Method for forming liquid crystal alignment layer

A liquid crystal alignment and alignment layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven electric field and poor alignment effect of liquid crystal displays, and achieve uniform electric field components, better molecular arrangement characteristics, and fast response. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Relevant detailed description and technical content of the present invention, now just explain as follows with respect to matching drawing:

[0042] The forming method of the liquid crystal alignment layer of the present invention comprises the following steps:

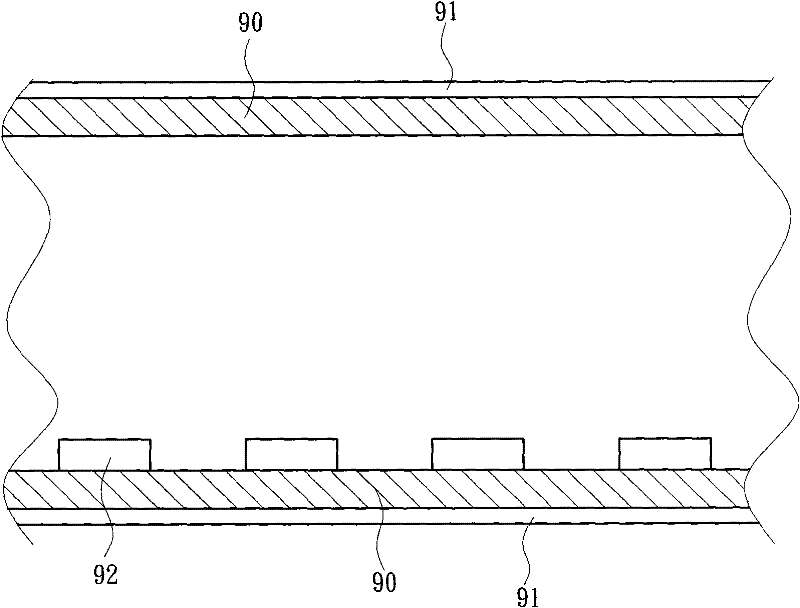

[0043] providing a first substrate, the first substrate has a first surface;

[0044] sequentially forming a conductive layer, an insulating layer covering the conductive layer, and a plurality of alignment electrodes arranged on the surface of the insulating layer on the first surface;

[0045] A second substrate is arranged parallel to the first substrate, the second substrate has a second surface corresponding to the first surface, and a liquid crystal accommodation space is formed between the first surface and the second surface;

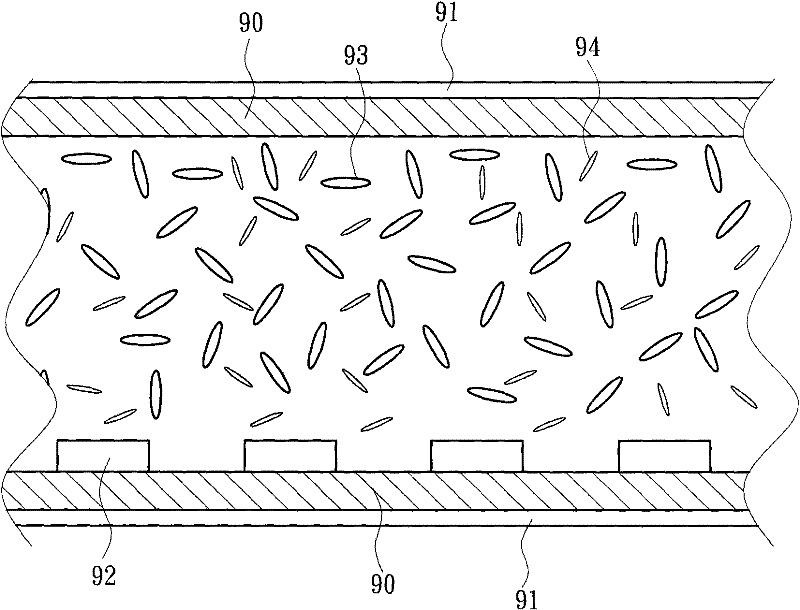

[0046] Mixing a liquid crystal alignment composition and a positive liquid crystal material into the liquid crystal containing space;

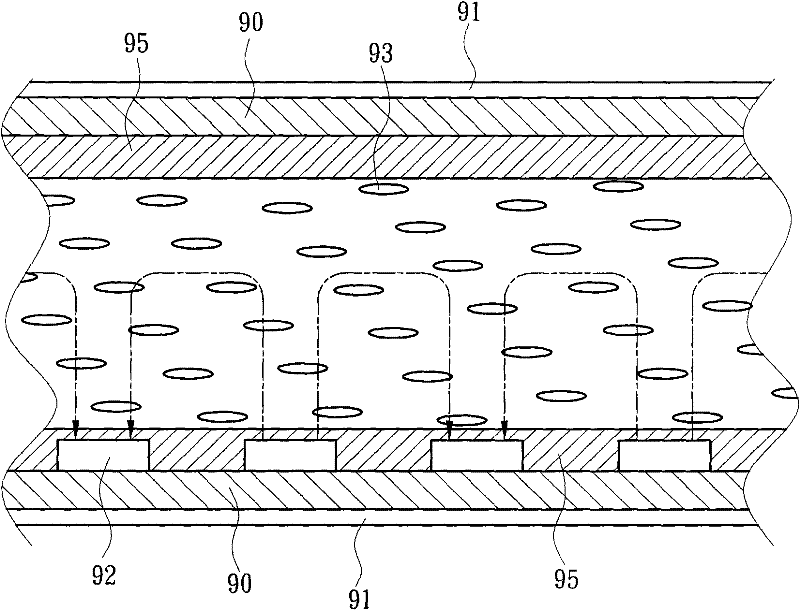

[0047] applying a voltage to the conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com