Voltage transformer

A technology for voltage transformers and components, applied in the field of transformers, can solve the problems of voltage transformer primary winding end breakdown, inability to meet the needs of power grid operation, and increased transformer volume, etc., and achieves large surface creepage and secondary load. Large, size-reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

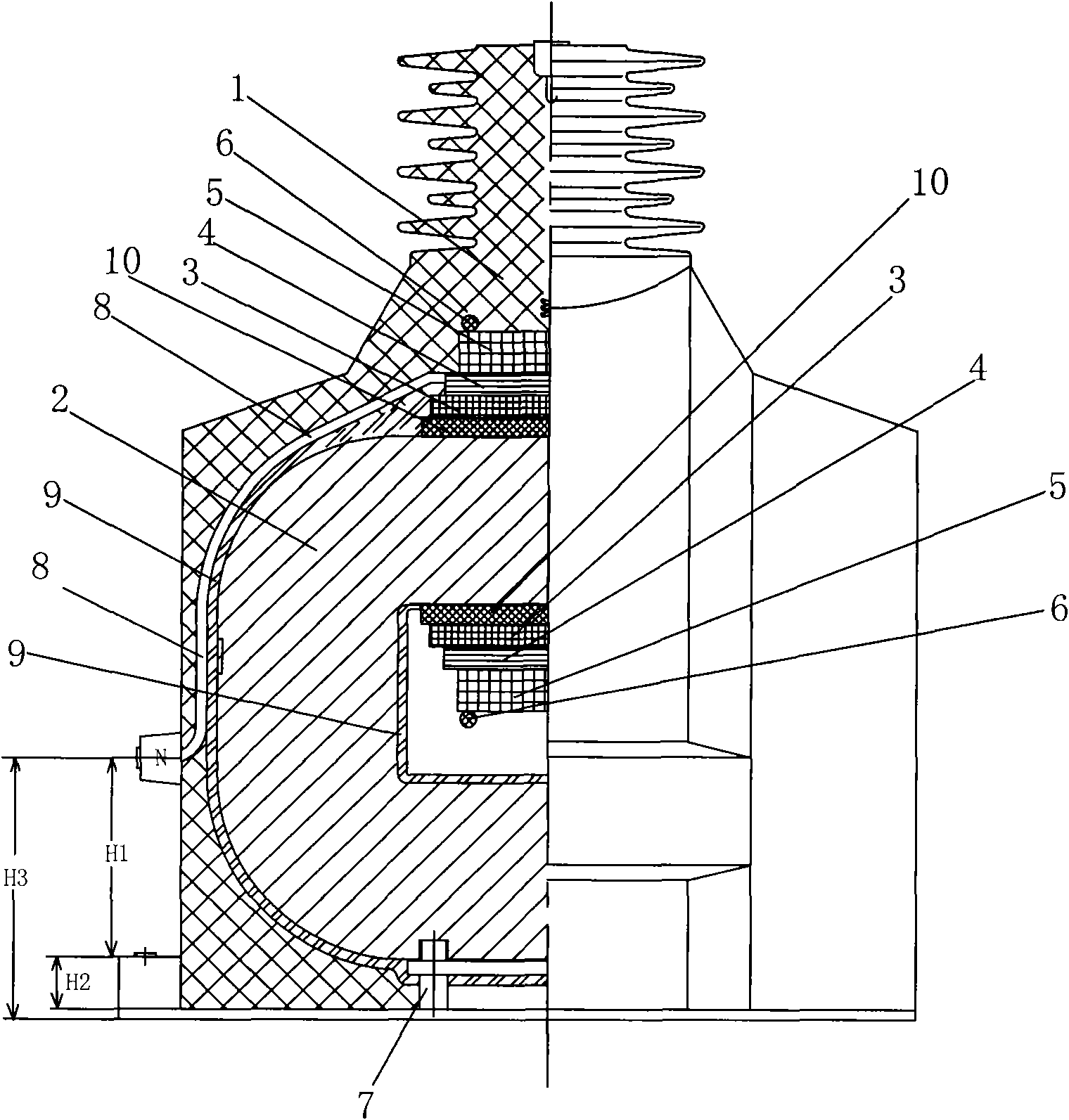

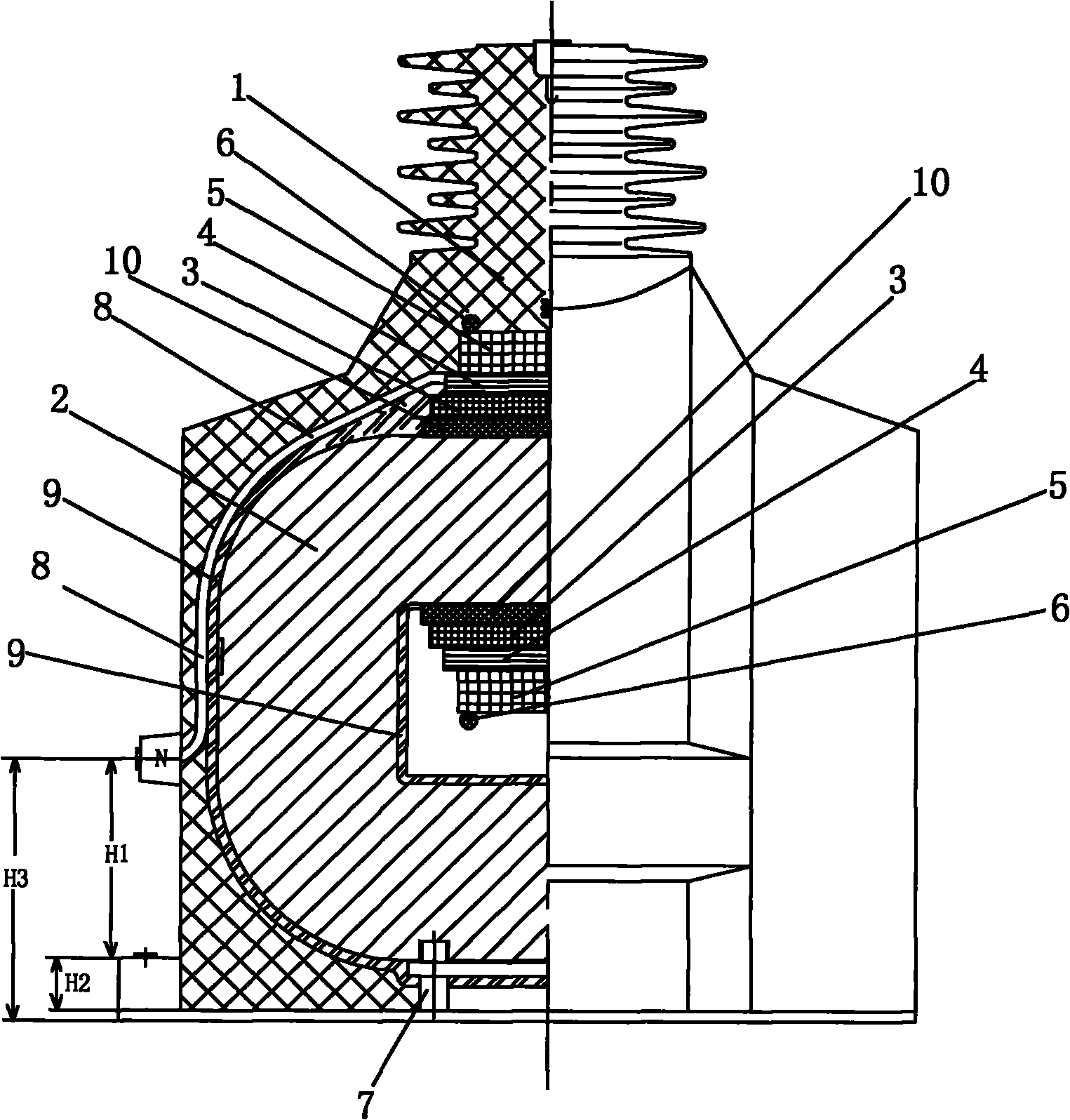

[0022] Such as figure 1 The shown 35KV voltage transformer includes an insulator 1 of conventional shape, the overall height of the insulator is 566 mm, and the inside of the insulator is sealed with an iron core 2 , winding components wound on the iron core 2 and a support frame. The iron core is in the shape of a "mouth", and the above-mentioned winding parts are wound on the horizontal axis of the iron core, and the winding parts include: the secondary winding 3 wound directly on the outer surface of the insulating copper 10 outside the iron core, wound on the The outer surface of the secondary winding is an insulating layer 4 with a thickness of 5 mm made of PMP polyester film capacitor paper, the primary winding 5 wound on the outer surface of the insulating layer, and the uniform winding wound on the outer surface of the primary winding. Pressure ring 6. The above-mentioned iron core wound with winding components is integrally installed on the support frame 7, and the s...

Embodiment 2

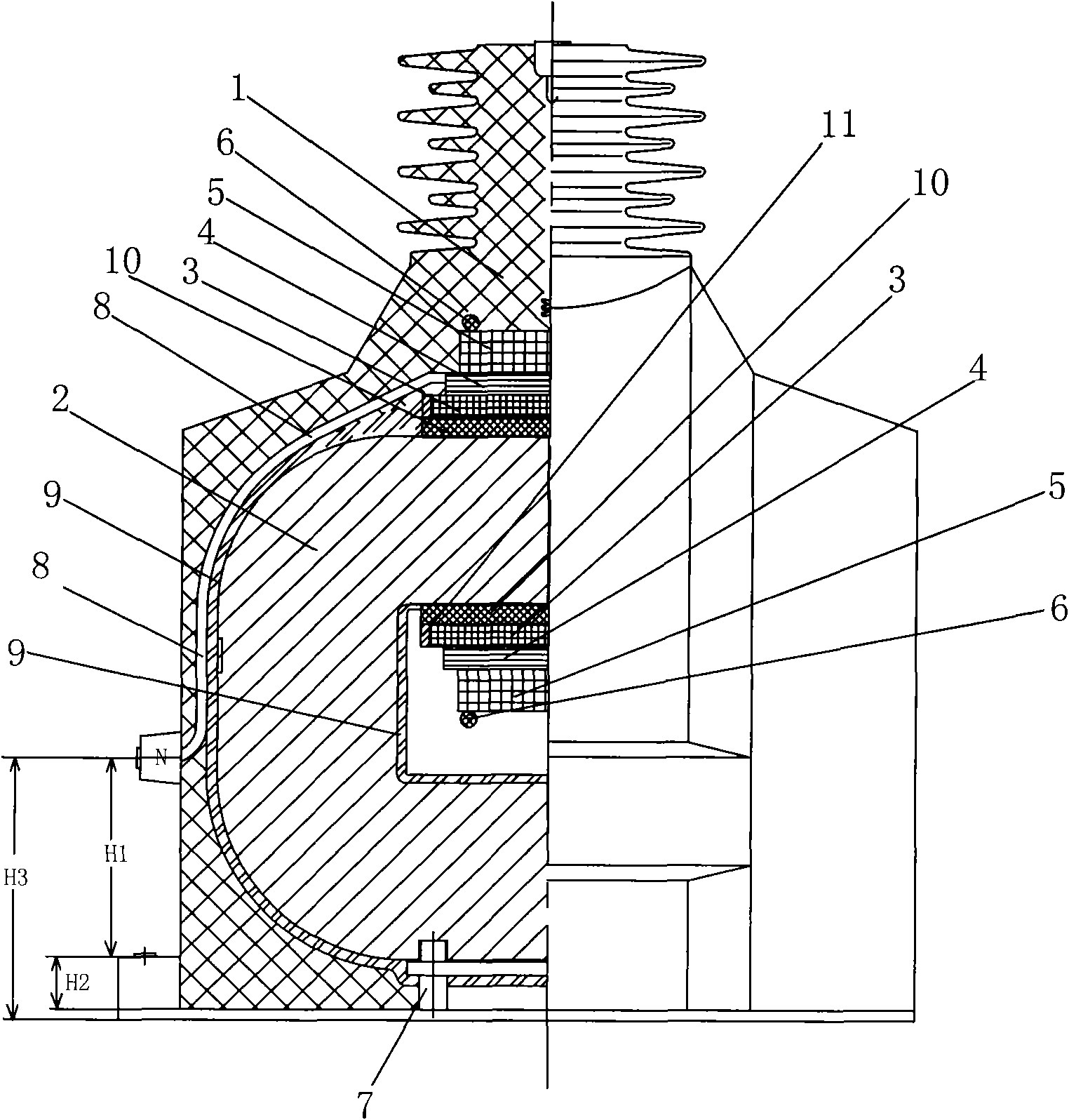

[0026] Different from the first embodiment, the winding component further includes a compensation coil 11 wound on the outer surface of the insulated copper outside the iron core and adjacent to the secondary winding. If the product has an unsatisfactory error after pouring, it can be adjusted through the additional compensation coil to make the error reach the best state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com