Hydraulic extruding machine for ceramic roller billet tube

A ceramic roller and extruder technology, applied in the field of machinery and equipment, can solve the problems of easy wear and tear of the screw shaft and the material barrel, the blank tube is not dense enough, and the maintenance cost is high. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

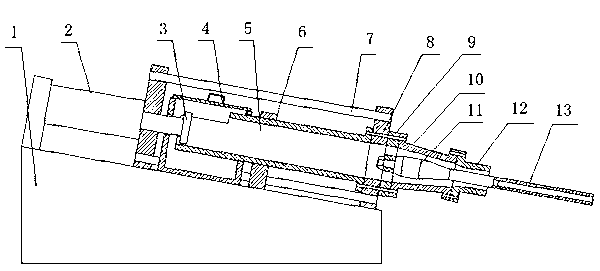

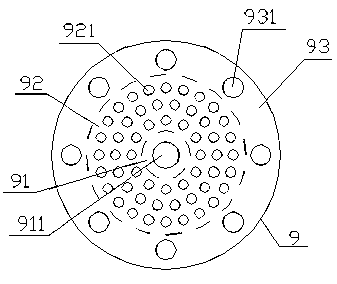

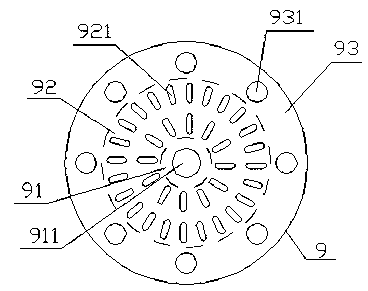

[0041] combine figure 1 , figure 2 , image 3 as well as Figure 4 , the embodiment of the present invention provides a ceramic roller billet tube hydraulic extruder, which is used for extrusion molding of ceramic roller billets. Barrel 5, barrel first support seat 6, pull rod 7, barrel second support seat 8, center needle seat 9, tapered tube 10, center needle 11, pipe outlet nozzle 12, tube core 13.

[0042] The oil cylinder 2, the vacuum box 4, the first support seat 6 of the barrel, the second support seat 8 of the barrel are installed on the frame 1 with an inclination angle, the barrel 5 is installed on the first support seat 6 of the barrel, and the second support seat 8 of the barrel On the second support seat 8; the oil cylinder 2 is driven to and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com