Pressure gel molding method of resin insulating dry-type transformer coil

A technology of dry-type transformer and pressure gel, which is applied in the direction of inductance/transformer/magnet manufacturing, encapsulation/impregnation, electrical components, etc. It can solve the problems of poor resin penetration, long gel time, high partial discharge of coils, etc., to achieve Effects of improving quality, increasing gel temperature, and reducing partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

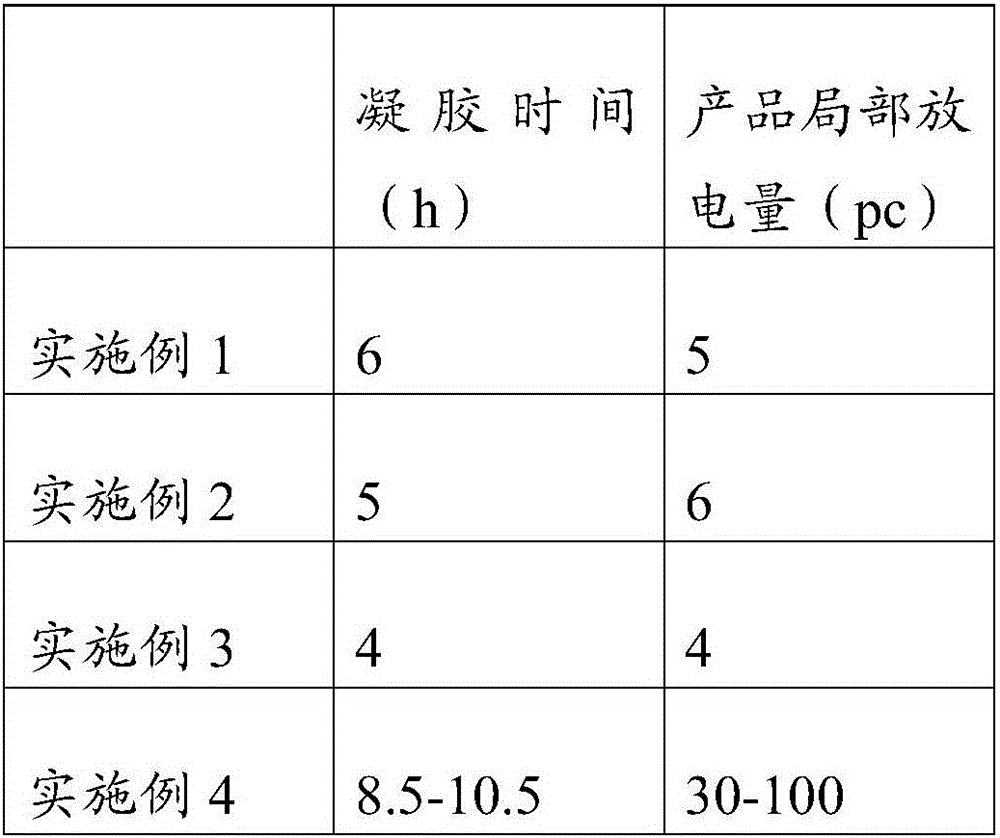

Embodiment 1

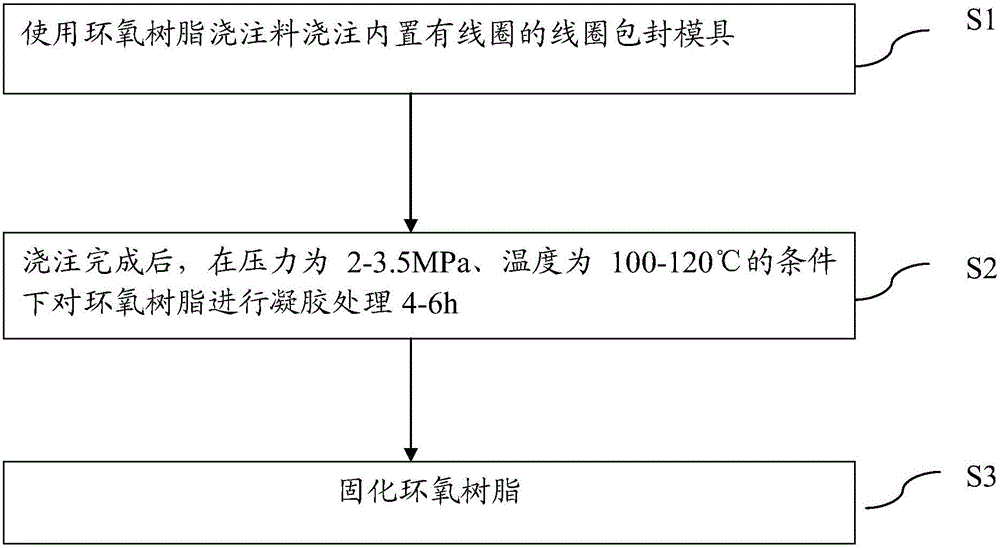

[0034] A resin-insulated dry-type transformer coil pressure gel forming method includes the following steps:

[0035] (1) Place the transformer coil in the coil encapsulation mold to obtain a coil encapsulation mold with a built-in coil;

[0036] Mix the epoxy resin and the curing agent under the conditions of a temperature of 60℃ and a vacuum of 150pa, and degas for 1 hour until no bubbles emerge on the surface, then add the accelerator and mix for 15 minutes to obtain an epoxy resin castable; , The epoxy resin is bisphenol A epoxy resin, the curing agent is tetrahydrophthalic anhydride, the accelerator is 2-ethyl-4-methylimidazole, and the weight ratio of epoxy resin, curing agent and accelerator is Epoxy resin: curing agent: accelerator=100:80:1;

[0037] (2) Adjust the temperature in the pouring furnace to 80℃ and the vacuum degree to 200pa. Place the coil encapsulation mold with the built-in coil in the pouring furnace for 3h. Adjust the vacuum to 800pa before pouring. After po...

Embodiment 2

[0041] A resin-insulated dry-type transformer coil pressure gel forming method includes the following steps:

[0042] (1) Place the transformer coil in the coil encapsulation mold to obtain a coil encapsulation mold with a built-in coil;

[0043] Mix the epoxy resin and the curing agent under the conditions of a temperature of 63°C and a vacuum of 180pa, and degas for 2 hours until no bubbles emerge on the surface. Then add the accelerator and mix for 20 minutes to obtain an epoxy resin castable; , The epoxy resin is bisphenol A epoxy resin, the curing agent is tetrahydrophthalic anhydride, the accelerator is 2-ethyl-4-methylimidazole, and the weight ratio of epoxy resin, curing agent and accelerator is Epoxy resin: curing agent: accelerator=100:80:1;

[0044] (2) Adjust the temperature in the pouring furnace to 83℃ and the vacuum degree to 250pa. Put the coil encapsulation mold with built-in coil in the pouring furnace for 4h. Adjust the vacuum degree to 900pa before pouring. After...

Embodiment 3

[0048] A resin-insulated dry-type transformer coil pressure gel forming method includes the following steps:

[0049] (1) Place the transformer coil in the coil encapsulation mold to obtain a coil encapsulation mold with a built-in coil;

[0050] Mix the epoxy resin and the curing agent under the conditions of a temperature of 65°C and a vacuum degree of 200 Pa, and degas for 2.5 hours until no bubbles emerge on the surface, then add the accelerator and mix for 30 minutes to obtain an epoxy resin castable; Among them, the epoxy resin is bisphenol A epoxy resin, the curing agent is tetrahydrophthalic anhydride, the accelerator is 2-ethyl-4-methylimidazole, and the weight ratio of epoxy resin, curing agent and accelerator For epoxy resin: curing agent: accelerator=100:80:1;

[0051] (2) Adjust the temperature in the pouring furnace to 85℃ and the vacuum degree to 300pa. Place the coil encapsulating mold with built-in coils in the pouring furnace for 5h. Adjust the vacuum to 1000pa bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com