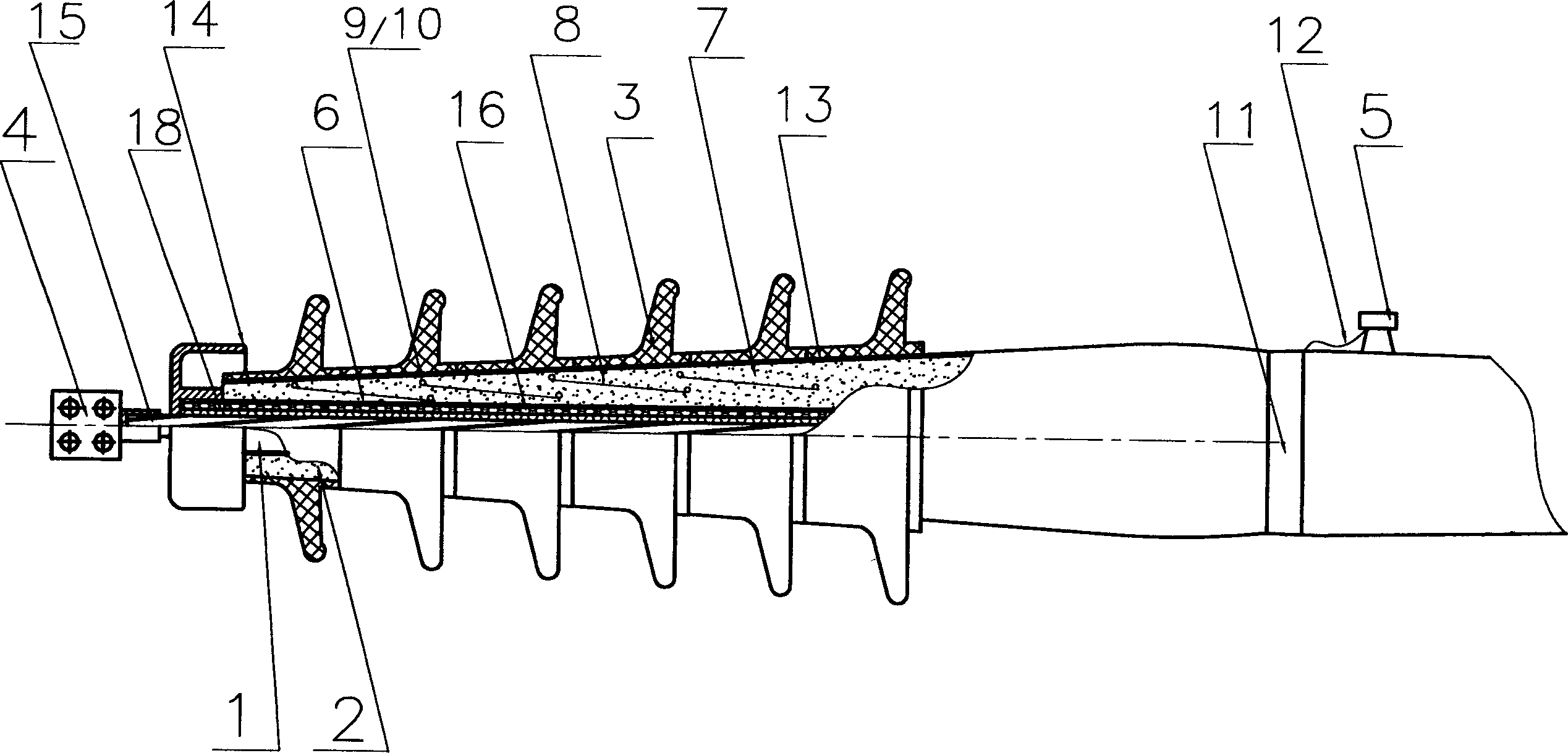

[0051] Taking the high-voltage insulating core body of 110kV, 600A cable terminal head as an example again, illustrate the manufacturing steps of the high-voltage insulating core body impregnated with epoxy resin fiber of the present invention:

[0052] a. Fix the rubber tube with tires;

[0053] b. Wrap the semi-conductive self-adhesive tape on the surface of the rubber tube.

[0054] The following are the same as steps c-h of Example 1.

[0055] i. The constant force spring clamps the copper braided wire and the wire mesh of the last screen is tightly connected, and the other end of the copper braided wire is connected to the cable grounding protection box.

[0056] j. Select the part with high field strength to install the non-linear resistance paint along the axial direction.

[0057] k. Glue the silicone rubber shed on the surface of the high-voltage insulation core not covered by the connecting cylinder.

[0058] l. Take out the mold in the rubber tube, press the powe...

example 3

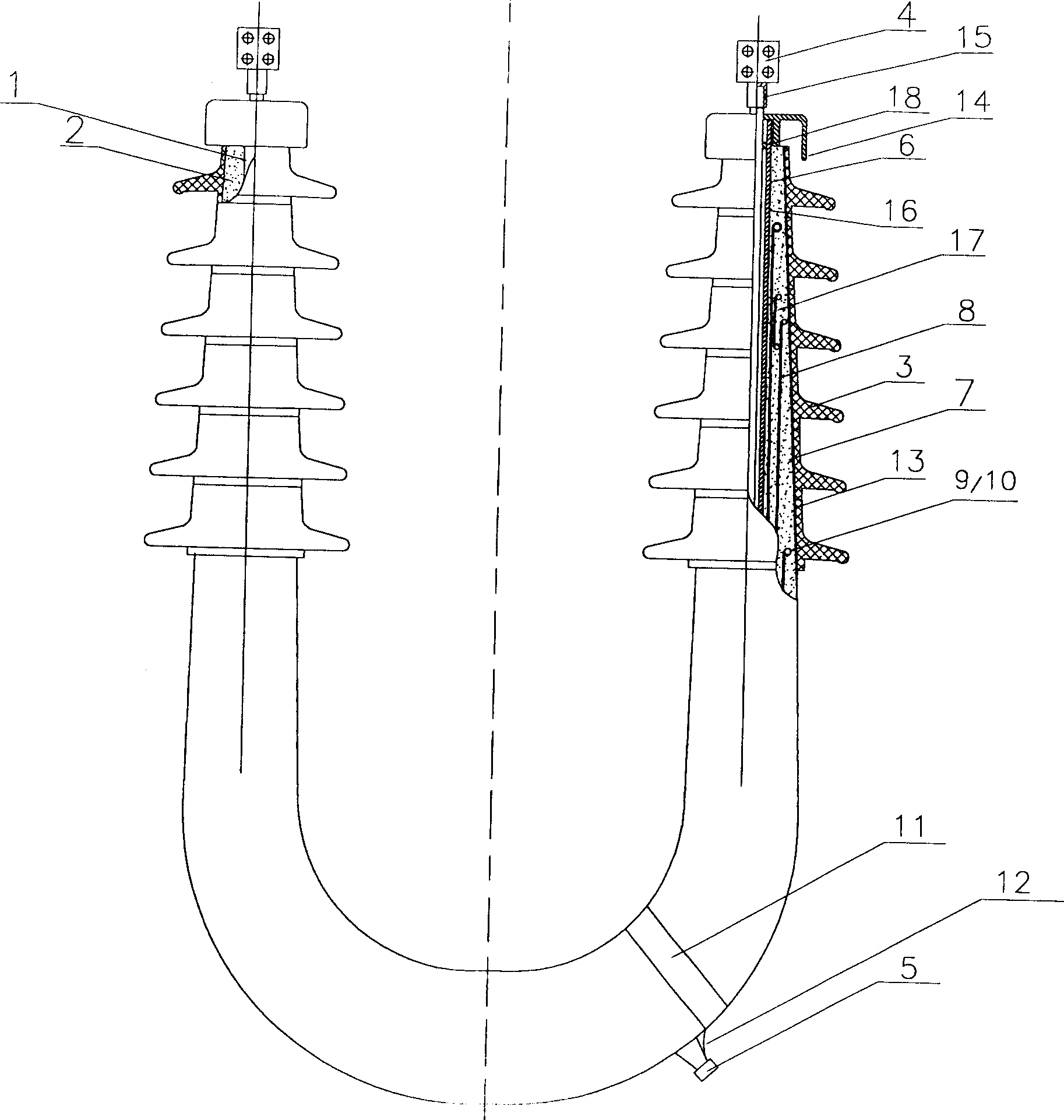

[0060] Taking the high-voltage insulating core body of 110kV, 600A current transformer as an example again, illustrate the manufacturing steps of the high-voltage insulating core body impregnated with epoxy resin fiber of the present invention:

[0061] a. Bend the φ50 stainless steel tube passing through the conductive rod or insulating cable into a U shape with a mould, one end of the conductive rod or insulating cable is electrically connected to the stainless steel tube, and the other end is insulated;

[0062] b. Semi-conductive heat-shrinkable tube with a thickness of 2 mm outside the metal tube;

[0063] c. Install the above-mentioned workpiece on a special machine tool. The wrapping head of this machine tool can rotate around the workpiece and can be adjusted arbitrarily in three-dimensional space.

[0064] d. The following steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com