Multi-core integrated branch cable and production method thereof

A technology of branch cables and branch cables, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., which can solve problems such as difficult installation, insufficient cable installation space, and lack of multi-core integrated branch cable structure. Uniform and convenient installation and wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

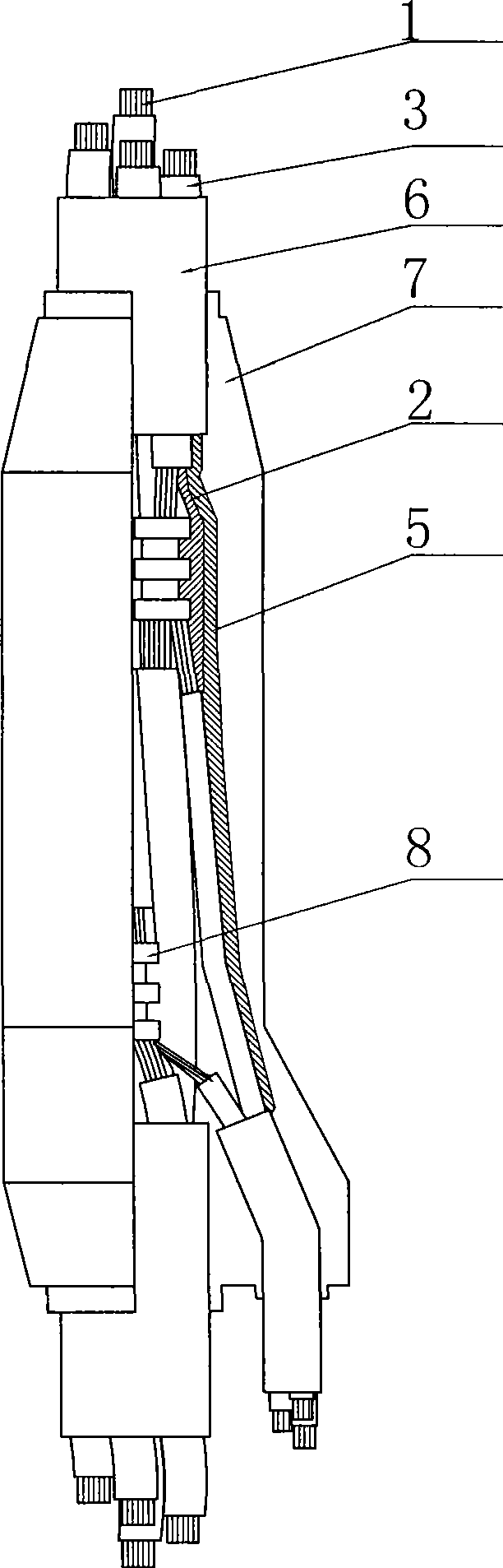

Image

Examples

Embodiment Construction

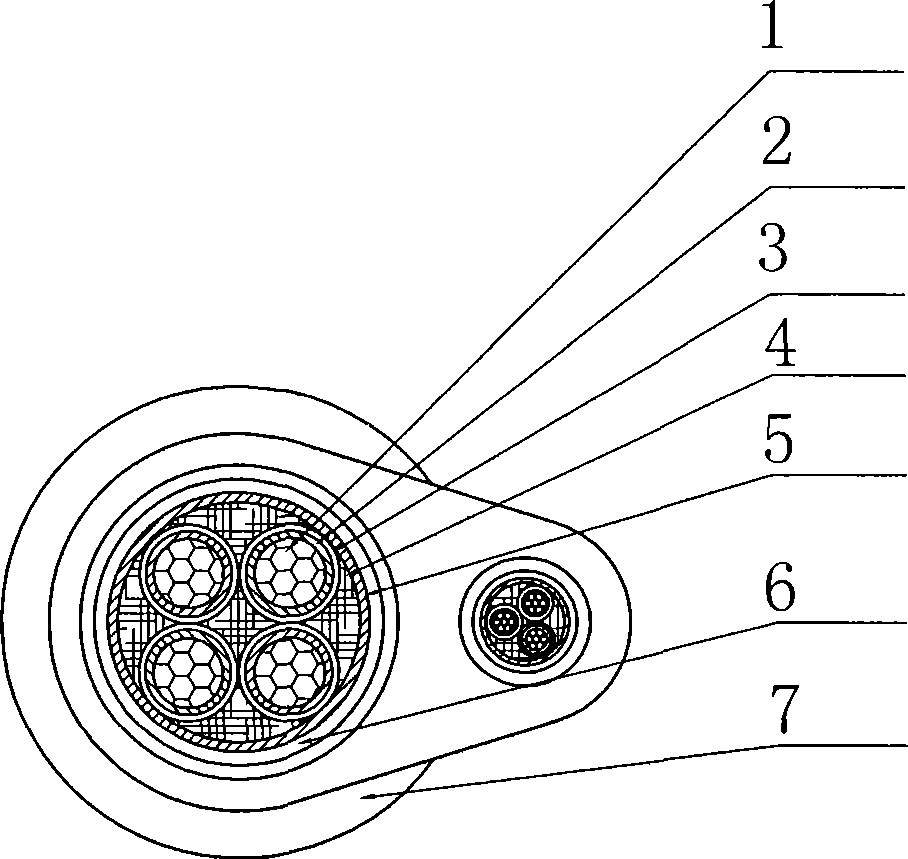

[0021] 1. The conductor 1 of the main cable and the branch cable is made of copper single wire twisted in accordance with the provisions of GB / T3953. The conductive core meets the requirements of type 2 conductors in GB / 3956, which ensures that the product has good electrical conductivity and softness.

[0022] 2. The conductor 1 is wrapped with a double layer of synthetic mica tape 2 (or fire-resistant mica tape) with high temperature resistance, the covering rate is 50% to 60%, and it can withstand the temperature of 1000°C.

[0023] 3. Extrude the cross-linked polyethylene insulating layer 3 on the synthetic mica tape to form the insulating core. Using cross-linked polyethylene as cable insulation material has better insulation strength and heat resistance stability than PVC.

[0024] 4. Use 2 to 5 insulated wire cores, and regularly twist them together to form core wires according to the standard cable pitch and uniform torsion force, and fill the gaps between the insulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com