Automatic thread nail beating device and automatic thread sewing system

An automatic, air-supply system technology, applied in the field of hollow needles, can solve the problems of broken pieces, slow working efficiency, easy punching of the knife eye, etc., to achieve the effect of improving efficiency and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

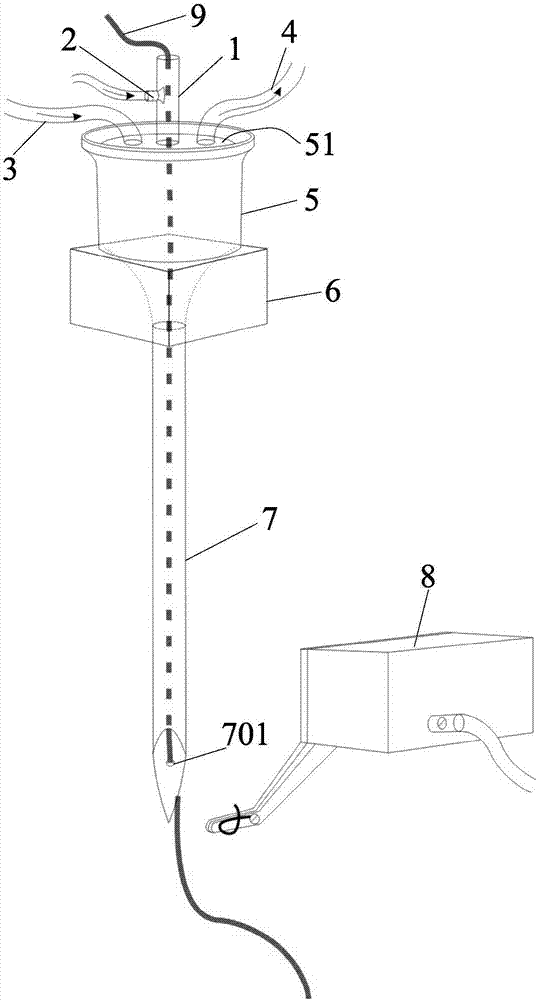

[0022] Such as figure 1 As shown, the automatic nailing device proposed by the present invention includes a wire conduit 1, a control valve 2, an automatic wire feeding pipe 3, an air suction cleaning pipe 4, an air cavity 5, a fixing member 6, and a core needle body 7;

[0023] The function of the conduit 1 is to pass the sewing thread 9 through. The control valve 2 is installed on the wall of the conduit. In this example, the control valve 2 is a pneumatic valve, and the control valve 2 can be activated by the air supply system to close the conduit 1. ; In other embodiments, the control valve 2 can also use a solenoid valve; the lower end of the wire conduit 1 is connected to the air chamber cover 51 on the top of the air chamber 5; a separate air chamber cover 51 is provided in this example, and in other implementations In the example, air cavity cover 51 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com