Thin-film transistor substrate, electric moistening type display apparatus method for manufacturing the thin-film transistor substrate

一种薄膜晶体管、制造方法的技术,应用在电湿润式显示装置领域,能够解决薄膜晶体管基板可靠性低等问题,达到显示效果佳、电场均匀、可靠性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

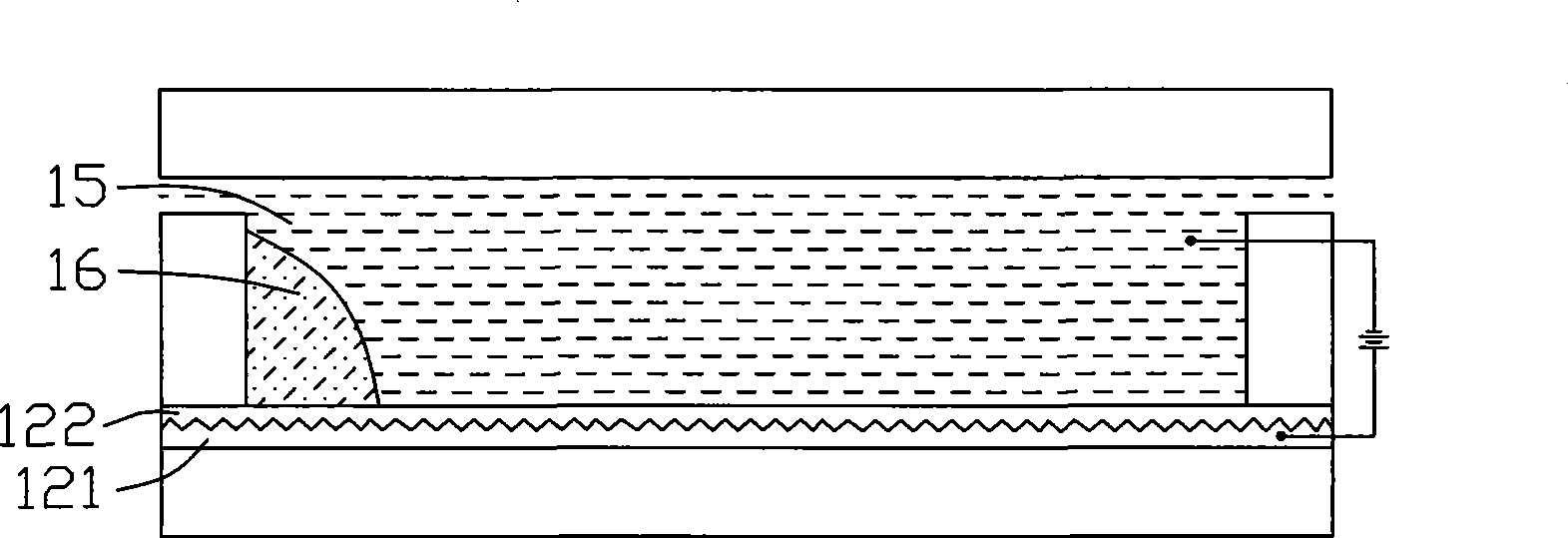

[0065] Compared with the first embodiment, since the second metal layer 533 of the electrowetting display device 5 is made of indium tin oxide or indium zinc oxide, which is stronger in texture and more stable in connection with other metals, the reflective electrode 521 The connection with the drain 546 is firmer and more stable.

[0066] see Figure 9 , is a schematic structural view of the third embodiment of the electrowetting display device of the present invention. The difference between the electrowetting display device 6 and the electrowetting display device 5 is that the reflective electrode 621 includes a first metal layer 631 , a second metal layer 633 , a buffer layer 634 and a protection layer 632 . The second metal layer 633 is disposed on the passivation layer 624 , and the buffer layer 634 is disposed on the second metal layer 633 with a thickness of 500A. The first metal layer 631 is disposed on the buffer layer 634 with a thickness of 1000A. The passivatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com